Gerber 408 retrofit

- MKMII

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

27 Sep 2022 01:20 #252818

by MKMII

Gerber 408 retrofit was created by MKMII

Hello,

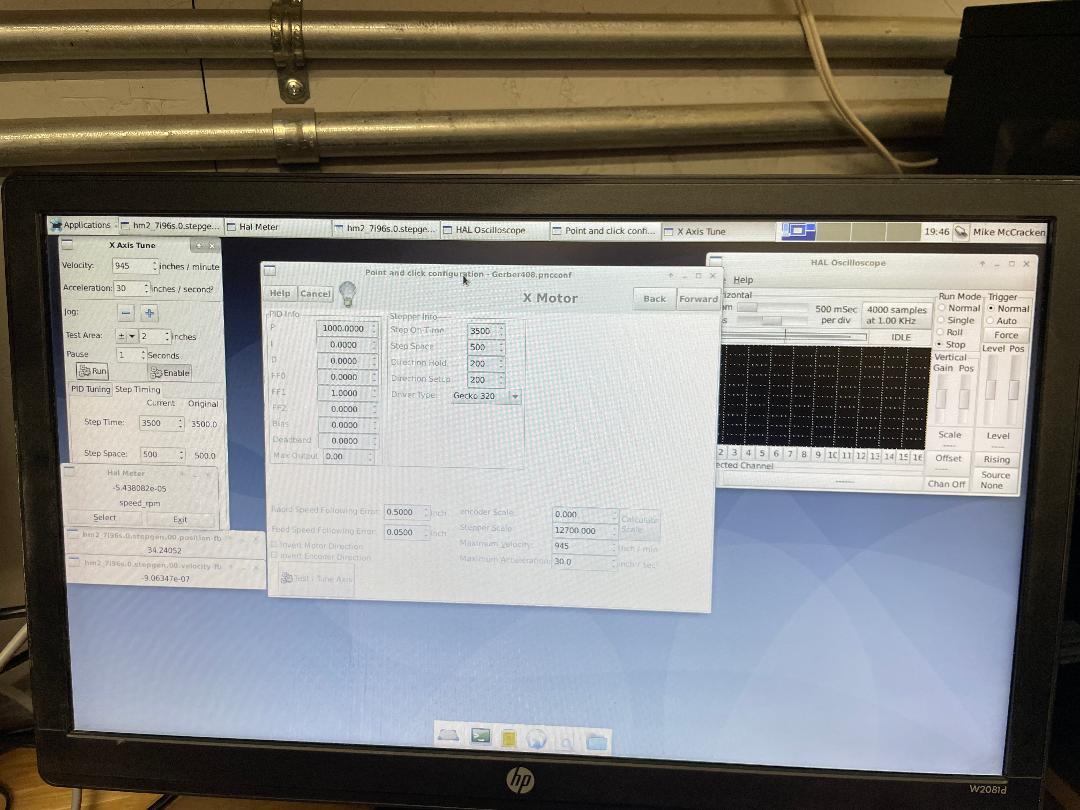

I am working on retrofitting a late 90's Gerber Sabre 408 with LinuxCNC. The PC that was running Gerbers proprietary software finally died so I decided to move to LinuxCNC.

My setup:

Mesa 7i96s

3x Gecko G320x servo drives

Original servo motors (Parker RX320ER1026)

Original Encoders (Renco 324599-03)

I got the software loaded, rewired everything (Gerber didn't make this part easy), Got the VFD changed to take a 0-10v signal, etc.

Where I am stuck is on the X, Y, Z configuration. Originally I used the Gecko 320 configuration from the drop down in the pncconf because I fugured that the "x" shouldn't change much. There was motion but not the distance I expected. Then I found the settings for the G320X and that provides no motion of the motors. This is my first build and I feel so lost when it comes to setting up the servos. I have no clue what the encoder counts are, how many steps per revolution, etc.

Any help on dip switch / software settings on this would be much appreciated.

I am working on retrofitting a late 90's Gerber Sabre 408 with LinuxCNC. The PC that was running Gerbers proprietary software finally died so I decided to move to LinuxCNC.

