- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- calling subroutine from G54, G55, G56, but it acts weird

calling subroutine from G54, G55, G56, but it acts weird

- johnbump

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 1

23 Nov 2025 00:19 #339013

by johnbump

calling subroutine from G54, G55, G56, but it acts weird was created by johnbump

I touch off G54, X=0, Y=0, Z=0. Then I run my program, which uses G10 to set up work offsets, in theory every 30mm away from G54, each calling the same subroutine. (Kinda weird subroutine: I'm trying to cut t-slots in the edge of oak and it tears out, so I'm finessing the toolbit into the wood.)

What I'm seeing is that I set all three axes at 0, then it switches to G55, and I very strongly think the G10 offset should read G10 L20 P2 X-30 Y0 Z0. If I do that, it runs to X-30, Y0, Z3. In all the subsequent, identical, work offsets, it also runs to Z3.

If I touch off X0 Y0 Z0 in G54, and then instead do, as the below program shows, G10 L20 P2 X-30 Y0 Z3, it runs perfectly.

I do not understand where three millimeters in Z is coming from, when both X and Y work exactly as I expected.

Is there a secret stateful variable somewhere I need to reset?

For that matter, is there a better way to do this? This is my first time trying work offsets. I've always previously either used a cam program or written multiple sites by hand as a single file without a subprogram, but I thought it would be fun to try learning work offsets.

Thanks for any advice. LinuxCNC, version 2.9.6.

G17 G21 G40 G49 G80 G90

M08

G54

M05

M09M6 T1

G10 L20 P1 X0 Y0 Z0

G10 L20 P2 X-30 Y0 Z3

G10 L20 P3 X-60 Y0 Z3

G10 L20 P4 X-90 Y0 Z3

G10 L20 P5 X-120 Y0 Z3

G10 L20 P6 X-150 Y0 Z3

o199 sub

G0 X2 Y-20

G1 Z-8 F20

G1 Y-12 F10

G0 Y-20

G0 X3.237

G1 Y-12 F10

G1 y-20 F40

G0 x-3.237

G1 y0 F10

g2 x0 Y3.237 R3.237

g2 x3.237 Y0 R3.237

g1 y-20

g0 z2

o199 endsub

G55

o199 call

G56

o199 call

G57

o199 call

G58

o199 call

G59

o199 call

G0 Z10

G54 G0 X0 Y0

M2

What I'm seeing is that I set all three axes at 0, then it switches to G55, and I very strongly think the G10 offset should read G10 L20 P2 X-30 Y0 Z0. If I do that, it runs to X-30, Y0, Z3. In all the subsequent, identical, work offsets, it also runs to Z3.

If I touch off X0 Y0 Z0 in G54, and then instead do, as the below program shows, G10 L20 P2 X-30 Y0 Z3, it runs perfectly.

I do not understand where three millimeters in Z is coming from, when both X and Y work exactly as I expected.

Is there a secret stateful variable somewhere I need to reset?

For that matter, is there a better way to do this? This is my first time trying work offsets. I've always previously either used a cam program or written multiple sites by hand as a single file without a subprogram, but I thought it would be fun to try learning work offsets.

Thanks for any advice. LinuxCNC, version 2.9.6.

G17 G21 G40 G49 G80 G90

M08

G54

M05

M09M6 T1

G10 L20 P1 X0 Y0 Z0

G10 L20 P2 X-30 Y0 Z3

G10 L20 P3 X-60 Y0 Z3

G10 L20 P4 X-90 Y0 Z3

G10 L20 P5 X-120 Y0 Z3

G10 L20 P6 X-150 Y0 Z3

o199 sub

G0 X2 Y-20

G1 Z-8 F20

G1 Y-12 F10

G0 Y-20

G0 X3.237

G1 Y-12 F10

G1 y-20 F40

G0 x-3.237

G1 y0 F10

g2 x0 Y3.237 R3.237

g2 x3.237 Y0 R3.237

g1 y-20

g0 z2

o199 endsub

G55

o199 call

G56

o199 call

G57

o199 call

G58

o199 call

G59

o199 call

G0 Z10

G54 G0 X0 Y0

M2

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4652

- Thank you received: 2077

23 Nov 2025 17:27 - 23 Nov 2025 17:28 #339063

by Aciera

touching off in G54 will actually run 'g10 l20 p1 z0' which will set the z-offset value in G54 such that the axis position is equal to zero. This is the value you would need in the other offset systems as well. Which I guess is 3.

Replied by Aciera on topic calling subroutine from G54, G55, G56, but it acts weird

If I touch off X0 Y0 Z0 in G54, and then instead do, as the below program shows, G10 L20 P2 X-30 Y0 Z3, it runs perfectly.

touching off in G54 will actually run 'g10 l20 p1 z0' which will set the z-offset value in G54 such that the axis position is equal to zero. This is the value you would need in the other offset systems as well. Which I guess is 3.

Last edit: 23 Nov 2025 17:28 by Aciera.

Please Log in or Create an account to join the conversation.

