Turret Lathe with Turret Tailstock Setup

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

I have a Hardinge Superslant I am done for the most part. This machine has 8 tools on the turret and 8 tools on the tailstock. Both rotate. Tools on the turret are numbered 1-8 and tailstock are 21-28.

https://i.imgur.com/PAHKyLT.mp4

https://i.imgur.com/WOJ7w8f.mp4

I am trying to use this machine either manually or with the computer. For most operations I will be facing parts manually, so that will be done with the jog wheels and/or a jog button. On the front panel I have X axis jog wheel, ZW axis jog wheels, jog wheel step size, select ZW axis button, rapid/rpm/feed dials, start/stop/step, coolant, index tool, index turret, and spindle load.

I am finding the LinuxCNC AXIS interface a little challenging as I am used to using a Dialog 11 controller. I want to recreate the interface of the Diaolg 11. The Dialog 11 has a Manual Mode, Auto Mode, and Programming.

In Manual Mode one can set the rpm with S#, feed with F#, and tool with T#. Using the jog buttons the machine will move in that direction at the set feed rate (unless the rapid button is pushed). The feed rate can be changed by turning the Feed override dial. Same with spindle and rapid. Numbers on the top show the feed/speed and the modified feed/speed as a result of the override dials.

Auto mode shows the current position, target position, and difference. It also shows the set feed/speed and the override values. It also shows the G commands.

Program mode is just for programming and communications.

Also, is there a way to show both tools (turret and tailstock) on the graphics screen?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19815

- Thank you received: 4614

is there a way to change the tool while in Jog mode? If I am facing a part and change my tool, is there a way to change tool without going to MDI mode? I find that stops the spindle.

I think you could do it through Python from a GUI button. And maybe with an MDI_COMMAND

Which GUI are you using? I suspect that stopping the spindle might be something the GUI is doing.

It would probably be better to call a G-code routine that does the facing operation in feed-per-rev mode. It should give a better finish. Again this could be an MDI_COMMAND (I think that G95 F0.1 G1 X0 is a valid single G-code block)I am trying to use this machine either manually or with the computer. For most operations I will be facing parts manually, so that will be done with the jog wheels and/or a jog button.

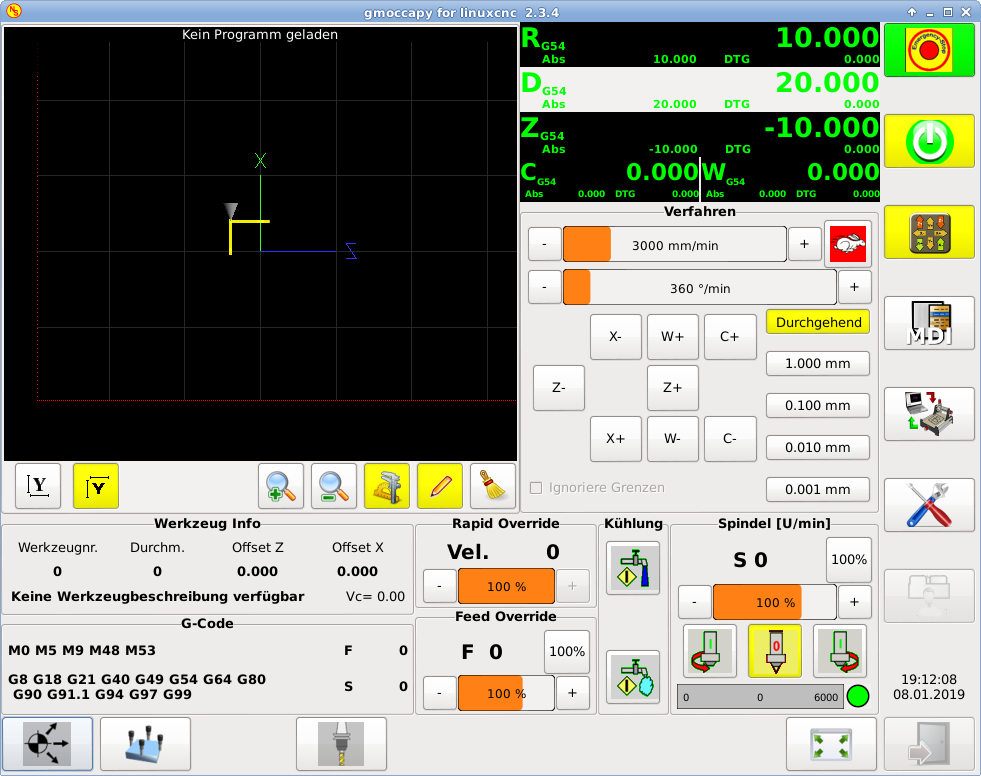

Yes, Axis might not be the best interface for a lathe. There are other GUIs available, I use "Touchy" but that probably isn't better (except that I can at least start the spondle and go to MDI mode without it stopping). But have a look at GmoccaPy, I think that has a lathe mode.I am finding the LinuxCNC AXIS interface a little challenging as I am used to using a Dialog 11 controller. I want to recreate the interface of the Diaolg 11. The Dialog 11 has a Manual Mode, Auto Mode, and Programming.

