Fusion 360 Milling post with G64 Pn

- spangledboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 10

24 Feb 2019 20:30 #127067

by spangledboy

Fusion 360 Milling post with G64 Pn was created by spangledboy

As promised in

this thread

, here is a copy of the Fusion 360 Post Processor, which I have modified as follows:

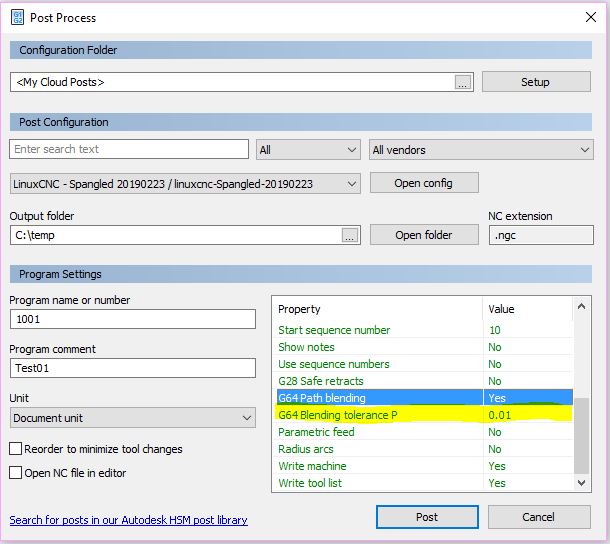

1) Added G64 to G Code preamble - can be enabled or disabled from the Fusion 360 Post Process dialogue as shown below.

2) Added the P value for G64 - this can also be modified from within the dialogue.

3) Added DEBUG command into tool comment during tool change so notification box pops up on the screen prompting for the tool to be used.

Let me know if this is useful and if you have any comments. In the thread mentioned above, it was suggested that a different P value would be useful for roughing/adaptive moves, which makes sense, however this is more challenging to code - particularly as I'm not a developer - it took me a while to work out what's going on in the post to get this much done!

All modified or added lines have been commented with //Spangled - search for these to check what I've done.

As usual, you test this file at your risk - it's not my fault if your machine crashes or your house catches fire etc. Check the output before running it on a physical machine!

1) Added G64 to G Code preamble - can be enabled or disabled from the Fusion 360 Post Process dialogue as shown below.

2) Added the P value for G64 - this can also be modified from within the dialogue.

3) Added DEBUG command into tool comment during tool change so notification box pops up on the screen prompting for the tool to be used.

Let me know if this is useful and if you have any comments. In the thread mentioned above, it was suggested that a different P value would be useful for roughing/adaptive moves, which makes sense, however this is more challenging to code - particularly as I'm not a developer - it took me a while to work out what's going on in the post to get this much done!

All modified or added lines have been commented with //Spangled - search for these to check what I've done.

As usual, you test this file at your risk - it's not my fault if your machine crashes or your house catches fire etc. Check the output before running it on a physical machine!

Attachments:

The following user(s) said Thank You: tommylight, Clive S, tivoi, racedirector, Leon82

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

25 Feb 2019 07:28 #127085

by pl7i92

Replied by pl7i92 on topic Fusion 360 Milling post with G64 Pn

Thank You

Beginner may Like it

Hard Yousers may do it there own Style

And Pros may not use The Cloud CAD system

Beginner may Like it

Hard Yousers may do it there own Style

And Pros may not use The Cloud CAD system

Please Log in or Create an account to join the conversation.

- spangledboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 10

25 Feb 2019 21:00 #127121

by spangledboy

Replied by spangledboy on topic Fusion 360 Milling post with G64 Pn

Errr, right.

Thank you for your eloquent and constructive comment.

Thank you for your eloquent and constructive comment.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- MartyJ

-

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 13

26 Feb 2019 21:23 - 26 Feb 2019 21:24 #127194

by MartyJ

Replied by MartyJ on topic Fusion 360 Milling post with G64 Pn

This is excellent, Spangled. I'm currently working off of your post and trying to add to it so that any operations with an explicitly specified smoothing factor will add a G64 with the operations "smoothingFilterTolerance" variable as the P value.

That'd be a perfect setup, overall G64 P0.010 or so for roughing (in Inches) so fast roughing doesn't get too crazy, and then a per-operation specific G64 P0.00n to dial in where precise motion is needed.

BTW I have verified that your post works in HSMWorks as well.

That'd be a perfect setup, overall G64 P0.010 or so for roughing (in Inches) so fast roughing doesn't get too crazy, and then a per-operation specific G64 P0.00n to dial in where precise motion is needed.

BTW I have verified that your post works in HSMWorks as well.

Last edit: 26 Feb 2019 21:24 by MartyJ.

