Search Results (Searched for: )

- ihavenofish

- ihavenofish

26 Dec 2024 18:08

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- 10K

26 Dec 2024 18:06

Replied by 10K on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- CNC_ANDI

- CNC_ANDI

26 Dec 2024 17:54

- MrStupid

26 Dec 2024 17:38

Replied by MrStupid on topic probe_basic_lathe vtk_backplot.py error

probe_basic_lathe vtk_backplot.py error

Category: QtPyVCP

- Aciera

26 Dec 2024 17:36

- Lcvette

26 Dec 2024 17:35

Replied by Lcvette on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- resmond

- resmond

26 Dec 2024 17:25

Replied by resmond on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- mhd325ic

- mhd325ic

26 Dec 2024 17:23 - 27 Dec 2024 03:06

Onsale: PM-25 converted linuxCNC milling machine was created by mhd325ic

Onsale: PM-25 converted linuxCNC milling machine

Category: User Exchange

- abdulasis12

- abdulasis12

26 Dec 2024 16:31

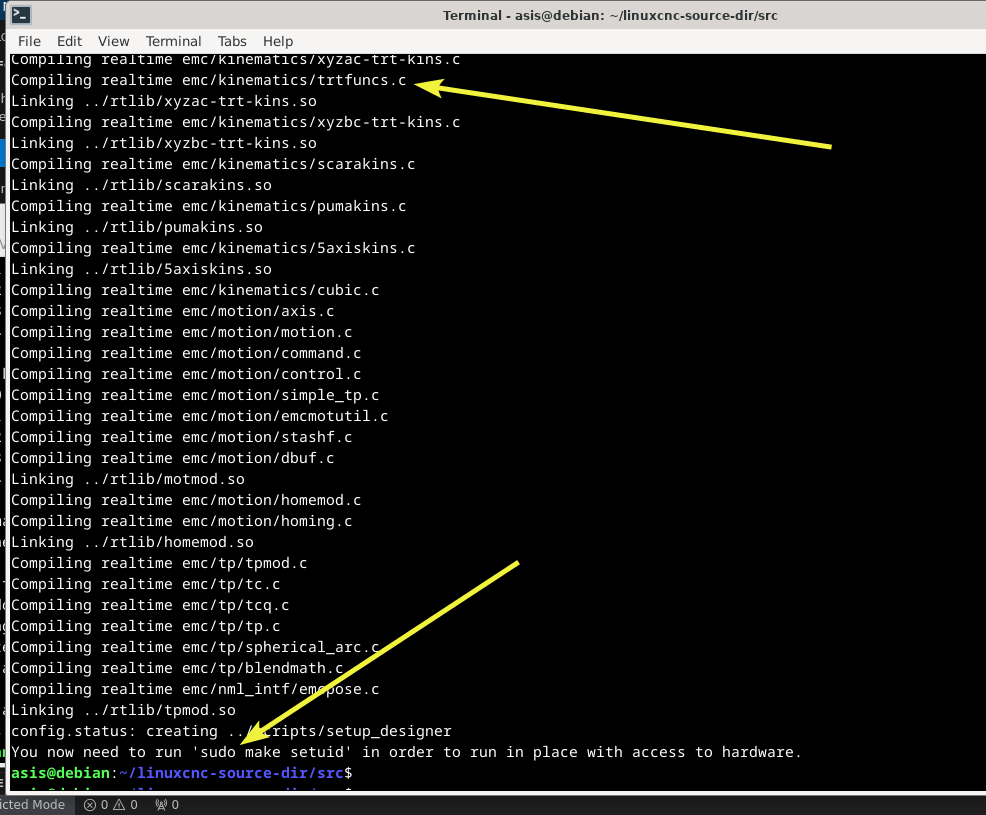

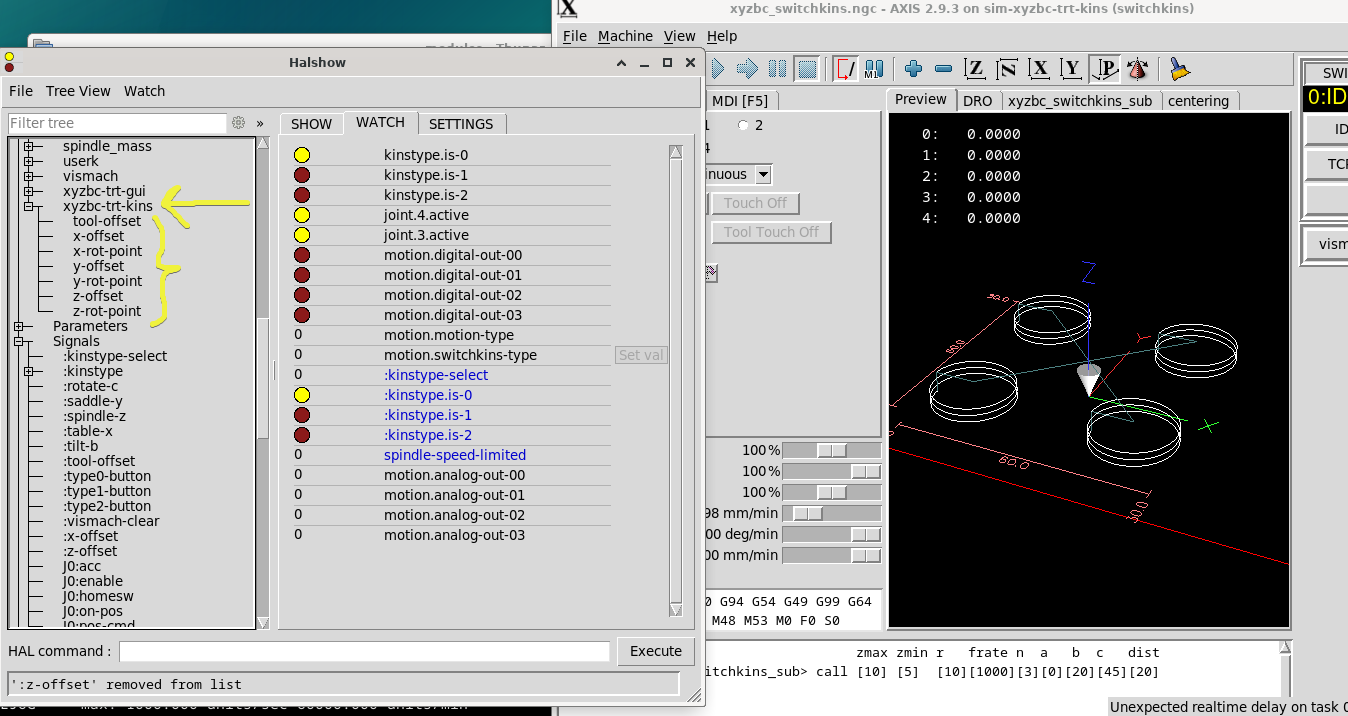

Replied by abdulasis12 on topic Skew correction/perpendicularity correction (millkins or millkins_xyz)

Skew correction/perpendicularity correction (millkins or millkins_xyz)

Category: Basic Configuration

- PCW

26 Dec 2024 16:19

Replied by PCW on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- PCW

26 Dec 2024 15:55

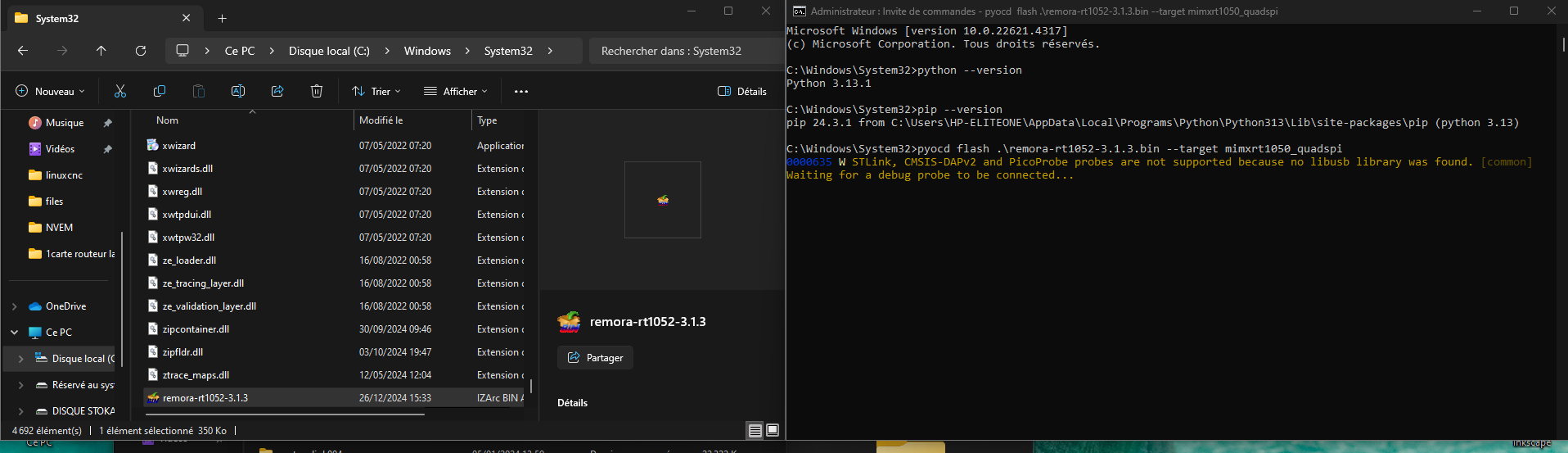

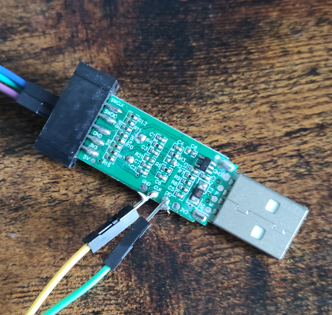

- beauxnez

- beauxnez

26 Dec 2024 15:46 - 26 Dec 2024 15:50

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- 10K

26 Dec 2024 15:39

Replied by 10K on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- Aciera

26 Dec 2024 15:33

- TooTall18T

26 Dec 2024 15:24

Replied by TooTall18T on topic Probe Basic is splitting into Stable and Develop apt branch

Probe Basic is splitting into Stable and Develop apt branch

Category: QtPyVCP

Time to create page: 0.692 seconds