- Other Stuff

- Off Topic and Test Posts

- What should an open source plasma cnc controller have ? At what price?

What should an open source plasma cnc controller have ? At what price?

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

15 Oct 2020 15:17 #186212

by AgentWD40

Replied by AgentWD40 on topic What should an open source plasma cnc controller have ? At what price?

If we had to pick *one* my vote would be for ethernet (mesa) and thcad  Seems a little more plug & play or versatile but I may be off base with that assumption.

Seems a little more plug & play or versatile but I may be off base with that assumption.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Online

- Moderator

-

Less

More

- Posts: 21152

- Thank you received: 7222

15 Oct 2020 15:20 #186213

by tommylight

Replied by tommylight on topic What should an open source plasma cnc controller have ? At what price?

Or something like this:

mediatoget.blogspot.com/2011/02/lpt-port-expander.html

mediatoget.blogspot.com/2011/02/lpt-port-expander.html

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Online

- Moderator

-

Less

More

- Posts: 21152

- Thank you received: 7222

15 Oct 2020 15:23 #186214

by tommylight

Replied by tommylight on topic What should an open source plasma cnc controller have ? At what price?

I think i stated in the first post that everything must have a Mesa THCAD and one of 7i92 for version with cheap drives, a 7i96 OR 7i76E for the one with expensive drives.

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

15 Oct 2020 15:42 - 15 Oct 2020 15:42 #186215

by AgentWD40

Replied by AgentWD40 on topic What should an open source plasma cnc controller have ? At what price?

Just for ethernet capability would you consider making the 7i96 an option for the cheap lower cost version?

Last edit: 15 Oct 2020 15:42 by AgentWD40.

Please Log in or Create an account to join the conversation.

- pinder

-

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

15 Oct 2020 16:00 - 15 Oct 2020 16:01 #186217

by pinder

this is the real way to do it.

I never thought of multiplexing inputs in linuxcnc.

My new target is now

parport+esp32(isolated arc to freq)+esp32 as multiplexer.

Replied by pinder on topic What should an open source plasma cnc controller have ? At what price?

A much better way would be to use ESP32 as IO and use multiplex/demux to a parallel port, that would still remain in the real time domain.

this is the real way to do it.

I never thought of multiplexing inputs in linuxcnc.

My new target is now

parport+esp32(isolated arc to freq)+esp32 as multiplexer.

Last edit: 15 Oct 2020 16:01 by pinder.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

15 Oct 2020 17:07 #186223

by AgentWD40

Bah!! I just realized the 7i92 IS ethernet. Please excuse my ignorance.

Replied by AgentWD40 on topic What should an open source plasma cnc controller have ? At what price?

Just for ethernet capability would you consider making the 7i96 an option for the

cheaplower cost version?

Bah!! I just realized the 7i92 IS ethernet. Please excuse my ignorance.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3903

