- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- 2 Motors on Y , linuxcnc 2.9 not moving together

2 Motors on Y , linuxcnc 2.9 not moving together

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 217

- Thank you received: 43

please be so kind and have a look at my ini and hal file .

I read forum.linuxcnc.org/49-basic-configuratio...-linuxcnc-2-8-master

checked my hal and ini and it seems it should be ok...seems ..but the y axis is moving only one motor when homing.

finally hardware seems to be ready , I had also home switches but want to use max limit and home as one.

I have a cartesian Linuxcnc coordinates question as well ... I read the manual but I somehow don't get it :

I first had the machine configured that standing in front the minimum is in front and the maximum opposite (on the back)..seems that is wrong ??

thank you

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 217

- Thank you received: 43

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7243

- Thank you received: 2109

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 217

- Thank you received: 43

if you delete one - it works!!

and I then I had to change to cabling of one motor none of the inv. settings changed the y motors to the same direction.

now I have to find out why x does not stop at the max home instead continues ...

puh ...but I am getting better

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7243

- Thank you received: 2109

linuxcnc.org/docs/2.8/html/config/ini-ho....html#_home_sequence

I's like to know what went wrong so I can improve pncconf.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 217

- Thank you received: 43

if you delete manually one of the minus - "it works!!"

I got

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = --1

still y or y2 motor inverting did not work either.

thanks for your work!

can you help me out if I have a cnc plasma do I have coordinate the table or the tool? maybe a stupid question ....

I am bit lost ...I home at right side xmax and home and can't move to the left side...

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7243

- Thank you received: 2109

did you try inverting the 'invert motor' on the Motor page?

I do se that inverting the direction pin on the mesa page does not seem to work.

Chris

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7243

- Thank you received: 2109

can you help me out if I have a cnc plasma do I have coordinate the table or the tool? maybe a stupid question ....

I think you are asking about direction of travel reference - it's tool movement.

In Pncconf when on the Axis page, press the help button - it should explain the direction designations.

Chris

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 217

- Thank you received: 43

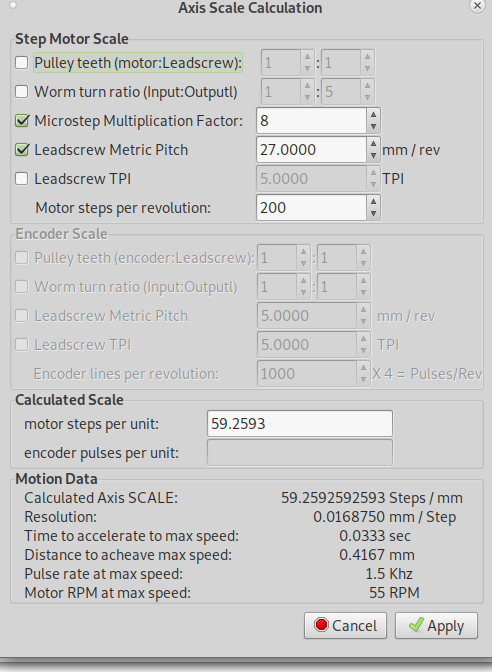

I have a precision gear on my nema 23 with 5:1 and rack and pinion . the pinion has 25teeth which gives it a travel of 25mm

I even tested and motor 5 revolutions the gear 1

so usually one rev should be 5mm , which is equal to pinion 25mm divided by 5 revolutions makes 1 revolution 5mm

but look which setting I had to do in order to get approx 1mm travel (I got 0.9) when requested 1mm

I tried 5mm but then it travels a big distance (not measured)

I think you are asking about direction of travel reference - it's tool movement.

In Pncconf when on the Axis page, press the help button - it should explain the direction designations.

thank you Chris, that is great!

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

- Posts: 7243

- Thank you received: 2109

8 times microsteps (200 x 8) = 1600 steps per revolution

5:1 reduction gear box: 5 motor turns to one output turn (5 x 1600 = 8000 steps per revolution

1 revolution of 25 tooth pinion = 25mm travel of table

or .04 revolution = 1mm

So 8000 x .04 = 320 steps per mm

If your scale differed from that then it suggests that your assumptions of the mechanics are wrong. My guess would be microsteps setting.

Chris

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- 2 Motors on Y , linuxcnc 2.9 not moving together