Arc voltage on piercing

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

13 Feb 2021 01:22 #198631

by rodw

Arc voltage on piercing was created by rodw

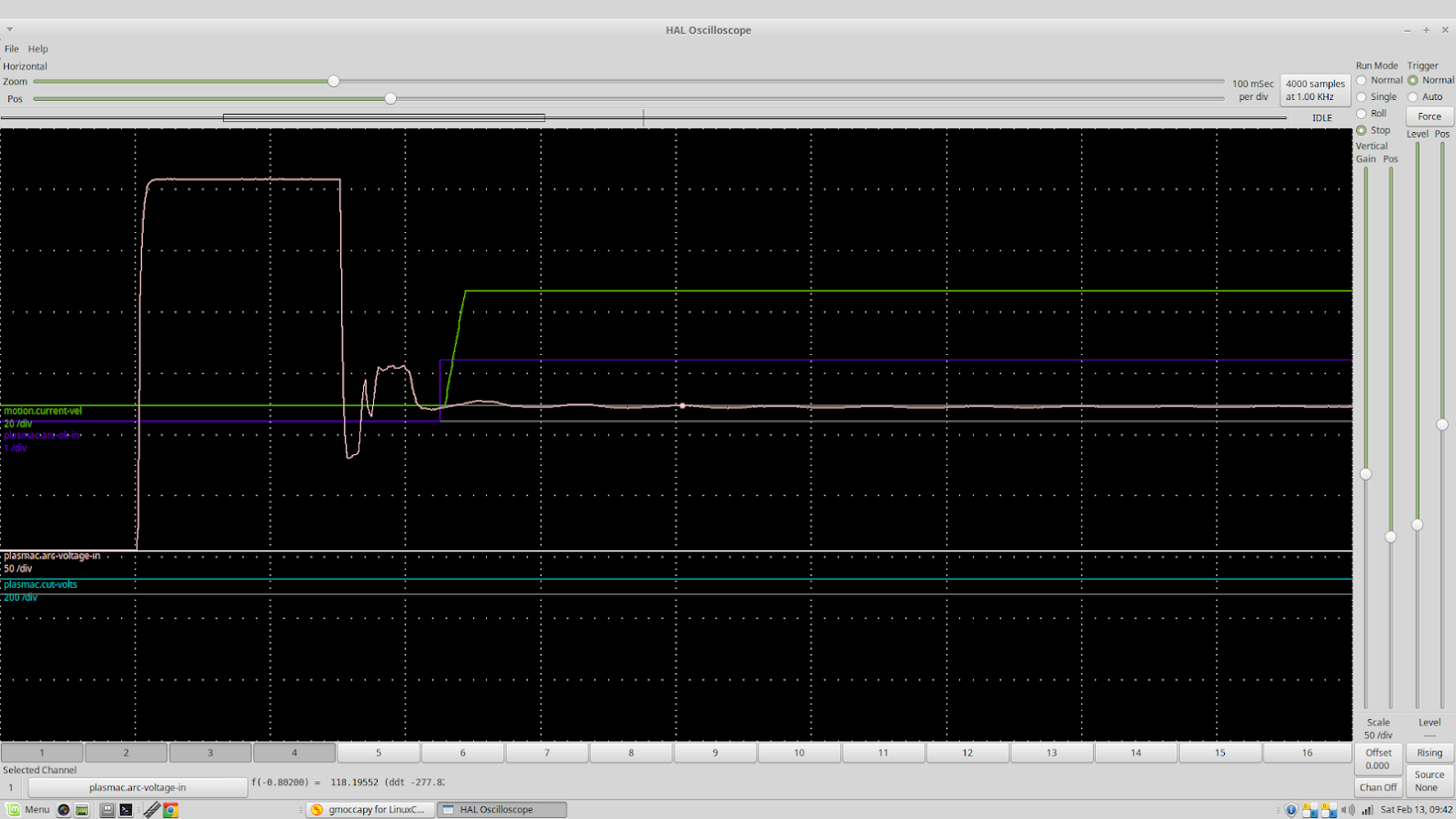

I've shot a video to go with this but here is a plot from today

Thermal Dynamics A120, 1.6mm mild steel 40 amps 2219 mm/min (book speed), 100 mm long cut

5 m/sec/sec acceleration (0.5G)

Plots from THCAD-10 with 300 volt full scale.

