Zwei von einander abhaengige Achsen ansteuern

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

10 Apr 2017 12:03 #91113

by wicki

Zwei von einander abhaengige Achsen ansteuern was created by wicki

Hi zusammen,

die Fragestellung ist etws komplex, so dass ich sie erst mal auf deutsch poste

und hoffe, dass sie verstaendlich rueberkommt. Und mir dann jemand bei der

Problemloesung helfen kann - oder mir sagt, wo ich am besten danach frage.

Also ich habe hier eine "cerec"-Dentalfraese zerlegt und die Mechanik an LinuxCNC

angeschlossen. Sie hat 2 Linearachsen, die gleichzeitig auch noch rotieren koennen.

An der (grundsaetzlich auch drehbaren) Z-Achse sitzt eine turbinengetriebene

Diamantscheibe.

Die Z-Achse ist z.Zt. fixiert und kann nur linear rauf und runter.

Die Y-Achse kann linear rein und raus - und die X-Achse kann rotieren.

Das ganze will ich zum innen- und aussengravieren von Rotationskoerpern

benutzen.

Systemimmannent bedingt jedoch eine Bewegung in X-Richtung (rotation) aber

zugleich eine Bewegunbg in Y-Richtung (rein oder raus).

D.h.: wenn ich nur eine Rotation wunesche, dann muss ich gegen diese

Zwangsbewegung in Y-Richtung gegensteuern.

Wo und wie bringe ich sowas unter? Gibt es dafuer eine Standard-Handling

oder muss ich mir mittels der Kinematics was eigenes basteln?

Der sinnvollste Ansatz scheint mir der des "Seilzug-Syroporschneiders" zu sein.

Sehe ich das richtig oder falsch oder hat da jemand einen besseren Tip ?

die Fragestellung ist etws komplex, so dass ich sie erst mal auf deutsch poste

und hoffe, dass sie verstaendlich rueberkommt. Und mir dann jemand bei der

Problemloesung helfen kann - oder mir sagt, wo ich am besten danach frage.

Also ich habe hier eine "cerec"-Dentalfraese zerlegt und die Mechanik an LinuxCNC

angeschlossen. Sie hat 2 Linearachsen, die gleichzeitig auch noch rotieren koennen.

An der (grundsaetzlich auch drehbaren) Z-Achse sitzt eine turbinengetriebene

Diamantscheibe.

Die Z-Achse ist z.Zt. fixiert und kann nur linear rauf und runter.

Die Y-Achse kann linear rein und raus - und die X-Achse kann rotieren.

Das ganze will ich zum innen- und aussengravieren von Rotationskoerpern

benutzen.

Systemimmannent bedingt jedoch eine Bewegung in X-Richtung (rotation) aber

zugleich eine Bewegunbg in Y-Richtung (rein oder raus).

D.h.: wenn ich nur eine Rotation wunesche, dann muss ich gegen diese

Zwangsbewegung in Y-Richtung gegensteuern.

Wo und wie bringe ich sowas unter? Gibt es dafuer eine Standard-Handling

oder muss ich mir mittels der Kinematics was eigenes basteln?

Der sinnvollste Ansatz scheint mir der des "Seilzug-Syroporschneiders" zu sein.

Sehe ich das richtig oder falsch oder hat da jemand einen besseren Tip ?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21192

- Thank you received: 7240

10 Apr 2017 20:53 #91146

by tommylight

Replied by tommylight on topic Zwei von einander abhaengige Achsen ansteuern

Das mit der Axis can ich nicht verstehen, gibt es bilder bitte?

