Downunder 4x2 build

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

11 Jul 2021 10:36 #214242

by RNJFAB

Replied by RNJFAB on topic Downunder 4x2 build

Hey Steve,

have a read through my build if you get a chance, I had my fair share of problems to work through.

Looks like you have a good plan in place for your build.

I did a lot of research before going with the unimig, and in all of that I never came across the sws speed cut plasma, looks bloody good on paper. will cut 4mm more than the unimig. and the consumables are cheap, like cheaper than the consumables I used to run on my Chinese plasma.

My unimig Cut 45 came with the starter kit and I had it at home for about $1300. this was with 10 tips and 5 electrodes and a bunch of other stuff. It is cnc compatible right out of the box and I just bought the plug to connect it up. Pretty easy overall. Its also setup to run 20:1 I think so works great with the THCAD-10. Electrodes are $32 for 5 and tips are the same.

My Build here

forum.linuxcnc.org/show-your-stuff/42411...p-plasma-cnc?start=0

have a read through my build if you get a chance, I had my fair share of problems to work through.

Looks like you have a good plan in place for your build.

I did a lot of research before going with the unimig, and in all of that I never came across the sws speed cut plasma, looks bloody good on paper. will cut 4mm more than the unimig. and the consumables are cheap, like cheaper than the consumables I used to run on my Chinese plasma.

My unimig Cut 45 came with the starter kit and I had it at home for about $1300. this was with 10 tips and 5 electrodes and a bunch of other stuff. It is cnc compatible right out of the box and I just bought the plug to connect it up. Pretty easy overall. Its also setup to run 20:1 I think so works great with the THCAD-10. Electrodes are $32 for 5 and tips are the same.

My Build here

forum.linuxcnc.org/show-your-stuff/42411...p-plasma-cnc?start=0

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

11 Jul 2021 23:15 #214342

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks mate. I've had a couple of reads through your thread already. Some great info there and plenty of challenges/solutions that I'm yet to deal with.

As you say - the SWS machine looks good on paper - will see how it goes in practice.

I've got a bit of construction to go yet before the power source is an issue!

Steve

As you say - the SWS machine looks good on paper - will see how it goes in practice.

I've got a bit of construction to go yet before the power source is an issue!

Steve

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

12 Jul 2021 12:22 #214391

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Weird how the tool that you spent hours looking for will show up pretty much as soon as you give up looking. Just after you do the job with something else, or buy another tool to replace it. Yesterday it was my bootlace crimpers that were playing hide-n-seek.

Was getting close to ordering some more ferrules anyway, so bought a kit with the tool and ferrules in it online last night. Lunchtime today I found them fallen down behind another bit of gear.

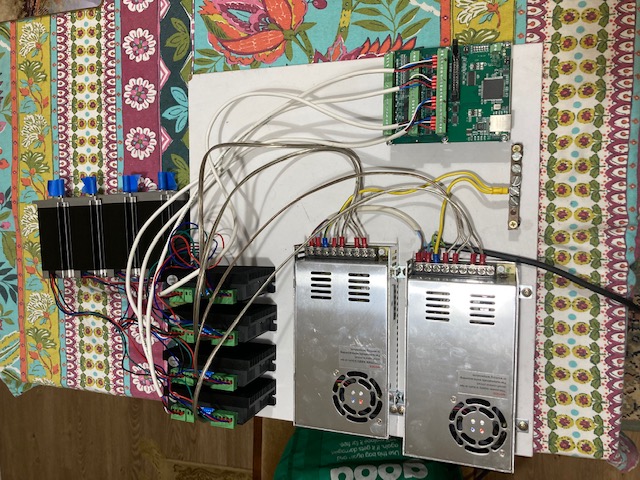

So, tonight was getting some bits connected so I can start to get my head around LinuxCNC.

Still need a 5v power supply for the 7i96 but will probably just use USB while its on thedining table workbench.

The main power supplies are the Stepperonline 36v-6.7A units.

A complete newbie question:

The current dip switches on the drivers - are they best left at the lowest current setting initially until you prove the wiring etc is all correct, or do they need to be set to match the motors up front to actually get them to work?

Steve

Was getting close to ordering some more ferrules anyway, so bought a kit with the tool and ferrules in it online last night. Lunchtime today I found them fallen down behind another bit of gear.

So, tonight was getting some bits connected so I can start to get my head around LinuxCNC.

Still need a 5v power supply for the 7i96 but will probably just use USB while its on the

The main power supplies are the Stepperonline 36v-6.7A units.

A complete newbie question:

The current dip switches on the drivers - are they best left at the lowest current setting initially until you prove the wiring etc is all correct, or do they need to be set to match the motors up front to actually get them to work?

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

12 Jul 2021 15:53 #214405

by tommylight

Does not matter much, but it is nice to use lower current until the machine is finished, it saves stuff from bending/destruction if something goes wrong, and it will sooner or later.

Replied by tommylight on topic Downunder 4x2 build

A complete newbie question:

The current dip switches on the drivers - are they best left at the lowest current setting initially until you prove the wiring etc is all correct, or do they need to be set to match the motors up front to actually get them to work?

Does not matter much, but it is nice to use lower current until the machine is finished, it saves stuff from bending/destruction if something goes wrong, and it will sooner or later.