- johnbump

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 1

25 Nov 2025 02:30 #339179

by johnbump

Replied by johnbump on topic calling subroutine from G54, G55, G56, but it acts weird

I wasn't good with my phrasing. I touch off G54, and explicitly set G10 L20 P1 X0 Y0 Z0 to force G54 (I may not need to do this? because it's what automatically happens when I touch off if I have the popup set to G54?), but don't ever use that except for touchoff/part location. (I *think* this is how I should be doing this?) Then I subsequently set up G10 P2, G10 P3, and so forth, and only machine at the work offsets referenced by those.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4652

- Thank you received: 2077

25 Nov 2025 06:43 #339187

by Aciera

Replied by Aciera on topic calling subroutine from G54, G55, G56, but it acts weird

'P0' will set the currently active offsets, while 'P1','P2' ... will set the values of a particular offset system.

You could also stay in G54 and use different G52 offsets.

You could also stay in G54 and use different G52 offsets.

Please Log in or Create an account to join the conversation.

- johnbump

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 1

28 Nov 2025 00:43 #339359

by johnbump

Replied by johnbump on topic calling subroutine from G54, G55, G56, but it acts weird

I will go read some more about G52, thanks!

Please Log in or Create an account to join the conversation.

- tlightus

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 19

26 Dec 2025 21:51 #340547

by tlightus

Replied by tlightus on topic calling subroutine from G54, G55, G56, but it acts weird

sorry if this is the wrong place to post this but it seemed appropriate.

i think i found a bug with subroutine calls

Conditions:

set up a pyvcp button to call an MDI_COMMAND

Set fixgure offsets for G54, G55

remain in G55 X0 Y0 and issue:

MDI_COMMAND = G0 G90 G54 X0 Y0

and that will work fine

Go back to G55 active offset at X0 Y0 and change the command to call a subroutine

MDI_COMMAND = o<work_zero> call

will fail not executing the subroutine command and sit at G55 zero

i tested this in both axis and flexgui with the exact same results

####### SUBROUTINE #######

o<work_zero> sub

G90 G54 G0 X0 Y0

o<work_zero> endsub

m2

#######

if you are still in G55 at X0 Y0 and issue

G0 G90 G54 X0 Y0 from the mdi command line it will go to G54 X0 Y0 also

i think i found a bug with subroutine calls

Conditions:

set up a pyvcp button to call an MDI_COMMAND

Set fixgure offsets for G54, G55

remain in G55 X0 Y0 and issue:

MDI_COMMAND = G0 G90 G54 X0 Y0

and that will work fine

Go back to G55 active offset at X0 Y0 and change the command to call a subroutine

MDI_COMMAND = o<work_zero> call

will fail not executing the subroutine command and sit at G55 zero

i tested this in both axis and flexgui with the exact same results

####### SUBROUTINE #######

o<work_zero> sub

G90 G54 G0 X0 Y0

o<work_zero> endsub

m2

#######

if you are still in G55 at X0 Y0 and issue

G0 G90 G54 X0 Y0 from the mdi command line it will go to G54 X0 Y0 also

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 508

- Thank you received: 212

26 Dec 2025 23:32 #340557

by MaHa

Replied by MaHa on topic calling subroutine from G54, G55, G56, but it acts weird

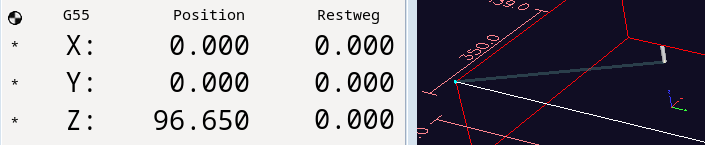

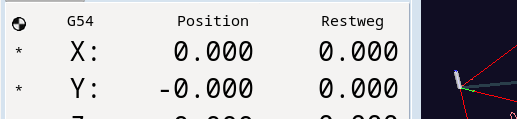

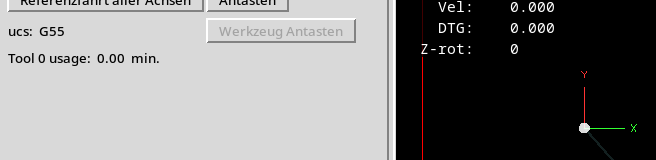

Attachments:

Please Log in or Create an account to join the conversation.

- tlightus

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 19

26 Dec 2025 23:59 #340559

by tlightus

Replied by tlightus on topic calling subroutine from G54, G55, G56, but it acts weird

thank you for testing. i have been getting a very different result but will go back and see if it was something i was doing wrong.

Please Log in or Create an account to join the conversation.

- tlightus

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 19

27 Dec 2025 16:33 #340586

by tlightus

Replied by tlightus on topic calling subroutine from G54, G55, G56, but it acts weird

i did notice you use machine zero as the G54 offset. try setting it off that and run the test.

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 508

- Thank you received: 212

27 Dec 2025 19:33 #340595

by MaHa

Replied by MaHa on topic calling subroutine from G54, G55, G56, but it acts weird

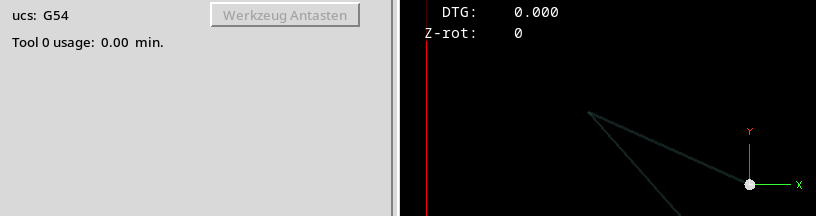

Attachments:

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- calling subroutine from G54, G55, G56, but it acts weird

Time to create page: 3.046 seconds