MFG

Tom

MFG

Tom

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

11 Apr 2017 03:42 #91163

by wicki

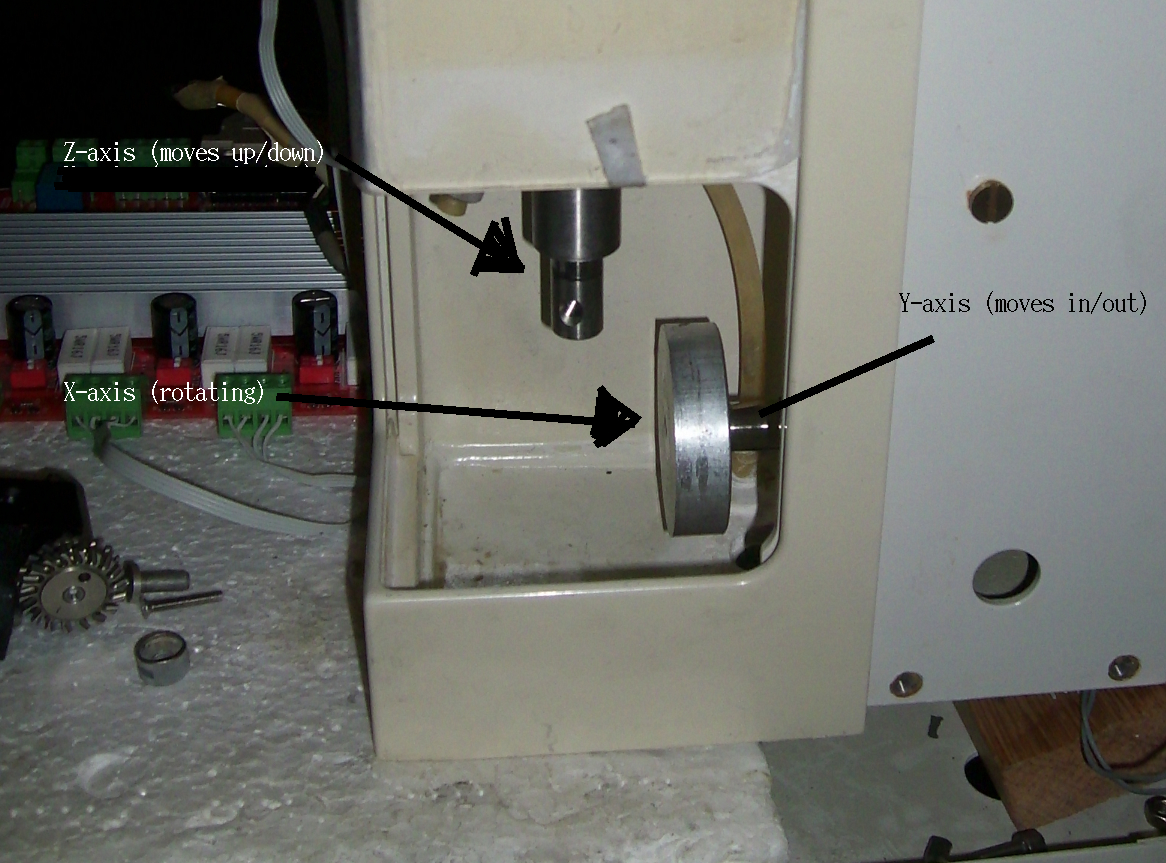

OK, let me try to explain together with pictures....

The Z-axis moves up and down, the Y-axis moves in and out, the X-axis is an angular axis.

But the mechanical construction implies a rotation of the X-axis while moving in/out.

So I have to correct the position of the (angular) X-axis while any Y-axis move.

Replied by wicki on topic Zwei von einander abhaengige Achsen ansteuern

gibt es bilder bitte?

OK, let me try to explain together with pictures....

The Z-axis moves up and down, the Y-axis moves in and out, the X-axis is an angular axis.

But the mechanical construction implies a rotation of the X-axis while moving in/out.

So I have to correct the position of the (angular) X-axis while any Y-axis move.

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

11 Apr 2017 06:00 - 11 Apr 2017 06:06 #91166

by wicki

Replied by wicki on topic something buggy in "check_config.tcl"

when I try to start a fresh compiled source from git, I get:

"this version of linuxcnc seperates the .... press YES to convert"

invalid command name "parse_ini"

while executing

"parse_ini $inifile"

#

# begin

package require Linuxcnc ;# parse_ini

set ::progname [file rootname [file tail [info script]]]

set inifile [lindex $::argv 0]

if ![file exists $inifile] {

err_exit

err_exit

check_config: ERROR

Missing [KINS]KINEMATICS=

Missing [KINS]JOINTS=

check_config validation failed

LinuxCNC terminated with an error. You can find more information in the log:

/home/xxx/linuxcnc_debug.txt

Can not find -sec EMC -var VERSION -num 1

"this version of linuxcnc seperates the .... press YES to convert"

when I say YES I get:

invalid command name "parse_ini"

while executing

"parse_ini $inifile"

a look into "check_config.tcl" offers, that there is no

"parse_ini" is defined:

line 81:"parse_ini" is defined:

#

# begin

package require Linuxcnc ;# parse_ini

set ::progname [file rootname [file tail [info script]]]

set inifile [lindex $::argv 0]

if ![file exists $inifile] {

err_exit

-

}

if !

