Stepper settings for rack and pinion

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 84

- Thank you received: 16

01 Jun 2020 09:15 #169635

by luftlupus

Stepper settings for rack and pinion was created by luftlupus

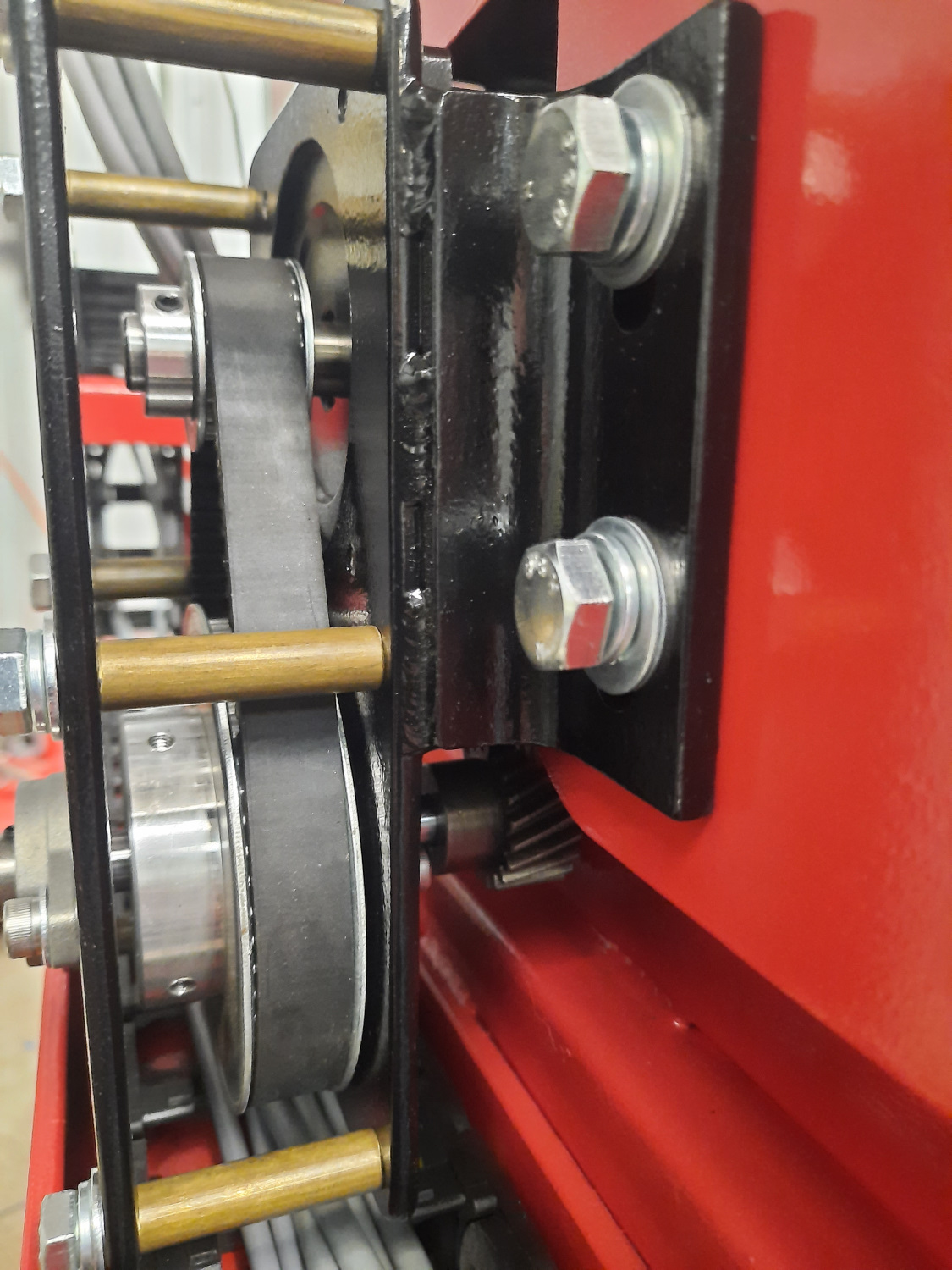

Ok i have built a plasma table and i am using the mesa 7i76 card,

i have it all working to a degree except i am having trouble figuring out the settings for what i am running to actually have accurate travel distance on my machine's rack and pinion.

