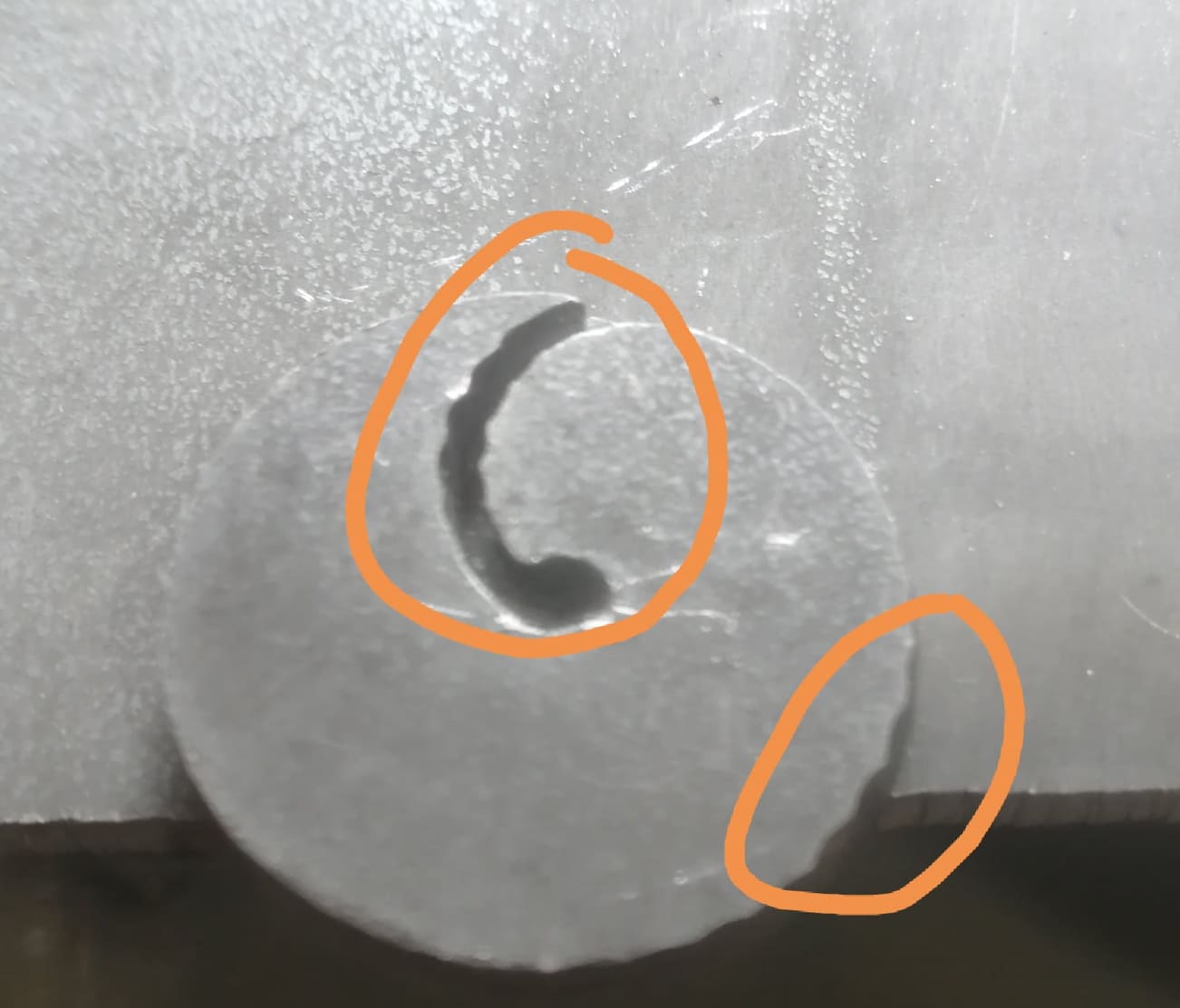

circle cutting test fusion

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

02 Oct 2021 19:13 - 02 Oct 2021 21:08 #222040

by paulsao

circle cutting test fusion was created by paulsao

Attachments:

Last edit: 02 Oct 2021 21:08 by paulsao.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

02 Oct 2021 21:52 #222053

by chris@cnc

Replied by chris@cnc on topic circle cutting test fusion

I guess you already adjust the PID many times. But finaly we have only two reason. Mechanic or PID loop. Mechanic could be not straight or parallel linear guides. And servo can not run smooth at this point.

