Lathe__PathPilot_5i25+5i77

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

18 Feb 2017 08:28 - 18 Feb 2017 11:54 #88163

by dinkata

Lathe__PathPilot_5i25+5i77 was created by dinkata

I try work Lathe PathPilot with Mesa 5i25 + 7i77.[This config work with Linuxcnc 2.7.8 ]

How to change all in metric system ? I try..

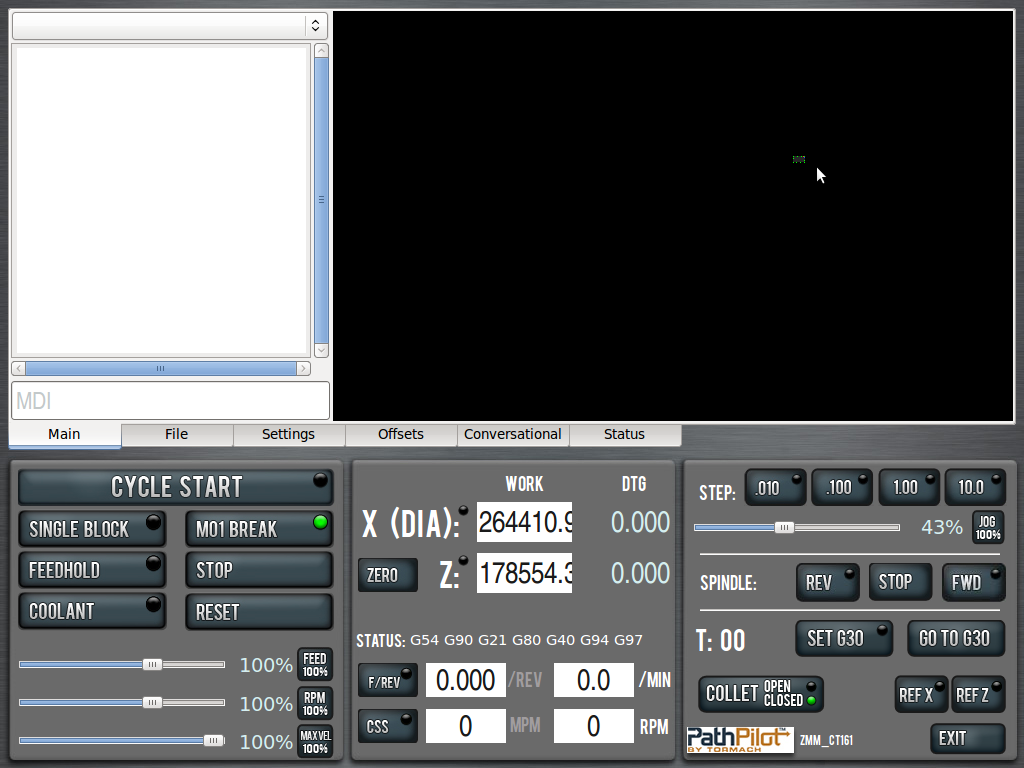

tormach_lathe_ui.py:inibut very little field work start up :

DRO show mm *25.4 !!??Here command G0 X-50 Z-100

Classicladder work ! Home work ! There is still work

Sorry for my language , i use google transalator

How to change all in metric system ? I try..

tormach_lathe_ui.py:

return 1.0 if self.g21 else 25.4RS274NGC_STARTUP_CODE = G7 G18 G21 G90[TRAJ]....LINEAR_UNITS = mmDRO show mm *25.4 !!??Here command G0 X-50 Z-100

Classicladder work ! Home work ! There is still work

Sorry for my language , i use google transalator

Last edit: 18 Feb 2017 11:54 by dinkata.

Please Log in or Create an account to join the conversation.

- rafferty

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 11

19 Feb 2017 05:44 - 19 Feb 2017 05:51 #88235

by rafferty

Replied by rafferty on topic Lathe__PathPilot_5i25+5i77

I changed the INI file, in the [RS274NGC] section change the line

RS274NGC_STARTUP_CODE = G8 G17 G20 G90 G64

to

RS274NGC_STARTUP_CODE = G8 G17 G21 G90 G64

No changes to TRAJ section.

