just another plasma build and then some :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

23 Feb 2020 03:03 #158269

by machinedude

Replied by machinedude on topic just another plasma build

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

25 Feb 2020 23:55 #158501

by machinedude

Replied by machinedude on topic just another plasma build

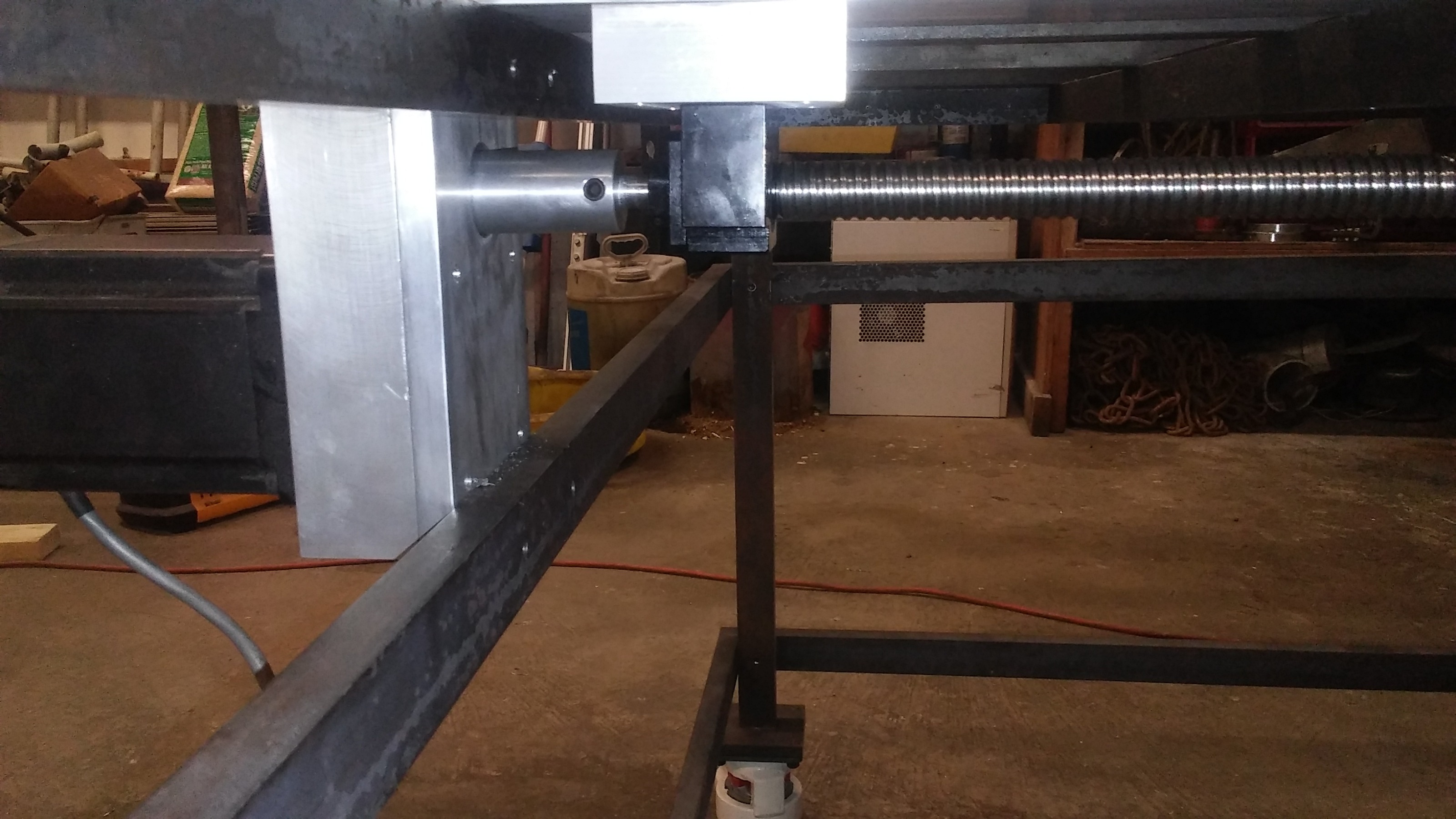

have all the basics finished on all the ball screw drives now so it's back to finish this table skeleton and think about how to frame stuff in so i can do some more Epoxy Granite on the table frame. i just pulled the trigger on a large order of Epoxy for the task. this should make for a good solid machine base. then the last major thing will be the table top. This project is over budget already  in case your wondering

in case your wondering  i feel like i'm casing after my ultimate build to date

i feel like i'm casing after my ultimate build to date  8 months later but starting to see the light at the end of the tunnel at least.