100 ms per vertical line (0.1 second)

The three signals of interest are Torch voltage (white), arc-ok (blue) and current velocity (green).

You can see on piercing, the voltage ramps up past 300 volts, beyond the full scale of the THCAD. This causes a plateau but that fine as we are not interested in the arc voltage. at that time.

Arc voltage then falls rapidly then overshoots the natural cut voltage, oscillates a bit, then tracks a stable voltage.

Then the plasma cutter returns an arcOK. This quite different to what I observed on my previous plasma cutter where arcOK started while the voltage was oscillating. And also on earlier plots on this machine with lower acceleration.

The other thing I observed was what chance is there of synthesising an ArcOK with those fluctuations by monitoring arc voltage? I think this plot clearly shows why people run into trouble with synthesised arc OK.

So in this case, it seems I could safely set a 0.1 second (100 ms) THC delay. But I would not go under 0.5 seconds without some testing as on my last machine I needed to wait for 1.5 seconds..

I recommend all plasma builders replicate this test before setting a THC delay and make sure the voltage has stabilised before enabling it. I think you are better off with a longer delay than a minimal THC delay.

Thermal Dynamics A120, 1.6mm mild steel 40 amps 2219 mm/min (book speed), 100 mm long cut

5 m/sec/sec acceleration (0.5G)

Plots from THCAD-10 with 300 volt full scale.

100 ms per vertical line (0.1 second)

The three signals of interest are Torch voltage (white), arc-ok (blue) and current velocity (green).

You can see on piercing, the voltage ramps up past 300 volts, beyond the full scale of the THCAD. This causes a plateau but that fine as we are not interested in the arc voltage. at that time.

Arc voltage then falls rapidly then overshoots the natural cut voltage, oscillates a bit, then tracks a stable voltage.

Then the plasma cutter returns an arcOK. This quite different to what I observed on my previous plasma cutter where arcOK started while the voltage was oscillating. And also on earlier plots on this machine with lower acceleration.

The other thing I observed was what chance is there of synthesising an ArcOK with those fluctuations by monitoring arc voltage? I think this plot clearly shows why people run into trouble with synthesised arc OK.

So in this case, it seems I could safely set a 0.1 second (100 ms) THC delay. But I would not go under 0.5 seconds without some testing as on my last machine I needed to wait for 1.5 seconds..

I recommend all plasma builders replicate this test before setting a THC delay and make sure the voltage has stabilised before enabling it. I think you are better off with a longer delay than a minimal THC delay.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17729

- Thank you received: 5186

13 Feb 2021 02:57 - 13 Feb 2021 02:58 #198639

by PCW

Replied by PCW on topic Arc voltage on piercing

Not sure how synthesiszed arc-ok works now but it does seem that the large fast drop

in voltage at arc start could be one part of the detection (via DVDT) then perhaps a

fixed wait = retriggerble one-shot, retriggered by any +- deviations > somelimit

in voltage at arc start could be one part of the detection (via DVDT) then perhaps a

fixed wait = retriggerble one-shot, retriggered by any +- deviations > somelimit

Last edit: 13 Feb 2021 02:58 by PCW.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

13 Feb 2021 03:37 #198640

by rodw

Yes, I agree. The voltage plot is actually very similar to the ones I did of void crossing which could be detected by a DV/DT algorithm.

