Motor Driver Electrical Question

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 10

I am currently driving my stepper motors via DMT556T's with a 48vdc source.

The motors are from Stepper-Online model 23HS45-4204S .

They can handle 4.2A based on the specs provided.

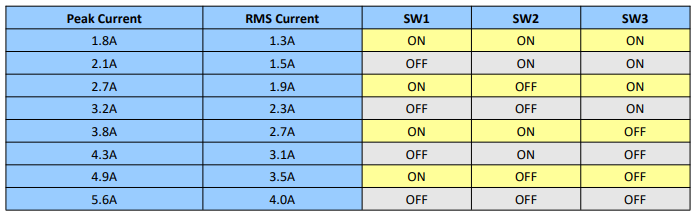

The current settings offered by the DMT556T are as follows:

My question, which Peak Current setting should I be using?

Attachments:

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 10

Stepper Online.

Here's a link to the DM556T drivers which were part of the kit. I could not find the kit online at this time.

On the Stepper Online web site I note the following documentation:Therefore, when setting the current on the stepper motor driver, please try to make the rated current of the motor close to the RMS value of the driver. If the motor needs to work continuously for a long time, you need to pay attention to the temperature rise of the motor. If you feel that the temperature of the motor is too high, you can properly reduce the current.In our experience, we usually match the RMS value on the driver to the rated current of the motor to ensure higher performance. When we feel that the motor is overheating, we match the rated current of the motor to the PEAK value on the driver.Additionally, under short-term working cycle conditions, we recommend using the RMS value, and under long-term working cycle conditions, we recommend using the PEAK value. This document is located here.

Honestly I see no reason why these motors can't be run at 48vdc.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21231

- Thank you received: 7249

And while testing, every 10 to 15 minutes do check the motor temperature with your hand, they might get warm and they might get hot and that is ok, as long as you can keep your hand on the motor all is good, and even when it feels it burns like hell, they are still OK, but you might want to lower the current a bit.

Please Log in or Create an account to join the conversation.

- unknown

- Offline

- Platinum Member

-

- Posts: 887

- Thank you received: 325

www.geckodrive.com/support/

This one is rather enlightening regard power draw and such

www.geckodrive.com/support/power-supply-basics/

I've had my mill setup for that long, using KL5066 drivers (no longer available) max PSU is 50v and I've been running them for years, 10+, on 48v with no ill affects. I think the motors are set for 4 or maybe 4.5 amp I thought I'd add I've run them on days where its been +35'C outside no idea what it's been in the workshop.....no issues

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11672

- Thank you received: 3934

Look at the motor's full data sheet www.omc-stepperonline.com/download/23HS45-4204S.pdf

The insulation is rated for 130 deg C so don't let it get hot enough for it to melt as that will destroy your drive.

The maximum temperature rise permissable is 80 deg C. Add that to 30 deg ambient temp (heck its been up to 39 degrees C here the last week or so). So 80+30 = 110 deg C which is hot enough to burn you but not melt the insulation. If the motor misses steps and it will only do that if it gets too hot (it will then let you know that its missing steps in a spectacular way).

If the drivers have a fault output, connect it to joint.N.fault-in. This will trigger if the motor gets too hot and stop Linuxcnc

If the drive misses steps or faults, reduce the curent to the next lower setting.

Don't be concerned about lowering the current if you need to. The actual current required for a given application may be well below the rated current if you do do a full design. eg one of my 2 amp motors only needs 1 amp to achieve 60 m/min rapids and > 5 m/sec/sec acceleration (tested to 8 m/sec/sec)

Typically, the Chinese drivers are rated based on peak voltage. Some Drivers (eg Lam Technologies) are rated for RMS so a 6 amp driver of theirs will give 6 amp RMS, enough to melt the average Chinese motor. So a 4.2 amp motor is probably run at 2-3 amps with Lam. This is why Tommy suggests a more conservative approach than me!

Ignore all other advice you have been given by others and just do it!

Please Log in or Create an account to join the conversation.

- unknown

- Offline

- Platinum Member

-

- Posts: 887

- Thank you received: 325

Ignore all other advice you have been given by others and just do it!

Yeah I'd second that.

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 10

Please Log in or Create an account to join the conversation.

- unknown

- Offline

- Platinum Member

-

- Posts: 887

- Thank you received: 325

The reason I mentioned the 48V not being necessarily ideal is some electronics are made with almost zero headroom above their limits.

For example, I own a 12V DELTA power supply that can be adjusted to output 14VDC; however, its filter caps are only rated for 16V!

That's 2V of headroom!

Which is absolutely fine, that is the way the designers intended.

Discussion on voltage values

www.eevblog.com/forum/beginners/is-there...igher-rated-voltage/

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 10

Thank to everyone that provided feedback!

Please Log in or Create an account to join the conversation.