just another plasma build and then some :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Feb 2020 09:18 #156851

by machinedude

Replied by machinedude on topic just another plasma build

yep that's the plan  have the epoxy granite material here already. need to make a end cap for one side and toss together i vibrating table to mount it on so i can get the air out of the mix. i will probably have to let it sit for a few days to get a full cure before i can put things back together and test some more with an indicator for deflection.

have the epoxy granite material here already. need to make a end cap for one side and toss together i vibrating table to mount it on so i can get the air out of the mix. i will probably have to let it sit for a few days to get a full cure before i can put things back together and test some more with an indicator for deflection.

if this would not work i can always loose the T slot and just do a solid flat bar i guess. i'm all in at this point a a few hundred more is a drop in the bucket

Haas sells a gantry mill they start at 120k so i have some wiggle room i think

if this would not work i can always loose the T slot and just do a solid flat bar i guess. i'm all in at this point a a few hundred more is a drop in the bucket

Haas sells a gantry mill they start at 120k so i have some wiggle room i think

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Feb 2020 12:03 #156867

by machinedude

Replied by machinedude on topic just another plasma build

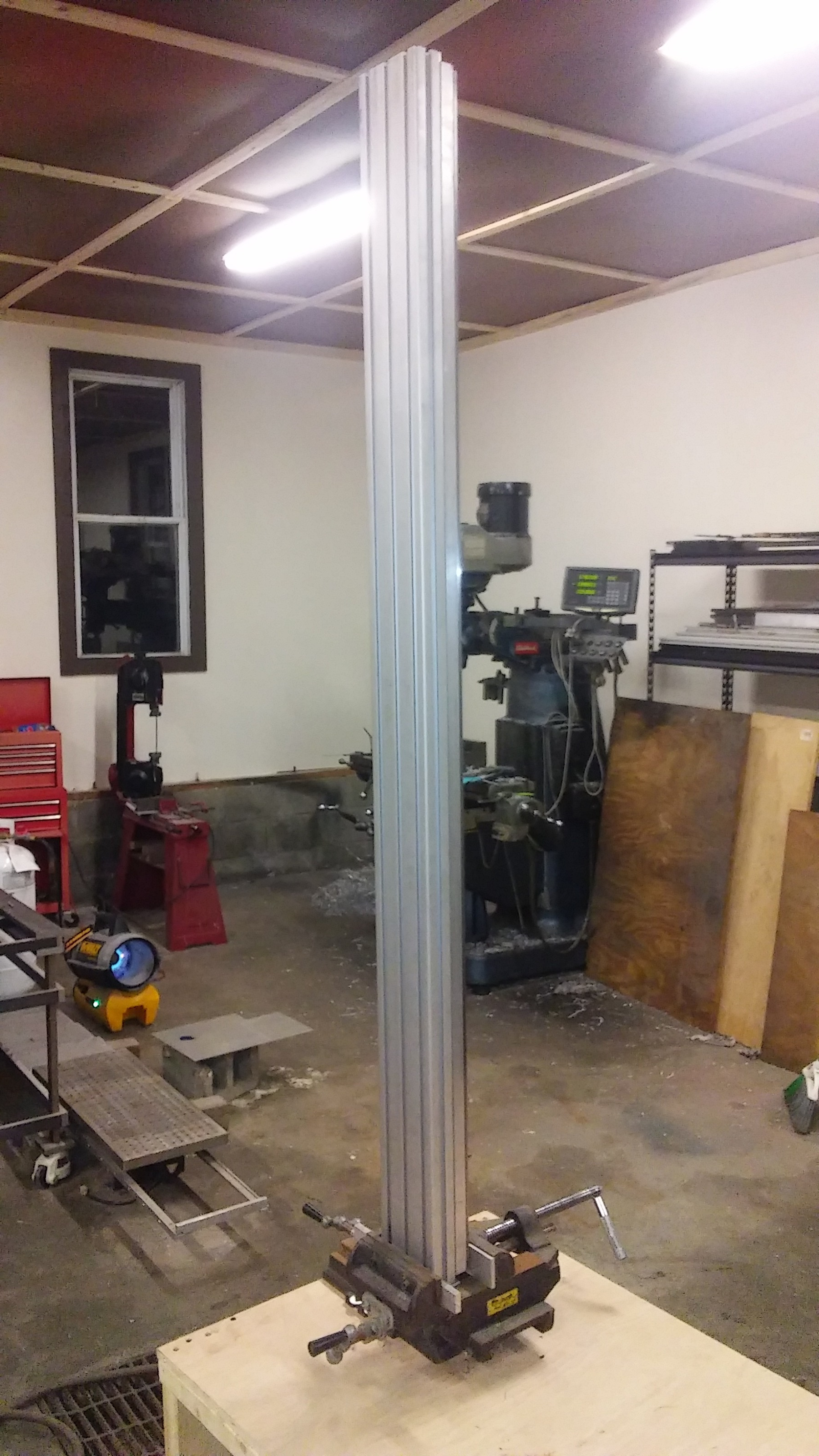

this should be interesting  i used a vibrating dry tumbler for a vibration source and built a quick table out of some left over lumber i had laying around. take note of the state of the art anti rotation mounting under the tumbler

i used a vibrating dry tumbler for a vibration source and built a quick table out of some left over lumber i had laying around. take note of the state of the art anti rotation mounting under the tumbler  much needed to keep the cord from getting wrapped around the tumbler

much needed to keep the cord from getting wrapped around the tumbler  the sliding vise i just screwed into the table top to hold the extrusion up right and i just used a bubble level to adjust things. with out it you would have to stand around and hold things and that's not something i care to do since it takes a long time before the air gets vibrated out of the mix.

the sliding vise i just screwed into the table top to hold the extrusion up right and i just used a bubble level to adjust things. with out it you would have to stand around and hold things and that's not something i care to do since it takes a long time before the air gets vibrated out of the mix.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Feb 2020 15:08 #156878