Its almost in same area, check mechanic there. Its sporadic somewhere, decrease your P term.

I remember you plot good circles on paper. I would do it again to indentify bad areas.

bad game....

Its almost in same area, check mechanic there. Its sporadic somewhere, decrease your P term.

I remember you plot good circles on paper. I would do it again to indentify bad areas.

bad game....

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

02 Oct 2021 22:29 #222055

by paulsao

Replied by paulsao on topic circle cutting test fusion

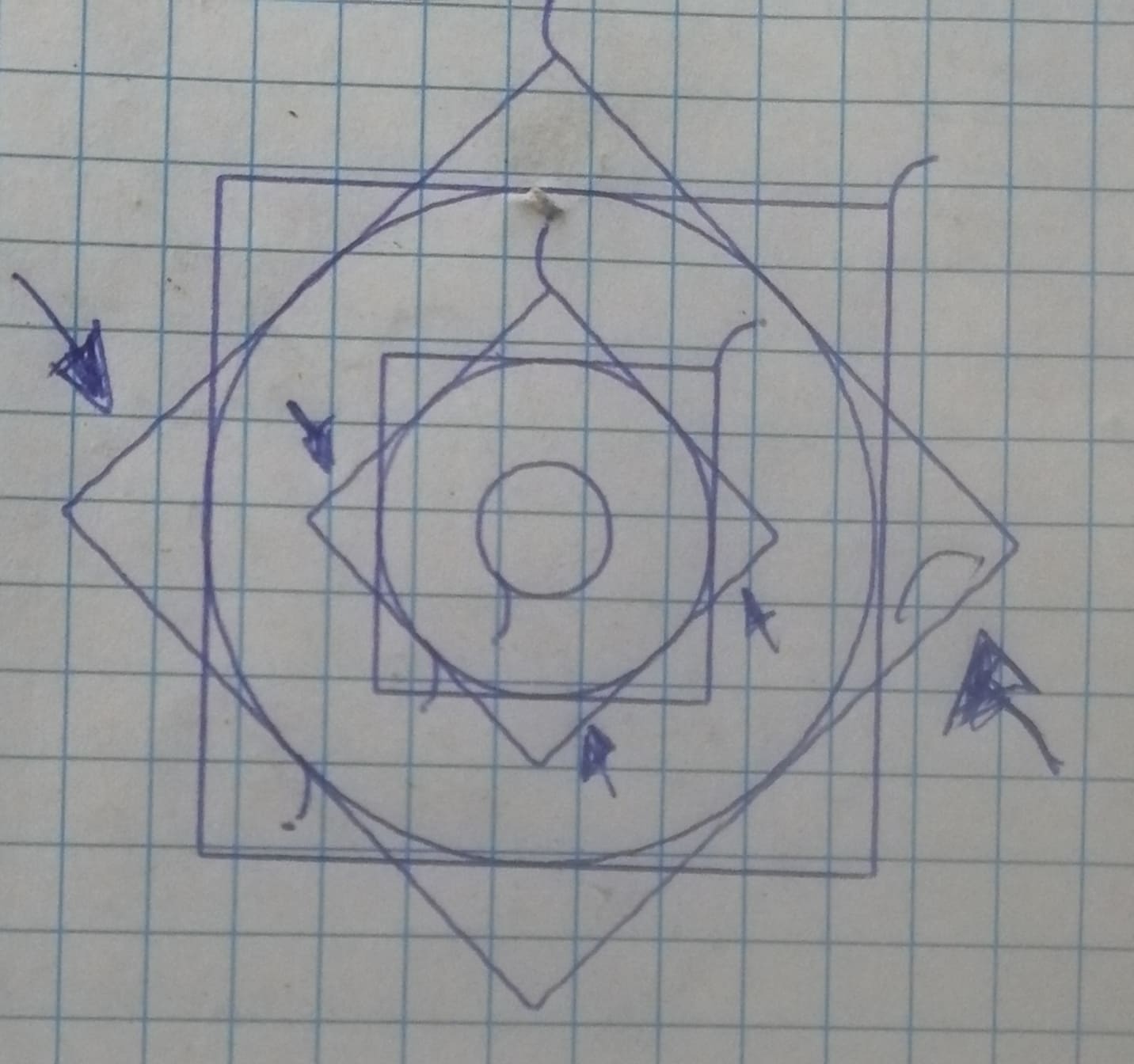

Thanks for your help, now I am going to carry out other tests but I have some doubts before:

