EasyProbe + PGFUN 3D probe

- theoneandonlyoreo

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

26 May 2025 13:55 #329161

by theoneandonlyoreo

EasyProbe + PGFUN 3D probe was created by theoneandonlyoreo

I had trouble installing Verser's v2.9 probing screen for the Axis GUI. Eventually I decided to try EasyProbe. Easy enough, except that the pocket probing function has a constant that only works for metric. But if you change ff_distance from 5 mm to 0.2, it appears that everything works.

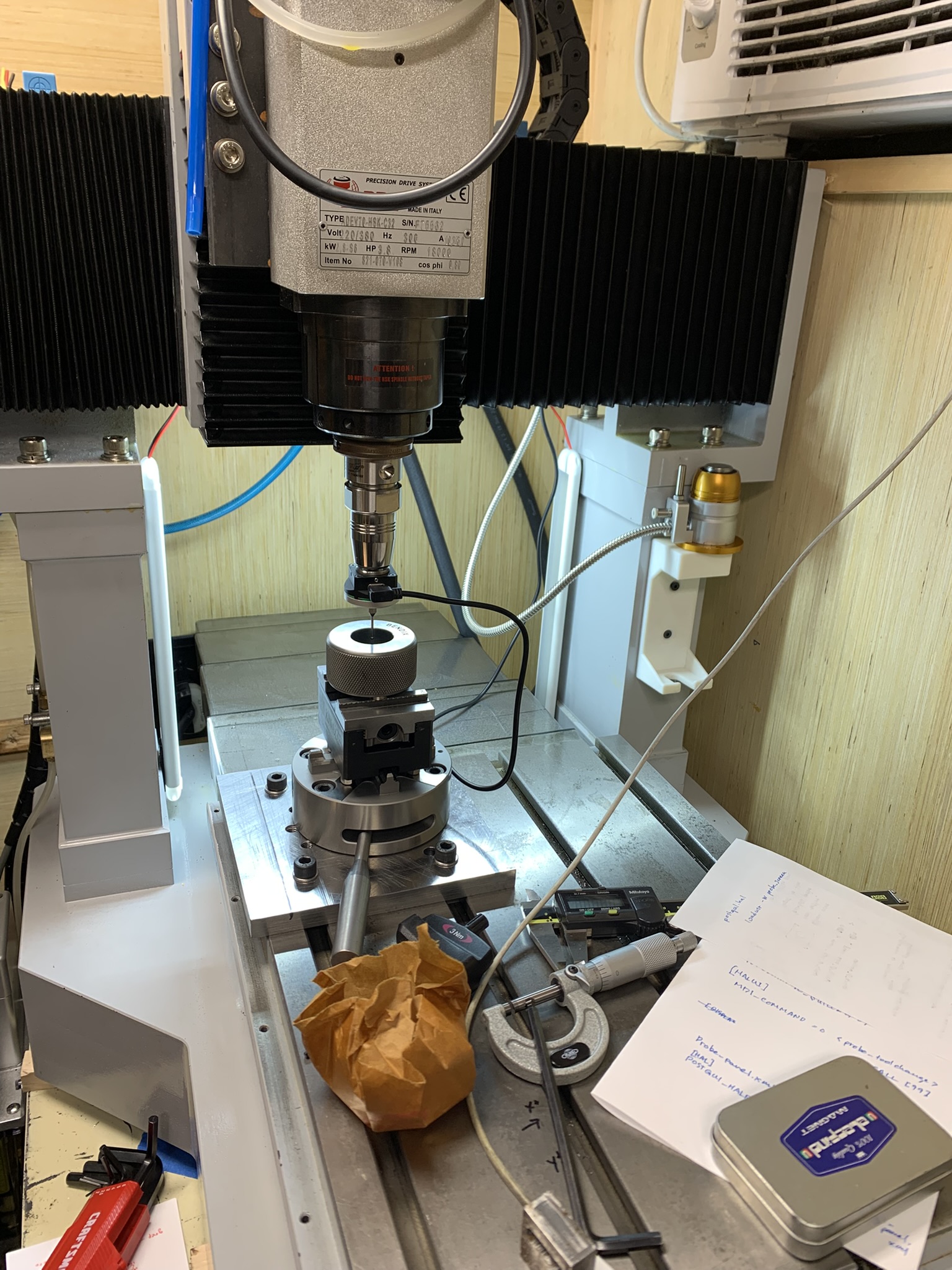

EasyProbe allows you to calibrate the probe tip, which avoids the complication of using an indicator to get the probe tip colinear with the axis of the spindle. The drawback is you must measure with the probe oriented as it was during calibration. Here's my calibration setup