err_exit

-

}

parse_ini $inifile

when I remove line 93 (parse_ini $inifile - because the header is in a wrong place)

I get:

I get:

check_config: ERROR

Missing [KINS]KINEMATICS=

Missing [KINS]JOINTS=

check_config validation failed

LinuxCNC terminated with an error. You can find more information in the log:

/home/xxx/linuxcnc_debug.txt

an in "linuxcnc_debug.txt" I find:

Can not find -sec EMC -var VERSION -num 1

Last edit: 11 Apr 2017 06:06 by wicki. Reason: stupid formatting

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

11 Apr 2017 06:13 #91167

by wicki

Replied by wicki on topic stupid format of "quick reply"

sorry, but it seems to be impossible, to put the above message in a clean format......

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21192

- Thank you received: 7240

12 Apr 2017 00:11 #91214

by tommylight

Replied by tommylight on topic stupid format of "quick reply"

Did you get past the Kinematics error?

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

12 Apr 2017 04:26 #91223

by wicki

yes...

just tested it again and now an old 2.7.x-conf was converted.

maybe the reason yesterday was an wrong path-setting while testing different versions

with wrong RIP-env.

but my axis-problem is not solved....

here is a video to show the problem:

asteb.de/cerec1.avi

I'm not sure, which is the right way to solve it:

by a kinematics-file or by a hal-config - or by g-code?

what I need is: rotation of one axis (here named X) should result in an lef/right move of the other axis...

Replied by wicki on topic stupid format of "quick reply"

Did you get past the Kinematics error?

yes...

just tested it again and now an old 2.7.x-conf was converted.

maybe the reason yesterday was an wrong path-setting while testing different versions

with wrong RIP-env.

but my axis-problem is not solved....

here is a video to show the problem:

asteb.de/cerec1.avi

I'm not sure, which is the right way to solve it:

by a kinematics-file or by a hal-config - or by g-code?

what I need is: rotation of one axis (here named X) should result in an lef/right move of the other axis...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21192

- Thank you received: 7240

13 Apr 2017 00:27 #91279

by tommylight

Replied by tommylight on topic stupid format of "quick reply"

Is the spindle on the vertical axis or the horizontal one?

Does the horizontal one have 2 separate motors ? In the video it looks like it has 2.

That is quite easy to set up in Linuxcnc and can be done in several ways.

One is having a normal X axis that rotates so you do the calculations of radius depending on the diameter of the part. The other is having that X axis set as A or B axis, rotational so it does the calculations in Linuxcnc, that is 4th axis.

Does the horizontal one have 2 separate motors ? In the video it looks like it has 2.

That is quite easy to set up in Linuxcnc and can be done in several ways.

One is having a normal X axis that rotates so you do the calculations of radius depending on the diameter of the part. The other is having that X axis set as A or B axis, rotational so it does the calculations in Linuxcnc, that is 4th axis.