15 Oct 2020 18:36 #186225

by rodw

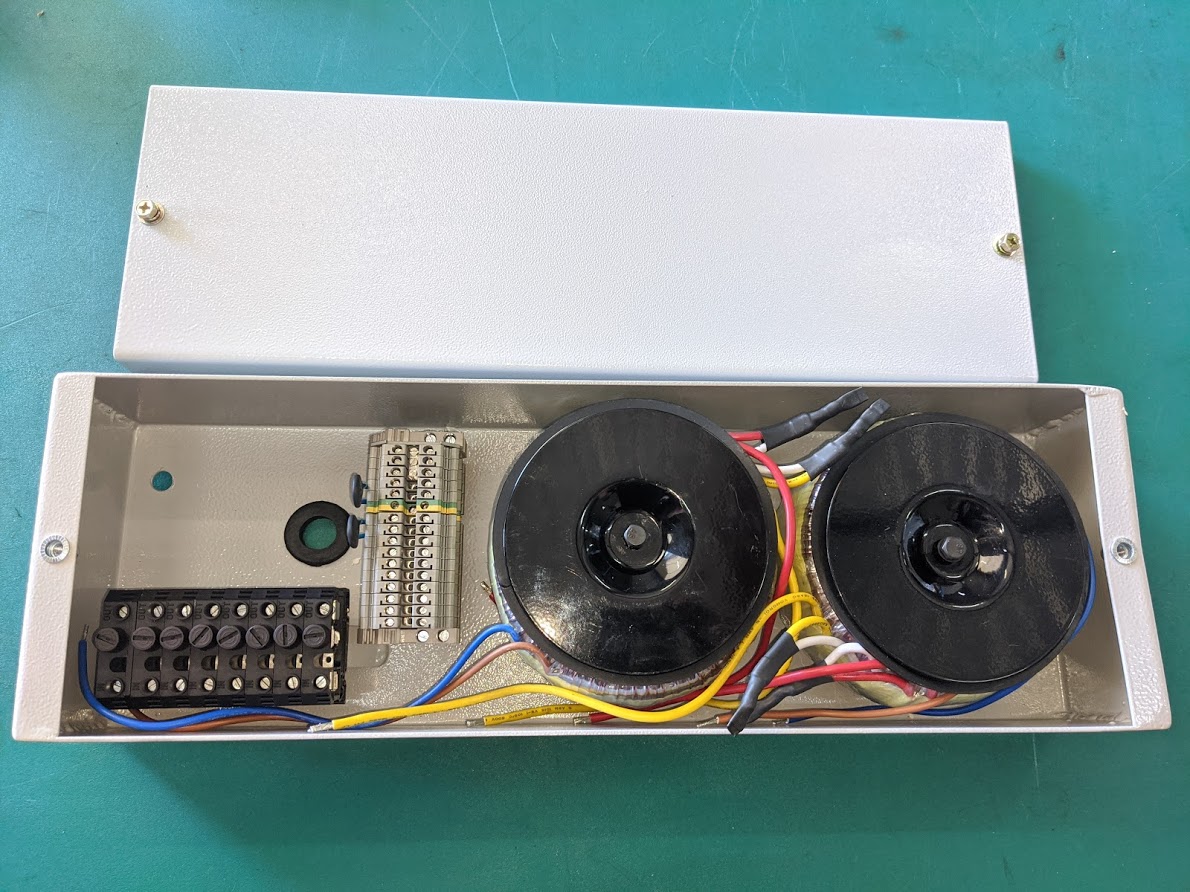

My idea was always to provide a fully assembled solution in a plasma cuttable box with a configured PC. The one I did for my power supply upgrade worked really well. I surprised myself.

This one used 2 x toroids because that was what was available, next time I will have a single custom made toroid.

Replied by rodw on topic What should an open source plasma cnc controller have ? At what price?

I'm curious what you have in mind for this as a project. Are you thinking of just spec'ing some known to work components with some working config files? Or full on control panel box, optimal layout of components, assembly instructions, etc.?

My idea was always to provide a fully assembled solution in a plasma cuttable box with a configured PC. The one I did for my power supply upgrade worked really well. I surprised myself.

This one used 2 x toroids because that was what was available, next time I will have a single custom made toroid.

Attachments:

The following user(s) said Thank You: abcdefg, AgentWD40

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

15 Oct 2020 20:04 #186228

by AgentWD40

Replied by AgentWD40 on topic What should an open source plasma cnc controller have ? At what price?

Rod, do you also intend it to be open source schematics, spec'ed parts list, etc.?

Please Log in or Create an account to join the conversation.

- abcdefg

- Offline

- Platinum Member

-

Less

More

- Posts: 1132

- Thank you received: 533

15 Oct 2020 21:11 #186235

by abcdefg

Seeing your builds Tom, I would comfortably say that your not going to end up like the other company!. Would it be possible to build a testing device that could replicate a real machine. That way you could just set the controller up and say let it run over night.

Then come up with some baseline parameters the customer can use and write them a instruction guide on how to fine tune the settings for their specific machine?

I personally believe that if you were to sell them for $3000 but if they did not break down or have any issues, you would have a hard time keeping up with demand once word got around.

If I can build a controller from reading your forum posts and have it run 10 hours a day for over a year with no issues, I am sure with your knowledge you will do much better than I can.

Replied by abcdefg on topic What should an open source plasma cnc controller have ? At what price?

But i am sure i do not want to end up like some other vendors that are mentioned often here for putting 500$ of stuff in a box and asking 3000$ for it with no support and with no bloody shielding and proper grounding.

I would rather spend two days assembling and two more days testing on a real machine then ship knowing that it is fully functional and ready to use. I prefer the "set it and forget it" way of doing things.