The ring gage is 1.0060 inches

After calibration, the I probed the pocket a few times. The measured diameters varied from the standard by

While working with EasyProbe, I encountered manual tool changing for the first time, with rapids set to 200 IPM. I had also set TOOL_CHANGE_QUILL_UP, which almost smashed the probe into the table. I had set up the axes using the right hand rule, with +Y moving away from the operator. This requires that +Z is up. I turned off the quill-up setting but had several close calls because M6 rapids the spindle to the tool change location, not caring about the Z position. So I've got to reverse the Y axis so I can take advantage of the quill-up setting.

EasyProbe allows you to calibrate the probe tip, which avoids the complication of using an indicator to get the probe tip colinear with the axis of the spindle. The drawback is you must measure with the probe oriented as it was during calibration. Here's my calibration setup

The ring gage is 1.0060 inches

After calibration, the I probed the pocket a few times. The measured diameters varied from the standard by

- 0.000,014 inches

- 0.000,006

- 0.000,114

- 0.000,097

While working with EasyProbe, I encountered manual tool changing for the first time, with rapids set to 200 IPM. I had also set TOOL_CHANGE_QUILL_UP, which almost smashed the probe into the table. I had set up the axes using the right hand rule, with +Y moving away from the operator. This requires that +Z is up. I turned off the quill-up setting but had several close calls because M6 rapids the spindle to the tool change location, not caring about the Z position. So I've got to reverse the Y axis so I can take advantage of the quill-up setting.

Please Log in or Create an account to join the conversation.

- langdons

-

- Offline

- Platinum Member

-

Less

More

- Posts: 776

- Thank you received: 93

26 May 2025 14:09 #329163

by langdons

Replied by langdons on topic EasyProbe + PGFUN 3D probe

Looks like the ring is past its due date.

(whatever that means)

(whatever that means)

Please Log in or Create an account to join the conversation.

- theoneandonlyoreo

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

27 May 2025 19:03 #329257

by theoneandonlyoreo

Replied by theoneandonlyoreo on topic EasyProbe + PGFUN 3D probe

After fooling around for a while, I decided to retain the positive-Z-up configuration. It's basically what modern CNC machines expect, I gather. Also, EasyProbe doesn't work in the positive-Z-down configuration.

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 109

- Thank you received: 52

27 May 2025 19:22 #329262

by juliankoenig87

Replied by juliankoenig87 on topic EasyProbe + PGFUN 3D probe

Hehe,

yes, I never ever thought about having z positive down

yes, I never ever thought about having z positive down

Please Log in or Create an account to join the conversation.

