Torch catches on slag of pierce

- cruzinone

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

28 Mar 2018 17:22 #108039

by cruzinone

Torch catches on slag of pierce was created by cruzinone

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

29 Mar 2018 01:38 #108054

by tommylight

Replied by tommylight on topic Torch catches on slag of pierce

Set the torch higher if possible, and you do have to clean that on every cut when dealing with thick material.

Also tour torch is not perpendicular to the material so you get that slag on one side only.

Also tour torch is not perpendicular to the material so you get that slag on one side only.

Please Log in or Create an account to join the conversation.

- cruzinone

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

29 Mar 2018 15:42 #108072

by cruzinone

Replied by cruzinone on topic Torch catches on slag of pierce

I will check that on being perpendicular and where would I set it higher at the pierce height? I did not realize I needed to clean it on cuts. thanks tommylight. I appreciate the input.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

30 Mar 2018 02:26 #108091

by tommylight

Replied by tommylight on topic Torch catches on slag of pierce

You will have to do some experimenting as setting the torch to high will mess up the cut quality or miss fire at start. The reality remains that you have to clean that slag after every pierce on thicker material.

Usually up to 10mm thick it poses no problem, beyond that to much slag will accumulate on every pierce.

That is easy to get rid off, just a light tap with a piece of metal or screw driver will remove it.

Usually up to 10mm thick it poses no problem, beyond that to much slag will accumulate on every pierce.

That is easy to get rid off, just a light tap with a piece of metal or screw driver will remove it.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

30 Mar 2018 12:34 #108106

by Todd Zuercher

Replied by Todd Zuercher on topic Torch catches on slag of pierce

(I know nothing about plasma cutting so take my ideas with a grain of salt.)

That doesn't really help him solve his problem (the torch snagging on the slag and moving the piece.