Now all UI displays and buttons are metric, but unfortunately all the values in the INI file still need to be imperial, I'm comfortable with either so it's not really a problem for me.

g21 appears 38 times in the current mill UI so not sure what your one line python change does.

Ken

RS274NGC_STARTUP_CODE = G8 G17 G20 G90 G64

to

RS274NGC_STARTUP_CODE = G8 G17 G21 G90 G64

No changes to TRAJ section.

Now all UI displays and buttons are metric, but unfortunately all the values in the INI file still need to be imperial, I'm comfortable with either so it's not really a problem for me.

g21 appears 38 times in the current mill UI so not sure what your one line python change does.

Ken

Last edit: 19 Feb 2017 05:51 by rafferty. Reason: More detail

The following user(s) said Thank You: dinkata

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

Less

More

- Posts: 231

- Thank you received: 42

19 Feb 2017 11:25 #88246

by racedirector

Replied by racedirector on topic Lathe__PathPilot_5i25+5i77

Path pilot runs on imperial and changes to metric as it needs. Everything in the ini file needs to be imperial, just the G21 line in RS274NGC is needed. I run my router on mm btw....

The following user(s) said Thank You: dinkata

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

20 Feb 2017 09:39 #88329

by dinkata

Replied by dinkata on topic Lathe__PathPilot_5i25+5i77

rafferty , racedirector Thank you for your participation.

I would like to know does anyone work PathPilot_5i25+5i77 .

I set ini

but when you move axis error : axis.0 following error .Maybe I can set up PID ?

This config work with Linuxcnc 2.7.8 .These are the PID settings :

I would like to know does anyone work PathPilot_5i25+5i77 .

I set ini

Warning: Spoiler!

#

# Tormach Lathe LinuxCNC for Mesa [56]i25 card INI

#

[EMC]

MACHINE = tormach_lathe

#DEBUG = 0

# Debug level, 0 means no messages. See src/emc/nml_intf/debugflags.h for others

#DEBUG = 0x00000002 # configuration

#DEBUG = 0x7FFFFFFF

#DEBUG = 0x7FFFDEFF #no interp,oword

#DEBUG = 0x00008000 # py only

#DEBUG = 0x0000E000 # py + remap + Oword

#DEBUG = 0x0000C002 # py + remap + config

#DEBUG = 0x0000C100 # py + remap + Interpreter

#DEBUG = 0x0000C140 # py + remap + Interpreter + NML msgs

#DEBUG = 0x0000C040 # py + remap + NML

#DEBUG = 0x0003E100 # py + remap + Interpreter + oword + signals + namedparams

#DEBUG = 0x10000000 # EMC_DEBUG_USER1 - trace statements

#DEBUG = 0x20000000 # EMC_DEBUG_USER2 - trap into Python debugger

#DEBUG = 0x7FFFFFFF # EMC_DEBUG_ALL

#DEBUG = 0x10008000 # USER1, PYTHON

#DEBUG = 0x30008000 # USER1,USER2, PYTHON # USER2 will cause involute to try to connect to pydev

#DEBUG = 0x00080000 #EMC_DEBUG_REDIS

DEBUG = 0x00000100 # Interpreter

[DISPLAY]

DISPLAY = tormach_lathe_ui.py

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 1.2

INTRO_GRAPHIC = tormach_lathe_splash.gif

INTRO_TIME = 2

PROGRAM_PREFIX = ~/gcode/subroutines

LATHE = 1

GEOMETRY = -XZ

[REDIS]

