LinuxCNC with DevFoamWing

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

01 Oct 2019 06:26 #146781

by Clive S

Replied by Clive S on topic LinuxCNC with DevFoamWing

Been thinking about this . Have you checked the cad to see if it is set to units = CM as that would cause the problem between CM and MM exactly 10

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

01 Oct 2019 07:09 #146784

by pl7i92

Replied by pl7i92 on topic LinuxCNC with DevFoamWing

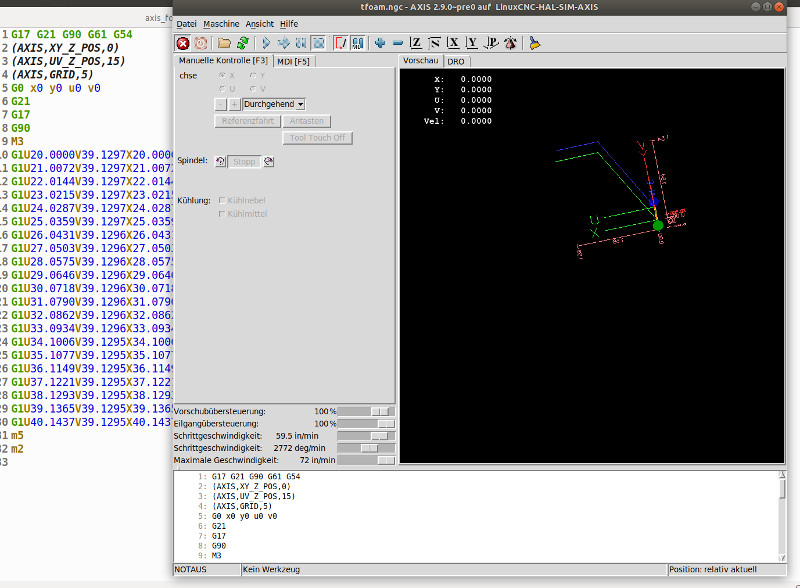

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

03 Oct 2019 04:49 #146944

by andypugh

This is because your G-code begins with a G61

linuxcnc.org/docs/2.7/html/gcode/g-code.html#gcode:g61-g61.1

Try G64 instead.

Replied by andypugh on topic LinuxCNC with DevFoamWing

2) On slopes, it runs a line of GCode, pauses, runs the next, pauses, etc, etc. You can hear and see the motors run, run, run, run instead of just running from one end to the other.

This is because your G-code begins with a G61

linuxcnc.org/docs/2.7/html/gcode/g-code.html#gcode:g61-g61.1

Try G64 instead.

Please Log in or Create an account to join the conversation.

- jeffgar2000@gmail.com

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

03 Oct 2019 14:47 #146981

by jeffgar2000@gmail.com

Replied by jeffgar2000@gmail.com on topic LinuxCNC with DevFoamWing

Probably worse, they are G1s

G1U21.0104V18.9463X20.8698Y61.2523

G1U21.9144V19.1432X21.7883Y61.3637

G1U22.8202V19.3391X22.7084Y61.4738

G1U23.7260V19.5351X23.6286Y61.5840

G1U24.6306V19.7293X24.5474Y61.6926

G1U25.5352V19.9236X25.4663Y61.8013

G1U26.4414V20.1168X26.3866Y61.9088

G1U27.3463V20.3098X27.3056Y62.0161

G1U28.2527V20.5019X28.2260Y62.1224

G1U29.1579V20.6937X29.1451Y62.2286

G1U30.0646V20.8846X30.0658Y62.3336

G1U30.9715V21.0754X30.9866Y62.4386

G1U31.8772V21.2646X31.9060Y62.5421

G1U32.7843V21.4540X32.8269Y62.6457

G1U33.6903V21.6419X33.7465Y62.7478

G1U34.5965V21.8296X34.6663Y62.8498

G1U35.5027V22.0173X35.5860Y62.9517

G1U36.4102V22.2039X36.5071Y63.0525

G1U37.3179V22.3905X37.4283Y63.1532

G1U38.2244V22.5755X38.3482Y63.2524

G1U21.0104V18.9463X20.8698Y61.2523

G1U21.9144V19.1432X21.7883Y61.3637

G1U22.8202V19.3391X22.7084Y61.4738

G1U23.7260V19.5351X23.6286Y61.5840

G1U24.6306V19.7293X24.5474Y61.6926

G1U25.5352V19.9236X25.4663Y61.8013

G1U26.4414V20.1168X26.3866Y61.9088

G1U27.3463V20.3098X27.3056Y62.0161

G1U28.2527V20.5019X28.2260Y62.1224

G1U29.1579V20.6937X29.1451Y62.2286

G1U30.0646V20.8846X30.0658Y62.3336

G1U30.9715V21.0754X30.9866Y62.4386

G1U31.8772V21.2646X31.9060Y62.5421

G1U32.7843V21.4540X32.8269Y62.6457

G1U33.6903V21.6419X33.7465Y62.7478

G1U34.5965V21.8296X34.6663Y62.8498

G1U35.5027V22.0173X35.5860Y62.9517

G1U36.4102V22.2039X36.5071Y63.0525

G1U37.3179V22.3905X37.4283Y63.1532

G1U38.2244V22.5755X38.3482Y63.2524

Please Log in or Create an account to join the conversation.

