5i25+7i76 Spindle control issue

- johnjsb

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

22 Aug 2013 00:13 #37935

by johnjsb

5i25+7i76 Spindle control issue was created by johnjsb

I can't seem to get the spindle working after a few days of wondering around the net. I had to jumper the enable pin on the spindle controller and the direction doesn't work. when i issue a m3 it turns clockwise looking from top of spindle(correct cutting direction). when i input m4 spindle stops with 0v on tb4-pin2. either m3 or m4 gives 5v on spindle_ena+ pin6 (which needs to be ground) and 5v on spindle-dir+ pin8(which needs to be 0v for ccw m4). m3 with s5000 gives me 9.07v at 5000rpm so thats good. Please help i think there needs to be more code here with some kind of -not or -invert somewhere.

here is my hal file:

here is my .ini as well:

here is my hal file:

# Generated by PNCconf at Tue Aug 20 18:17:20 2013

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt probe_parport

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=2 num_pwmgens=0 num_3pwmgens=0 num_stepgens=8 sserial_port_0=0100xxxx "

setp hm2_5i25.0.watchdog.timeout_ns 10000000

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt classicladder_rt numPhysInputs=15 numPhysOutputs=15 numS32in=10 numS32out=10 numFloatIn=10 numFloatOut=10

loadrt mux16 names=jogincr,foincr,soincr

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf classicladder.0.refresh servo-thread

addf jogincr servo-thread

addf foincr servo-thread

addf soincr servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf hm2_5i25.0.write servo-thread

addf hm2_5i25.0.pet_watchdog servo-thread

# external output signals

# external input signals

# --- PROBE-IN ---

net probe-in <= hm2_5i25.0.7i76.0.0.input-10-not

# --- ESTOP-EXT ---

net estop-ext <= hm2_5i25.0.7i73.0.1.input-00

# --- DIN-00 ---

net din-00 <= hm2_5i25.0.7i73.0.1.input-04

# --- DIN-01 ---

net din-01 <= hm2_5i25.0.7i73.0.1.input-05

# --- JOINT-SELECT-A ---

net joint-select-a <= hm2_5i25.0.7i73.0.1.input-10

# --- JOINT-SELECT-B ---

net joint-select-b <= hm2_5i25.0.7i73.0.1.input-11

# --- JOINT-SELECT-C ---

net joint-select-c <= hm2_5i25.0.7i73.0.1.input-12

# --- JOINT-SELECT-D ---

net joint-select-d <= hm2_5i25.0.7i73.0.1.input-13

# --- FO-ENABLE ---

net fo-enable <= hm2_5i25.0.7i73.0.1.input-14

# --- MVO-ENABLE ---

net mvo-enable <= hm2_5i25.0.7i73.0.1.input-15

#*******************

# AXIS X

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [AXIS_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [AXIS_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [AXIS_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [AXIS_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [AXIS_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 0

setp hm2_5i25.0.stepgen.00.maxaccel 25.0

setp hm2_5i25.0.stepgen.00.maxvel 5.2

net x-pos-fb axis.0.motor-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-cmd axis.0.motor-pos-cmd => hm2_5i25.0.stepgen.00.position-cmd

net x-enable axis.0.amp-enable-out => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [AXIS_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [AXIS_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [AXIS_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [AXIS_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [AXIS_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 0

setp hm2_5i25.0.stepgen.01.maxaccel 25.0

setp hm2_5i25.0.stepgen.01.maxvel 5.2

net y-pos-fb axis.1.motor-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-cmd axis.1.motor-pos-cmd => hm2_5i25.0.stepgen.01.position-cmd

net y-enable axis.1.amp-enable-out => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => axis.1.home-sw-in

net y-neg-limit => axis.1.neg-lim-sw-in

net y-pos-limit => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.02.dirsetup [AXIS_2]DIRSETUP

