Downunder 4x2 build

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

07 Jul 2021 11:31 #213961

by OxxAndBert

Downunder 4x2 build was created by OxxAndBert

I've been collecting bits and pieces for my first CNC Plasma build for a while now, so time to get a reality check on what I've got planned.

I also needed to say a huge thanks those of you who have shared your knowledge through this forum. Its an amazing resource and so valuable for a newbie!

Here's my current plan:

4'x2' (actually 1220x650mm) table, with the Y axis being the shorter one. Small sheets here are 1200x2400 so I can feed a a full sheet in.

I was originally planning a 4x4 table, but I'm a bit pushed for space in the workshop so have decided to reduce it to 4x2 thinking I can easily add add an extension to the table later if required and only need longer Y rails and belts - plus larger water pan.

Main frame:

Welded from some 1.5m offcuts of 75x50x4mm RHS I picked up for scrap price.

Gantry:

Most likely some 50x50x2 SHS that I already have lying around

Water pan:

75mm deep stainless steel (from a larger salvaged delicatessen pan) with 50x3 slats

Clearance under gantry 250mm

Z travel 150-200mm

Control/Motion:

Mesa 7i96

2x THCAD10 - one for THC and one for ohmic sensing (THCAD5 was out of stock when I placed the order)

Stepperonline 3Nm Nema23 for X and Y (2 motors on Y) - these have 10mm shafts.

Stepperonline DM556T drivers

2x Meanwell 36v 250W power supplies

HTD-3M 15mm belt drive for X and Y with 3:1 reduction 60T/20T

PNP inductive proximity sensors 6-36v NC

Linear rails - I have 2 pairs of HGR rails that I salvaged off an old machine that got scrapped. One pair is HGR15 the other is HGR20, and each rail has 2 carriages on it. They are all 1.8m long.

I also have plenty of ball bearing runners removed from computer server racks that could be used for a rough and ready Z carriage.

With the exception of the belts and pulleys I pretty much have everything else at hand.

Currently I've only got a cheap HF start 35A plasma which I'll move on when I get a better machine. My current thinking is one of these swswelding.com.au/collections/machines/p...ma-cutter-buy-online

I'd love to hear your thoughts - particularly if you think there's anything really dumb there!!

Steve

I also needed to say a huge thanks those of you who have shared your knowledge through this forum. Its an amazing resource and so valuable for a newbie!

Here's my current plan:

4'x2' (actually 1220x650mm) table, with the Y axis being the shorter one. Small sheets here are 1200x2400 so I can feed a a full sheet in.

I was originally planning a 4x4 table, but I'm a bit pushed for space in the workshop so have decided to reduce it to 4x2 thinking I can easily add add an extension to the table later if required and only need longer Y rails and belts - plus larger water pan.

Main frame:

Welded from some 1.5m offcuts of 75x50x4mm RHS I picked up for scrap price.

Gantry:

Most likely some 50x50x2 SHS that I already have lying around

Water pan:

75mm deep stainless steel (from a larger salvaged delicatessen pan) with 50x3 slats

Clearance under gantry 250mm

Z travel 150-200mm

Control/Motion:

Mesa 7i96

2x THCAD10 - one for THC and one for ohmic sensing (THCAD5 was out of stock when I placed the order)

Stepperonline 3Nm Nema23 for X and Y (2 motors on Y) - these have 10mm shafts.

Stepperonline DM556T drivers

2x Meanwell 36v 250W power supplies

HTD-3M 15mm belt drive for X and Y with 3:1 reduction 60T/20T

PNP inductive proximity sensors 6-36v NC

Linear rails - I have 2 pairs of HGR rails that I salvaged off an old machine that got scrapped. One pair is HGR15 the other is HGR20, and each rail has 2 carriages on it. They are all 1.8m long.

I also have plenty of ball bearing runners removed from computer server racks that could be used for a rough and ready Z carriage.

With the exception of the belts and pulleys I pretty much have everything else at hand.

Currently I've only got a cheap HF start 35A plasma which I'll move on when I get a better machine. My current thinking is one of these swswelding.com.au/collections/machines/p...ma-cutter-buy-online

I'd love to hear your thoughts - particularly if you think there's anything really dumb there!!

Steve

The following user(s) said Thank You: Joco, Coachbuilder

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

07 Jul 2021 13:21 #213968

by tommylight

Replied by tommylight on topic Downunder 4x2 build

Start building !

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

07 Jul 2021 20:11 #213988

by rodw

Replied by rodw on topic Downunder 4x2 build

Great to see another Aussie on the forum.

You might also like to look at the Unimig Razrcut45 plasma cutter as it includes a CNC interface and they offer a machine torch for it as well.

RNJFAB another Aussie is using one now after problems trying to get a HF start machine running. HE told me the other day he was very happy with it.