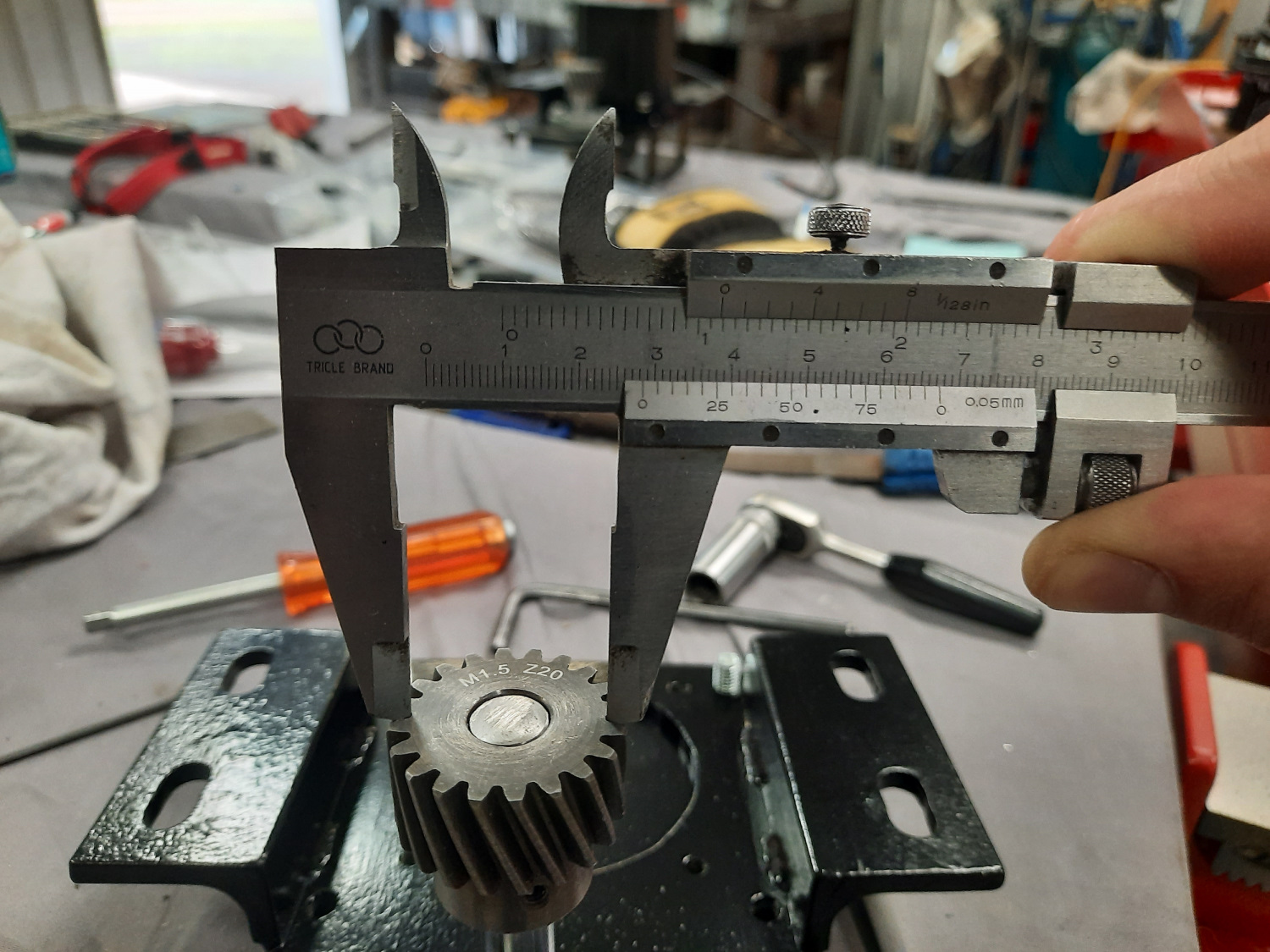

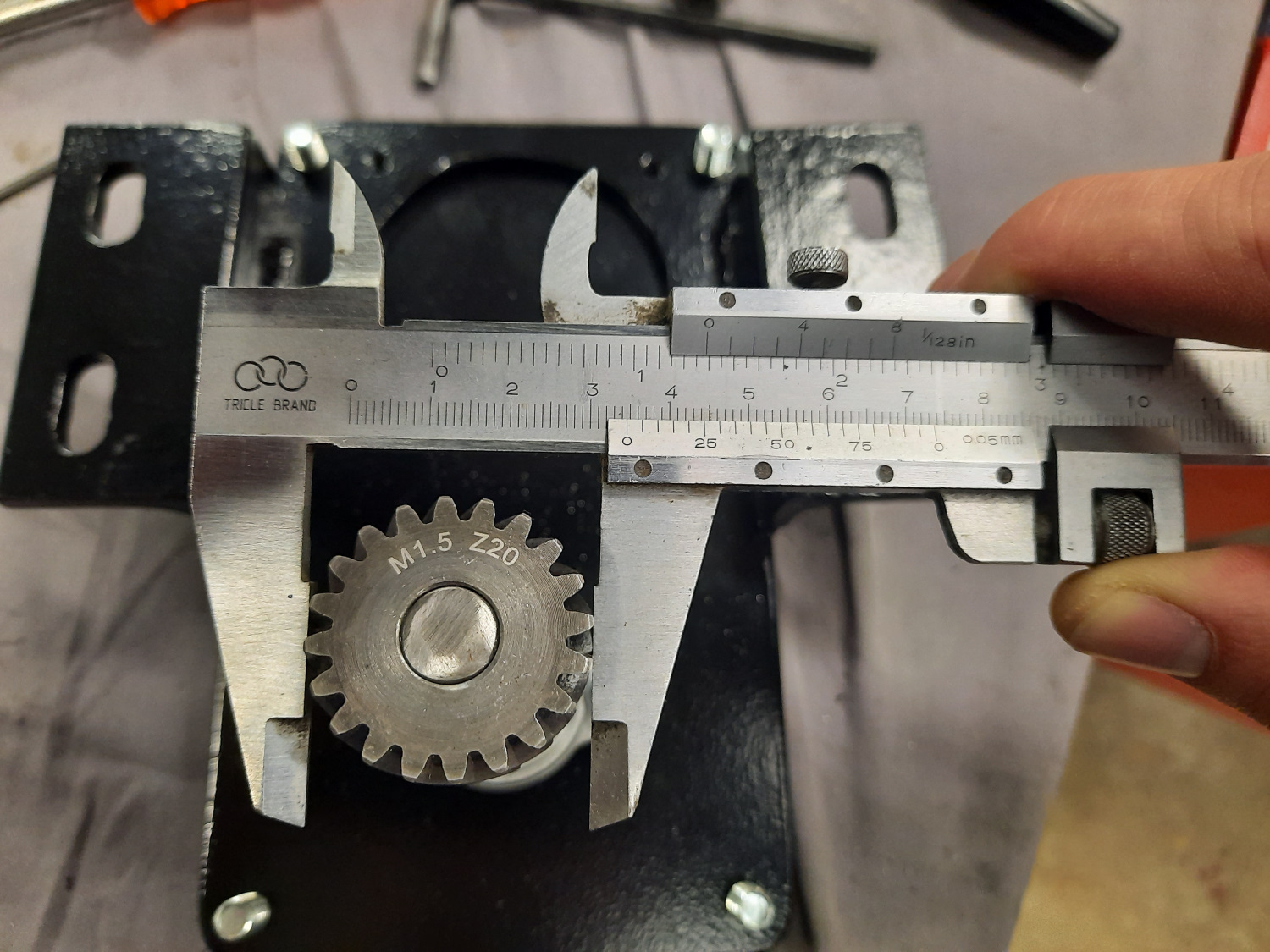

The rack and pinion is MOD 1.5 Helical and i am running a 3:1 reduction from the steppers to the pinion gear