1) In circles the PID also enters the game? I have P = 25

2) I have carried out some tests and I see that the vibrations occur when the 2 axes come into operation at the same time but right in some corner it smells of something of the acceleration I do not know how to adjust those values.

1) In circles the PID also enters the game? I have P = 25

2) I have carried out some tests and I see that the vibrations occur when the 2 axes come into operation at the same time but right in some corner it smells of something of the acceleration I do not know how to adjust those values.

Attachments:

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

02 Oct 2021 22:33 #222056

by chris@cnc

Replied by chris@cnc on topic circle cutting test fusion

I forgot to say electromagnetic noise could be also one reason. If all circles ok, look to your cables. This subject is discuss many times.

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

02 Oct 2021 22:47 - 02 Oct 2021 22:51 #222058

by chris@cnc

Replied by chris@cnc on topic circle cutting test fusion

P=25 is not much. Maybe you show your ini file to see all numbers. And what kind of Hardware did you use? And which axis does that? May you have to tune your amplifier gain.Thanks for your help, now I am going to carry out other tests but I have some doubts before:

1) In circles the PID also enters the game? I have P = 25

2) I have carried out some tests and I see that the vibrations occur when the 2 axes come into operation at the same time but right in some corner it smells of something of the acceleration I do not know how to adjust those values.

Last edit: 02 Oct 2021 22:51 by chris@cnc. Reason: i wish this preview button back

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

02 Oct 2021 23:15 #222060

by paulsao

Replied by paulsao on topic circle cutting test fusion

I am using dm556 drivers with 1/64 microstep divisions, nema 23 motors, the x axis has that problem, coincidentally that axis has a nema 23 motor but different from those of the (y) axis, it consumes more current and is not very quiet, now that I check my stepper motor cable it does not have protection against electromagnetism, I think I will replace that to eliminate all possibilities, I did a test reducing the acceleration and I no longer have the oscillations, but I think it is not good for the thc anymore that it would not reach the desired speeds. I am attaching my ini file.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

02 Oct 2021 23:50 #222064

by chris@cnc

Replied by chris@cnc on topic circle cutting test fusion

I take a look in your ini.P = 1000.0 not 25.

andis minimum limit in leadshine manual. Here could you go little longer for test. And last try set Max_Velocity and Max_Acceleration on all joints equal. They must do all the same...

[AXIS_X]

# set to double the value in the corresponding joint

MAX_VELOCITY = 200.0

# set to double the value in the corresponding joint

MAX_ACCELERATION = 1000

# shares the above two equally between the joint and the offset

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -1

MAX_LIMIT = 1525.0

[JOINT_0]

TYPE = LINEAR

HOME = 10

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 100

MAX_ACCELERATION = 500

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 125

STEPGEN_MAXACCEL = 625

P = 1000.0and

DIRSETUP = 5000

DIRHOLD = 10000

STEPLEN = 2500

STEPSPACE = 2500

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

03 Oct 2021 16:43 #222119

by paulsao

Replied by paulsao on topic circle cutting test fusion

I managed to correct the vibration error by reducing the acceleration a bit I think it is not very good for the thc but for now I am going to leave it that way, since the only solution is to place a reduction system in the motors and bands system because I have it connected directly and that influences the vibrations, thanks for your time and help.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4698

- Thank you received: 1441

07 Oct 2021 20:48 #222485

by Todd Zuercher

Replied by Todd Zuercher on topic circle cutting test fusion

I have seen similar vibrations caused by slop in an axis from a worn or maladjusted bearing or loose belt.

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

Time to create page: 0.135 seconds