# IMPORTANT: redis-server has a bad side effect where if *any* arguments are provided

# it clears the default save parameters and then *never* saves changes.

# The default save parameters must be restored by including them as args.

# appendServerSaveParams(60*60,1); /* save after 1 hour and 1 change */

# appendServerSaveParams(300,100); /* save after 5 minutes and 100 changes */

# appendServerSaveParams(60,10000); /* save after 1 minute and 10000 changes */

SERVER_ARGS = --dir ~/lathe_data --dbfilename dump.rdb --save 3600 1 --save 300 100 --save 60 10000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = ~/lathe_data/emc.var

RS274NGC_STARTUP_CODE = G7 G18 G21 G90 G64

SUBROUTINE_PATH = ~/tmc/subroutines:~/gcode/subroutines

# Set bit 6 for Fanuc style tool offsets

FEATURES = 64

SINGLE_BLOCK_LOCAL_SUB = YES

SINGLE_BLOCK_EXTERNAL_SUB = NO

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

# BITFILE0=mesa/tormach_lathe.bit

BITFILE0=mesa/5i25_7i77x2.bit

[HAL]

HALUI = halui

HALFILE = tormach_lathe_5i25CT161.hal

POSTGUI_HALFILE = postgui_tormach_lathe_5i25CT161.hal

[TRAJ]

AXES = 4

COORDINATES = X Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_VELOCITY = 0.5

MAX_LINEAR_VELOCITY = 1.0

# NO_FORCE_HOMING = 1

POSITION_FILE = ~/lathe_data/position.txt

DEFAULT_TOLERANCE = 0.01

DEFAULT_NAIVECAM_TOLERANCE = 0.0

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = ~/lathe_data/tool.tbl

TOOL_CHANGE_WITH_SPINDLE_ON = 1

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 15.0

P = 1.0

I = 0.001

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -50799.998

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -8.464566929

MAX_LIMIT = 0.393700787

HOME_OFFSET = -1.377952756

HOME_SEARCH_VEL = 0.590551181

HOME_LATCH_VEL = 0.039370079

HOME_FINAL_VEL = 0.5000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 15.0

P = 1.0

I = 0.001

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -25399.999

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -18.11023622

MAX_LIMIT = 0.393700787

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.590551181

HOME_LATCH_VEL = 0.039370079

HOME_FINAL_VEL = 0.5000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Spindle

#********************

[SPINDLE_9]

MAX_OUTPUT = 2000.0

ENCODER_SCALE = -4096.0

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

# Tormach Lathe LinuxCNC for Mesa [56]i25 card INI

#

[EMC]

MACHINE = tormach_lathe

#DEBUG = 0

# Debug level, 0 means no messages. See src/emc/nml_intf/debugflags.h for others

#DEBUG = 0x00000002 # configuration

#DEBUG = 0x7FFFFFFF

#DEBUG = 0x7FFFDEFF #no interp,oword

#DEBUG = 0x00008000 # py only

#DEBUG = 0x0000E000 # py + remap + Oword

#DEBUG = 0x0000C002 # py + remap + config

#DEBUG = 0x0000C100 # py + remap + Interpreter

#DEBUG = 0x0000C140 # py + remap + Interpreter + NML msgs

#DEBUG = 0x0000C040 # py + remap + NML

#DEBUG = 0x0003E100 # py + remap + Interpreter + oword + signals + namedparams

#DEBUG = 0x10000000 # EMC_DEBUG_USER1 - trace statements

#DEBUG = 0x20000000 # EMC_DEBUG_USER2 - trap into Python debugger

#DEBUG = 0x7FFFFFFF # EMC_DEBUG_ALL

#DEBUG = 0x10008000 # USER1, PYTHON

#DEBUG = 0x30008000 # USER1,USER2, PYTHON # USER2 will cause involute to try to connect to pydev

#DEBUG = 0x00080000 #EMC_DEBUG_REDIS

DEBUG = 0x00000100 # Interpreter

[DISPLAY]

DISPLAY = tormach_lathe_ui.py

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 1.2

INTRO_GRAPHIC = tormach_lathe_splash.gif

INTRO_TIME = 2

PROGRAM_PREFIX = ~/gcode/subroutines

LATHE = 1

GEOMETRY = -XZ

[REDIS]