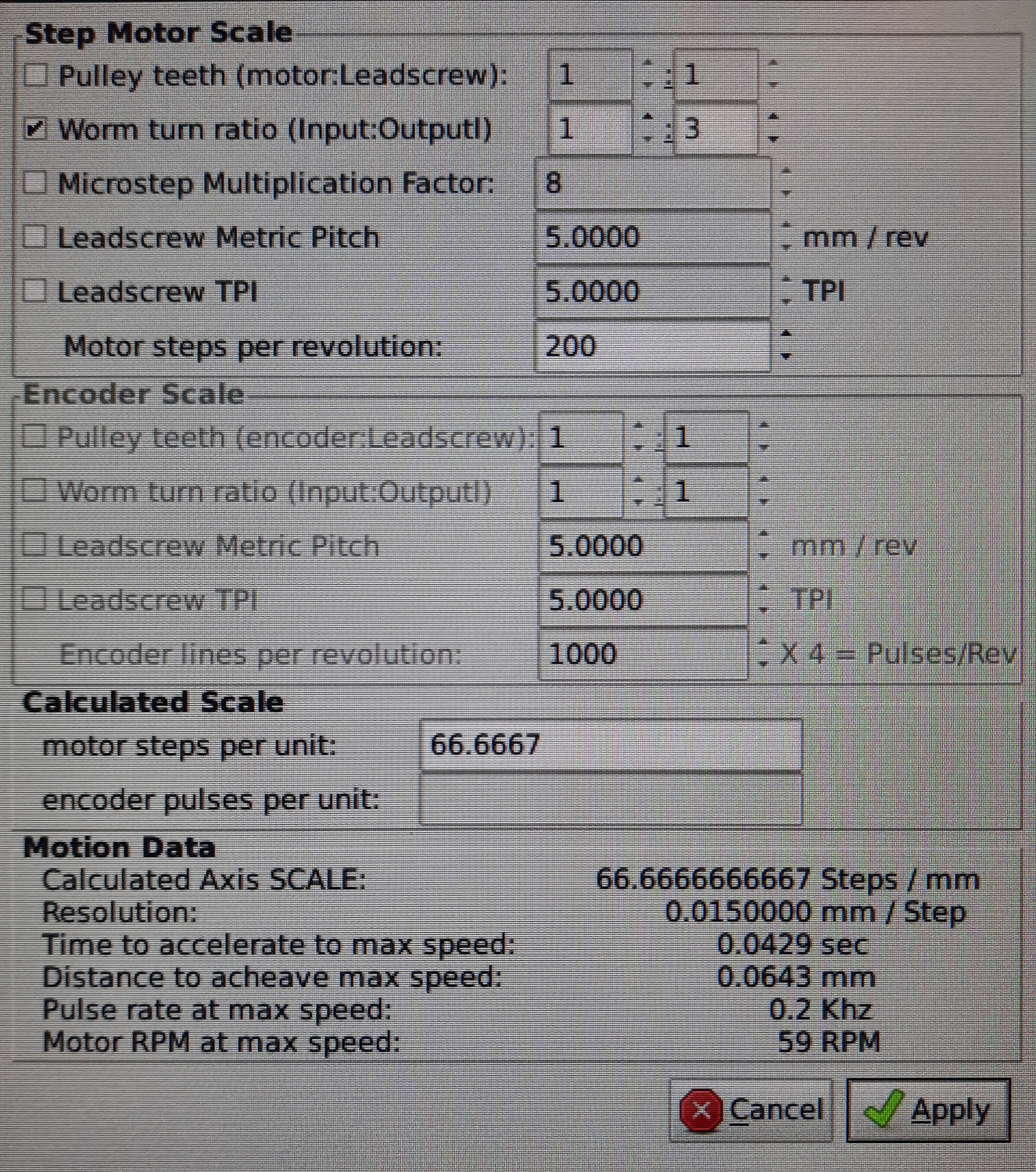

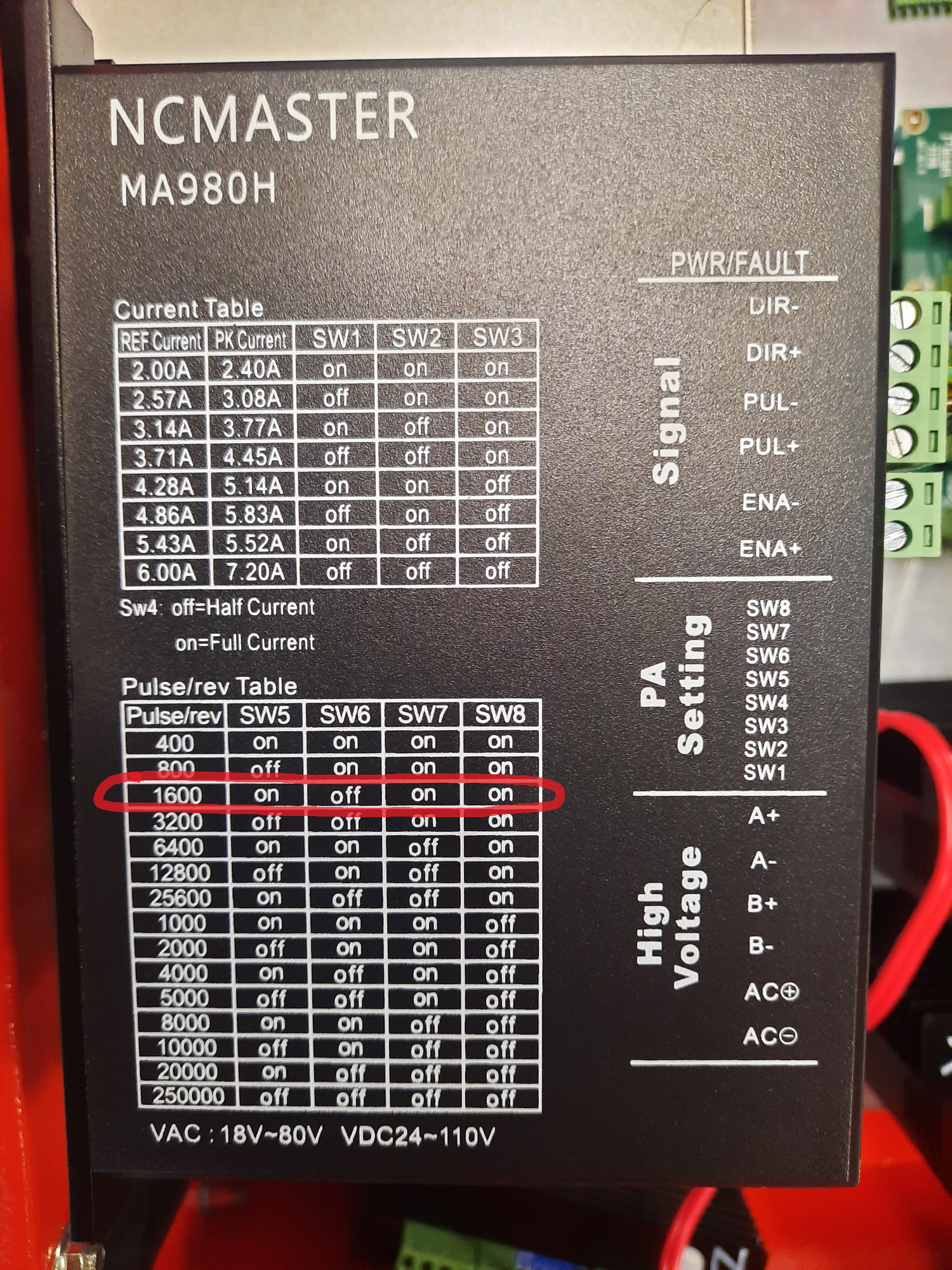

The stepper drivers are set at 1600