- theoneandonlyoreo

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

31 May 2025 18:51 #329462

by theoneandonlyoreo

Replied by theoneandonlyoreo on topic EasyProbe + PGFUN 3D probe

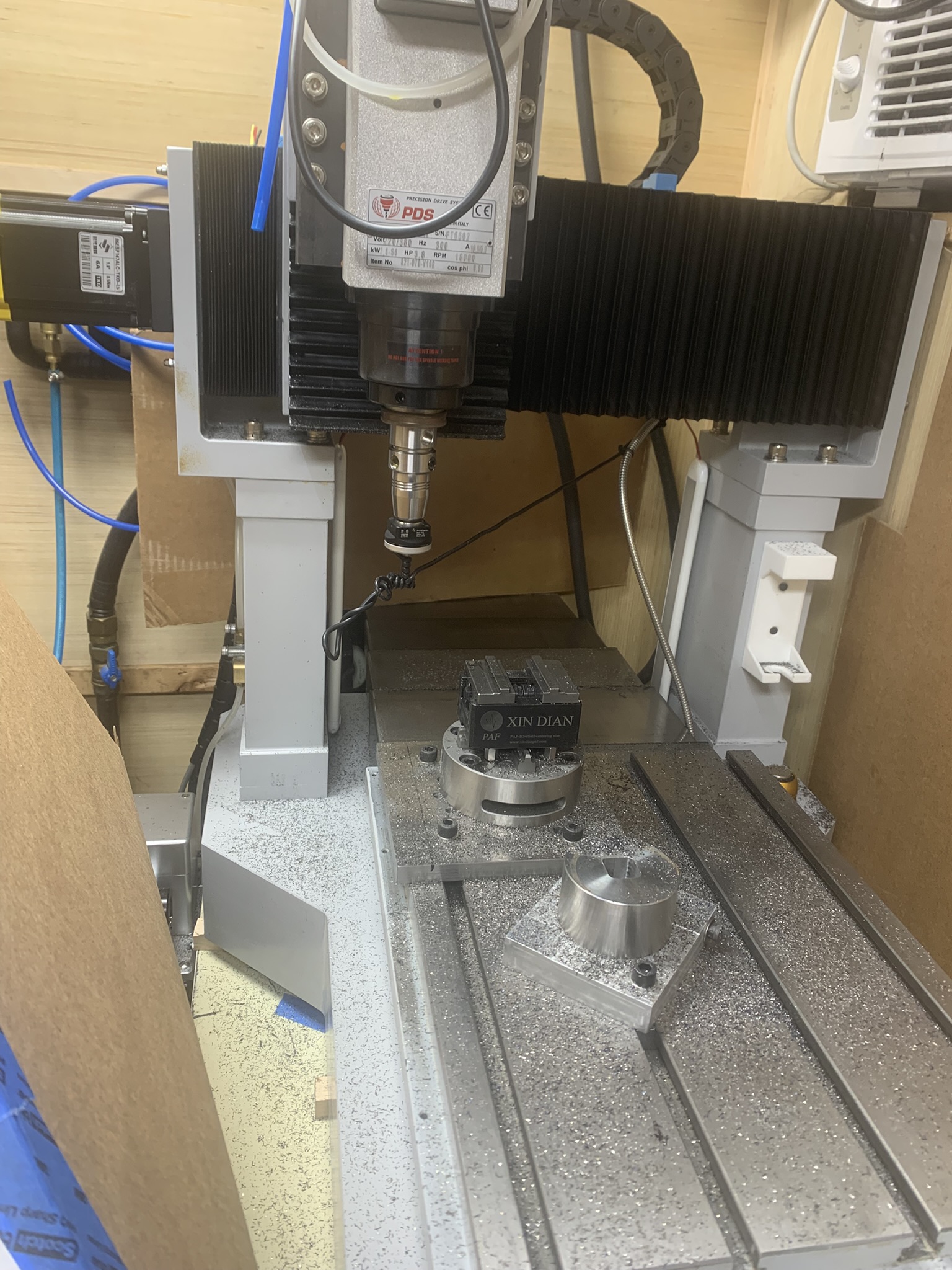

Oops. I'll have to add an interlock for the probe when it's in storage, on the right column.

Getting the gage length of the probe isn't as easy as normal tooling. It's a dual-contact spindle nose, so normally you can measure the length of tools on the surface plate. But with the added variable of Z travel in the probe, you can't measure directly. I ended up touching off on the 1-2-3 block and doing the guess-and-check on a gage-block stack to find the length. A big gage block, adjustable parallels, and a micrometer would have been less dramatic but I didn't think of that until later.

Getting the gage length of the probe isn't as easy as normal tooling. It's a dual-contact spindle nose, so normally you can measure the length of tools on the surface plate. But with the added variable of Z travel in the probe, you can't measure directly. I ended up touching off on the 1-2-3 block and doing the guess-and-check on a gage-block stack to find the length. A big gage block, adjustable parallels, and a micrometer would have been less dramatic but I didn't think of that until later.

Attachments:

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 109

- Thank you received: 52

31 May 2025 19:05 #329463

by juliankoenig87

Replied by juliankoenig87 on topic EasyProbe + PGFUN 3D probe

One of the safest way to have the probe and the tool touch sensor on the same hight would be to install a rigid piece of metal and facing it with an meassured tool. After that calibration of the probe with this new face.

Btw. Cool machine. Do you have somewhere more info about it? Right now I retrofitting a Kuhlmann P20. Looks quite similar.

Btw. Cool machine. Do you have somewhere more info about it? Right now I retrofitting a Kuhlmann P20. Looks quite similar.

Please Log in or Create an account to join the conversation.

- theoneandonlyoreo

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

31 May 2025 20:06 #329468

by theoneandonlyoreo

Replied by theoneandonlyoreo on topic EasyProbe + PGFUN 3D probe

It's from LY CNC, which you can find on Alibaba. This is the 3040 model. I watched Stephan Gotteswinter's video about his new micro mill, and was inspired to do something similar. It was going to be difficult to get the same epoxy-granite frame he started with, here in the states. This cast-iron frame was a similar design, so I decided to try it out. There was a fair amount of waiting involved but the machine seems fairly sound.