8 months later but starting to see the light at the end of the tunnel at least.

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

27 Feb 2020 19:24 #158683

by machinedude

Replied by machinedude on topic just another plasma build

started pricing the Aluminum for my table top. all i can is ouch  epoxy was bad by itself with a table top it's like a double death tap to the wallet

epoxy was bad by itself with a table top it's like a double death tap to the wallet  after this stage i have to slow down i think

after this stage i have to slow down i think

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 19459

- Thank you received: 6529

27 Feb 2020 19:54 #158687

by tommylight

Replied by tommylight on topic just another plasma build

Aluminium parts tend to get very expensive very fast for these types of builds, for sure.

In the process of gathering and sourcing aluminium parts for two plasma's and very soon i am gona be broke, again !

In the process of gathering and sourcing aluminium parts for two plasma's and very soon i am gona be broke, again !

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

27 Feb 2020 22:58 - 28 Feb 2020 02:53 #158695

by machinedude

Replied by machinedude on topic just another plasma build

the bad part of T slot table tops is they require some thick material to start with. so 1" thick across a 5' by 10' frame is going to cost around $1,900 USD with me making it myself. so add another $1,500 for epoxy granite material and your set back close to $3,500

on the plus side if i build it well i might be able to up the HP on the spindle later down the road? i have to see how the gantry does with cutting forces. But Haas does a machine like this milling part of mine and they only have the 1" aluminum for their table tops but their machines start at 120k so even with my modest attempt i am well under that price tag

i think once i add the extra steel and E.G. the last little bit of flex i am getting might go away. the rest of what i am seeing could be coming from my table part of the frame since it's not in a finished state just yet and has some improvements being made.

my hardner was on back order for my resin so i probably won't see those materials til next week sometime. i won't get to the forms for the E.G. until Saturday most likely so hopefully i can get that don'e by next weekend so i have the weekend to do the E.G.

it will take some time for that part i'm probably looking at 750 lbs of mixed material there. so another 650 lbs of aluminum should make for a machine around 3,000 lbs when i am done. ton of work but worth it i think

on the plus side if i build it well i might be able to up the HP on the spindle later down the road? i have to see how the gantry does with cutting forces. But Haas does a machine like this milling part of mine and they only have the 1" aluminum for their table tops but their machines start at 120k so even with my modest attempt i am well under that price tag

i think once i add the extra steel and E.G. the last little bit of flex i am getting might go away. the rest of what i am seeing could be coming from my table part of the frame since it's not in a finished state just yet and has some improvements being made.

my hardner was on back order for my resin so i probably won't see those materials til next week sometime. i won't get to the forms for the E.G. until Saturday most likely so hopefully i can get that don'e by next weekend so i have the weekend to do the E.G.

it will take some time for that part i'm probably looking at 750 lbs of mixed material there. so another 650 lbs of aluminum should make for a machine around 3,000 lbs when i am done. ton of work but worth it i think

Last edit: 28 Feb 2020 02:53 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

01 Mar 2020 12:44 - 01 Mar 2020 12:45 #158889

by machinedude

Replied by machinedude on topic just another plasma build

extra steel is in place so i think i am going to see if i can get some movement under power today. if so i can toss together a down and dirty set up to cut material for forms for the epoxy granite. i bought a few sheets of PVC plastic for my other build but since this is more important it's fair game  might pick a sheet MDF board to bolt down just to screw the plastic into just as a hold down for now. 4' x 8' sheet is what this thing was built for. so if it works good my life just got a lot easier

might pick a sheet MDF board to bolt down just to screw the plastic into just as a hold down for now. 4' x 8' sheet is what this thing was built for. so if it works good my life just got a lot easier

will be good to test the drives out to see how every thing works under power.

will be good to test the drives out to see how every thing works under power.