My setup:

Mesa 7i96s

3x Gecko G320x servo drives

Original servo motors (Parker RX320ER1026)

Original Encoders (Renco 324599-03)

I got the software loaded, rewired everything (Gerber didn't make this part easy), Got the VFD changed to take a 0-10v signal, etc.

Where I am stuck is on the X, Y, Z configuration. Originally I used the Gecko 320 configuration from the drop down in the pncconf because I fugured that the "x" shouldn't change much. There was motion but not the distance I expected. Then I found the settings for the G320X and that provides no motion of the motors. This is my first build and I feel so lost when it comes to setting up the servos. I have no clue what the encoder counts are, how many steps per revolution, etc.

Any help on dip switch / software settings on this would be much appreciated.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17697

- Thank you received: 5174

27 Sep 2022 02:24 #252822

by PCW

Replied by PCW on topic Gerber 408 retrofit

One thing to remember on step length settings is that the manufacturers numbers are

_minimum_ values so these should not be used in a real system. Unless it interferes

with the maximum speed, I would start with values double the manufacturers minimums.

As far as scaling goes, if you know the ball screw pitch, the number of steps per turn

and any gearing between the motor and the ball screw, this can be calculated. If you dont have this information you can determine it with successive approximation (as long as you have good measuring tools)

_minimum_ values so these should not be used in a real system. Unless it interferes

with the maximum speed, I would start with values double the manufacturers minimums.

As far as scaling goes, if you know the ball screw pitch, the number of steps per turn

and any gearing between the motor and the ball screw, this can be calculated. If you dont have this information you can determine it with successive approximation (as long as you have good measuring tools)

Please Log in or Create an account to join the conversation.

- MKMII

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

27 Sep 2022 02:37 #252825

by MKMII

Replied by MKMII on topic Gerber 408 retrofit

So, if I understand correctly, the step on time, step space, direction hold, direction space should be doubled as a starting point?

I found this info online and believe that it may be accurate:

for the X, and Y axis which should allow me to calculate my scaling.

servo encoder counts per revolution: 4000

Servo teeth: 28

Lead screw teeth: 70

Pitch: 20mm

counts per mm: 500

I found this info online and believe that it may be accurate:

for the X, and Y axis which should allow me to calculate my scaling.

servo encoder counts per revolution: 4000

Servo teeth: 28

Lead screw teeth: 70

Pitch: 20mm

counts per mm: 500

Please Log in or Create an account to join the conversation.

- SkyMoCo

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 4

13 Mar 2023 17:39 #266577

by SkyMoCo

Replied by SkyMoCo on topic Gerber 408 retrofit

I am looking at doing the same. Did you get this working?

Please Log in or Create an account to join the conversation.

- MKMII

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

13 Mar 2023 17:47 #266578

by MKMII

Replied by MKMII on topic Gerber 408 retrofit

Yes, I have the machine up and running. Being the first CNC retrofit it was a bit of a challenge. I started with using the original motors and gecko drives. I was not successful at tuning the servos so l scrapped that idea and went with new stepper motors and drives. I had to make room for the new motors but maybe I could have gone with a size smaller. I can post some pictures later of what I did to make it work. I’m no expert, and im sure everything isn’t proper but it was definitely a learning experience.

Please Log in or Create an account to join the conversation.

- SkyMoCo

- Offline

- Junior Member

-

Less

More

- Posts: 32

- Thank you received: 4

13 Mar 2023 17:51 #266579

by SkyMoCo

Replied by SkyMoCo on topic Gerber 408 retrofit

Pictures would be great. What drives did you go with? Something like the the Teknic? Are they standard Nema 34's?

Please Log in or Create an account to join the conversation.

- gerb

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

30 Mar 2023 06:02 #267888

by gerb

Replied by gerb on topic Gerber 408 retrofit

Hi Guys,

Retrofiting a 408 Gerber as well.

Starting from scratch, pre-itch really, as I'm without a pc.

Aiming for Mesa FPGA setup.

A Fanuc om-d controlled CNC Mill is used for aluminum machining at the shop and hoping to get this router up to speed to pick up the load.

Any advice is welcome, specially where to start and what to focus on, to get this ball rolling.

Looking forward to any replies

Cheers,

Retrofiting a 408 Gerber as well.