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

13 Apr 2017 04:44 - 13 Apr 2017 04:45 #91283

by wicki

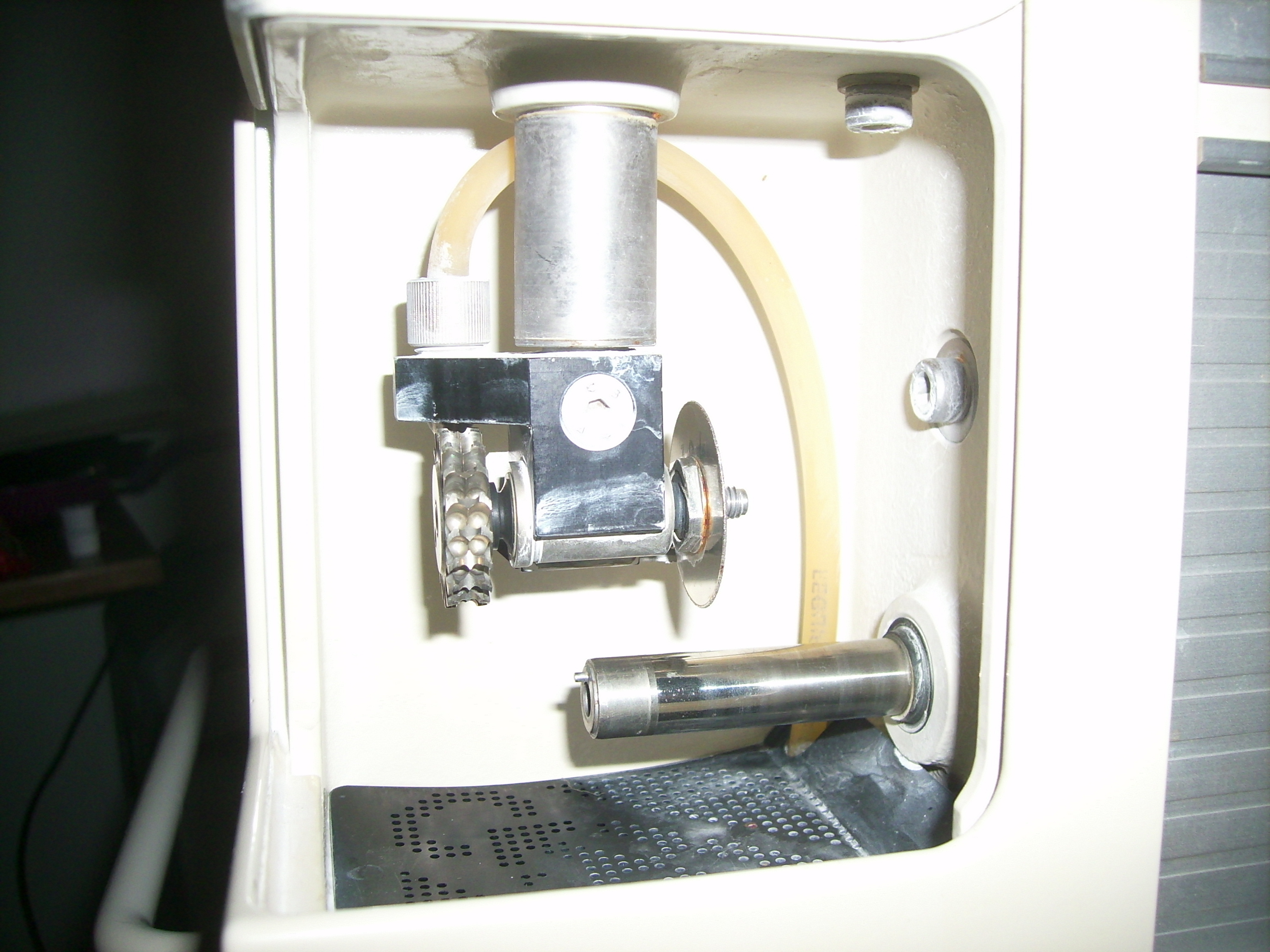

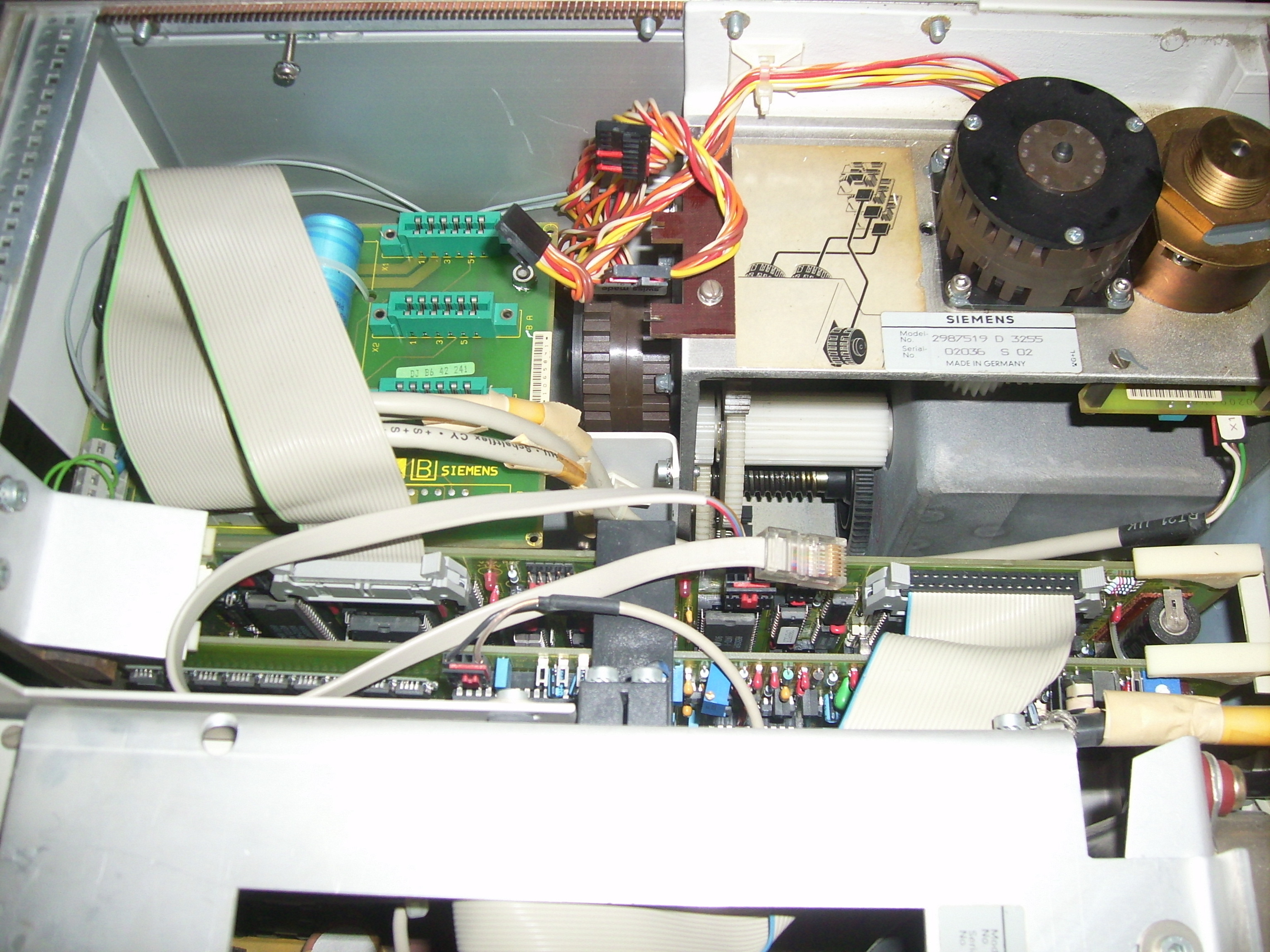

The "spidle" is on the Z-axis - you can see it in the picture lying on the left side in front of the controller.

It is a water-steam-driven turbine.

I want to use the rotating axis as an X-axis - yes, is has 2 motors.

The Z-axis is theoretically also able to rotate (but no second motor is installed on this axis).

First I tried the x/y-linking with a kinematic-file - it works rudimentary but it is not nice

for testing and debugging.

Now I'm trying it with HAL and a python-program. It seems to be the faster way for testing.

What I have to solve now: If X for example moves form 0 to 10,

I must calculate the position-correction for Y for every motor-step, to hold the Y-axis in place.

Let's see, if it works

Replied by wicki on topic back to the problem... ;-)

Is the spindle on the vertical axis or the horizontal one?

Does the horizontal one have 2 separate motors ? In the video it looks like it has 2.

The "spidle" is on the Z-axis - you can see it in the picture lying on the left side in front of the controller.

It is a water-steam-driven turbine.

I want to use the rotating axis as an X-axis - yes, is has 2 motors.

