Search Results (Searched for: )

- gravedigger

- gravedigger

21 Dec 2025 10:43 - 21 Dec 2025 10:44

Replied by gravedigger on topic Habe mit Chat GPT gespielt....ist hier was sinnvolles rausgekommen?

Habe mit Chat GPT gespielt....ist hier was sinnvolles rausgekommen?

Category: Deutsch

- gravedigger

- gravedigger

21 Dec 2025 10:40 - 21 Dec 2025 11:06

Habe mit Chat GPT gespielt....ist hier was sinnvolles rausgekommen? was created by gravedigger

Habe mit Chat GPT gespielt....ist hier was sinnvolles rausgekommen?

Category: Deutsch

- Nator

- Nator

21 Dec 2025 08:28

- Hakan

- Hakan

21 Dec 2025 08:26

- alexandrap

- alexandrap

21 Dec 2025 08:24

- tommylight

21 Dec 2025 00:12

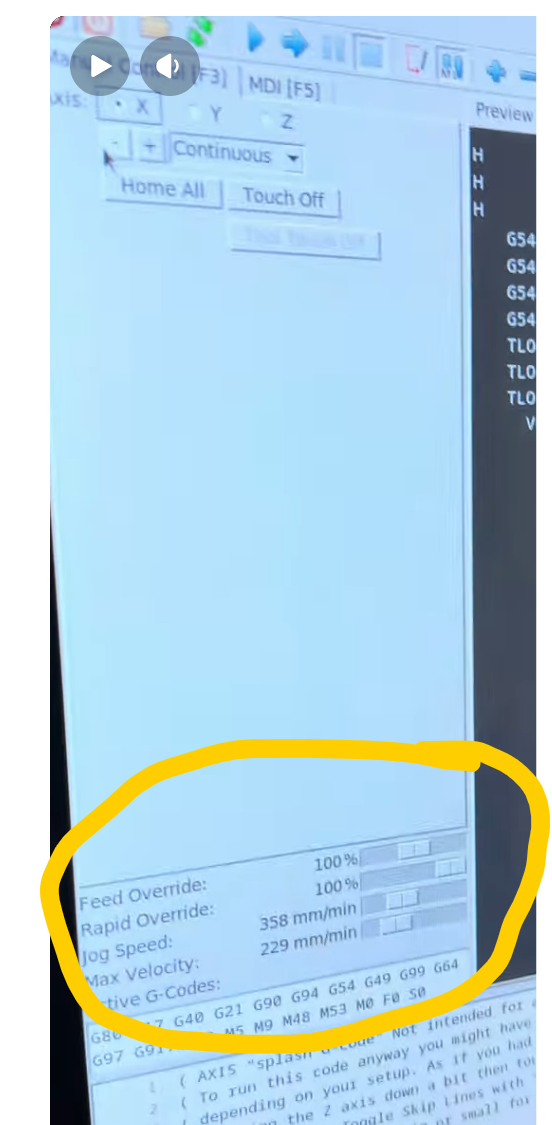

Replied by tommylight on topic I can't get my tabs (or code) to load

I can't get my tabs (or code) to load

Category: Plasmac

- LearningLinuxCNC

20 Dec 2025 23:15

Replied by LearningLinuxCNC on topic Pico Universal PWM Won't boot Random pins not working

Pico Universal PWM Won't boot Random pins not working

Category: Driver Boards

- NWE

- NWE

20 Dec 2025 22:51 - 23 Dec 2025 19:08

Replied by NWE on topic Linuxcnc Image for Raspberry Pi 3

Linuxcnc Image for Raspberry Pi 3

Category: General LinuxCNC Questions

- MaHa

- MaHa

20 Dec 2025 22:35 - 21 Dec 2025 09:26

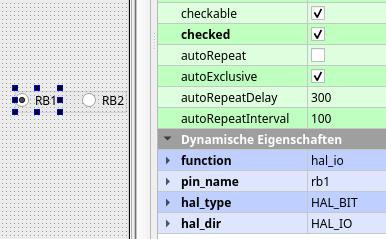

inconsistency with radiobutton and hal_pin was created by MaHa

inconsistency with radiobutton and hal_pin

Category: Flex GUI

- PCW

20 Dec 2025 22:23

Replied by PCW on topic Stepcraft M700 with 7i92TM

Stepcraft M700 with 7i92TM

Category: PnCConf Wizard

- xkonni

- xkonni

20 Dec 2025 20:23

Replied by xkonni on topic Stepcraft M700 with 7i92TM

Stepcraft M700 with 7i92TM

Category: PnCConf Wizard

- JeremyMakesThings

20 Dec 2025 20:12

I can't get my tabs (or code) to load was created by JeremyMakesThings

I can't get my tabs (or code) to load

Category: Plasmac

- T.Frei

- T.Frei

20 Dec 2025 19:11

- xkonni

- xkonni

20 Dec 2025 18:07

Replied by xkonni on topic Stepcraft M700 with 7i92TM

Stepcraft M700 with 7i92TM

Category: PnCConf Wizard

- et

- et

20 Dec 2025 16:57

Replied by et on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Time to create page: 0.500 seconds