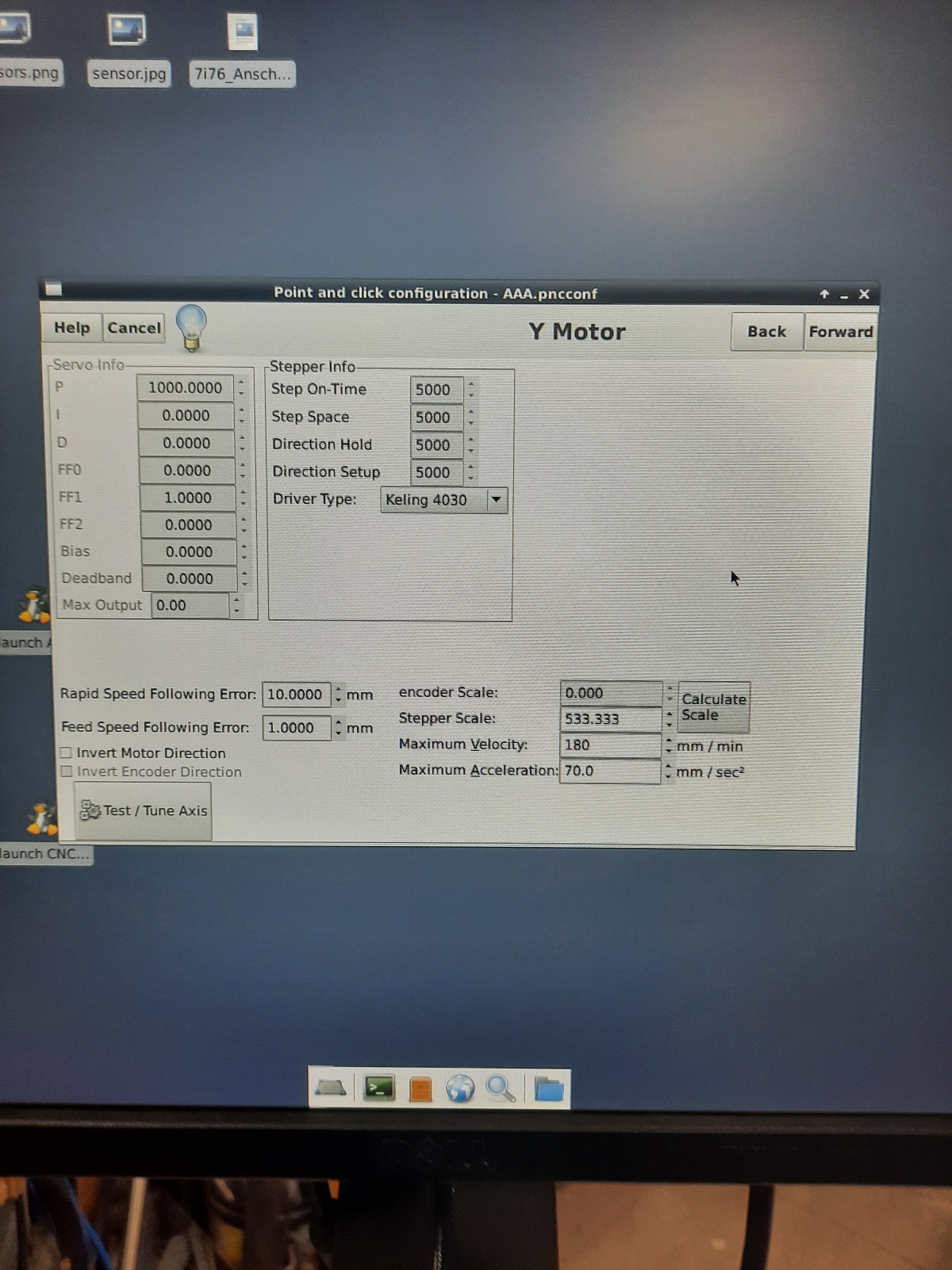

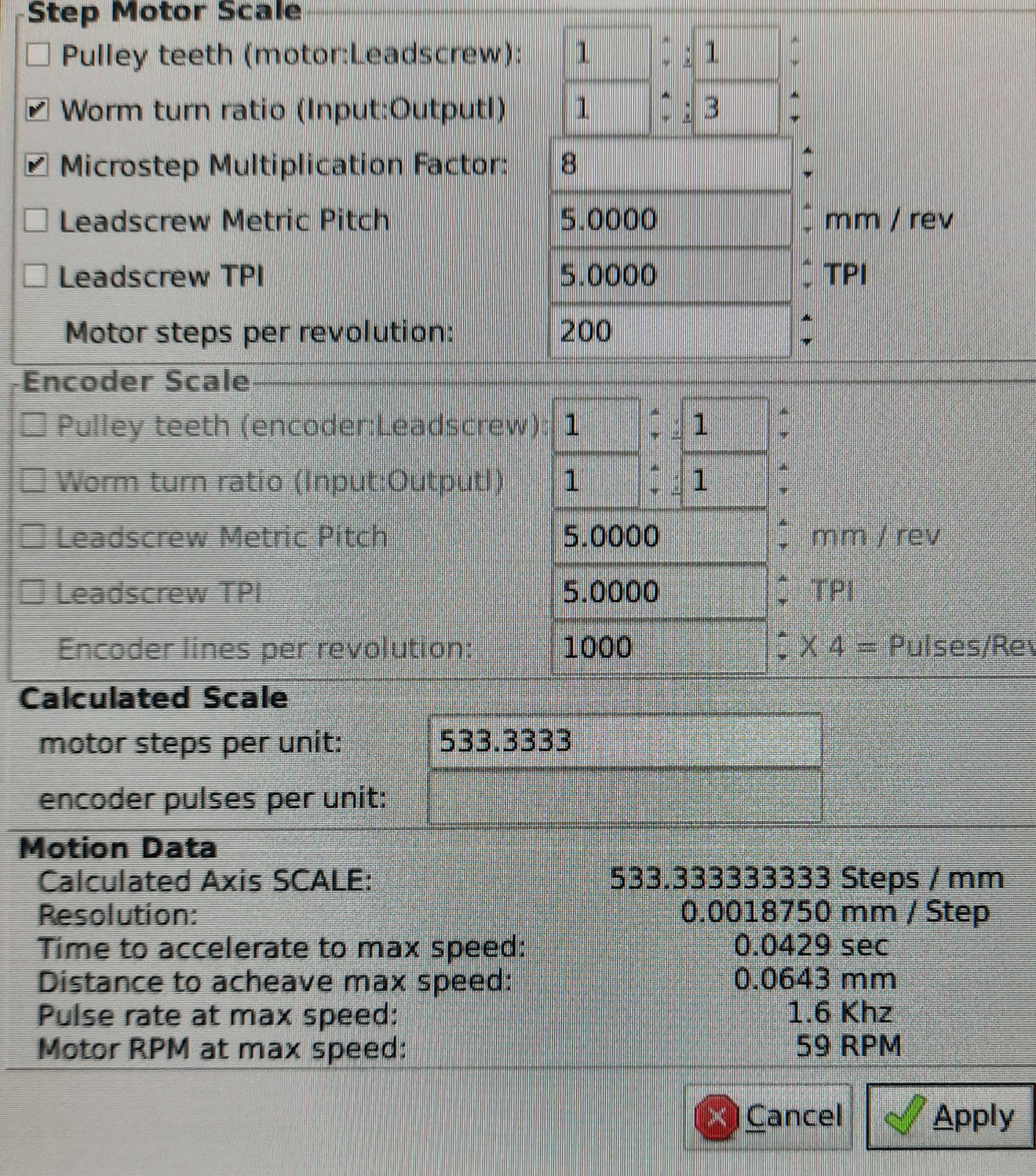

I have tried unchecking the microstep multiplication factor and just using the worm turn ratio but then the steppers slow down a lot and i would have to put the acceleration and velocity up crazy high to make the motors move at a reasonable speed. as seen in the pictures. any guidance would be greatly appreciated. Thanks