Seeing your builds Tom, I would comfortably say that your not going to end up like the other company!. Would it be possible to build a testing device that could replicate a real machine. That way you could just set the controller up and say let it run over night.

Then come up with some baseline parameters the customer can use and write them a instruction guide on how to fine tune the settings for their specific machine?

I personally believe that if you were to sell them for $3000 but if they did not break down or have any issues, you would have a hard time keeping up with demand once word got around.

If I can build a controller from reading your forum posts and have it run 10 hours a day for over a year with no issues, I am sure with your knowledge you will do much better than I can.

The following user(s) said Thank You: tommylight, pinder

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3903

15 Oct 2020 21:26 #186236

by rodw

To tell you the truth, I don't really know. I have had this idea for a couple of years becasue I thought there were a lot of people who could build a plasma table but their eyes glazed over when they saw the insides of the control box. But a lot of pieces have fallen together for me in the last little while so I thought I'd better get on with it!

I have two custom made toroid power supplies getting made for me which are dual wound 110v/240V and I just found the perfect IEC connector with a voltage selector switch, fuse and RFI filter so I ordered a couple of them this last hour. So already I'm probably sitting at AUD $500 and I still have to order the Odroids and touch screen monitors. That will be another AUD $700 maybe then there will be AUD $1200 for the stepper controllers and AUD $800 for the motors and AUD $250 for a safety relay. Add another AUD $300 for the 433 mHz pendant hardwired into the 7i76e. So there is probably no change out of AUD $5k in parts alone. Scary! I think its in the AUD $7000-$10000 range (USD $5k-$7k)

So there will also be a custom Z axis to go with it that an associate is building his first prototype of and it will be USD $1500-$2k.

And we still have not added the planetary gear boxes which at up to AUD $500 each, will add another AUD $2k

So in answer to your question, this is probably not going to be a DIY cheap as chips kit of components. Its going to be rolls royce high end OHS compliant gear and maybe thats not really conducive to open source, particularly where we want to lock the motors in to our engineered model to guarantee performance. We would not want to have people complaining their $20 chinese motors melted at 90 volts!

I know Tommy is the master of building amazing machines on the cheap and I think if he could lock down a similar build in a bigger market with much lower buying prices than we get, he would be on a winner. I have no idea if my concepta will sell. But I do know there is nothing on the market like it!

Replied by rodw on topic What should an open source plasma cnc controller have ? At what price?

Rod, do you also intend it to be open source schematics, spec'ed parts list, etc.?

To tell you the truth, I don't really know. I have had this idea for a couple of years becasue I thought there were a lot of people who could build a plasma table but their eyes glazed over when they saw the insides of the control box. But a lot of pieces have fallen together for me in the last little while so I thought I'd better get on with it!

I have two custom made toroid power supplies getting made for me which are dual wound 110v/240V and I just found the perfect IEC connector with a voltage selector switch, fuse and RFI filter so I ordered a couple of them this last hour. So already I'm probably sitting at AUD $500 and I still have to order the Odroids and touch screen monitors. That will be another AUD $700 maybe then there will be AUD $1200 for the stepper controllers and AUD $800 for the motors and AUD $250 for a safety relay. Add another AUD $300 for the 433 mHz pendant hardwired into the 7i76e. So there is probably no change out of AUD $5k in parts alone. Scary! I think its in the AUD $7000-$10000 range (USD $5k-$7k)

So there will also be a custom Z axis to go with it that an associate is building his first prototype of and it will be USD $1500-$2k.

And we still have not added the planetary gear boxes which at up to AUD $500 each, will add another AUD $2k

So in answer to your question, this is probably not going to be a DIY cheap as chips kit of components. Its going to be rolls royce high end OHS compliant gear and maybe thats not really conducive to open source, particularly where we want to lock the motors in to our engineered model to guarantee performance. We would not want to have people complaining their $20 chinese motors melted at 90 volts!

I know Tommy is the master of building amazing machines on the cheap and I think if he could lock down a similar build in a bigger market with much lower buying prices than we get, he would be on a winner. I have no idea if my concepta will sell. But I do know there is nothing on the market like it!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Other Stuff

- Off Topic and Test Posts

- What should an open source plasma cnc controller have ? At what price?

Time to create page: 0.137 seconds