The Z-axis is theoretically also able to rotate (but no second motor is installed on this axis).

First I tried the x/y-linking with a kinematic-file - it works rudimentary but it is not nice

for testing and debugging.

Now I'm trying it with HAL and a python-program. It seems to be the faster way for testing.

What I have to solve now: If X for example moves form 0 to 10,

I must calculate the position-correction for Y for every motor-step, to hold the Y-axis in place.

Let's see, if it works

Last edit: 13 Apr 2017 04:45 by wicki. Reason: re-changed topic...

Please Log in or Create an account to join the conversation.

- wicki

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 183

- Thank you received: 21

13 Apr 2017 16:20 - 13 Apr 2017 16:24 #91324

by wicki

Replied by wicki on topic back to the problem... ;-)

Back again...

now a little help would be fine...

The Program below does what I need.

The "jog"-line moves the Y-axis against the wrong movement while turning the

X-axis.

But what I need now (if (xdiff!=0)): the X-movement should stop until the

correction of the "Y"-axis (here done by "linuxcnc.JOG_INCREMENT") is ready.

And: this solution only works in jog-mode - in mdi-mode errors are thrown:

can't do that (EMC_AXIS_INCR_JOG:125) in MDI mode

can't do that (EMC_AXIS_ABORT:120) in MDI mode

Any hints for me ?

