Plasma GUI?

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

13 Sep 2017 00:56 #98906

by rodw

Replied by rodw on topic Plasma GUI?

You may be overthinking it. There is probably only minor modifications required to your existing postprocessor so I'd investigate that as my preferred option.

In sheetcam, the kerf width is defined for each given material and plate thickness (eg. for 2mm Mild Steel) so it knows what offset to apply. Basically all of the key cutting parameters are contained within the material definition (pierce height, cut height, pierce delay etc..)

Sheetcam also supports plasma drilling operations.

I'm still learning about this myself this morning but it may be possible to send RS485 commands to the plasma cutter via the Mesa 7i76e serial interface with the required firmware and software config (eg set Hypertherm current and air pressure etc.)

In sheetcam, the kerf width is defined for each given material and plate thickness (eg. for 2mm Mild Steel) so it knows what offset to apply. Basically all of the key cutting parameters are contained within the material definition (pierce height, cut height, pierce delay etc..)

Sheetcam also supports plasma drilling operations.

I'm still learning about this myself this morning but it may be possible to send RS485 commands to the plasma cutter via the Mesa 7i76e serial interface with the required firmware and software config (eg set Hypertherm current and air pressure etc.)

Please Log in or Create an account to join the conversation.

- scubawarm

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

13 Sep 2017 12:43 #98919

by scubawarm

Replied by scubawarm on topic Plasma GUI?

But you see this is reversed from a big boy industrial control and nesting software. At least from my experience.

The CAM programmer should only be concerned with the selected amps and standard feed rate for that material type, grade and thickness. Each has a code to send to the control for the offsets.

The control uses that code to search its database for the required parameters. If the parameters are off the operator can adjust them for that run (material variences etc) and even future runs in the control if just wrong. Also keeping in mind as consumables age things change...

Neither CAM programmer nor operator are concerned with the pierce height, gas flows etc. The control manufacture has that all in the control and optimized the the material and thickness.

I realize this is a different sandbox, and most likely I will learn it can be done both ways. Just pointing out how in my experience it has been done before the latest industrial controllers.

A point worth making is.... With all the true hole technology and beveled cuts etc... The control/torch manufactures are requiring you to also use their CAM nesting software... Only way they can control things enough to get desired results. Which I guess is the same as what we are trying to do.

The CAM programmer should only be concerned with the selected amps and standard feed rate for that material type, grade and thickness. Each has a code to send to the control for the offsets.

The control uses that code to search its database for the required parameters. If the parameters are off the operator can adjust them for that run (material variences etc) and even future runs in the control if just wrong. Also keeping in mind as consumables age things change...

Neither CAM programmer nor operator are concerned with the pierce height, gas flows etc. The control manufacture has that all in the control and optimized the the material and thickness.

I realize this is a different sandbox, and most likely I will learn it can be done both ways. Just pointing out how in my experience it has been done before the latest industrial controllers.

A point worth making is.... With all the true hole technology and beveled cuts etc... The control/torch manufactures are requiring you to also use their CAM nesting software... Only way they can control things enough to get desired results. Which I guess is the same as what we are trying to do.

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

13 Sep 2017 13:27 #98921

by rodw

Replied by rodw on topic Plasma GUI?

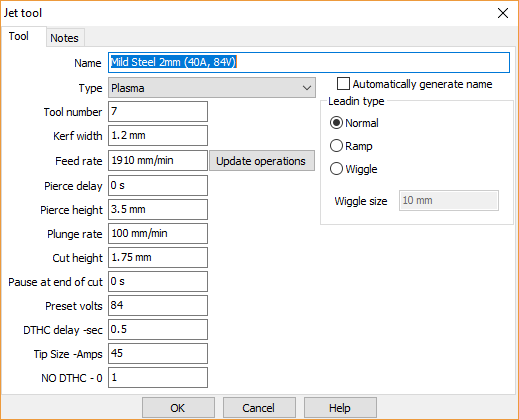

Very similar I think. Here is a sheetcam tool definition for 2mm mild steel.

Pressure and amps are missing but I've disabled the RS485 option in my post processor which is probably why they are not showing.