Starting from scratch, pre-itch really, as I'm without a pc.

Aiming for Mesa FPGA setup.

A Fanuc om-d controlled CNC Mill is used for aluminum machining at the shop and hoping to get this router up to speed to pick up the load.

Any advice is welcome, specially where to start and what to focus on, to get this ball rolling.

Looking forward to any replies

Cheers,

Please Log in or Create an account to join the conversation.

- fdarling

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 14

30 Mar 2023 15:30 #267920

by fdarling

Replied by fdarling on topic Gerber 408 retrofit

I have retrofit two Gerber Sabre 408's with LinuxCNC, and plan on retrofitting at least one more in the near future. I use Mesa cards and custom adapter PCBs mounted onto a plate that becomes a bolt-in replacement for the original Gerber motherboard in the top of the electrical cabinet.

Here is a video of the first machine I did (it has an after-market ISO30 ATC spindle):

Gerber Sabre 408 retrofit with LinuxCNC 3D routing foam

If your original setup had the "high frequency spindle" option, then you have a Perske (non-ATC) or Colombo (ATC) spindle with a Saftronics/Yaskawa VFD in it's own electrical box. This box is controlled by two signals: a relay to turn the spindle on, and Modbus over RS-232 (not RS-485!) to control the spindle speed.

If you have a "dumb" 120V router (like a Porter Cable, etc.) hooked to the outlet on the side of the Z axis, then your spindle is controlled by a relay within the main electrical cabinet. (None of our machines are like this.)

My current setup provides access to the following:

If you are interested in buying a retrofit kit from me, please private message me.

--Forest

Here is a video of the first machine I did (it has an after-market ISO30 ATC spindle):

Gerber Sabre 408 retrofit with LinuxCNC 3D routing foam

If your original setup had the "high frequency spindle" option, then you have a Perske (non-ATC) or Colombo (ATC) spindle with a Saftronics/Yaskawa VFD in it's own electrical box. This box is controlled by two signals: a relay to turn the spindle on, and Modbus over RS-232 (not RS-485!) to control the spindle speed.

If you have a "dumb" 120V router (like a Porter Cable, etc.) hooked to the outlet on the side of the Z axis, then your spindle is controlled by a relay within the main electrical cabinet. (None of our machines are like this.)

My current setup provides access to the following:

- encoder feedback from the servo encoders

- analog torque / enable signals to torque-mode brushed DC servo drives

- limit/home switches

- +5V & +24V power from the motherboard power connector

- controlling the "high frequency spindle" electrical cabinet via Modbus

- respecting the physical E-stop buttons on the machine itself

- no pendant support (the original pendant was proprietary with a brain of it's own)

- controlling the 120V "dumb" spindle electrical outlet on the side of the Z axis

- controlling the 120V vacuum electrical outlet on the electrical cabinet (for dust collection?)

- listening to the optional auxiliary sensors on the side of the Z axis (does anyone ever use them? Our machines just have hole plugs and no connectors...)

If you are interested in buying a retrofit kit from me, please private message me.

--Forest

The following user(s) said Thank You: Salted-Pork_

Please Log in or Create an account to join the conversation.

- Ajvr

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

13 Aug 2023 21:41 #277881

by Ajvr

Replied by Ajvr on topic Gerber 408 retrofit

Has anyone else made progress on this recently?

Am looking to do the same but am new to CNC controllers and finding it hard to judge the overall cost

Am looking to do the same but am new to CNC controllers and finding it hard to judge the overall cost

Please Log in or Create an account to join the conversation.

- fdarling

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 14

13 Aug 2023 22:05 #277884

by fdarling

I expect to have prototypes within a month, I'll keep you all posted.

Replied by fdarling on topic Gerber 408 retrofit

I am actively working on a monolithic motherboard replacement, attached is a photo of the physical form factor. I am 90% done with the schematic, and then will knock out the trace/component layout on the board. The motherboard is huge (14x17") so there aren't space issues thankfully.Has anyone else made progress on this recently?

Am looking to do the same but am new to CNC controllers and finding it hard to judge the overall cost

I expect to have prototypes within a month, I'll keep you all posted.

The following user(s) said Thank You: tommylight, SkyMoCo

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.214 seconds