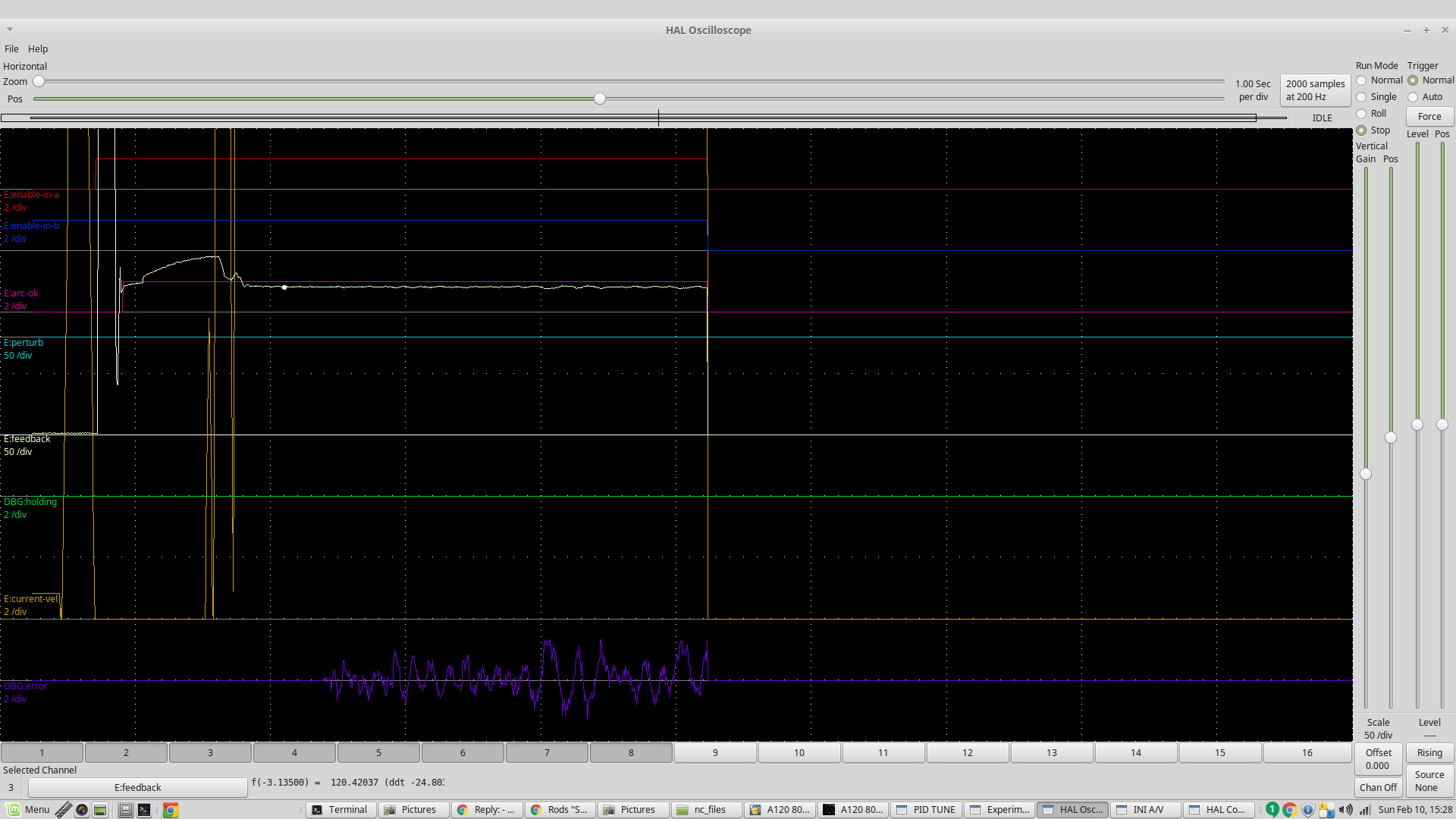

This earlier plot from an Everlast 50s that is included in the plasma primer shows a very different story.

(The original file at a higher res than the primer)

linuxcnc.org/docs/devel/html/plasma/plas...imer.html#_thc_delay

Here the ArcOK (in pink) is enabled before the voltage settles to its equilibrium point.

Here you need to wait out the hump before enabling thc or sampling volts.

So perhaps the better quality machines have better ArcOK algorithims.

I think we need a few more data points not just one machine to base decisions on.

Maybe some others could repeat this experiment

Replied by rodw on topic Arc voltage on piercing

Not sure how synthesiszed arc-ok works now but it does seem that the large fast drop

in voltage at arc start could be one part of the detection (via DVDT) then perhaps a

fixed wait = retriggerble one-shot, retriggered by any +- deviations > somelimit

Yes, I agree. The voltage plot is actually very similar to the ones I did of void crossing which could be detected by a DV/DT algorithm.