With the spindle half-way down, I'm getting 0.000,5 in (13 microns) deflection with 20 lbf (88 N) pressing against the spindle nose. I think those are similar numbers to Gotteswinter's thumb test.

I got out the master square to check the perpendicularity of the X and Y axes. They're very square--within a few tenths (0.000,1 inch = 3 microns) over 10 inches (250 mm). The YZ plane leans back about 0.002" over the 7 inch travel of Z. In the XZ plane, there's 0.003" deviation over the same distance. I might eventually try to correct that but the parts I'm making are fairly small, so maybe it won't be a problem.

Do you have a thread about your retrofit?

With the spindle half-way down, I'm getting 0.000,5 in (13 microns) deflection with 20 lbf (88 N) pressing against the spindle nose. I think those are similar numbers to Gotteswinter's thumb test.

I got out the master square to check the perpendicularity of the X and Y axes. They're very square--within a few tenths (0.000,1 inch = 3 microns) over 10 inches (250 mm). The YZ plane leans back about 0.002" over the 7 inch travel of Z. In the XZ plane, there's 0.003" deviation over the same distance. I might eventually try to correct that but the parts I'm making are fairly small, so maybe it won't be a problem.

Do you have a thread about your retrofit?

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 109

- Thank you received: 52

31 May 2025 21:51 - 31 May 2025 21:52 #329471

by juliankoenig87

Replied by juliankoenig87 on topic EasyProbe + PGFUN 3D probe

Ah cool. I think this is a good example for the fact that you can get quality in China if you are willing to pay for it. Looks good.

I dont have a thread for my current project. It was a fast decision thing, because the price was low. Looks smaller on the picture than in real life. Weights 500kg (machine + table). Dont have the fancy pc table .

.

Old Berger Lahr 5 phase steppers. Drives invented 1987. Machine is build in 1992. I want to safe the old drives, because I like to maintain such old hardware. I already ordered some caps for replacement (known as fault reasons).

Machine is all cast iron! But with supported round rails instead of linear rails. But I will keep them. It will be sufficient for al lot of my work. Travel is 400x400x100. Machine is only 900x800xhight (didnt meassured it yet).

I dont have a thread for my current project. It was a fast decision thing, because the price was low. Looks smaller on the picture than in real life. Weights 500kg (machine + table). Dont have the fancy pc table

Old Berger Lahr 5 phase steppers. Drives invented 1987. Machine is build in 1992. I want to safe the old drives, because I like to maintain such old hardware. I already ordered some caps for replacement (known as fault reasons).

Machine is all cast iron! But with supported round rails instead of linear rails. But I will keep them. It will be sufficient for al lot of my work. Travel is 400x400x100. Machine is only 900x800xhight (didnt meassured it yet).

Last edit: 31 May 2025 21:52 by juliankoenig87.

Please Log in or Create an account to join the conversation.

- theoneandonlyoreo

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

02 Jun 2025 20:30 - 03 Jun 2025 21:51 #329567

by theoneandonlyoreo

Replied by theoneandonlyoreo on topic EasyProbe + PGFUN 3D probe

The LY mill has 300 (X) by 400 (Y) mm travel and about 180 in Z. The overall machine is 1000 mm deep, 600 wide, and 600 high. Weight is 375 kg.

Re-capping a few boards seems manageable. There is less patience for old electronics. I think it reflects a lack of widespread electronics knowledge.

That PC stand is something else.

These were sold as engraving machines. I assume a spindle/VFD upgrade is in order?Will you be doing anything beyond aluminum?

Re-capping a few boards seems manageable. There is less patience for old electronics. I think it reflects a lack of widespread electronics knowledge.

That PC stand is something else.

These were sold as engraving machines. I assume a spindle/VFD upgrade is in order?Will you be doing anything beyond aluminum?

Last edit: 03 Jun 2025 21:51 by theoneandonlyoreo.

Please Log in or Create an account to join the conversation.

- langdons

-

- Offline

- Platinum Member

-

Less

More

- Posts: 776

- Thank you received: 93

03 Jun 2025 00:47 #329580

by langdons

Replied by langdons on topic EasyProbe + PGFUN 3D probe

In my experience, old electronics actually seem to funtion suprisingly well with old, worn-out caps.

Though you can buy good caps from LCSC.com for very cheap.

Though you can buy good caps from LCSC.com for very cheap.

Please Log in or Create an account to join the conversation.

Time to create page: 0.151 seconds