Gantry Limit switches & homing question.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21212

- Thank you received: 7245

21 Jan 2019 21:43 #124568

by tommylight

Replied by tommylight on topic Gantry Limit switches & homing question.

Does the machine use DC servo drives and motors ?

That is the only case that the extreme limit switches are not negotiable, they should be there and they should cut power to the drives through relays that should also be wired to the E-stop and to "machine power" in Linuxcnc.

In all other cases, they are not required, but it is nice to have them.

In case of a short of the power transistors/mosfet's/IGBT on the drive, that would cause all of the voltage gouin in the drive to pass through and get to the motor, and in case of DC motors they would run at full speed ( usually that is way more than what can be run during normal operation ), and no amount of disable signal will stop them, braking the machine badly. In case of AC, brushless DC and stepper motors, that would cause a winding in the motor to burn, nothing more, if there are no fuses at all.

As Andy said, in no case ever should the motor wires be disconnected from the motor while it is powered up and enabled on the drive. While disabled it is all good, but do not tempt your luck.

That is the only case that the extreme limit switches are not negotiable, they should be there and they should cut power to the drives through relays that should also be wired to the E-stop and to "machine power" in Linuxcnc.

In all other cases, they are not required, but it is nice to have them.

In case of a short of the power transistors/mosfet's/IGBT on the drive, that would cause all of the voltage gouin in the drive to pass through and get to the motor, and in case of DC motors they would run at full speed ( usually that is way more than what can be run during normal operation ), and no amount of disable signal will stop them, braking the machine badly. In case of AC, brushless DC and stepper motors, that would cause a winding in the motor to burn, nothing more, if there are no fuses at all.

As Andy said, in no case ever should the motor wires be disconnected from the motor while it is powered up and enabled on the drive. While disabled it is all good, but do not tempt your luck.

Please Log in or Create an account to join the conversation.

- superlen

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 8

21 Jan 2019 23:43 #124574

by superlen

Ah!!! Rod, this cleared up my confusion. I didn't realize that LCNC was expecting dedicated limit switch inputs. I was assuming it just had a home signal and used SW limit by default. I'll have to waffle some more on using the existing limits on the machine for these or adding a second pair. I really like the redundancy & complete software independence of having my existing switches drop out power to drives, but this may be overkill. One factor in this decision is also that the entire gantry is close to 14' in the Xaxis & the outer 2' on both the left and right are not really useful in my design. So I might need to add a second pair closer to my work window anyhow.

Regardless of how I finally wire it, I'm clear on my options now and what I need to plan for.

Thanks again.

Len

Replied by superlen on topic Gantry Limit switches & homing question.

I was thinking you'd Add your home switches and use your existing limit switches as LinuxCNC limit switch inputs and add 2 more switches, one at each end of the table for your hardware override. But I guess you'll need to do that on the gantry axis as well.

Ah!!! Rod, this cleared up my confusion. I didn't realize that LCNC was expecting dedicated limit switch inputs. I was assuming it just had a home signal and used SW limit by default. I'll have to waffle some more on using the existing limits on the machine for these or adding a second pair. I really like the redundancy & complete software independence of having my existing switches drop out power to drives, but this may be overkill. One factor in this decision is also that the entire gantry is close to 14' in the Xaxis & the outer 2' on both the left and right are not really useful in my design. So I might need to add a second pair closer to my work window anyhow.

Regardless of how I finally wire it, I'm clear on my options now and what I need to plan for.

Thanks again.

Len

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- superlen

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 8

21 Jan 2019 23:54 #124575

by superlen

Replied by superlen on topic Gantry Limit switches & homing question.

Tommy,

They are Kollmorgen servostar linear motors, effectively an ac servo split and spread out in a straight line. You can make the axis as long as desired by just adding magnets to your axis for the motor to see. A shorted output can't result in a runaway, but I was considering the case where the +/-10V signal feeding the drive goes full scale. I'm just now learning about servos and drives so maybe my worry is unfounded. In my design, it's no problem to add a 2nd set of limits to feed LCNC and then use the existing limits to drop power to the drives externally.