by machinedude

Replied by machinedude on topic just another plasma build

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Feb 2020 16:18 #156884

by machinedude

Replied by machinedude on topic just another plasma build

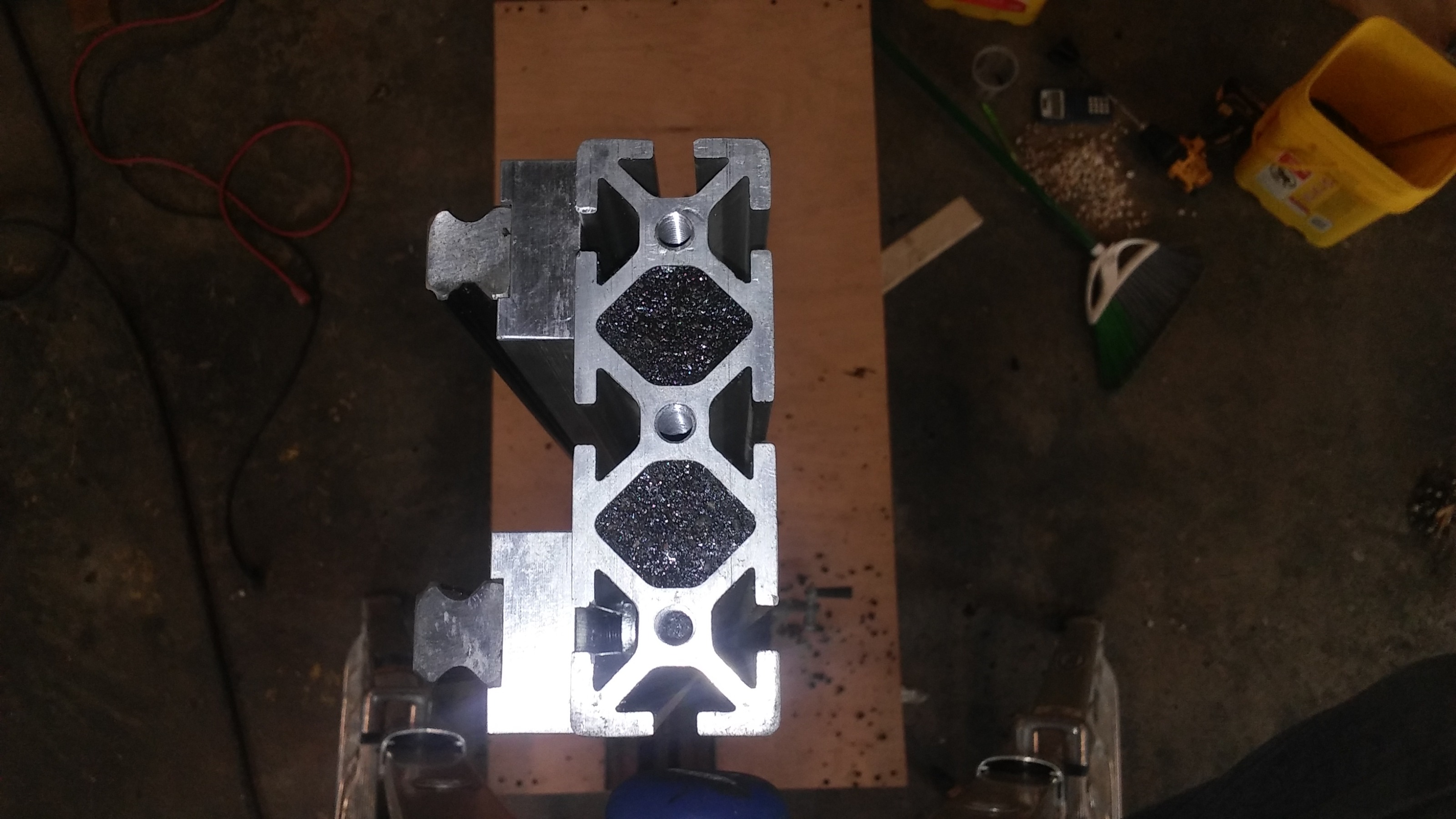

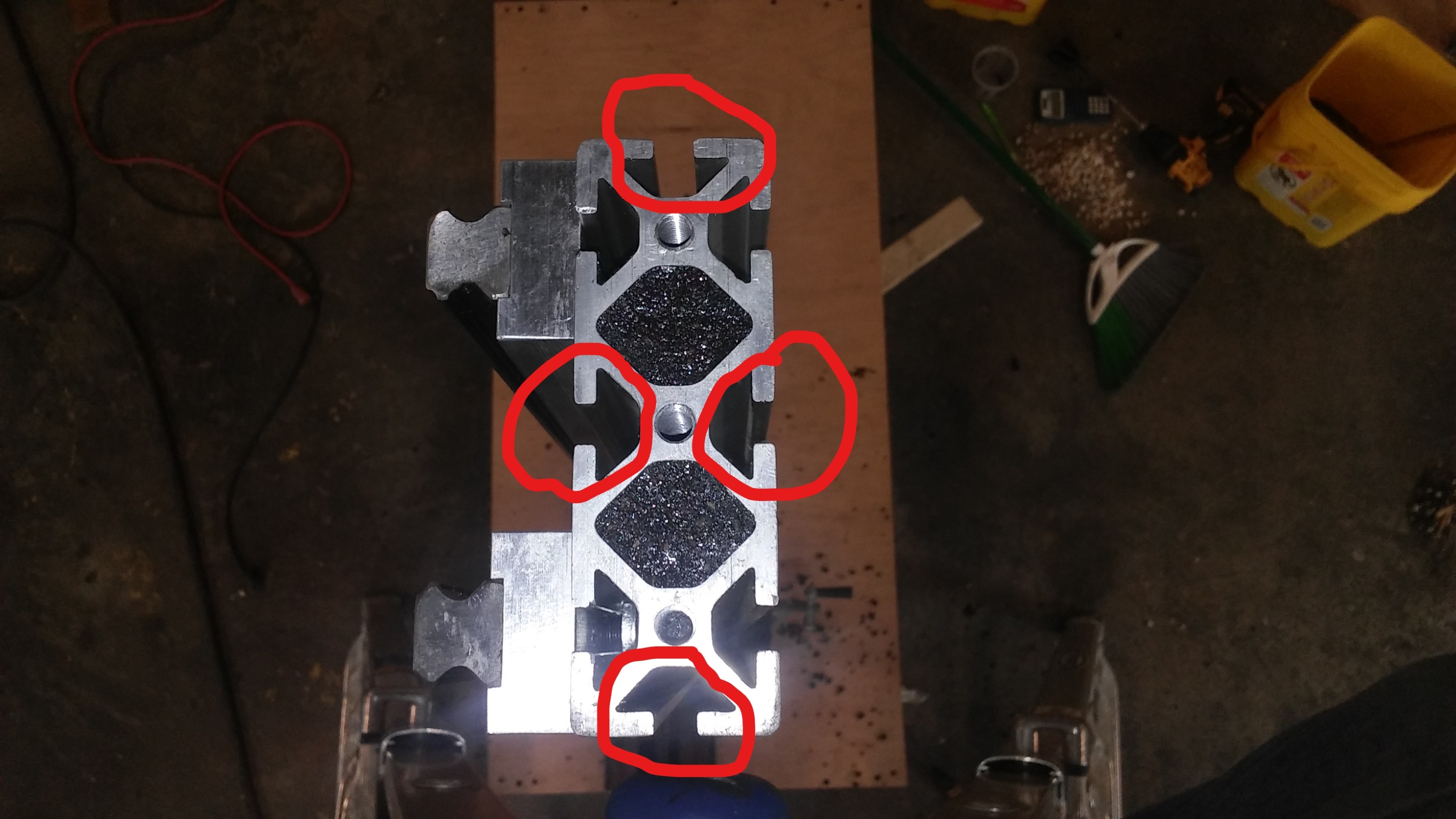

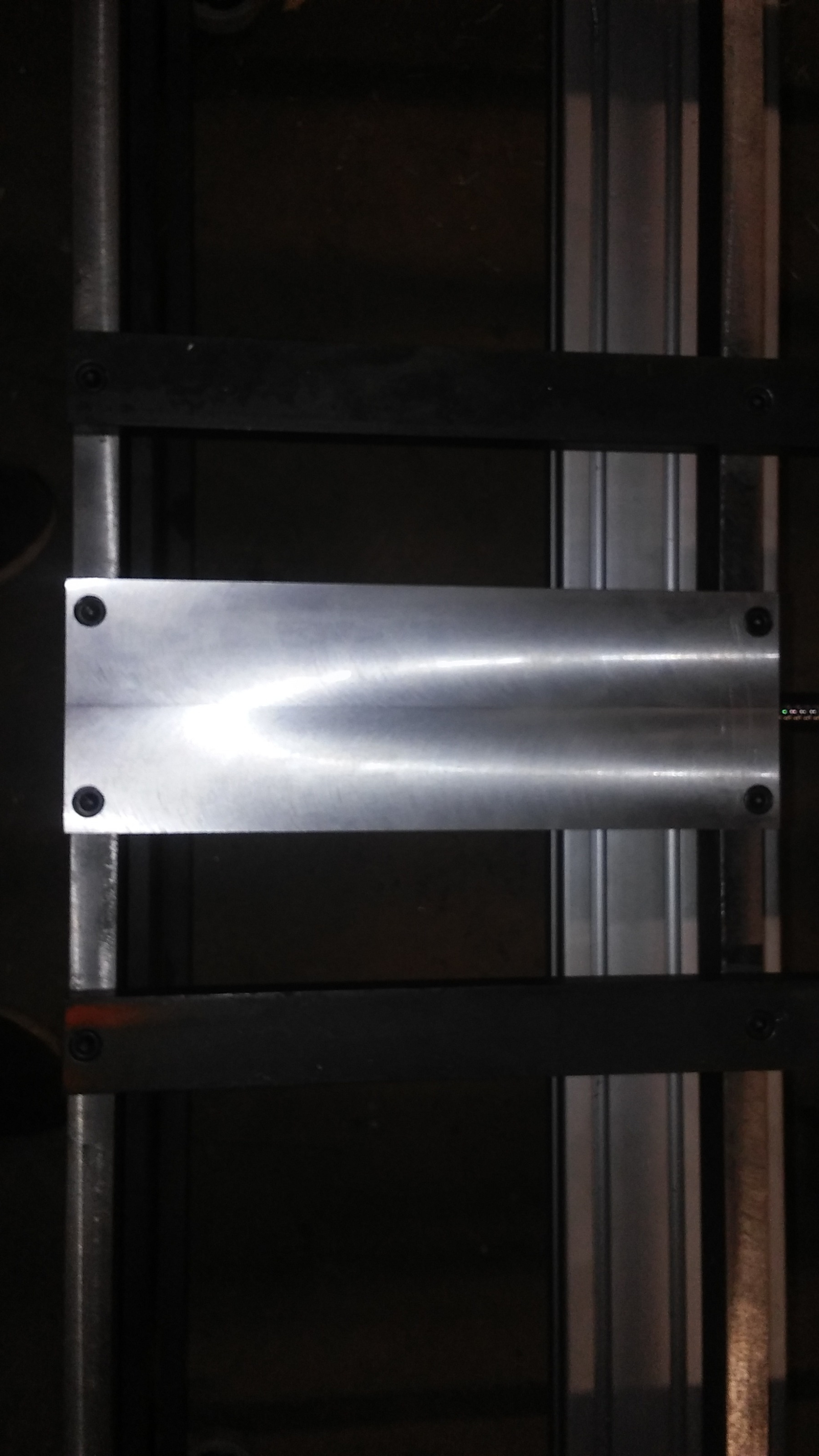

every time i play around with this stuff i am amazed by what it does to dampen vibration. i think i might go a step further and fill in the T slots that i have no need for and block off the ends of the ones i do use and fill the center section that is not used.