The following user(s) said Thank You: spangledboy

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

27 Feb 2019 16:52 #127266

by pl7i92

Replied by pl7i92 on topic Fusion 360 Milling post with G64 Pn

i like to thank you 2 dispite i Dont like Windows and Fusion its a real need for people making fast g-code moves

on woodwork or plastic

on woodwork or plastic

Please Log in or Create an account to join the conversation.

- spangledboy

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 10

28 Feb 2019 08:38 #127314

by spangledboy

Replied by spangledboy on topic Fusion 360 Milling post with G64 Pn

Good stuff Marty - I must admit that I was in a quandy as to what name to use for the variable - whatever seems most appropriate is fine with me.

If you have the time/ability to create the code to have separate P values for roughing and finishing moves then that would be awesome - perhaps adding in the naive CAM detector - Q - option as well would be good for the roughing moves?

I may also submit this on the Autodesk Fusion360 post processor request board - it would be good to get this officially supported and anything that improves support for LinuxCNC can only be agood thing from my point of view.

Are there any other LinuxCNC features which haven't been implemented in this post that anyone has noticed?

If you have the time/ability to create the code to have separate P values for roughing and finishing moves then that would be awesome - perhaps adding in the naive CAM detector - Q - option as well would be good for the roughing moves?

I may also submit this on the Autodesk Fusion360 post processor request board - it would be good to get this officially supported and anything that improves support for LinuxCNC can only be agood thing from my point of view.

Are there any other LinuxCNC features which haven't been implemented in this post that anyone has noticed?

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

28 Feb 2019 14:12 #127329

by pl7i92

Replied by pl7i92 on topic Fusion 360 Milling post with G64 Pn

G76 has no support

Please Log in or Create an account to join the conversation.

- MartyJ

-

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 13

28 Feb 2019 17:44 - 28 Feb 2019 17:45 #127344

by MartyJ

Replied by MartyJ on topic Fusion 360 Milling post with G64 Pn

OK all, here's what I ended up doing.

I was going to start with Spangled's post, because I was going to have an overall G64 P0.0x value, combined with a per-operation G64 P0.0x value based on if the operation has a "smoothing" parameter applied.

But then I thought, that's not really what the smoothing is for. What we're really talking about is the overall tolerance of the operation, and a lot of operations which may need tight tolerance machining at high speeds may not have a Smoothing parameter, or you may not want to use Smoothing just to get your machine to not round corners under acceleration.

So I made it post out a G64 P0.0x block on every operation, which inherits the Tolerance value from that operation. (I am aware that this will actually result in a tolerance zone of double the input tolerance value. I'm fine with that, though it will undoubtedly cause some confusion. Fine for my purposes, I'll just put a conservative tolerance zone in there.)

I'm going to try using it like this for a bit, I haven't used it to run a machine yet, so keep yer finger on the E-stop button until you've run a test program.

I was going to start with Spangled's post, because I was going to have an overall G64 P0.0x value, combined with a per-operation G64 P0.0x value based on if the operation has a "smoothing" parameter applied.

But then I thought, that's not really what the smoothing is for. What we're really talking about is the overall tolerance of the operation, and a lot of operations which may need tight tolerance machining at high speeds may not have a Smoothing parameter, or you may not want to use Smoothing just to get your machine to not round corners under acceleration.

So I made it post out a G64 P0.0x block on every operation, which inherits the Tolerance value from that operation. (I am aware that this will actually result in a tolerance zone of double the input tolerance value. I'm fine with that, though it will undoubtedly cause some confusion. Fine for my purposes, I'll just put a conservative tolerance zone in there.)

I'm going to try using it like this for a bit, I haven't used it to run a machine yet, so keep yer finger on the E-stop button until you've run a test program.

Last edit: 28 Feb 2019 17:45 by MartyJ.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

02 Mar 2019 13:58 #127502

by pl7i92

Replied by pl7i92 on topic Fusion 360 Milling post with G64 Pn

You can change at any time theoperation Tolerance to G61

Its manly thaught for Engraving and 3D parts in wood plastic ...

Its manly thaught for Engraving and 3D parts in wood plastic ...

Please Log in or Create an account to join the conversation.

- MartyJ

-

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 13

02 Mar 2019 14:20 #127509

by MartyJ

Replied by MartyJ on topic Fusion 360 Milling post with G64 Pn

98% of what I do is 3d parts in wood, so G64 is on most of the time. Does make me think I should put some code in the post which automatically switches to G61 if the operation tolerance is set below 0.003"/0.08mm or so, since the programmer's intention is to make a part as accurately as possible at that point.

Please Log in or Create an account to join the conversation.

Time to create page: 0.131 seconds