- jeffgar2000@gmail.com

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

03 Oct 2019 14:49 #146982

by jeffgar2000@gmail.com

Replied by jeffgar2000@gmail.com on topic LinuxCNC with DevFoamWing

I thought the CM thing too but can't find anything that looks like that anywhere. I will get the ini file and hal posted soon. I lost my network out to the shop so I need to grab a thumb drive and run out there to get it.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

04 Oct 2019 01:48 #147067

by andypugh

Replied by andypugh on topic LinuxCNC with DevFoamWing

G1 is correct. But there was a G61 at the very top of the file, which puts the machine in "exact stop" mode (it's a modal code)

Please Log in or Create an account to join the conversation.

- jeffgar2000@gmail.com

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

04 Oct 2019 02:14 #147075

by jeffgar2000@gmail.com

Replied by jeffgar2000@gmail.com on topic LinuxCNC with DevFoamWing

You are correct. I missed that. Other than that and the scaling being a little odd x10 it is running really well. I think we will run it a while and see what shakes out.

Thank you all for helping get to this point.

Thank you all for helping get to this point.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

04 Oct 2019 04:20 #147088

by andypugh

Replied by andypugh on topic LinuxCNC with DevFoamWing

As for the x10 thing, is it making things 10x bigger than the G-code or is the G-code 10x bigger than the model?

Please Log in or Create an account to join the conversation.

- jeffgar2000@gmail.com

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

04 Oct 2019 14:31 #147116

by jeffgar2000@gmail.com

Replied by jeffgar2000@gmail.com on topic LinuxCNC with DevFoamWing

My machine is 900mm x 900mm x 1500mm.

Manually from the mdi it moves the correct distances. G0 X30 U30 moves the X and U axes 30mm. I generate Gcode that looks right and shows dimensions of 40mm, 50mm etc but when I see it go to those, it moves 400 and 500.

The way we caught it the first time was my oldest son and I were calibrating the scales on the machine. I'd tell him "Take the X and U axes 100mm." He'd do it through the mdi (G0 X100 U100) and I'd measure, calc the distance it was off on my calculator and tell him to adjust scaling in the ini file, save, reload and retry. All went as you would expect and we had it nailing the distances.

Then we loaded up a very small constant chord wing test with 40mm chord. It would have been a useless wing but I wanted something to prove it was reading my GCode that looked like a wing. It moved way past of the small piece of foam we had and tried to cut it as a 400mm chord.

I thought I had screwed up measuring or my son who was running the machine and entering scaling in the ini had screwed up his saves. Nope. All looked right and we performed our scaling checks and again and then confirmed the GCode size error again.

My wife is also an engineer with so I had her stand and watch. She thought she caught a few things we did wrong but each time the numbers were right until we go to automatically cut code.

I think it has to be something in the GCode but I can't see it.

Like I said though, other than that (and a old shaft coupler we broke yesterday) it is running really well so I will probably just run it a while. Usually I find issues where I did something stupid that way.

Manually from the mdi it moves the correct distances. G0 X30 U30 moves the X and U axes 30mm. I generate Gcode that looks right and shows dimensions of 40mm, 50mm etc but when I see it go to those, it moves 400 and 500.

The way we caught it the first time was my oldest son and I were calibrating the scales on the machine. I'd tell him "Take the X and U axes 100mm." He'd do it through the mdi (G0 X100 U100) and I'd measure, calc the distance it was off on my calculator and tell him to adjust scaling in the ini file, save, reload and retry. All went as you would expect and we had it nailing the distances.

Then we loaded up a very small constant chord wing test with 40mm chord. It would have been a useless wing but I wanted something to prove it was reading my GCode that looked like a wing. It moved way past of the small piece of foam we had and tried to cut it as a 400mm chord.

I thought I had screwed up measuring or my son who was running the machine and entering scaling in the ini had screwed up his saves. Nope. All looked right and we performed our scaling checks and again and then confirmed the GCode size error again.

My wife is also an engineer with so I had her stand and watch. She thought she caught a few things we did wrong but each time the numbers were right until we go to automatically cut code.

I think it has to be something in the GCode but I can't see it.

Like I said though, other than that (and a old shaft coupler we broke yesterday) it is running really well so I will probably just run it a while. Usually I find issues where I did something stupid that way.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

04 Oct 2019 15:09 #147118

by tommylight

Replied by tommylight on topic LinuxCNC with DevFoamWing

Are you using a Gecko G540 or similar ?

Please Log in or Create an account to join the conversation.

Time to create page: 0.263 seconds