So you apply this toolset to your job (nest) and it knows everything about how to cut 2mm mild steel. You generate the gcode with a mouse click and the gcode sets all the parameters. As you say the operator should know nothing.

I don't think it would be hard to maintain a database of these settings and have Linuxcnc retrieve the correct record and set it up the same way. It would be the python language processing this and it makes file handling very trivial. In fact, it looks like there might even be a python database library so you could maintain indexed data files and use a separate python program to manage your database.

So how do you select the material you are cutting? on the console or in gcode?

Pressure and amps are missing but I've disabled the RS485 option in my post processor which is probably why they are not showing.

So you apply this toolset to your job (nest) and it knows everything about how to cut 2mm mild steel. You generate the gcode with a mouse click and the gcode sets all the parameters. As you say the operator should know nothing.

I don't think it would be hard to maintain a database of these settings and have Linuxcnc retrieve the correct record and set it up the same way. It would be the python language processing this and it makes file handling very trivial. In fact, it looks like there might even be a python database library so you could maintain indexed data files and use a separate python program to manage your database.

So how do you select the material you are cutting? on the console or in gcode?

Please Log in or Create an account to join the conversation.

- scubawarm

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 96

- Thank you received: 2

14 Sep 2017 15:30 - 14 Sep 2017 15:35 #98951

by scubawarm

Replied by scubawarm on topic Plasma GUI?

OK finally got my laptop with touch screen to have a dual boot.

Built a 4.9.4 RT Mint 18.1 32bit. (tried others but nothing but problems - almost killed me to put on 32 bit though LOL)

Built dgarr/external_offsets LinuxCNC dev branch.

Trying to learn what HAL is all about.

One thing I noticed is the Plasma gmoccapy seems much more broken then the base package, can't seem to home, move around, etc. etc. I found a really good man/html on it, but for the life of me can't find it again. LOL information overload.

EDIT right G search found it for me again. wiki.linuxcnc.org/cgi-bin/wiki.pl?Gmoccapy_Plasma

Is that yours? Or you have one you have fixed up?

As to the material size question. That is being done in the nesting software, currently only passed to controller via comments, as it only has a roller at this point.

Built a 4.9.4 RT Mint 18.1 32bit. (tried others but nothing but problems - almost killed me to put on 32 bit though LOL)

Built dgarr/external_offsets LinuxCNC dev branch.

Trying to learn what HAL is all about.

One thing I noticed is the Plasma gmoccapy seems much more broken then the base package, can't seem to home, move around, etc. etc. I found a really good man/html on it, but for the life of me can't find it again. LOL information overload.

EDIT right G search found it for me again. wiki.linuxcnc.org/cgi-bin/wiki.pl?Gmoccapy_Plasma

Is that yours? Or you have one you have fixed up?

As to the material size question. That is being done in the nesting software, currently only passed to controller via comments, as it only has a roller at this point.

Last edit: 14 Sep 2017 15:35 by scubawarm. Reason: Found docs

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

14 Sep 2017 20:49 #98972

by rodw

Replied by rodw on topic Plasma GUI?

I just tried the gmoccappy plasma sim and it works for me

Start sim,

press estop top right

press power on below it

press home select bottom right

press home all

all DRO's go green

This is what I am using for a GUI but pretty heavilly modified

Written by MArius who is using it on a Hypertherm 260

I'm off line for the next 3 days travelling 600 km for a wedding....

Start sim,

press estop top right

press power on below it

press home select bottom right

press home all

all DRO's go green

This is what I am using for a GUI but pretty heavilly modified

Written by MArius who is using it on a Hypertherm 260

I'm off line for the next 3 days travelling 600 km for a wedding....

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11571

- Thank you received: 3885

14 Sep 2017 20:56 #98973

by rodw

Replied by rodw on topic Plasma GUI?

Forgot. If you are running the external offset branch, drill down to sim/axis/external offsets

and run hpid or hpid_mm (which is the metric version)

This branch has changed in the last few days. Dewey implemented a suggestion of mine so I am behind you I think as I have not recompiled

and run hpid or hpid_mm (which is the metric version)

This branch has changed in the last few days. Dewey implemented a suggestion of mine so I am behind you I think as I have not recompiled

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.088 seconds