#!/usr/bin/python

import hal, time, serial,subprocess,string

import linuxcnc

c = linuxcnc.command()

h = hal.component("ceradjust")

x = hal.component("X")

y = hal.component("Y")

z = hal.component("Z")

x.newpin("inx", hal.HAL_FLOAT, hal.HAL_IN)

x.newpin("outx", hal.HAL_FLOAT, hal.HAL_OUT)

x.ready();

y.newpin("iny", hal.HAL_FLOAT, hal.HAL_IN)

y.newpin("outy", hal.HAL_FLOAT, hal.HAL_OUT)

y.ready();

z.newpin("inz", hal.HAL_FLOAT, hal.HAL_IN)

z.newpin("outz", hal.HAL_FLOAT, hal.HAL_OUT)

z.ready();

loop=0

maxloop=100

def getstat():

global znowpos,serval,loop,loopdiv,you,yin,xou,xin

stat=linuxcnc.stat()

stat.poll()

zin=stat.axis[2]["input"]

zou=stat.axis[2]["output"]

xin=stat.axis[0]["input"]

xou=stat.axis[0]["output"]

yin=stat.axis[1]["input"]

you=stat.axis[1]["output"]

if (loop>=maxloop):

print "A2 input: xin: %3.5f yin: %3.5f zin %3.5f loop: %i maxloop=%3.5f" %(xin,yin,zin,loop,maxloop)

loop=0

loop=loop+1

znowpos=stat.axis[2]["output"]

return

print "cerec started....."

getstat()

lastx=xou

while (1 != 9):

try:

getstat()

xdiff=.5*(lastx-xou)

if (xdiff!=0):

print "move axis 1 %3.5f " %( xdiff)

#jog(linuxcnc.JOG_INCREMENT, axis, velocity, distance)

c.jog(linuxcnc.JOG_INCREMENT, 1, 150, xdiff)

c.jog(linuxcnc.JOG_STOP,0)

lastx=xou

except KeyboardInterrupt:

raise SystemExit[/li]

now a little help would be fine...

The Program below does what I need.

The "jog"-line moves the Y-axis against the wrong movement while turning the

X-axis.

But what I need now (if (xdiff!=0)): the X-movement should stop until the

correction of the "Y"-axis (here done by "linuxcnc.JOG_INCREMENT") is ready.

And: this solution only works in jog-mode - in mdi-mode errors are thrown:

can't do that (EMC_AXIS_INCR_JOG:125) in MDI mode

can't do that (EMC_AXIS_ABORT:120) in MDI mode

Any hints for me ?

#!/usr/bin/python

import hal, time, serial,subprocess,string

import linuxcnc

c = linuxcnc.command()

h = hal.component("ceradjust")

x = hal.component("X")

y = hal.component("Y")

z = hal.component("Z")

x.newpin("inx", hal.HAL_FLOAT, hal.HAL_IN)

x.newpin("outx", hal.HAL_FLOAT, hal.HAL_OUT)

x.ready();

y.newpin("iny", hal.HAL_FLOAT, hal.HAL_IN)

y.newpin("outy", hal.HAL_FLOAT, hal.HAL_OUT)

y.ready();

z.newpin("inz", hal.HAL_FLOAT, hal.HAL_IN)

z.newpin("outz", hal.HAL_FLOAT, hal.HAL_OUT)

z.ready();

loop=0

maxloop=100

def getstat():

global znowpos,serval,loop,loopdiv,you,yin,xou,xin

stat=linuxcnc.stat()

stat.poll()

zin=stat.axis[2]["input"]

zou=stat.axis[2]["output"]

xin=stat.axis[0]["input"]

xou=stat.axis[0]["output"]

yin=stat.axis[1]["input"]

you=stat.axis[1]["output"]

if (loop>=maxloop):

print "A2 input: xin: %3.5f yin: %3.5f zin %3.5f loop: %i maxloop=%3.5f" %(xin,yin,zin,loop,maxloop)

loop=0

loop=loop+1

znowpos=stat.axis[2]["output"]

return

print "cerec started....."

getstat()

lastx=xou

while (1 != 9):

try:

getstat()

xdiff=.5*(lastx-xou)

if (xdiff!=0):

print "move axis 1 %3.5f " %( xdiff)

#jog(linuxcnc.JOG_INCREMENT, axis, velocity, distance)

c.jog(linuxcnc.JOG_INCREMENT, 1, 150, xdiff)

c.jog(linuxcnc.JOG_STOP,0)

lastx=xou

except KeyboardInterrupt:

raise SystemExit[/li]

Last edit: 13 Apr 2017 16:24 by wicki. Reason: format...

Please Log in or Create an account to join the conversation.

Time to create page: 0.132 seconds