Len

They are Kollmorgen servostar linear motors, effectively an ac servo split and spread out in a straight line. You can make the axis as long as desired by just adding magnets to your axis for the motor to see. A shorted output can't result in a runaway, but I was considering the case where the +/-10V signal feeding the drive goes full scale. I'm just now learning about servos and drives so maybe my worry is unfounded. In my design, it's no problem to add a 2nd set of limits to feed LCNC and then use the existing limits to drop power to the drives externally.

Len

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

22 Jan 2019 00:11 #124576

by andypugh

You _might_ be the first big linear-motor LinuxCNC application. I think we have seen some small ones.

Thinking about this further... It seems likely that you will have unusually fast motion available. So that makes for an interesting design decision. If you hit a limit at high speed and choose to cut servo power then you will free-wheel into the hard stops. If you hit the limits and issue a "stop" command to the motor drivers then they can (at the least) do DC braking. But if, and only if, the controller tells them to.

If it ever goes wrong I can point out where you made the wrong choice. But without a time-machine this seems a genuinely difficult decision.

But without a time-machine this seems a genuinely difficult decision.

This question comes up quite often with spindles, should you cut all power or make a controlled stop?

(And I just realised that I made a bad choice, my lathe spindle has a brake, e-stop should operate that regardless. That's added to my to-do list)

Replied by andypugh on topic Gantry Limit switches & homing question.

They are Kollmorgen servostar linear motors, effectively an ac servo split and spread out in a straight line.

You _might_ be the first big linear-motor LinuxCNC application. I think we have seen some small ones.

Thinking about this further... It seems likely that you will have unusually fast motion available. So that makes for an interesting design decision. If you hit a limit at high speed and choose to cut servo power then you will free-wheel into the hard stops. If you hit the limits and issue a "stop" command to the motor drivers then they can (at the least) do DC braking. But if, and only if, the controller tells them to.

If it ever goes wrong I can point out where you made the wrong choice.

This question comes up quite often with spindles, should you cut all power or make a controlled stop?

(And I just realised that I made a bad choice, my lathe spindle has a brake, e-stop should operate that regardless. That's added to my to-do list)

Please Log in or Create an account to join the conversation.

- superlen

- Offline

- Junior Member

-

Less

More

- Posts: 33

- Thank you received: 8

22 Jan 2019 01:39 #124589

by superlen

Replied by superlen on topic Gantry Limit switches & homing question.

Yes, I can envision the head getting up to some serious speed in 14' of travel! I just finished up my wiring diagram for the limits and I elected to add a prox for LCNC limit & use the existing hard switches as servo-kill-power-oh-sh@t. The limit proxes will be about 12" inside the mechanical switches (at least on the x-axi). There are also some pretty beefy mechanical stops in place. At least it won't hit the stop and continue to drive into full power.

Each ServoStar drive is rated at 3.5kW. There are two on Y axis (1/side with about 6' of travel) and only one on the X-axis with 14'. I don't have the datasheet handy on the motors themselves, I'm sure they are a bit less.

The machine is ideal for a high speed motion (it's intended use of flying left & right spraying ink on a banner with no load other than it's own weight). It will remain to be seen how useful it is for CNC router & 5-axis milling of say a gunstock. There is no belting up to sacrifice speed for torque. The oversize motors will help & my educated(slightly) guess is that I'll be fine milling wood & aluminum.

Len

Each ServoStar drive is rated at 3.5kW. There are two on Y axis (1/side with about 6' of travel) and only one on the X-axis with 14'. I don't have the datasheet handy on the motors themselves, I'm sure they are a bit less.

The machine is ideal for a high speed motion (it's intended use of flying left & right spraying ink on a banner with no load other than it's own weight). It will remain to be seen how useful it is for CNC router & 5-axis milling of say a gunstock. There is no belting up to sacrifice speed for torque. The oversize motors will help & my educated(slightly) guess is that I'll be fine milling wood & aluminum.