setp hm2_5i25.0.stepgen.02.dirhold [AXIS_2]DIRHOLD

setp hm2_5i25.0.stepgen.02.steplen [AXIS_2]STEPLEN

setp hm2_5i25.0.stepgen.02.stepspace [AXIS_2]STEPSPACE

setp hm2_5i25.0.stepgen.02.position-scale [AXIS_2]STEP_SCALE

setp hm2_5i25.0.stepgen.02.step_type 0

setp hm2_5i25.0.stepgen.02.control-type 0

setp hm2_5i25.0.stepgen.02.maxaccel 25.0

setp hm2_5i25.0.stepgen.02.maxvel 5.2

net z-pos-fb axis.2.motor-pos-fb <= hm2_5i25.0.stepgen.02.position-fb

net z-pos-cmd axis.2.motor-pos-cmd => hm2_5i25.0.stepgen.02.position-cmd

net z-enable axis.2.amp-enable-out => hm2_5i25.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# AXIS A

#*******************

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.03.dirsetup [AXIS_3]DIRSETUP

setp hm2_5i25.0.stepgen.03.dirhold [AXIS_3]DIRHOLD

setp hm2_5i25.0.stepgen.03.steplen [AXIS_3]STEPLEN

setp hm2_5i25.0.stepgen.03.stepspace [AXIS_3]STEPSPACE

setp hm2_5i25.0.stepgen.03.position-scale [AXIS_3]STEP_SCALE

setp hm2_5i25.0.stepgen.03.step_type 0

setp hm2_5i25.0.stepgen.03.control-type 0

setp hm2_5i25.0.stepgen.03.maxaccel 1000.0

setp hm2_5i25.0.stepgen.03.maxvel 833.3

net a-pos-fb axis.3.motor-pos-fb <= hm2_5i25.0.stepgen.03.position-fb

net a-pos-cmd axis.3.motor-pos-cmd => hm2_5i25.0.stepgen.03.position-cmd

net a-enable axis.3.amp-enable-out => hm2_5i25.0.stepgen.03.enable

# ---setup home / limit switch signals---

net a-home-sw => axis.3.home-sw-in

net a-neg-limit => axis.3.neg-lim-sw-in

net a-pos-limit => axis.3.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

# ---digital potentionmeter output signals/setup---

setp hm2_5i25.0.7i76.0.0.spinout-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-scalemax [SPINDLE_9]OUTPUT_SCALE

net spindle-vel-cmd => hm2_5i25.0.7i76.0.0.spinout

net machine-is-enabled => hm2_5i25.0.7i76.0.0.spinena

#setp hm2_5i25.0.7i76.0.0.spindir-invert 1

net spindle-ccw => hm2_5i25.0.7i76.0.0.spindir

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd <= motion.spindle-speed-out

net spindle-on <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

# Use COMMANDED spindle velocity from LinuxCNC because no spindle encoder was specified

# COMMANDED velocity is signed so we use absolute component to remove sign

net spindle-vel-cmd => abs.spindle.in

net absolute-spindle-vel <= abs.spindle.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net joint-select-d halui.joint.3.select

net a-is-homed halui.joint.3.is-homed

net jog-a-pos halui.jog.3.plus

net jog-a-neg halui.jog.3.minus

net jog-a-analog halui.jog.3.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---jogwheel signals to mesa encoder - shared MPG---