This earlier plot from an Everlast 50s that is included in the plasma primer shows a very different story.

(The original file at a higher res than the primer)

linuxcnc.org/docs/devel/html/plasma/plas...imer.html#_thc_delay

Here the ArcOK (in pink) is enabled before the voltage settles to its equilibrium point.

Here you need to wait out the hump before enabling thc or sampling volts.

So perhaps the better quality machines have better ArcOK algorithims.

I think we need a few more data points not just one machine to base decisions on.

Maybe some others could repeat this experiment

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17729

- Thank you received: 5186

13 Feb 2021 03:51 #198644

by PCW

Replied by PCW on topic Arc voltage on piercing

The voltage plot actually looks pretty similar to the first plot except for the much longer

settling time after the arc was established (this might be material + thickness related)

settling time after the arc was established (this might be material + thickness related)

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

13 Feb 2021 04:18 #198649

by rodw

Yes but in the second case, the ArcOK is returned before stable volts is achieved so there is a risk of sampling torch voltage or enabling the THC too early and cutting above the desired height. I think (much) slower acceleration has something to do with that.

Replied by rodw on topic Arc voltage on piercing

The voltage plot actually looks pretty similar to the first plot except for the much longer

settling time after the arc was established (this might be material + thickness related)

Yes but in the second case, the ArcOK is returned before stable volts is achieved so there is a risk of sampling torch voltage or enabling the THC too early and cutting above the desired height. I think (much) slower acceleration has something to do with that.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

13 Feb 2021 04:44 #198652

by rodw

Replied by rodw on topic Arc voltage on piercing

So anybody wanting to add to the data points, the halscope tutorial is here

linuxcnc.org/docs/devel/html/hal/tutorial.html#_halscope

linuxcnc.org/docs/devel/html/hal/tutorial.html#_halscope

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21362

- Thank you received: 7286

13 Feb 2021 09:46 #198657

by tommylight

Replied by tommylight on topic Arc voltage on piercing

Thank you Rod for confirming that.

I have been using a THC delay of 0.1 for 5 months without issues.

As for ARCOK, there were some changes made from version 186 i think as there was a situation where the torch would fire while the torch was still traveling to pierce height causing a lost arc. Also some other functions were added regarding lost arc.

As with everything else, plasma is a complicated process, dependet on a lot of variables, so troubleshooting and fixing issues is not easy by any stretch.

ARC voltage varies a lot, from material being cut to grid voltage will cause fluctuations, on transformer type plasmas more that inverter ones, thin power wires and low/bad grid supply will cause lost arc very often as the supply voltage will drop a lot the moment the arc transfers as confirmed on two machines and two sites, a Hypertherm 3070 had lost arcs very often on one site/shop with anything over 60A while the same machine has no issues in the current shop at full power, but a 400A Hypertherm has that issue in the same shop.

Plasma sources use a lot of power, typically at 100A they use over 25KW and that is way over what most normal grids can handle, and any drop in grid voltage will cause lost arcs. Inverter type plasmas are much better regarding this due to built in capacitors and voltage/current regulation.

To long.........

I have been using a THC delay of 0.1 for 5 months without issues.

As for ARCOK, there were some changes made from version 186 i think as there was a situation where the torch would fire while the torch was still traveling to pierce height causing a lost arc. Also some other functions were added regarding lost arc.

As with everything else, plasma is a complicated process, dependet on a lot of variables, so troubleshooting and fixing issues is not easy by any stretch.

ARC voltage varies a lot, from material being cut to grid voltage will cause fluctuations, on transformer type plasmas more that inverter ones, thin power wires and low/bad grid supply will cause lost arc very often as the supply voltage will drop a lot the moment the arc transfers as confirmed on two machines and two sites, a Hypertherm 3070 had lost arcs very often on one site/shop with anything over 60A while the same machine has no issues in the current shop at full power, but a 400A Hypertherm has that issue in the same shop.

Plasma sources use a lot of power, typically at 100A they use over 25KW and that is way over what most normal grids can handle, and any drop in grid voltage will cause lost arcs. Inverter type plasmas are much better regarding this due to built in capacitors and voltage/current regulation.

To long.........

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.167 seconds