i tapped a unfilled section with something metallic and it rang like a tuning fork i did the same on this section i filled the center voids on and taking a educated guess i would say it got reduced by 75% possibly.

if it does as good with deflection i will be a happy camper

i tapped a unfilled section with something metallic and it rang like a tuning fork i did the same on this section i filled the center voids on and taking a educated guess i would say it got reduced by 75% possibly.

if it does as good with deflection i will be a happy camper

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 Feb 2020 18:58 - 11 Feb 2020 18:59 #157091

by machinedude

Replied by machinedude on topic just another plasma build

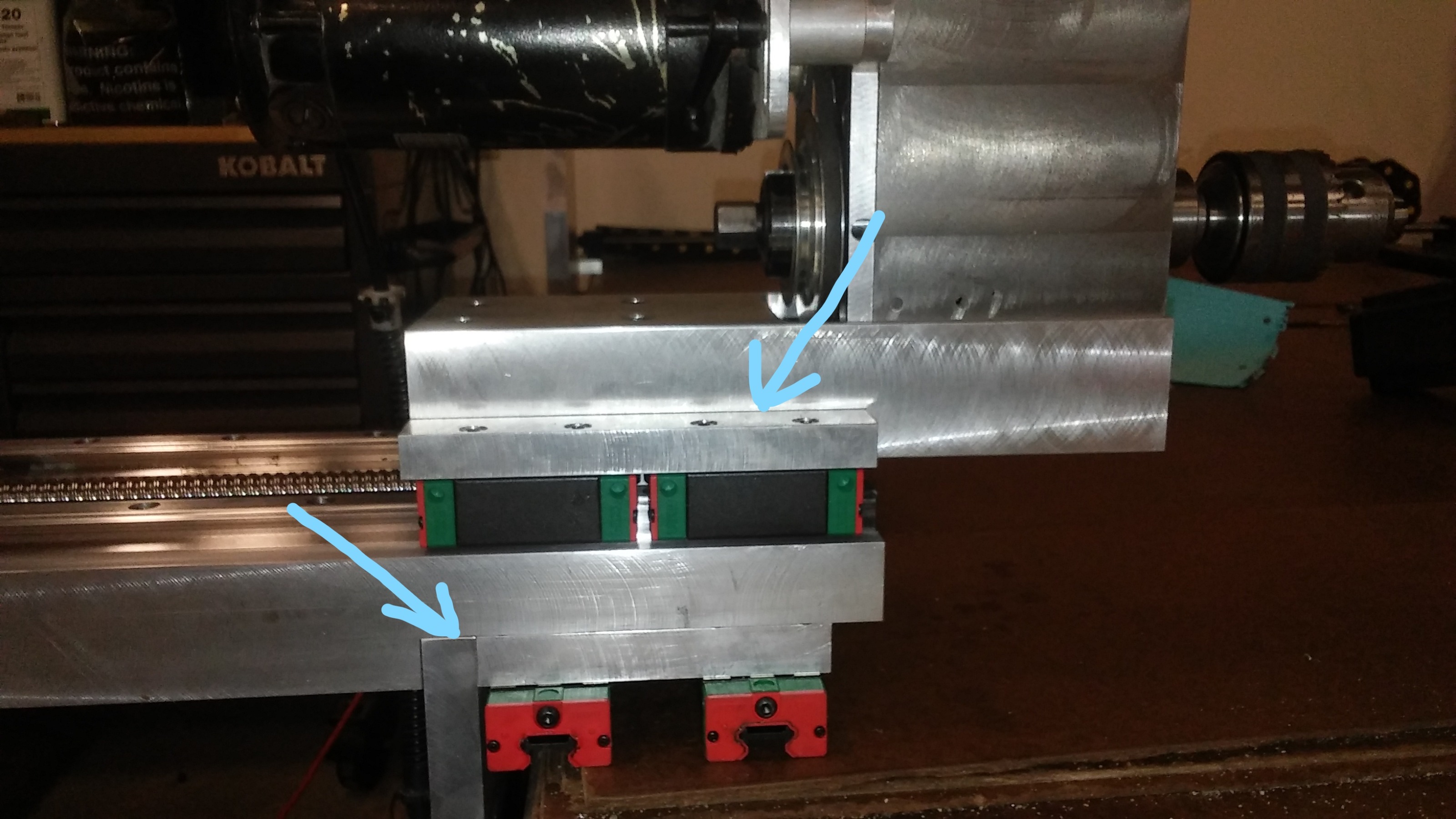

i did some testing with an indicator and it would appear like the deflection is getting smaller by a decent amount but things were off the machine and on the bridgeport for some quick testing. the problem with the extrusion is more of a twisting kind of deflection so i think filling the t slots in the same way will help deal with this.