net joint-selected-count <= hm2_5i25.0.7i73.0.1.enc0

# ---mpg signals---

# for axis x MPG

setp axis.0.jog-vel-mode 0

net selected-jog-incr => axis.0.jog-scale

net joint-select-a => axis.0.jog-enable

net joint-selected-count => axis.0.jog-counts

# for axis y MPG

setp axis.1.jog-vel-mode 0

net selected-jog-incr => axis.1.jog-scale

net joint-select-b => axis.1.jog-enable

net joint-selected-count => axis.1.jog-counts

# for axis z MPG

setp axis.2.jog-vel-mode 0

net selected-jog-incr => axis.2.jog-scale

net joint-select-c => axis.2.jog-enable

net joint-selected-count => axis.2.jog-counts

# for axis a MPG

setp axis.3.jog-vel-mode 0

net selected-jog-incr => axis.3.jog-scale

net joint-select-d => axis.3.jog-enable

net joint-selected-count => axis.3.jog-counts

# connect selectable mpg jog increments

net jog-incr-a => jogincr.sel0

net jog-incr-b => jogincr.sel1

net jog-incr-c => jogincr.sel2

net jog-incr-d => jogincr.sel3

net selected-jog-incr <= jogincr.out-f

setp jogincr.debounce-time 0.200000

setp jogincr.use-graycode False

setp jogincr.suppress-no-input False

setp jogincr.in00 0.001000

setp jogincr.in01 0.000100

setp jogincr.in02 0.000500

setp jogincr.in03 0.001000

setp jogincr.in04 0.005000

setp jogincr.in05 0.010000

setp jogincr.in06 0.050000

setp jogincr.in07 0.100000

setp jogincr.in08 0.000000

setp jogincr.in09 0.000000

setp jogincr.in10 0.000000

setp jogincr.in11 0.000000

setp jogincr.in12 0.000000

setp jogincr.in13 0.000000

setp jogincr.in14 0.000000

setp jogincr.in15 0.000000

# connect feed overide increments - MPG

setp halui.feed-override.direct-value false

setp halui.feed-override.scale .01

net fo-enable => halui.feed-override.count-enable

net joint-selected-count => halui.feed-override.counts

# connect spindle overide increments - MPG

setp halui.spindle-override.direct-value false

setp halui.spindle-override.scale .01

net so-enable => halui.spindle-override.count-enable

net joint-selected-count => halui.spindle-override.counts

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

net din-00 => motion.digital-in-00

net din-01 => motion.digital-in-01

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Load Classicladder without GUI (can reload LADDER GUI in AXIS GUI

loadusr classicladder --nogui custom.clp

# --- Classicladder signals for Z axis Auto touch off program---

net auto-touch-z => classicladder.0.in-00

net MDI-mode => classicladder.0.in-01

net in-position => classicladder.0.in-02

net z-touchoff-cmd classicladder.0.out-00 => halui.mdi-command-04

net z-zero-cmd classicladder.0.out-01 => halui.mdi-command-05

net rapid-away-cmd classicladder.0.out-02 => halui.mdi-command-06here is my .ini as well:

# Generated by PNCconf at Tue Aug 20 18:17:20 2013

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = SX2_Mini_Mill

DEBUG = 0

[DISPLAY]

DISPLAY = axis

EMBED_TAB_NAME = GladeVCP

EMBED_TAB_COMMAND = halcmd loadusr -Wn gladevcp gladevcp -c gladevcp -H gvcp_call_list.hal -x {XID} gvcp-panel.ui

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/john/linuxcnc/nc_files

PYVCP = pyvcp-panel.xml

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

EDITOR = gedit

GEOMETRY = xyza

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[HAL]

HALUI = halui

HALFILE = SX2_Mini_Mill.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

MDI_COMMAND = G10 L20 P0 X0 ( Set X to zero )

MDI_COMMAND = G10 L20 P0 Y0 ( Set Y to zero )

MDI_COMMAND = G10 L20 P0 Z0 ( Set Z to zero )

MDI_COMMAND = G10 L20 P0 A0 ( Set A to zero )

MDI_COMMAND = G38.2 Z-2 F16 ( search for touch off plate )

MDI_COMMAND = G10 L20 P0 Z.25 ( Ofset current Origin by plate thickness )

MDI_COMMAND = G0 Z.5 ( Rapid away from touch off plate )

[TRAJ]

