THC Problem - Linux/THCAD10/SheetCam

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

02 May 2021 22:23 - 02 May 2021 22:43 #207687

by RNJFAB

THC Problem - Linux/THCAD10/SheetCam was created by RNJFAB

Hey All,

Now everything running I'm having a few issues I would like to fix and need some guidance.

1st issue - from time to time, when cutting the Z axis will dive down and trigger the probe sensor. I'm guessing that its trying to get the voltage high and is diving to try and make this happen.

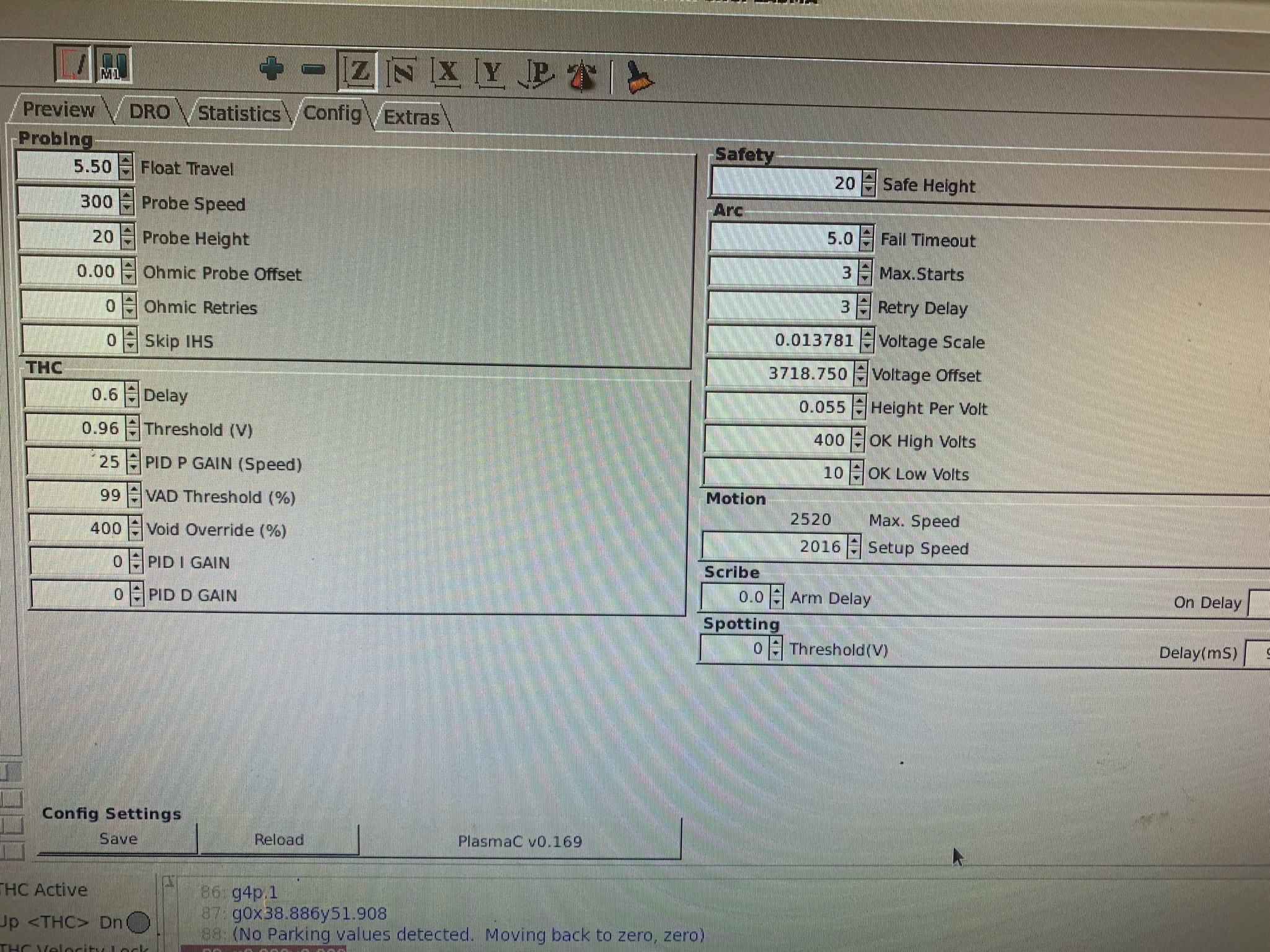

2nd issue - diving on corners. I know this can be adjusted in the settings or post processor. I just don't know how. these are my current settings.

3rd issue - PNP sensors on the limit switches trip out. I know I need some sort of debouncing in the Hal file, I just don't know what this looks like or how to do it. If someone has the lines of code for this can you post it please.

Link to my build with most details.

forum.linuxcnc.org/show-your-stuff/42411...ade-cheap-plasma-cnc

Now everything running I'm having a few issues I would like to fix and need some guidance.

1st issue - from time to time, when cutting the Z axis will dive down and trigger the probe sensor. I'm guessing that its trying to get the voltage high and is diving to try and make this happen.

2nd issue - diving on corners. I know this can be adjusted in the settings or post processor. I just don't know how. these are my current settings.

3rd issue - PNP sensors on the limit switches trip out. I know I need some sort of debouncing in the Hal file, I just don't know what this looks like or how to do it. If someone has the lines of code for this can you post it please.

Link to my build with most details.

forum.linuxcnc.org/show-your-stuff/42411...ade-cheap-plasma-cnc

Attachments:

Last edit: 02 May 2021 22:43 by RNJFAB.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

02 May 2021 22:50 #207690

by tommylight

Replied by tommylight on topic THC Problem - Linux/THCAD10/SheetCam

Height per volt seems wrong, default is 1 and it should work just fine.

