Overriding feed rate in a subroutine

- DaBit

- Offline

- Elite Member

-

- Posts: 203

- Thank you received: 19

For some repeating tasks I prefer to write a subroutine and call that either from a GUI, MDI or a small piece of G-code.

I also like to pass as little parameters as possible to the subroutines. For example: a 'mill circular hole' subroutine usually only needs diameter and depth; the current coordinates, tool radius, etc. are all accessible though numbered parameters (#5000-#5601). Feed rate, spindle speed, etc. should be aready set just like you do for a G1 move or canned cycle for example.

But sometimes I would like to temporarily reduce or increase feedrate in a subroutine. Sharp corners, a plunge move, a finish pass, etcetera.

Is there a method to alter the current set feedrate? Either by changing it percentually, or by accessing the current feed rate, doing the math, and executing an F #<NewFeedRate> command?

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 239

If you use the master (not sure how much has migrated down to 2.5)

see www.linuxcnc.org/docs/devel/html/gcode/o...ub:system-parameters

eg. F[#<_feed> * 0.8] would reduce by 20%

regards

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

JT

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Elite Member

-

- Posts: 203

- Thank you received: 19

Hi

If you use the master (not sure how much has migrated down to 2.5)

This is exactly what I need.

But unfortunately running an F1234 followed by (debug, #<_feed>) in the MDI window of axis 2.5.3 results in '######'. So I suppose it is not supported in 2.5

Is there a guide on how to 'use the master'? And is it stable enough to run a hobby machine? I do not mind a glitch here and there, but endmills and stock material still cost money.

[edit]

Just found this: wiki.linuxcnc.org/cgi-bin/wiki.pl?Installing_LinuxCNC

Might be the answer to the previous question

[/edit]

[edit2]

I compiled 2.6.0~pre in a local VirtualBox session, and f1234 followed by (debug, #<_feed>) in MDI results in ' 1234.0'. Yay!

Might want to do that on the machine control PC too...

[/edit2]

If your using Axis just move the Feed Override slider or press help to see the keyboard shortcuts.

I am aware of that slider and it' s associated shortcut keys, but I want to do this from within an O-word subroutine.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 239

Looks like you got there

Is there a guide on how to 'use the master'? And is it stable enough to run a hobby machine? I do not mind a glitch here and there, but endmills and stock material still cost money.

If you download the master as a snapshot release from buildbot, rather than the current git repo, you should get a pretty stable build.

I use it all the time, unless trying to answer a query specific to 2.5.x and have no problems.

Make sure you use the docs at

www.linuxcnc.org/docs/devel/html

and you should have all the correct info for the various changes

regards

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Elite Member

-

- Posts: 203

- Thank you received: 19

I will do the same on the CNC box.

Is there a list somewhere with 2.6.0-pre differences/enhancements compared to 2.5.3?

Since I'm running a pre-release now, are there specific areas the developers would like some testing/feedback?

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 239

www.linuxcnc.org/docs/devel/html/remap/structure.html

but there are changes all over.

I should just use it however suits you and if you hit a problem that seems to be a bug, shout out (after checking several times

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Elite Member

-

- Posts: 203

- Thank you received: 19

I have two more:

- How do I rotate the coordinate system in such a way that jogging is also included? I am aware of 'G10 L2 P0 Rxx', but that doesn't work for jogging. The reason behind this: I would like to clamp a workpiece to the table without perfectly aligning it, touch off two known features, and calculate a coordinate transform. It would be nice if I can plug in a 4x4 matrix somewhere to convert workpiece coordinates to machine coordinates.

- How does one create a 'perfect spiral'? I can approximate one using line or (better) arc segments, but it is not a 'perfect continuous' spiral.

If you would like me to create separate topics for this: fine with me.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 239

How does one create a 'perfect spiral'? I can approximate one using line or (better) arc segments, but it is not a 'perfect continuous' spiral.

Depends exactly what you mean by spiral.

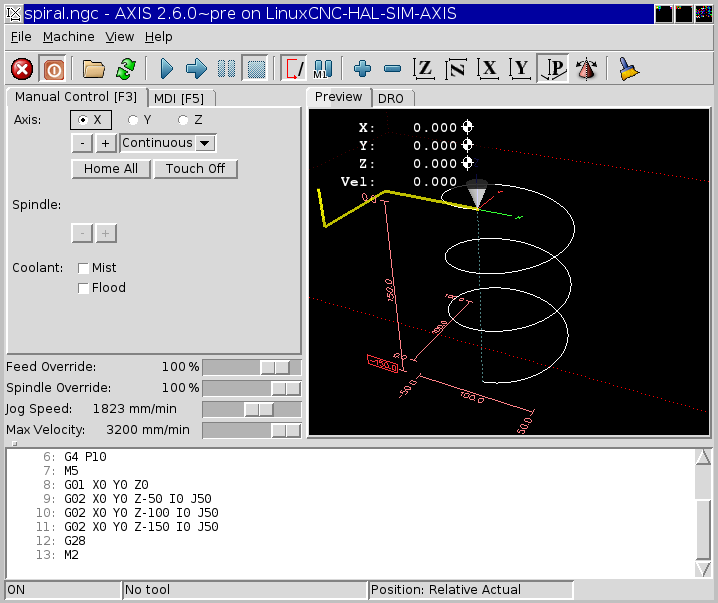

This will produce a downwards cutting helix

G01 X0 Y0 Z0

G02 X0 Y0 Z-50 I0 J50

G02 X0 Y0 Z-100 I0 J50

G02 X0 Y0 Z-150 I0 J50

Or do you mean a plot which remains in the same Z plane and goes from outside diameter to the centre?

regards

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Elite Member

-

- Posts: 203

- Thank you received: 19

Code used to generate this is also in the image, and is hacked together quickly (so not too good).

Quite a close approximation to a spiral, but still an approximation consisting of multiple arc segments.

I keep on thinking that such a basic shape as a spiral should be very easy to generate, but I just don't see it.

Please Log in or Create an account to join the conversation.