AXES = 4

COORDINATES = X Y Z A

MAX_ANGULAR_VELOCITY = 666.67

DEFAULT_ANGULAR_VELOCITY = 60.00

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 0.42

MAX_LINEAR_VELOCITY = 4.17

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_QUILL_UP = 1

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.005

MIN_FERROR = 0.0005

MAX_VELOCITY = 4.16666666667

MAX_ACCELERATION = 20.0

# these are in nanoseconds

DIRSETUP = 700

DIRHOLD = 700

STEPLEN = 1500

STEPSPACE = 2500

STEP_SCALE = -10000.0

MIN_LIMIT = -6.0

MAX_LIMIT = 6.0

HOME_OFFSET = 0.0

#********************

# Axis Y

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.005

MIN_FERROR = 0.0005

MAX_VELOCITY = 4.16666666667

MAX_ACCELERATION = 20.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 10000.0

MIN_LIMIT = -2.375

MAX_LIMIT = 2.375

HOME_OFFSET = 0.0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.5

FERROR = 0.005

MIN_FERROR = 0.0005

MAX_VELOCITY = 4.16666666667

MAX_ACCELERATION = 20.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 10000.0

MIN_LIMIT = -9.0

MAX_LIMIT = 0.501

HOME_OFFSET = 0.5

#********************

# Axis A

#********************

[AXIS_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.005

MIN_FERROR = 0.0005

MAX_VELOCITY = 666.666666667

MAX_ACCELERATION = 800.0

# these are in nanoseconds

DIRSETUP = 700

DIRHOLD = 700

STEPLEN = 1500

STEPSPACE = 2500

STEP_SCALE = -200.0

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

HOME_OFFSET = 0.0

#********************

# Spindle

#********************

[SPINDLE_9]

OUTPUT_SCALE = 5000.0

OUTPUT_MIN_LIMIT = 0.0

OUTPUT_MAX_LIMIT = 5000.0Please Log in or Create an account to join the conversation.

- johnjsb

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

22 Aug 2013 05:12 #37943

by johnjsb

Replied by johnjsb on topic 5i25+7i76 Spindle control issue

Here are some links to what i am using for controller and the mill.

HiTorque Mini Mill

CNC Spindle Control Upgrade Kit for SX2, SC2

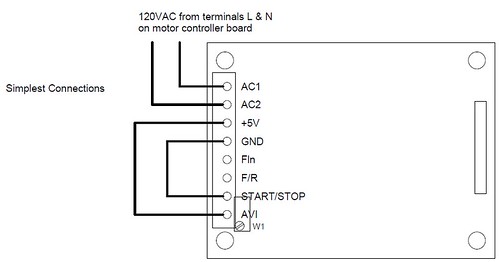

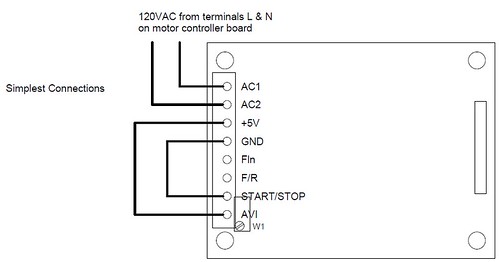

here are some images of the connections:

HiTorque Mini Mill

spindle control pic 1

spindle control pic 2

HiTorque Mini Mill

CNC Spindle Control Upgrade Kit for SX2, SC2

here are some images of the connections:

HiTorque Mini Mill

spindle control pic 1

spindle control pic 2

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 19129

- Thank you received: 5282

22 Aug 2013 09:22 - 22 Aug 2013 09:22 #37946

by PCW

Replied by PCW on topic 5i25+7i76 Spindle control issue

How is the 7I76 wired to the motor controller board?

it should be:

7I76 TB4 pin 1 SPINDLE- --> Motorcontroller GND

7I76 TB4 pin 2 SPINDLE OUT --> Motorcontroller AVI

7I76 TB4 pin 3 SPINDLE+ --> Motorcontroller +5V

7I76 TB4 pin 5 SPINDLE ENA- --> Motor controller GND

7I76 TB4 pin 6 SPINDLE ENA+ --> Motor controller START/STOP

7I76 TB4 pin 7 SPINDLE DIR- --> Motor controller GND

7I76 TB4 pin 8 SPINDLE DIR+ --> Motor controller F/R

it should be:

7I76 TB4 pin 1 SPINDLE- --> Motorcontroller GND

7I76 TB4 pin 2 SPINDLE OUT --> Motorcontroller AVI

7I76 TB4 pin 3 SPINDLE+ --> Motorcontroller +5V

7I76 TB4 pin 5 SPINDLE ENA- --> Motor controller GND

7I76 TB4 pin 6 SPINDLE ENA+ --> Motor controller START/STOP

7I76 TB4 pin 7 SPINDLE DIR- --> Motor controller GND

7I76 TB4 pin 8 SPINDLE DIR+ --> Motor controller F/R

Last edit: 22 Aug 2013 09:22 by PCW.

Please Log in or Create an account to join the conversation.

- johnjsb

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

22 Aug 2013 18:50 #37961

by johnjsb

Replied by johnjsb on topic 5i25+7i76 Spindle control issue

7I76 TB4 pin 1 SPINDLE- --> Motorcontroller GND

7I76 TB4 pin 2 SPINDLE OUT --> Motorcontroller AVI

7I76 TB4 pin 3 SPINDLE+ --> +10Vdc Power Supply

7I76 TB4 pin 5 SPINDLE ENA- --> Floating didn't know it had to be used i thought these were just inverted signal

7I76 TB4 pin 6 SPINDLE ENA+ --> Motor controller START/STOP

7I76 TB4 pin 7 SPINDLE DIR- --> Floating

7I76 TB4 pin 8 SPINDLE DIR+ --> Motor controller F/R

so the 2 i left floating need to be grounded? i was under the impression they were outputs.

7I76 TB4 pin 2 SPINDLE OUT --> Motorcontroller AVI

7I76 TB4 pin 3 SPINDLE+ --> +10Vdc Power Supply

7I76 TB4 pin 5 SPINDLE ENA- --> Floating didn't know it had to be used i thought these were just inverted signal

7I76 TB4 pin 6 SPINDLE ENA+ --> Motor controller START/STOP

7I76 TB4 pin 7 SPINDLE DIR- --> Floating

7I76 TB4 pin 8 SPINDLE DIR+ --> Motor controller F/R

so the 2 i left floating need to be grounded? i was under the impression they were outputs.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 19129

- Thank you received: 5282

22 Aug 2013 19:23 #37964

by PCW

Replied by PCW on topic 5i25+7i76 Spindle control issue

The 7I76 spindle enable and direction outputs are floating switches (optocoupler outputs). Each is a independent isolated switch so you always need to use both + and - connections of each.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23527

- Thank you received: 5005

22 Aug 2013 20:17 #37969

by andypugh

Replied by andypugh on topic 5i25+7i76 Spindle control issue

It is worth bearing in mind that in the case of many of those mills (with the KBIC motor controller) the speed-adjust pot sits at +100V.

I _think_ that the Mesa 7i76 spindle control is happy with this situation, and that you probably don't need the SC2, but you would want confirmation from PCW on that matter.

I _think_ that the Mesa 7i76 spindle control is happy with this situation, and that you probably don't need the SC2, but you would want confirmation from PCW on that matter.

Please Log in or Create an account to join the conversation.

- johnjsb

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

22 Aug 2013 20:51 #37971

by johnjsb

Replied by johnjsb on topic 5i25+7i76 Spindle control issue

I believe the KBIC controller is for the older model mini mill, never the less good info on that controller. i happen to have one around here that i was going to use for a lathe conversion so thats nice to know. This controller is a brushless controller with a add on board that gives a proper signal.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.075 seconds