[code]Also, is there a way to show both tools (turret and tailstock) on the graphics screen?[/quote]

I don't think that there is. Though you might, as a hack, be able to overlay two Gremlin screens with a transparent background.

Please Log in or Create an account to join the conversation.

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

I have a copy of my working Axis included below. I tried replacing Axis with GMOCCAPY, but it indicated errors in launching. I was able to get GMOCCAPY to work on a test configuration, but some element of my finished configuration is causing it to crash.

My bets are in the *.ini file I have 9 axis under [TRAJ]. This was left over from the configuration I received from RobH who gave me his working Hardinge Superslant configuration. I believe the 9 axis relate to the different coordinate systems. I am not 100% how to change it to 3 without causing a crash.

The turret and tail stock changing commands are currently done using a MDI_COMMAND. I believe the spindle stops spinning because it is going from JOG to MDI mode.

A challenge I have with this machine is the keyboard and mouse is hard to use. I can set up a station with a keyboard, but I am somewhat used to hand controls for doing simple facing. I do want to learn how to use the G code commands for facing, but I would like a comfortable interface with the machine before letting it do things automatically. It took me a while to get cycles working on my mill. Now that I do, I use them all the time, but that is a different beast.

drive.google.com/open?id=1a9-ORnd4xD0nQQp7pmuLblhM5xWRS6oI

A slightly cleaned up version of the code

drive.google.com/open?id=1vRl_wg2sF6FjuT8kHzMc09vPIP21es_9

Please Log in or Create an account to join the conversation.

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

The challenge is the machine expects a Y axis and needs that axis to be homed. It is also having issues moving the W axis but I almost have it going.

What I did was rename the W axis to A axis and changed it from [AXIS_1] to [AXIS_3] so that it is:

AXIS_0 = X

AXIS_2 = Z

AXIS_3 = W

It seems to want to home the Y axis, the axis that does not exist, before going to MDI mode. I am unsure the reason for this, but I can force it to home the Y and that works. At its core, it does not like having 3 axis and not having one as a Y axis. I am going to make a fake stepper-like Y axis with no IO and say it is always homed as a fix for this.

drive.google.com/open?id=1e30vB6w0gb6IiO1n3Zar20-FewapLPVI

EDIT:

Presently I have the following in the INI file

[TRAJ]

AXES = 9

COORDINATES = X Y Z W

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 0.10

MAX_LINEAR_VELOCITY = 1.0However, when running GMOCCAPY I can home X, Z and W, but not Y and it demands Y be homed in order to run MDI. I tried running the config as a 3 axis milling machine with the Y axis having a HOME_SEQUENCE = -1. That allowed me to go into MDI, and it did it even before I had W homed, so again, something up there!

As is, I can move W with my jog wheel and see its position in AXIS, but GMOCCAPY does not update the position on the screen of the W axis and nor does it home. I have its HOME_SEQUENCE = 2, but nope, it jumps to the Z axis before the W is homed.

How can I state that an axis is homed when the machine is turned on? I just want something like:

setp halui.joint.1.is-homed TRUEPlease Log in or Create an account to join the conversation.

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

#********************

# Axis Y Fake

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 30.0

STEPGEN_MAXACCEL = 37.5

SCALE = 8000.0

FERROR = 0.05

MIN_FERROR = 0.01

MIN_LIMIT = -0.01

MAX_LIMIT = 8.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 0

HOME_USE_INDEX = NO

HOME_SEQUENCE = 0I do not have the W axis homing yet, but it is much closer now.

Please Log in or Create an account to join the conversation.

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

I also got the 5-pin dials I have for controlling Feed and Rapid, a value equivalent to a mux32, done with a mux-gen.

drive.google.com/open?id=1jEdZUms26VRzNWKKmKcdAibE1XFcKs6N

I am unsure about the offset and tool table at this time. I wonder what the offset values will be when I change the turret or tailstock. I will keep my live center at an offset of 0, so if I change any tool that will remain, but if I used a drill, its offset will change.

Things to think about, but overall a successful day.

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Moderator

-

- Posts: 1931

- Thank you received: 394

sorry for jumping in so late. I am just about to push gmoccapy 3.0 and the new one will support also lathes with additional axis like the one you describe. The layout may not be exactly what you want, but IMHO it is quite near.

If you are willing to test, just get a copy from

gmoccapy github

That branch do include several lathe configs.

Norbert

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19815

- Thank you received: 4614

I just copy an paste another axis for 1,3,4,5,6,7.

Master/2.8 deals with this a lot better. You would have axes X,Z,W mapped to joints 0.1.2

Please Log in or Create an account to join the conversation.

- Vitran

- Offline

- Senior Member

-

- Posts: 74

- Thank you received: 1

Is there anything for having a tailstock tool and turret tool in the gmoccapy 3.0?

Please Log in or Create an account to join the conversation.