the down side is every side has to be done and you can only do one at a time and have to wait 24 hours for it to cure and i would be doing 4 sides so this could take some time to nail down for sure.

i was looking at the pictures at work had seen some places i can draw the spindle in closer to the frame and made the one change last night but did not have time to see if that helped any? but at the very least i got back almost an inch of travel the closer the spindle gets to the rails and blocks takes away some of the mechanical advantage that is aiding in the twisting deflection

the closer the spindle gets to the rails and blocks takes away some of the mechanical advantage that is aiding in the twisting deflection

the methods i used payed off in the accuracy department as well. over about 6.5 inches i had the squareness stay within .0005 imperial with zero flex where everything was in the vise.

the down side is every side has to be done and you can only do one at a time and have to wait 24 hours for it to cure and i would be doing 4 sides so this could take some time to nail down for sure.

i was looking at the pictures at work had seen some places i can draw the spindle in closer to the frame and made the one change last night but did not have time to see if that helped any? but at the very least i got back almost an inch of travel

the methods i used payed off in the accuracy department as well. over about 6.5 inches i had the squareness stay within .0005 imperial with zero flex where everything was in the vise.

Last edit: 11 Feb 2020 18:59 by machinedude.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

12 Feb 2020 23:22 - 14 Feb 2020 00:13 #157228

by machinedude

Replied by machinedude on topic just another plasma build

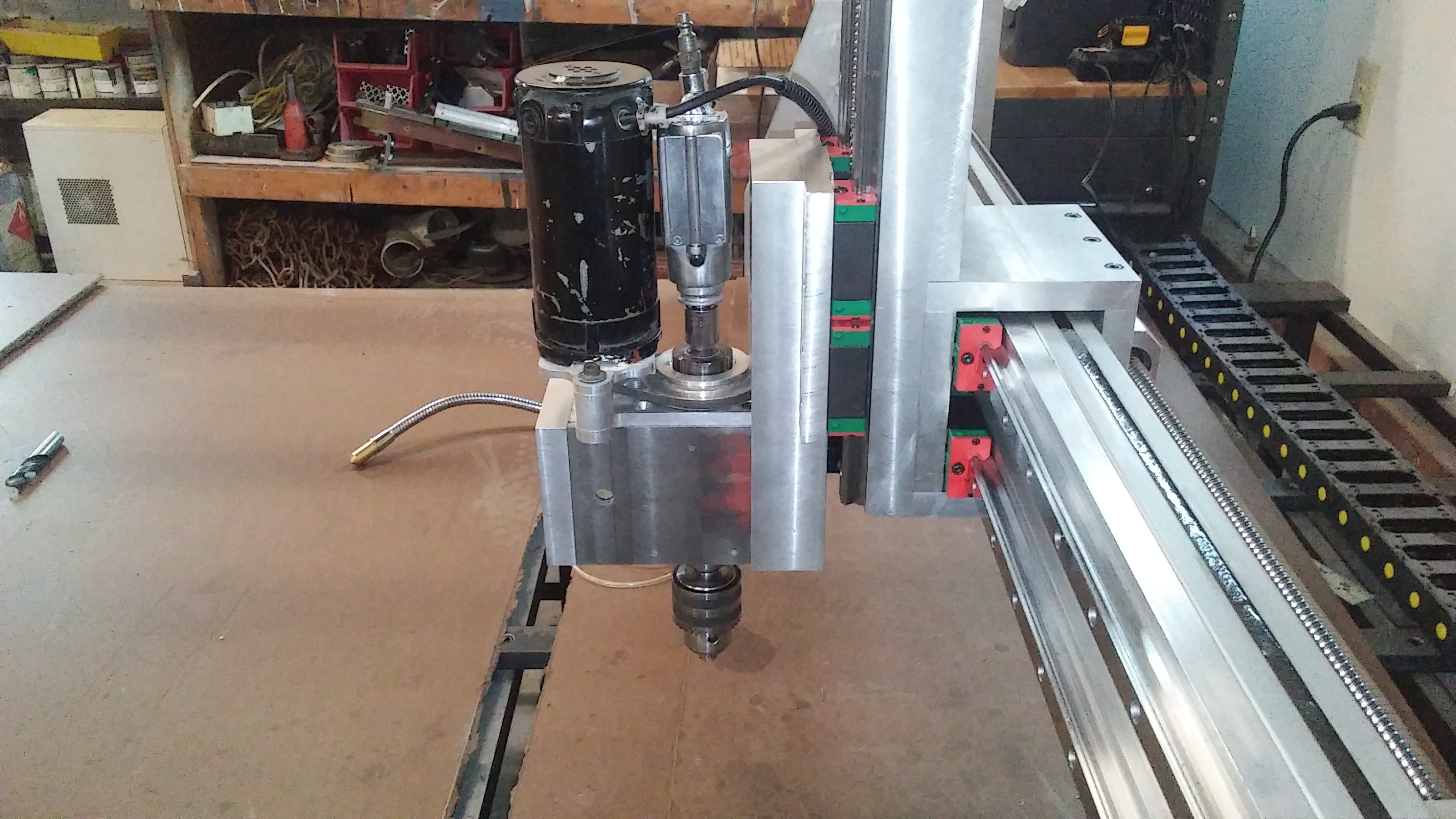

was going to fill a side of the extrusion but the battery in my scale died so i did the other modification on the gantry and Z axis instead. these two changes brought the spindle center line back 1.5 inches in total. so at the very least a gain in travel by that much.

i think i got all i can get now. the plates that mount to the bearing blocks is .750 thick so i was able to cut away that thickness on two parts to bring everything back. since i bolted the plates to the sections i cut away i did not really loose anything by doing so. it just looks more balanced i think.

i think i got all i can get now. the plates that mount to the bearing blocks is .750 thick so i was able to cut away that thickness on two parts to bring everything back. since i bolted the plates to the sections i cut away i did not really loose anything by doing so. it just looks more balanced i think.

Attachments:

Last edit: 14 Feb 2020 00:13 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

16 Feb 2020 08:17 #157506

by machinedude

Replied by machinedude on topic just another plasma build

have the 4 t slots filled i am not using and the last side is several hours away from being dry completely. sitting around waiting for stuff to dry is not my strong suit. i would rather be able to toss things together so i can see what i gained but can't do this with this particular material.taking a guess i would say i have somewhere around 10 lbs of epoxy granite material worked into the extrusion at this point. hopefully i have enough time to put things back together and get an indicator on things so i cane see where i stand with the modifications and the E.G. filling