# IMPORTANT: redis-server has a bad side effect where if *any* arguments are provided

# it clears the default save parameters and then *never* saves changes.

# The default save parameters must be restored by including them as args.

# appendServerSaveParams(60*60,1); /* save after 1 hour and 1 change */

# appendServerSaveParams(300,100); /* save after 5 minutes and 100 changes */

# appendServerSaveParams(60,10000); /* save after 1 minute and 10000 changes */

SERVER_ARGS = --dir ~/lathe_data --dbfilename dump.rdb --save 3600 1 --save 300 100 --save 60 10000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = ~/lathe_data/emc.var

RS274NGC_STARTUP_CODE = G7 G18 G21 G90 G64

SUBROUTINE_PATH = ~/tmc/subroutines:~/gcode/subroutines

# Set bit 6 for Fanuc style tool offsets

FEATURES = 64

SINGLE_BLOCK_LOCAL_SUB = YES

SINGLE_BLOCK_EXTERNAL_SUB = NO

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

# BITFILE0=mesa/tormach_lathe.bit

BITFILE0=mesa/5i25_7i77x2.bit

[HAL]

HALUI = halui

HALFILE = tormach_lathe_5i25CT161.hal

POSTGUI_HALFILE = postgui_tormach_lathe_5i25CT161.hal

[TRAJ]

AXES = 4

COORDINATES = X Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_VELOCITY = 0.5

MAX_LINEAR_VELOCITY = 1.0

# NO_FORCE_HOMING = 1

POSITION_FILE = ~/lathe_data/position.txt

DEFAULT_TOLERANCE = 0.01

DEFAULT_NAIVECAM_TOLERANCE = 0.0

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = ~/lathe_data/tool.tbl

TOOL_CHANGE_WITH_SPINDLE_ON = 1

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 15.0

P = 1.0

I = 0.001

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -50799.998

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -8.464566929

MAX_LIMIT = 0.393700787

HOME_OFFSET = -1.377952756

HOME_SEARCH_VEL = 0.590551181

HOME_LATCH_VEL = 0.039370079

HOME_FINAL_VEL = 0.5000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 15.0

P = 1.0

I = 0.001

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -25399.999

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -18.11023622

MAX_LIMIT = 0.393700787

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 0.590551181

HOME_LATCH_VEL = 0.039370079

HOME_FINAL_VEL = 0.5000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Spindle

#********************

[SPINDLE_9]

MAX_OUTPUT = 2000.0

ENCODER_SCALE = -4096.0

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

but when you move axis error : axis.0 following error .Maybe I can set up PID ?

This config work with Linuxcnc 2.7.8 .These are the PID settings :

Warning: Spoiler!

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 450.0

P = 10.0

I = 0.01

D = 0.001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -2000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -215.0

MAX_LIMIT = 15.0

HOME_OFFSET = -35.000

HOME_SEARCH_VEL = 15.000

HOME_LATCH_VEL = 1.000

HOME_FINAL_VEL = 2.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 450.0

P = 5.0

I = 0.01

D = 0.001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -1000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -460.0

MAX_LIMIT = 15.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 15.000

HOME_LATCH_VEL = 1.000

HOME_FINAL_VEL = 2.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Spindle

#********************

[SPINDLE_9]

MAX_OUTPUT = 3000.0

ENCODER_SCALE = -4096.0

OUTPUT_SCALE = 3000

OUTPUT_MIN_LIMIT = -3000

OUTPUT_MAX_LIMIT = 3000

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 450.0

P = 10.0

I = 0.01

D = 0.001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -2000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -215.0

MAX_LIMIT = 15.0

HOME_OFFSET = -35.000

HOME_SEARCH_VEL = 15.000

HOME_LATCH_VEL = 1.000

HOME_FINAL_VEL = 2.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5.0

MIN_FERROR = 0.1

MAX_VELOCITY = 20.0

MAX_ACCELERATION = 450.0

P = 5.0

I = 0.01

D = 0.001

FF0 = 0.0

FF1 = 0.002

FF2 = 0.0002

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -1000.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

