Search Results (Searched for: THCAD)

- rodw

11 Feb 2025 12:13

Replied by rodw on topic Converting a THCAD-300 to a THCAD-10?

Converting a THCAD-300 to a THCAD-10?

Category: Plasma & Laser

- Boogie

- Boogie

11 Feb 2025 12:07

Replied by Boogie on topic Converting a THCAD-300 to a THCAD-10?

Converting a THCAD-300 to a THCAD-10?

Category: Plasma & Laser

- rodw

11 Feb 2025 10:18

Replied by rodw on topic Converting a THCAD-300 to a THCAD-10?

Converting a THCAD-300 to a THCAD-10?

Category: Plasma & Laser

- kn612

- kn612

10 Feb 2025 22:54

- PCW

10 Feb 2025 19:08

Replied by PCW on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- Sandro

- Sandro

10 Feb 2025 17:32 - 10 Feb 2025 17:33

Replied by Sandro on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- rodw

09 Feb 2025 22:36

Replied by rodw on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- PCW

09 Feb 2025 22:32 - 09 Feb 2025 22:41

Replied by PCW on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- Hakan

- Hakan

09 Feb 2025 21:22

Replied by Hakan on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- rodw

09 Feb 2025 20:42

Replied by rodw on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- tommylight

09 Feb 2025 20:32

Replied by tommylight on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- Sandro

- Sandro

09 Feb 2025 18:31 - 10 Feb 2025 17:18

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss was created by Sandro

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- Boogie

- Boogie

09 Feb 2025 12:41

Replied by Boogie on topic Converting a THCAD-300 to a THCAD-10?

Converting a THCAD-300 to a THCAD-10?

Category: Plasma & Laser

- beauxnez

- beauxnez

08 Feb 2025 21:49

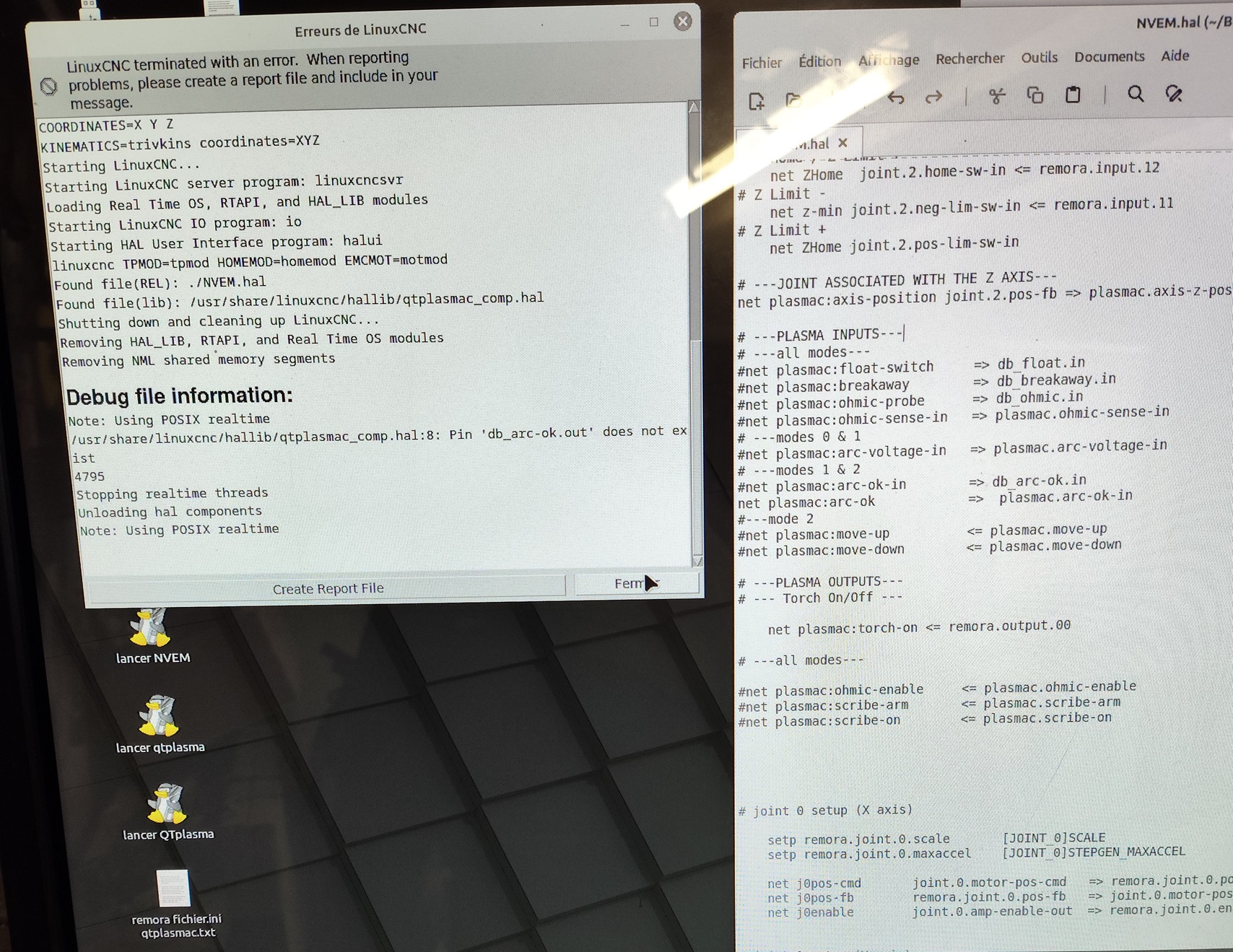

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Uthayne

- Uthayne

08 Feb 2025 18:43

Replied by Uthayne on topic Converting a THCAD-300 to a THCAD-10?

Converting a THCAD-300 to a THCAD-10?

Category: Plasma & Laser

Time to create page: 2.358 seconds