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

16 Feb 2020 17:10 - 16 Feb 2020 18:19 #157517

by machinedude

Replied by machinedude on topic just another plasma build

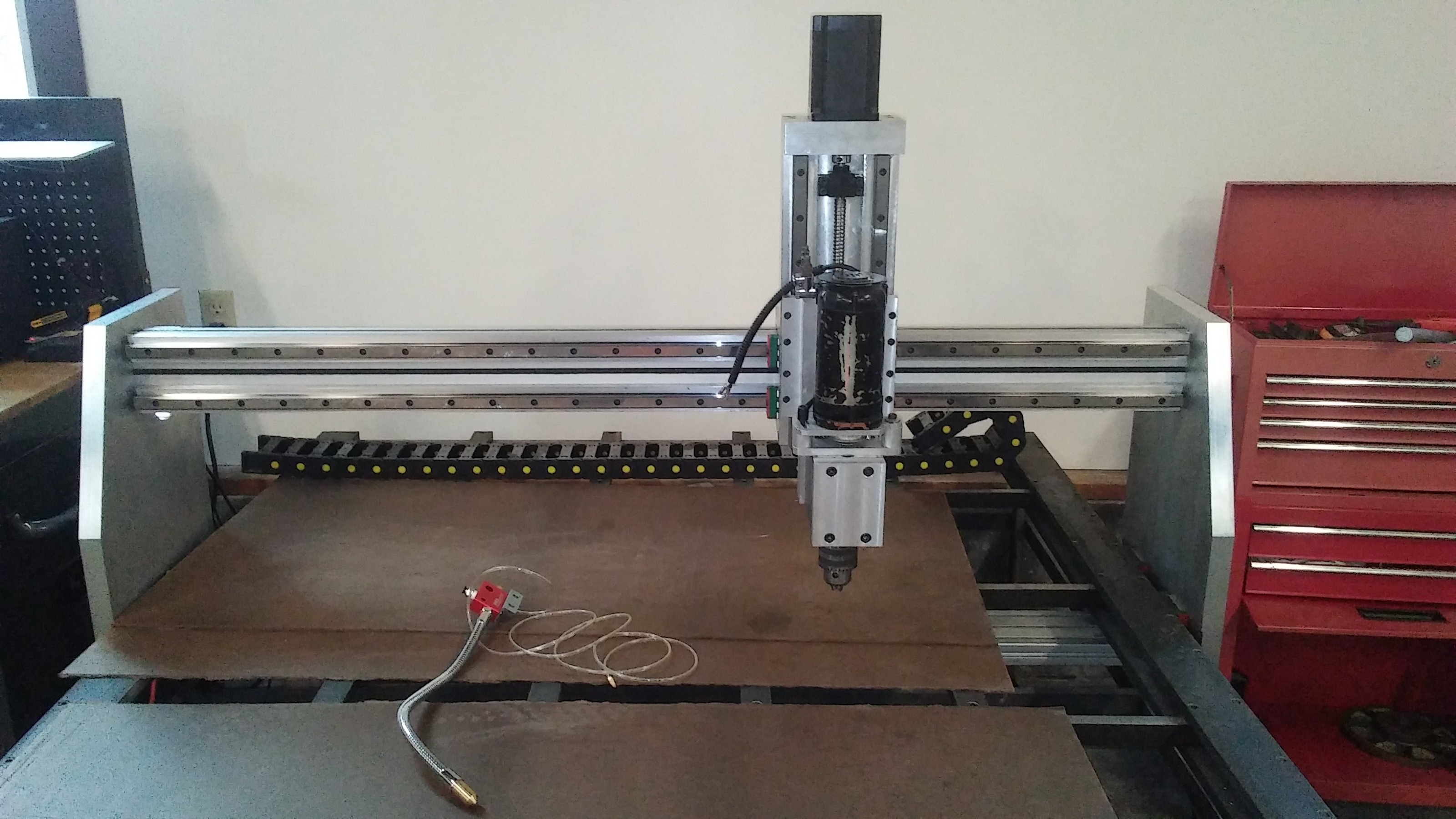

all this made a big improvement but it still flexes a little bit. i think it's probably around .005 inches at the extreme side of things. i did a check of the same kind on my Bridgeport and got .003 inches on that machine so i'm close to where i need to be i think. only way to see for sure is to get this thing finished and do some test cutting to see how it does? i think with finishing passes it's not going to see the forces needed to move things but that's just my hunch at this point.

i did get up on the gantry in the center and with 200lbs it only moves .005 inched with downward force (downward force being me doing a my best high wire impersonation ) so i think .005 on the push and pull and downward force is probably what to expect on the extreme side of things.

so i think .005 on the push and pull and downward force is probably what to expect on the extreme side of things.

i did get up on the gantry in the center and with 200lbs it only moves .005 inched with downward force (downward force being me doing a my best high wire impersonation )

Attachments:

Last edit: 16 Feb 2020 18:19 by machinedude. Reason: added some pictures back together.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Feb 2020 23:58 #157909

by machinedude

Replied by machinedude on topic just another plasma build

started the ball screw mounting for the 8' axis. i was able to drive the gantry up and down the table with a cordless drill with the clutch set to the lowest setting so you can stop it with your hand super easy. everything works with no troubles. this gantry weighs around 230lbs so not to bad on moving it around.

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Feb 2020 11:15 - 22 Feb 2020 11:28 #158191