i have it all working to a degree except i am having trouble figuring out the settings for what i am running to actually have accurate travel distance on my machine's rack and pinion.

The rack and pinion is MOD 1.5 Helical and i am running a 3:1 reduction from the steppers to the pinion gear

The stepper drivers are set at 1600

I have tried unchecking the microstep multiplication factor and just using the worm turn ratio but then the steppers slow down a lot and i would have to put the acceleration and velocity up crazy high to make the motors move at a reasonable speed. as seen in the pictures. any guidance would be greatly appreciated. Thanks

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

01 Jun 2020 10:30 #169642

by rodw

Replied by rodw on topic Stepper settings for rack and pinion

I never use stepconf or pncconf so here goes

Pinion travel = 20t x 1.5mod * pi = 94.247778 mm/pinion rev

3:1 gearing = 94.247778 / 3 = 31.4159265359 mm per motor revolution

1600 step / rev

steps per mm = 1600 / 31.4159265359 = 50.9295817894 steps per mm

So just save your setup to create your ini file and rewrite it so for that joint,

STEP_SCALE = 50.9295817894

Pinion travel = 20t x 1.5mod * pi = 94.247778 mm/pinion rev

3:1 gearing = 94.247778 / 3 = 31.4159265359 mm per motor revolution

1600 step / rev

steps per mm = 1600 / 31.4159265359 = 50.9295817894 steps per mm

So just save your setup to create your ini file and rewrite it so for that joint,

STEP_SCALE = 50.9295817894

The following user(s) said Thank You: luftlupus

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 84

- Thank you received: 16

02 Jun 2020 08:33 #169773

by luftlupus

Replied by luftlupus on topic Stepper settings for rack and pinion

Thanks for the reply i changed the step scale to what you said and moved the machine 500mm and came up at 530mm, should i just keep adjusting the step scale slightly until its correct or am i missing something still? cheers

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

02 Jun 2020 08:42 - 02 Jun 2020 08:48 #169775

by Clive S

Yes you can. But you can also work out the percentage it is out by and change the scale by the same percentage

edit : 530-500 = 30 30/500*100 = 6%

Replied by Clive S on topic Stepper settings for rack and pinion

Thanks for the reply i changed the step scale to what you said and moved the machine 500mm and came up at 530mm, should i just keep adjusting the step scale slightly until its correct or am i missing something still? cheers

Yes you can. But you can also work out the percentage it is out by and change the scale by the same percentage

edit : 530-500 = 30 30/500*100 = 6%

Last edit: 02 Jun 2020 08:48 by Clive S.

The following user(s) said Thank You: luftlupus

Please Log in or Create an account to join the conversation.

- luftlupus

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 84

- Thank you received: 16

02 Jun 2020 08:43 #169776

by luftlupus

Replied by luftlupus on topic Stepper settings for rack and pinion

nice i didn't think of that ill try that tomorrow cheers

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

02 Jun 2020 09:06 #169778

by rodw

Funny you say that. I had one axis where the maths gave perfect results but on the other it took a lot of trial and error to dial it in the way Clive suggested.

Replied by rodw on topic Stepper settings for rack and pinion

Thanks for the reply i changed the step scale to what you said and moved the machine 500mm and came up at 530mm, should i just keep adjusting the step scale slightly until its correct or am i missing something still? cheers

Funny you say that. I had one axis where the maths gave perfect results but on the other it took a lot of trial and error to dial it in the way Clive suggested.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.237 seconds