Diving issue, do you have corner lock on and at what percentage ?

If the sensors are tripping at torch fire, no amount of debounce will help. That will be grounding/shielding issue and has to be dealt with before ending up with something in smoke, besides the cutting smoke.

If they trip during homing, debounce helps so have a look at the existing machine config there are some debounces there so just add as much as you need and connect them to sensors in hal.

Diving issue, do you have corner lock on and at what percentage ?

If the sensors are tripping at torch fire, no amount of debounce will help. That will be grounding/shielding issue and has to be dealt with before ending up with something in smoke, besides the cutting smoke.

If they trip during homing, debounce helps so have a look at the existing machine config there are some debounces there so just add as much as you need and connect them to sensors in hal.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 May 2021 08:01 #207707

by robertspark

Replied by robertspark on topic THC Problem - Linux/THCAD10/SheetCam

issue 1, you have it the wrong way around

torch will dive to lower the voltage, the voltage gets bigger when the gap gets wider. that is why when the torch slows, the kerf gets wider, the voltage gets higher and with thc the torch dives to LOWER the voltage sensed

torch will dive to lower the voltage, the voltage gets bigger when the gap gets wider. that is why when the torch slows, the kerf gets wider, the voltage gets higher and with thc the torch dives to LOWER the voltage sensed

The following user(s) said Thank You: RNJFAB, Coachbuilder

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 May 2021 09:27 #207710

by robertspark

Replied by robertspark on topic THC Problem - Linux/THCAD10/SheetCam

issue 3, could be a few things. what plasma cutter are you using (make, model, link?)

how have you wired your proximity sensors?

(sketch the circuit please)

how much load do you have on the sensors, do they feed directly to an input pin. the impedance of the Mesa input pins on 7i76 is about 20k

automation-insights.blog/wp-content/uplo...-768x1000_update.jpg

how have you wired your proximity sensors?

(sketch the circuit please)

how much load do you have on the sensors, do they feed directly to an input pin. the impedance of the Mesa input pins on 7i76 is about 20k

automation-insights.blog/wp-content/uplo...-768x1000_update.jpg

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

09 May 2021 00:32 #208348

by RNJFAB

Replied by RNJFAB on topic THC Problem - Linux/THCAD10/SheetCam

Thanks Tommylight,

I'll change the heigh per volt now.

corner lock on 99%.

I'll change the heigh per volt now.

corner lock on 99%.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

09 May 2021 00:33 #208349

by RNJFAB

Replied by RNJFAB on topic THC Problem - Linux/THCAD10/SheetCam

Thanks Robertspark,

I'll try adjusting the set voltage to a higher voltage.

I'll try adjusting the set voltage to a higher voltage.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

09 May 2021 11:33 #208363

by tommylight

Replied by tommylight on topic THC Problem - Linux/THCAD10/SheetCam

I leave corner lock at 60 to 80%.

Height per volt is roughly 0.1, i think RodW came to that conclusion from his extensive testing.

Height per volt is roughly 0.1, i think RodW came to that conclusion from his extensive testing.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

11 May 2021 12:49 #208542

by RNJFAB

Replied by RNJFAB on topic THC Problem - Linux/THCAD10/SheetCam

Thanks Guys,

Settings changed, works great.

However tonight I cut some parts from ally, all went well with new settings, then boop, no more torch fire. can't get the board to fire the torch. tried resetting and using the pulse button in the GUI. NOTHING. every now and then the board will light up to say it has turned the torch on, and the relay will light up, but no spark.

Any ideas?

Settings changed, works great.

However tonight I cut some parts from ally, all went well with new settings, then boop, no more torch fire. can't get the board to fire the torch. tried resetting and using the pulse button in the GUI. NOTHING. every now and then the board will light up to say it has turned the torch on, and the relay will light up, but no spark.

Any ideas?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

11 May 2021 13:00 #208543

by tommylight

Replied by tommylight on topic THC Problem - Linux/THCAD10/SheetCam

-Dirty nozzle/electrode

-loose electrode

-not enough air pressure

-to much air pressure

-faulty pilot arc circuit (if pilot arc start)

-faulty current limiting (if blow back start)

Is it inverter or transformer type?

On transformer types there is a distinct laud "click" when the big relay inside engages, turn off the compressor and listen for that click.

On inverter types the only outside noticeable sound is the fan changing (lowering) speed by just a bit (more noticeable in US than Europe) when firing.

-loose electrode

-not enough air pressure

-to much air pressure

-faulty pilot arc circuit (if pilot arc start)

-faulty current limiting (if blow back start)

Is it inverter or transformer type?

On transformer types there is a distinct laud "click" when the big relay inside engages, turn off the compressor and listen for that click.

On inverter types the only outside noticeable sound is the fan changing (lowering) speed by just a bit (more noticeable in US than Europe) when firing.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

11 May 2021 20:53 #208582

by RNJFAB

Replied by RNJFAB on topic THC Problem - Linux/THCAD10/SheetCam

changed nozzle/electrode (first thought)

all tight

60psi

Plasma will start (pilot arc) if I short out the start circuit.

MESA board will light up to say that the torch should be on (sometimes), relay will trigger to tell the plasma to start, plasma will try and fire then stop. then mesa will stop triggering the relay.

Tried changing relays, restarted the system several times, changed wires, etc.

No errors in LinuxCNC.

all tight

60psi

Plasma will start (pilot arc) if I short out the start circuit.

MESA board will light up to say that the torch should be on (sometimes), relay will trigger to tell the plasma to start, plasma will try and fire then stop. then mesa will stop triggering the relay.

Tried changing relays, restarted the system several times, changed wires, etc.

No errors in LinuxCNC.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.205 seconds