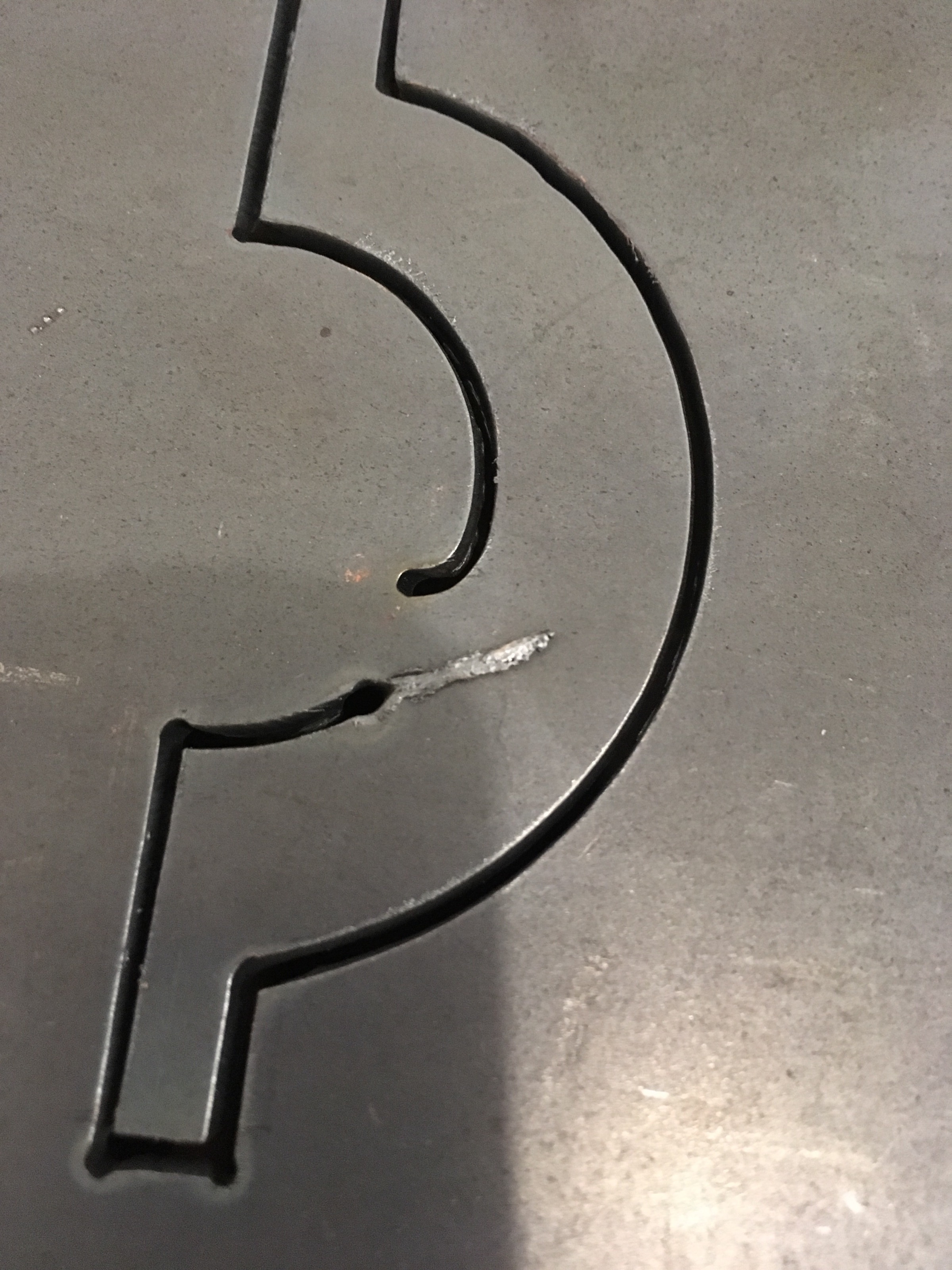

And from the photo the problem isn't that the slag build-up snags on the torch at the start of the cut, but at the end.

From the sound of it the slag will always be a problem, so it would seem to me that the solution to the real problem is to use a lead in move so that the pierce point (and the slag build up) are off of the piece and out of the way of the torch when it comes around and finishes the cut.

That doesn't really help him solve his problem (the torch snagging on the slag and moving the piece.

And from the photo the problem isn't that the slag build-up snags on the torch at the start of the cut, but at the end.

From the sound of it the slag will always be a problem, so it would seem to me that the solution to the real problem is to use a lead in move so that the pierce point (and the slag build up) are off of the piece and out of the way of the torch when it comes around and finishes the cut.

The following user(s) said Thank You: Plasmaguy

Please Log in or Create an account to join the conversation.

- cruzinone

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

30 Mar 2018 18:04 #108115

by cruzinone

Replied by cruzinone on topic Torch catches on slag of pierce

It is at the beginning of the cut that it snags on the piece

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

30 Mar 2018 18:53 #108117

by Todd Zuercher

Replied by Todd Zuercher on topic Torch catches on slag of pierce

Huh? Ok, from the photo I was guessing that it hit at the end causing the little hook turn, and preventing it from finishing it off. Goes to show how little I know.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

30 Mar 2018 20:36 #108136

by islander261

Replied by islander261 on topic Torch catches on slag of pierce

Hi

On larger industrial level plasma cutters there is a section of the torch height profile for raising up over the pierce slag puddle before going to the actual cut height. This is usually done on the beginning of the lead in for the cut so the torch is at cut height by the time it gets to the work. This will take some integration with your post processor to make it work. The usual work around is to pierce all the start points on a thick sheet then stop the machine and clean off the dross. Then the machine is restarted to make the cuts. While some what cumbersome this can be done with hand edited files.

John

On larger industrial level plasma cutters there is a section of the torch height profile for raising up over the pierce slag puddle before going to the actual cut height. This is usually done on the beginning of the lead in for the cut so the torch is at cut height by the time it gets to the work. This will take some integration with your post processor to make it work. The usual work around is to pierce all the start points on a thick sheet then stop the machine and clean off the dross. Then the machine is restarted to make the cuts. While some what cumbersome this can be done with hand edited files.

John

The following user(s) said Thank You: jawneelogik

Please Log in or Create an account to join the conversation.

- jawneelogik

-

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

01 Aug 2018 11:48 #115299

by jawneelogik

Replied by jawneelogik on topic Torch catches on slag of pierce

This is a problem I have experienced almost every time I try to cut 3/4" material. I have a HT PM85 which --according to the specs-- is capable of piercing 3/4". I follow the manual to a 'T' regarding Pierce Height, Pierce Delay, Etc. I'm using Sheetcam and set my Leadins to 3/4" as is also recommended in the pm85 manual. However, on almost every cut, the torch comes down to cut height and immediately gets hung up on the pile of slag which has formed in the cut path. On far too many occasions, this has resulted in the destruction of $$$ worth of consumables including blown out Shields AND Retaining Caps! I've learned the hard way that the HT Duramax torch does NOT like to touch the material at all while cutting!

What I was wondering is: has anyone that uses Sheetcam ever tried the "wiggle" or "ramp" leadin option and if so how did you set the various other parameters (pierce delay, plunge rate, etc.)?

john

What I was wondering is: has anyone that uses Sheetcam ever tried the "wiggle" or "ramp" leadin option and if so how did you set the various other parameters (pierce delay, plunge rate, etc.)?

john

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

01 Aug 2018 21:22 #115345

by rodw

Replied by rodw on topic Torch catches on slag of pierce

Not specifically related to sheetcam (which I do have) but I had made a mote to try the ramp leadin as from what I had read, it would be much kinder on consumables. Let me know what you find.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.145 seconds