Last edit: 01 Mar 2020 12:45 by machinedude.

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

Less

More

- Posts: 1130

- Thank you received: 533

04 Mar 2020 03:14 #159142

by thefabricator03

Do you think your castors will support all that weight? So roughly about 1370 kg for the table + your material your cutting.

Is it going to be a water table? Or downdraft? If water, what size will the pan be? Say a pan of 2400x1200x75 would hold 226 liters so about 226kg of water when full.

Just as a guide, a 2400x1200x10 sheet of mild steel grade 250 weights around 225kg.

So 1370kg can add up to around 1820kg pretty easily.

Replied by thefabricator03 on topic just another plasma build

it will take some time for that part i'm probably looking at 750 lbs of mixed material there. so another 650 lbs of aluminum should make for a machine around 3,000 lbs when i am done. ton of work but worth it i think

Do you think your castors will support all that weight? So roughly about 1370 kg for the table + your material your cutting.

Is it going to be a water table? Or downdraft? If water, what size will the pan be? Say a pan of 2400x1200x75 would hold 226 liters so about 226kg of water when full.

Just as a guide, a 2400x1200x10 sheet of mild steel grade 250 weights around 225kg.

So 1370kg can add up to around 1820kg pretty easily.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

04 Mar 2020 06:17 #159151

by machinedude

Replied by machinedude on topic just another plasma build

i think they are rated 1,100 lbs per caster and i have 8 in total on my frame. so i think i will be ok? i guess i will find out if i find the table sitting on the floor  they way i took the rating was i can have the machine weigh over 8,000 lbs and be in line with the rating for the casters. worst that can happen i think is the wheels give out and then it lands on the rubber pads. so if they don't take the weight i just won't be able to roll the table around if it needs moved. i think i will be ok though.

they way i took the rating was i can have the machine weigh over 8,000 lbs and be in line with the rating for the casters. worst that can happen i think is the wheels give out and then it lands on the rubber pads. so if they don't take the weight i just won't be able to roll the table around if it needs moved. i think i will be ok though.

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

Less

More

- Posts: 1130

- Thank you received: 533

04 Mar 2020 06:25 - 04 Mar 2020 06:27 #159152

by thefabricator03

Yeah you probably should be right with eight castors.

I have some steel baskets in our workshop that get filled with pipe webbing for our trusses. I brought some castors for them that were rated at 250kg each and installed a castor in each corner of the basket. They failed in a couple of months in ways I would of never imagined. Replaced them with new castors rated at 500kg each and all is well. The baskets never get loaded about 750kg so I thought four 250kg castors would be fine.

Replied by thefabricator03 on topic just another plasma build

i think they are rated 1,100 lbs per caster and i have 8 in total on my frame. so i think i will be ok? i guess i will find out if i find the table sitting on the floor

they way i took the rating was i can have the machine weigh over 8,000 lbs and be in line with the rating for the casters. worst that can happen i think is the wheels give out and then it lands on the rubber pads. so if they don't take the weight i just won't be able to roll the table around if it needs moved. i think i will be ok though.

Yeah you probably should be right with eight castors.

I have some steel baskets in our workshop that get filled with pipe webbing for our trusses. I brought some castors for them that were rated at 250kg each and installed a castor in each corner of the basket. They failed in a couple of months in ways I would of never imagined. Replaced them with new castors rated at 500kg each and all is well. The baskets never get loaded about 750kg so I thought four 250kg castors would be fine.

Last edit: 04 Mar 2020 06:27 by thefabricator03.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 674

- Thank you received: 294

04 Mar 2020 06:33 #159154

by machinedude

Replied by machinedude on topic just another plasma build

they are just amazon specials coming out of china but they seemed well made and i have not had any issues so far with them. i think i'm double what i will end up with. so with all the stuff i am adding now and a water table, water and sheet of material i don't think i will get over 4,500 total for a weight. so 1,100 x 8 is 8,800 lbs so i think i am beefed up past a overly rated rating on a caster. i tend to go over board so i don't have issues by cutting things to close.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.132 seconds