Len

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

22 Jan 2019 08:58 #124602

by rodw

Replied by rodw on topic Gantry Limit switches & homing question.

Great you have a strategy now. I would experiment with your limit switches. 12" to slow down is a long way. When my stepper machine hits a limit, it stops pretty much instantly but it coasts a long way when it hits the home switch. By applying your brakes you might be able to keep the operating envelope bigger than you think. When I home my machine, the final position is barely a millimeter from the limit switches.....

The following user(s) said Thank You: superlen

Please Log in or Create an account to join the conversation.

- michaelrommel

-

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

06 May 2019 21:34 #133001

by michaelrommel

Replied by michaelrommel on topic Gantry Limit switches & homing question.

Hi,

I am considering to use a proximity sensor on an axis as min and max and home switch, if that is possible.

My thought is, that the switch is kept closed while it is between the two notches of the aluminium plate and that hitting on of the notches would act as limit.

The machine would during homing back off the notches towards the middle.

I would use a pin from my 7i76e to create a "combined-y-limit" signal from this input and then feed this signal to the three pins of the axis.

Is there a drawback to this approach (apart from losing a little bit of travel, because the gantry has to move back to the solid middle part after homing)?

Thanks for your insights!

Michael.

I am considering to use a proximity sensor on an axis as min and max and home switch, if that is possible.

My thought is, that the switch is kept closed while it is between the two notches of the aluminium plate and that hitting on of the notches would act as limit.

The machine would during homing back off the notches towards the middle.

I would use a pin from my 7i76e to create a "combined-y-limit" signal from this input and then feed this signal to the three pins of the axis.

Is there a drawback to this approach (apart from losing a little bit of travel, because the gantry has to move back to the solid middle part after homing)?

Thanks for your insights!

Michael.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

06 May 2019 22:23 #133005

by andypugh

Replied by andypugh on topic Gantry Limit switches & homing question.

A target wth a slot can't work as the system has no way to know which way to move to find the slot.

A target that covers half the axis can be used as a centre-positioned home sensor.

Home and both limits can be 1, 2 or 3 sensors, and LinuxCNC can be configured to move one way if the home sensor is not tripped and the other way if it is. And then there is the option of using HAL logic to combine them. So I think that a pair of sensors close together and a long target with a gap at one end and a narrow pip at the other end could work. (NOT A + B = min limit, A + NOT B = max limit, use A alone as a home sensor. )

A target that covers half the axis can be used as a centre-positioned home sensor.

Home and both limits can be 1, 2 or 3 sensors, and LinuxCNC can be configured to move one way if the home sensor is not tripped and the other way if it is. And then there is the option of using HAL logic to combine them. So I think that a pair of sensors close together and a long target with a gap at one end and a narrow pip at the other end could work. (NOT A + B = min limit, A + NOT B = max limit, use A alone as a home sensor. )

The following user(s) said Thank You: michaelrommel

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

06 May 2019 22:34 - 06 May 2019 22:35 #133007

by rodw

Replied by rodw on topic Gantry Limit switches & homing question.

You have plenty of inputs on your 7i76e so why don't you do it properly?