Don't get me wrong, it is possible to use a HF start machine but it really raises the bar with RFI management when setting up the electronics and wiring. You would be better off leaving that to people like Tommy !

I'd recommend you upgrade your plasma at the beginning.

You might also like to look at the Unimig Razrcut45 plasma cutter as it includes a CNC interface and they offer a machine torch for it as well.

RNJFAB another Aussie is using one now after problems trying to get a HF start machine running. HE told me the other day he was very happy with it.

Don't get me wrong, it is possible to use a HF start machine but it really raises the bar with RFI management when setting up the electronics and wiring. You would be better off leaving that to people like Tommy !

I'd recommend you upgrade your plasma at the beginning.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

08 Jul 2021 09:43 #214016

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks guys!

RodW - I'll definitely be upgrading the plasma beforehand rather than trying to get the crappy one to work. I'm sure the learning curve will be steep anyway without throwing on a bunch of HF issues to contend with.

A mate of mine has a SWS brand AC/DC TIG and its a lovely bit of gear. If their plasma is anywhere near as good it should be a nice machine. About the same price as the Razor 45 by the time you get the CNC interface added, but a claimed 45% duty cycle at 50A compared to the Razor's 25% at 45A.

They are currently out of stock with another shipment due in late this month, so no rush right now.

Made a start tonight by getting the steel for the table frame cut to length:

Also had the prox sensors turn up, but I managed to order the 8mm diam ones instead of the 18mm

Is that likely to cause any issues?

Steve

RodW - I'll definitely be upgrading the plasma beforehand rather than trying to get the crappy one to work. I'm sure the learning curve will be steep anyway without throwing on a bunch of HF issues to contend with.

A mate of mine has a SWS brand AC/DC TIG and its a lovely bit of gear. If their plasma is anywhere near as good it should be a nice machine. About the same price as the Razor 45 by the time you get the CNC interface added, but a claimed 45% duty cycle at 50A compared to the Razor's 25% at 45A.

They are currently out of stock with another shipment due in late this month, so no rush right now.

Made a start tonight by getting the steel for the table frame cut to length:

Also had the prox sensors turn up, but I managed to order the 8mm diam ones instead of the 18mm

Is that likely to cause any issues?

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

08 Jul 2021 10:11 #214018

by rodw

Replied by rodw on topic Downunder 4x2 build

Ahh, I missed the CNC option. Not one I was familiar with.

I don't think the size of the sensors will matter. I used 12mm ones.

PNP is preferred with Mesa cards...

Duty cycle is a funny thing. My plasma is rated 100% @100 amps from memory and I've had it overheat cutting at 40 amps! Must have been the sheer number of pierces..

I don't think the size of the sensors will matter. I used 12mm ones.

PNP is preferred with Mesa cards...

Duty cycle is a funny thing. My plasma is rated 100% @100 amps from memory and I've had it overheat cutting at 40 amps! Must have been the sheer number of pierces..

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

08 Jul 2021 10:59 #214020

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks - I've got PNP ones as I'd read a few posts previously saying they were preferred type.

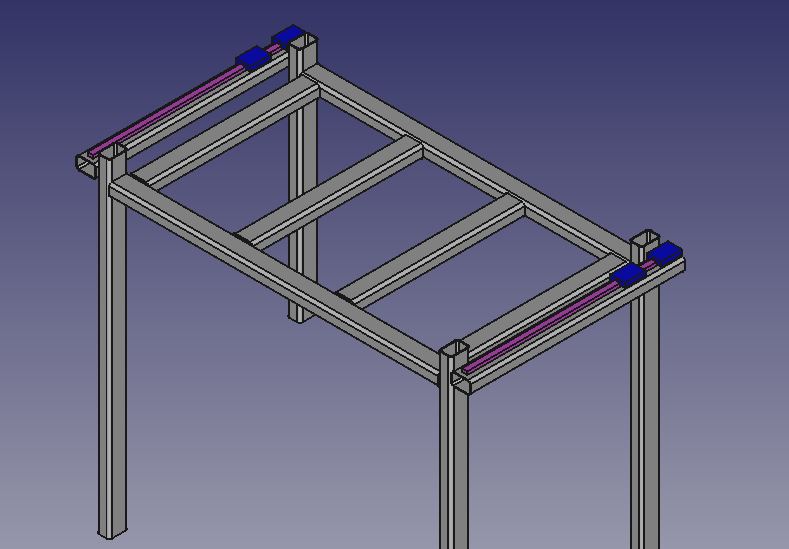

This is what I've got planned for the main frame construction.

I thought about putting the rails on the edge, but looked like alignment would be harder and more likely to get screwed up by any distortion during welding.

