tool change

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

12 Nov 2015 19:36 - 12 Nov 2015 19:37 #65182

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic tool change

Have you changed things in your config since you last posted it?

If so post it again and I will take another look.

What exactly is it doing when you try to use the auto tool measurement? What is not working?

If so post it again and I will take another look.

What exactly is it doing when you try to use the auto tool measurement? What is not working?

Last edit: 12 Nov 2015 19:37 by LearningLinuxCNC. Reason: Added another question.

Please Log in or Create an account to join the conversation.

- thor44

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 2

13 Nov 2015 04:20 #65195

by thor44

Replied by thor44 on topic tool change

my understanding is that when a tool change is given in the g code file the machine moves to a specified location the tool is changed manually and then the machine automatically does a tool touch off for the tool height and then returns to the g code file to finish the job.

When the tool change comes up the message appears and when you click continue the machine continues, no movement to the specified location and no touch off.

Here is the newest config files.

Thanks

When the tool change comes up the message appears and when you click continue the machine continues, no movement to the specified location and no touch off.

Here is the newest config files.

Thanks

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

13 Nov 2015 13:30 #65201

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic tool change

Looks like you have almost everything correct.

You have a # in front of the line

Remove the # to uncomment the line

Also you still have the value of MAXPROBE being a positive value. If positive is up on your Z axis then you want the value of MAXPROBE to be a negative value so that it moves down when probing.

There are also some leading spaces on some of the lines in your INI file. I don't think this will cause and issue but you might remove them to make it more consistent.

You have a # in front of the line

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=change epilog=change_epilogRemove the # to uncomment the line

Also you still have the value of MAXPROBE being a positive value. If positive is up on your Z axis then you want the value of MAXPROBE to be a negative value so that it moves down when probing.

There are also some leading spaces on some of the lines in your INI file. I don't think this will cause and issue but you might remove them to make it more consistent.

The following user(s) said Thank You: newbynobi, thor44

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

13 Nov 2015 13:43 #65202

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic tool change

Another thing that I noticed is that you have

FEATURES =30

followed by

FEATURES = 12

You can remove the FEATURES = 12 since the previous statement already covers that.

FEATURES =30

followed by

FEATURES = 12

You can remove the FEATURES = 12 since the previous statement already covers that.

Please Log in or Create an account to join the conversation.

- thor44

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 2

13 Nov 2015 14:45 #65203

by thor44

Replied by thor44 on topic tool change

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

13 Nov 2015 14:58 #65204

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic tool change

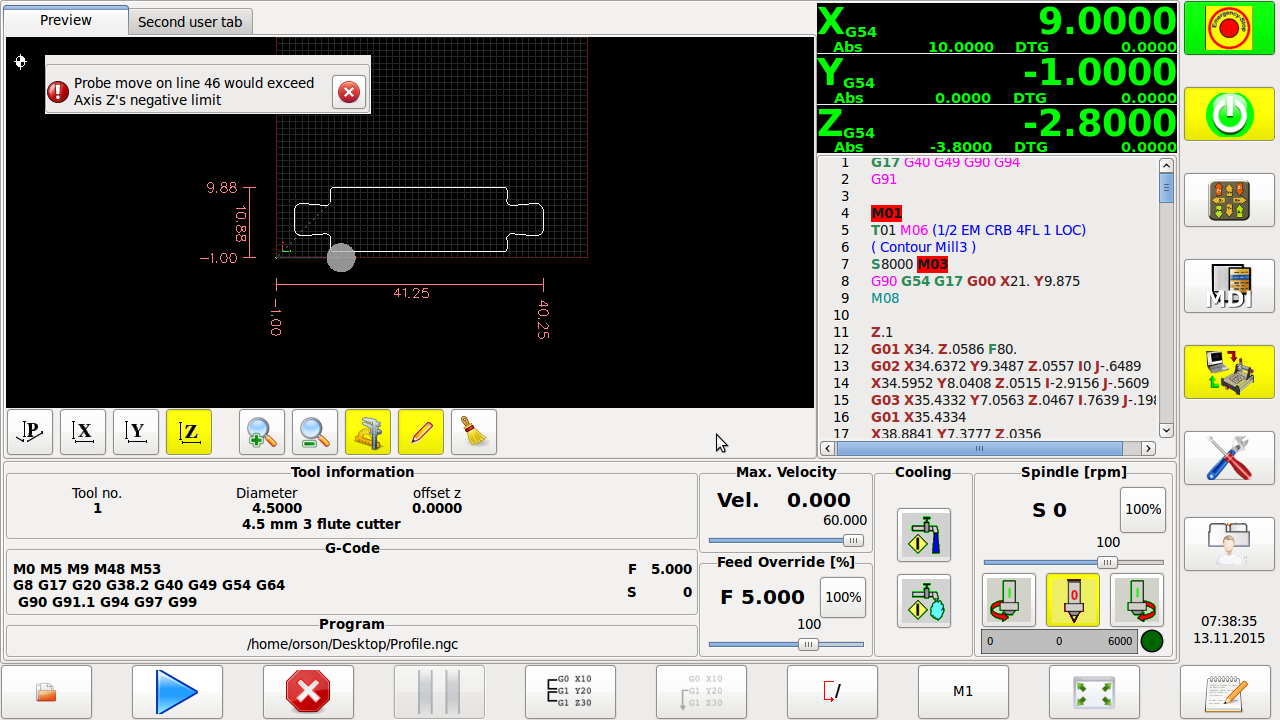

The way the tool measurement routine works is that it moves to the "CHANGE POSITION" you do the tool change. Then it moves to the "TOOLSENSOR" X and Y position then the "TOOLSENSOR" Z position. After that it begins a probing move in the Z axis with a maximum probing distance of "MAXPROBE"

It sounds like you need to tweak your "MAXPROBE" value to make the probe routine work.

All of these specific moves can be found in the change.ngc file in the macros folder.

It sounds like you need to tweak your "MAXPROBE" value to make the probe routine work.

All of these specific moves can be found in the change.ngc file in the macros folder.

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

13 Nov 2015 15:40 #65205

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic tool change

Looking at the AXIS_2 section in your INI file. I see that your 0 position is in the middle of the axis. The min limit is -3.9 and the max limit is 3.

Your TOOLCHANGE position is at -3 so I assume the the -3 position is near the top of the Z axis travel. I told you earlier to make the MAXPROBE value negative but it appears that you have positive Z travel in the downward direction. This is rather unconventional and may cause issues down the road.

Your TOOLCHANGE position is at -3 so I assume the the -3 position is near the top of the Z axis travel. I told you earlier to make the MAXPROBE value negative but it appears that you have positive Z travel in the downward direction. This is rather unconventional and may cause issues down the road.

Please Log in or Create an account to join the conversation.

Moderators: newbynobi, HansU

Time to create page: 0.109 seconds