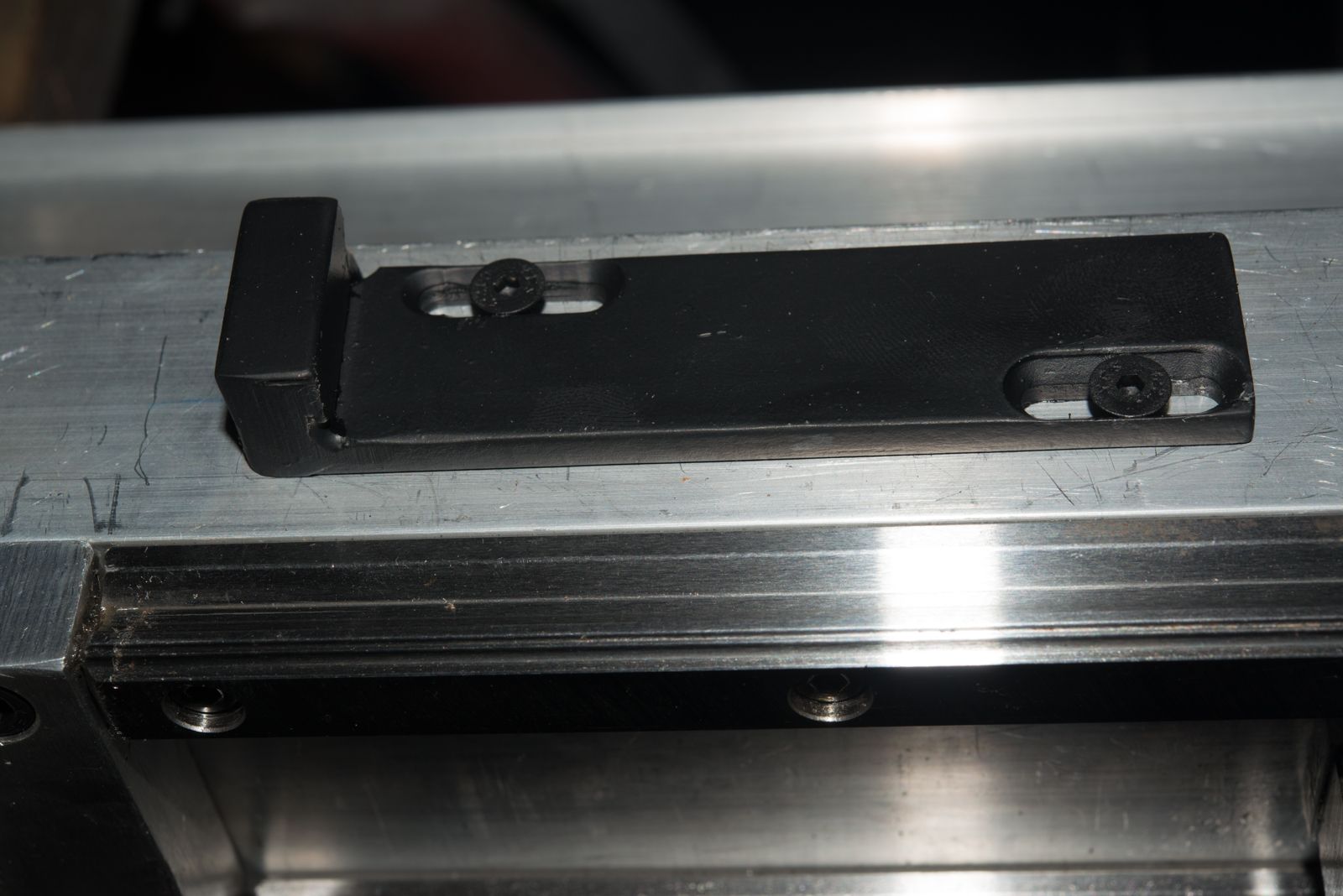

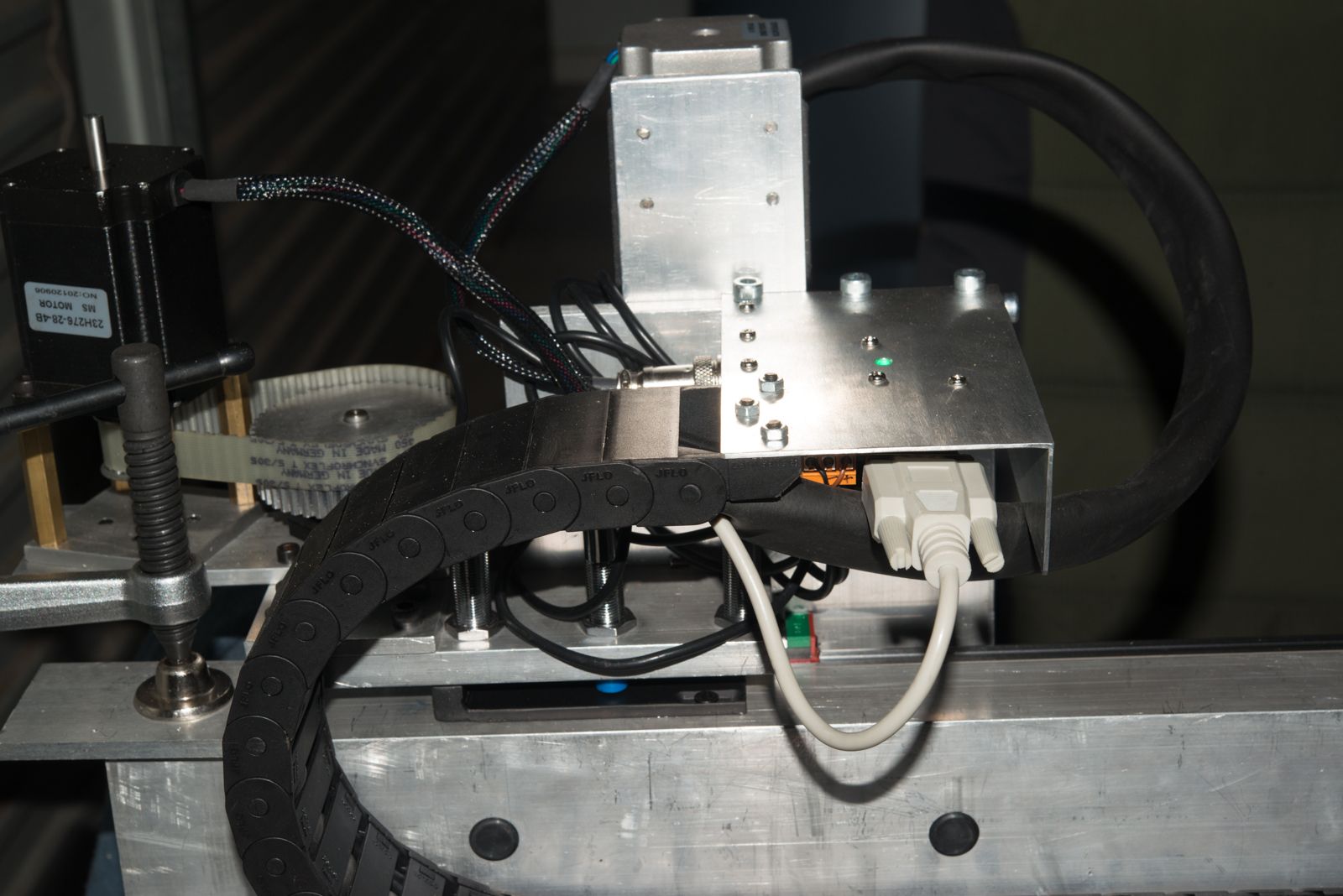

I have two prox sensors on the moving part of the gantry. One for home and another for limit. The home sensor is mounted lower than the limit sensor so it sees the flat mounting plate. The limit sensor sees the raised section. The flat section is to allow the axis to coast to a stop during homing without triggering a limit or crashing.

I just move a home offset to finish homing 1mm from the limits. The sensor on the right is for the opposite limit.

I have two prox sensors on the moving part of the gantry. One for home and another for limit. The home sensor is mounted lower than the limit sensor so it sees the flat mounting plate. The limit sensor sees the raised section. The flat section is to allow the axis to coast to a stop during homing without triggering a limit or crashing.

I just move a home offset to finish homing 1mm from the limits. The sensor on the right is for the opposite limit.

Last edit: 06 May 2019 22:35 by rodw.

The following user(s) said Thank You: michaelrommel

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

07 May 2019 16:54 #133058

by Mike_Eitel

Replied by Mike_Eitel on topic Gantry Limit switches & homing question.

Hi Tommy

Especially DC drives, when in movement, will blow their driver when source is cut.

Mike

Especially DC drives, when in movement, will blow their driver when source is cut.

Mike

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.099 seconds