I'll fit a sheetmetal cover over the sides to stop crap getting on the rails.

Belts will run under the RHS to protect them.

Steve

This is what I've got planned for the main frame construction.

I thought about putting the rails on the edge, but looked like alignment would be harder and more likely to get screwed up by any distortion during welding.

I'll fit a sheetmetal cover over the sides to stop crap getting on the rails.

Belts will run under the RHS to protect them.

Steve

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

08 Jul 2021 12:44 #214025

by rodw

Replied by rodw on topic Downunder 4x2 build

Looks a good start. And a good layout to keep rails clean. I did devise a way to mount the rails on the side but it cost me about $800 in custom laser cut mounting rails! Yours should mean you have a shorter, stiffer gantry ends too.

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

09 Jul 2021 12:21 #214088

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks Rod - good to know I'm heading down a reasonable track.

Started tacking up the frame today, but not enough progress to warrant a photo. The 75x50x5 RHS is complete overkill for such a small table, but I guess some mass in the frame won't hurt - and at less than $50 total the price was right

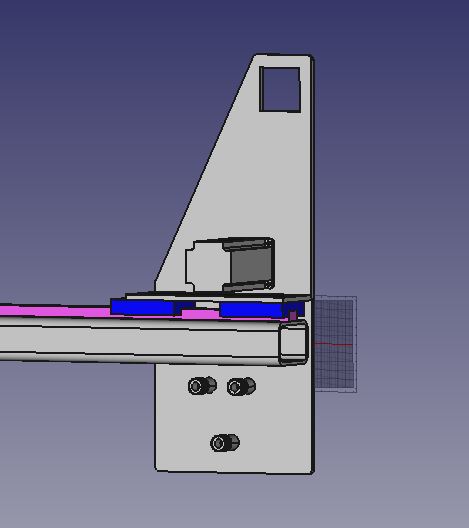

Finished modelling up the gantry supports and drive setup. Apologies - but modeling up the belt was beyond my minimal CAD skills, but it runs over the idlers at the top, then loops down around the drive pulley. 3:1 reduction (20T/60T) between the stepper and drive pulley.

6mm steel for the supports, with the horizontal plate welded on. Thinking that if I bolt them to the linear rail carriages then I should be able to get the gantry beam in place and trued up, then weld it to the supports.

Planning to drill and tap the side plate and bolt the idlers to it with some spacers. Haven't decided on a shaft/bearing arrangement for the drive pulley yet.

Can anyone recommend a good size/style of drag chain for a small table like this? And is there a rule of thumb for how much chain is needed?

Steve

Started tacking up the frame today, but not enough progress to warrant a photo. The 75x50x5 RHS is complete overkill for such a small table, but I guess some mass in the frame won't hurt - and at less than $50 total the price was right

Finished modelling up the gantry supports and drive setup. Apologies - but modeling up the belt was beyond my minimal CAD skills, but it runs over the idlers at the top, then loops down around the drive pulley. 3:1 reduction (20T/60T) between the stepper and drive pulley.

6mm steel for the supports, with the horizontal plate welded on. Thinking that if I bolt them to the linear rail carriages then I should be able to get the gantry beam in place and trued up, then weld it to the supports.

Planning to drill and tap the side plate and bolt the idlers to it with some spacers. Haven't decided on a shaft/bearing arrangement for the drive pulley yet.

Can anyone recommend a good size/style of drag chain for a small table like this? And is there a rule of thumb for how much chain is needed?

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

09 Jul 2021 14:55 #214115

by tommylight

Replied by tommylight on topic Downunder 4x2 build

20 to 40% more than half of the movement depending on the bend radius.

The following user(s) said Thank You: OxxAndBert

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

10 Jul 2021 10:38 #214172

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks Tommy.

Glad I asked as I was thinking it would be a bit more than the full length of movement. Obviously a newbie here!

I've ordered a couple of 1m lengths of 25x77 size.

Got the table frame welded together today.

Haven't added the supports for the rails yet as I'm thinking it might be better to bolt them on to make initial alignment easier, then tack them in place to prevent any further movement.

I looked around the shop for some 6mm steel for the gantry side supports, but only have 5mm and 12mm. The 5mm should be stiff enough - I can always add some gussets later if it does flex.

Steve

Glad I asked as I was thinking it would be a bit more than the full length of movement. Obviously a newbie here!

I've ordered a couple of 1m lengths of 25x77 size.

Got the table frame welded together today.

Haven't added the supports for the rails yet as I'm thinking it might be better to bolt them on to make initial alignment easier, then tack them in place to prevent any further movement.

I looked around the shop for some 6mm steel for the gantry side supports, but only have 5mm and 12mm. The 5mm should be stiff enough - I can always add some gussets later if it does flex.

Steve

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.284 seconds