BACKLASH = 0.0

MIN_LIMIT = -460.0

MAX_LIMIT = 15.0

HOME_OFFSET = 0.000000

HOME_SEARCH_VEL = 15.000

HOME_LATCH_VEL = 1.000

HOME_FINAL_VEL = 2.000

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Spindle

#********************

[SPINDLE_9]

MAX_OUTPUT = 3000.0

ENCODER_SCALE = -4096.0

OUTPUT_SCALE = 3000

OUTPUT_MIN_LIMIT = -3000

OUTPUT_MAX_LIMIT = 3000

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

21 Feb 2017 08:43 - 21 Feb 2017 14:19 #88422

by dinkata

Replied by dinkata on topic Lathe__PathPilot_5i25+5i77

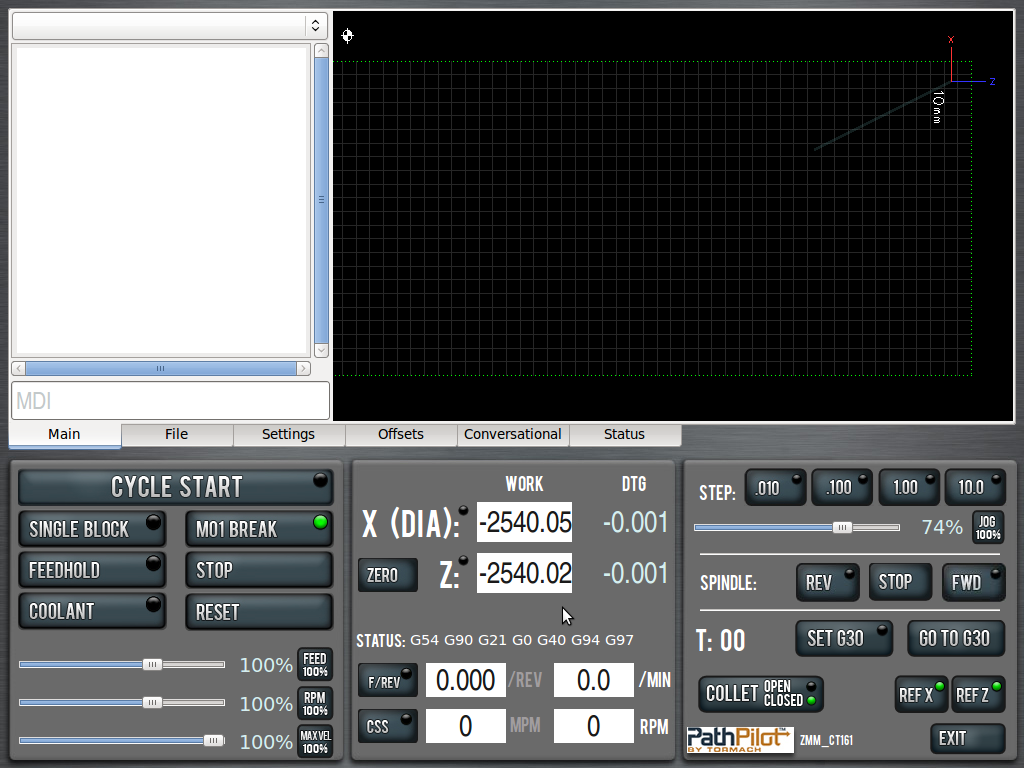

First step ready

it's in progress cycle:

it's in progress cycle:

o100 do

M66 P0 L0

o101 if [#5399 NE 1]

G91 G1 X50 Z50 F1000

G4 P2

G91 G1 X-50 Z-50 F1000

G4 P2

o101 else

o100 break

o101 endif

o100 while [#<_task> NE 0]

M2

Last edit: 21 Feb 2017 14:19 by dinkata.

Please Log in or Create an account to join the conversation.

Time to create page: 0.114 seconds