by machinedude

Replied by machinedude on topic just another plasma build

i started to think about what this machine can do well and not do well to devise a plan for a roughing strategy for milling operations. since the machine will have good acceleration i started to think about high feed mills. this style of milling is not so much about hogging with a really deep cut and more about moving things around really fast to get a good material removal rate. since the spindle is not large by any means being only .8 HP this might be a good plan, i can't drive the really big feed mills but they make a mini version that falls around the 3/4 diameter range which i think is about as big as i can get away with. after looking at the specs for some of these cutters they only recommend a max depth of cut of around .030 deep imperial. i do lack high rpm with is spindle but it does get over 4,000 rpm so i think something like this will still work well just not as good as it could. i still think it might do over a 100 IPM in aluminum cutting with this kind of cutter. having said that if it does work i think i will be making some side shields out of some impact resistant material.

did some other digging to see how fast my drill runs in high range and found out it does 2000 rpm so when i was driving with it i was doing around 400 IPM and one of my concerns was screw whip. but it did just fine at 400 IPM so i feel good about pushing it harder to see where i want to max out at.

did some other digging to see how fast my drill runs in high range and found out it does 2000 rpm so when i was driving with it i was doing around 400 IPM and one of my concerns was screw whip. but it did just fine at 400 IPM so i feel good about pushing it harder to see where i want to max out at.

Last edit: 22 Feb 2020 11:28 by machinedude.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.460 seconds