PlasmaC Holes and Arcs

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

05 Aug 2019 00:02 #141377

by phillc54

PlasmaC Holes and Arcs was created by phillc54

The GCode parser recently had the following optional features added:

1. If a hole is less than n diameter then reduce the feed rate to 60%

2. If a hole is less then n diameter then turn the torch off and using code from @docwelch , continue the path for 4mm (0.16"). Also reduce the feed rate as above.

3. The default diameter is 32mm (0.126") and can also be changed.

My question is:

If either of these options was selected should these also apply to all arcs or to holes only?

1. If a hole is less than n diameter then reduce the feed rate to 60%

2. If a hole is less then n diameter then turn the torch off and using code from @docwelch , continue the path for 4mm (0.16"). Also reduce the feed rate as above.

3. The default diameter is 32mm (0.126") and can also be changed.

My question is:

If either of these options was selected should these also apply to all arcs or to holes only?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

05 Aug 2019 00:27 - 05 Aug 2019 00:28 #141379

by rodw

Replied by rodw on topic PlasmaC Holes and Arcs

Probably have a checkbox to enable it on arcs.

I think also a minimum arc radius to exclude adjustment would be good.

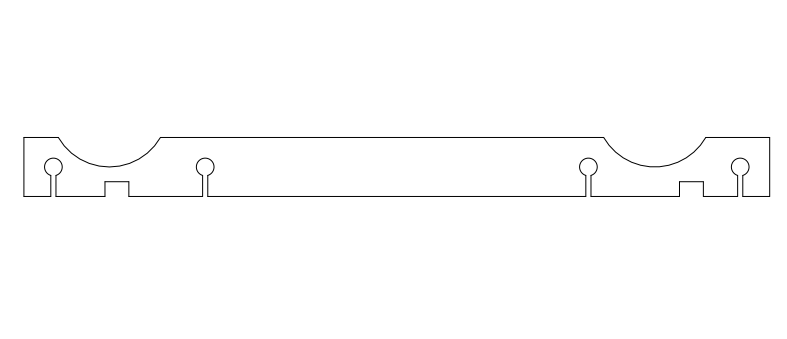

When I tried to cut this part to reduce piercing on 16mm steel , I wanted to exclude the small arcs on entry to the passages and just slow down the holes. I could not get it in Sheetcam.

The little fillets were just there to avoid a 90 degree corner to help the plasma out.

I think also a minimum arc radius to exclude adjustment would be good.

When I tried to cut this part to reduce piercing on 16mm steel , I wanted to exclude the small arcs on entry to the passages and just slow down the holes. I could not get it in Sheetcam.

The little fillets were just there to avoid a 90 degree corner to help the plasma out.

Attachments:

Last edit: 05 Aug 2019 00:28 by rodw.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

05 Aug 2019 01:25 #141383

by phillc54

Replied by phillc54 on topic PlasmaC Holes and Arcs

It would need to be simple, something along the lines of a gcode #<all_arcs> = 1 would then do all the arcs less than the set diameter.

I would rather not add anything to the GUI's for this as it is only for folk who don't have a postprocessor or whose postprocessor is unable to accomplish it.

I would rather not add anything to the GUI's for this as it is only for folk who don't have a postprocessor or whose postprocessor is unable to accomplish it.

Do you mean that if the arc is greater than diameter1 or less than diameter2 then slow down else do nothingI think also a minimum arc radius to exclude adjustment would be good.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

05 Aug 2019 01:46 #141386

by rodw

Replied by rodw on topic PlasmaC Holes and Arcs

Yes, if the arc falls between the two diameters action it otherwise ignore it. I did try to put some cascading rules in place for sheetcam so < 5mm radius was not touched but either it did not support it I I did not know how to drive it!

I generally put a small fillet on corners so the torch is not faced with an instant 90 degree change of direction at one point. The corner lock kicks in anyway. cut quality seemed to diminish if we slowed down for the corners but it was good for the holes.

I generally put a small fillet on corners so the torch is not faced with an instant 90 degree change of direction at one point. The corner lock kicks in anyway. cut quality seemed to diminish if we slowed down for the corners but it was good for the holes.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.085 seconds