The following user(s) said Thank You: OxxAndBert

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

13 Jul 2021 11:53 - 13 Jul 2021 11:54 #214556

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

Thanks Tommy - that was my line of thinking too.

Bit more progress tonight...

Dragged out the old PC that I installed LinuxCNC (Debian10) from LiveCD about 6 months ago.

Connected it up to the 7i96, powered on, configured the network interface and can ping the Mesa card.

Powered up the drive power supplies - all green LED's and no smoke.

Looking good so far

Ran PncConf, flicked through a couple of the pages - and decided I have no idea where to go next!

Time for some more reading I think.....

Steve

Bit more progress tonight...

Dragged out the old PC that I installed LinuxCNC (Debian10) from LiveCD about 6 months ago.

Connected it up to the 7i96, powered on, configured the network interface and can ping the Mesa card.

Powered up the drive power supplies - all green LED's and no smoke.

Looking good so far

Ran PncConf, flicked through a couple of the pages - and decided I have no idea where to go next!

Time for some more reading I think.....

Steve

Last edit: 13 Jul 2021 11:54 by OxxAndBert.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

13 Jul 2021 11:58 #214559

by tommylight

Replied by tommylight on topic Downunder 4x2 build

Reading helps a lot !

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

14 Jul 2021 13:56 #214739

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

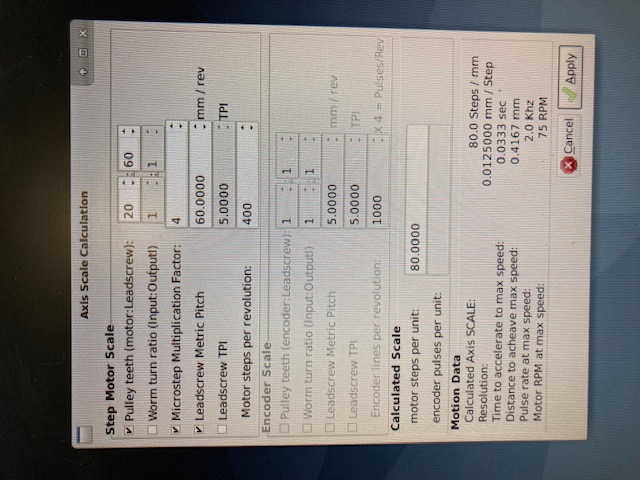

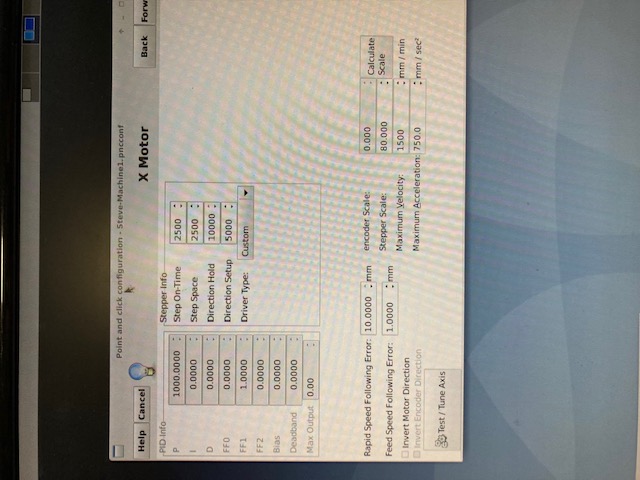

Done LOTS of reading, watched a few videos, run an AXIS simulation, run PncConf to configure a tandem Y axis, and X/Z.

Even ran the "LinuxCNC" file and got my steppers to move, but they were moving sooooooo slowly that I didn't even notice at first that they were moving at all.

Tried to set the axis config to more reasonable values, but now its not moving at all and I can't work out how to replicate what I had earlier!

I'm a complete newbie to steppers, microstepping etc, and not getting my head around how it all hangs together and what I need to set in the PncConf wizard.

Anyone give me a sanity check on these values:

Drivers are DM566T

From the wiki page on stepper drive timing:

StepTime:2500 StepSpace:2500 DirectionHold:10000 DirectionSetup:5000 StepsOn:Rising Edge

Out of the box the dip switches are set at 1600 pulse/rev

In the axis scale calculator I have set:

Pulley Teeth 20:60

Leadscrew metric pitch 60mm/rev (20T gear and HDT-3M belt)

Motor steps per rev 400

Microstep multiplication factor 4

Steve

Even ran the "LinuxCNC" file and got my steppers to move, but they were moving sooooooo slowly that I didn't even notice at first that they were moving at all.

Tried to set the axis config to more reasonable values, but now its not moving at all and I can't work out how to replicate what I had earlier!

I'm a complete newbie to steppers, microstepping etc, and not getting my head around how it all hangs together and what I need to set in the PncConf wizard.

Anyone give me a sanity check on these values:

Drivers are DM566T

From the wiki page on stepper drive timing:

StepTime:2500 StepSpace:2500 DirectionHold:10000 DirectionSetup:5000 StepsOn:Rising Edge

Out of the box the dip switches are set at 1600 pulse/rev

In the axis scale calculator I have set:

Pulley Teeth 20:60

Leadscrew metric pitch 60mm/rev (20T gear and HDT-3M belt)

Motor steps per rev 400

Microstep multiplication factor 4

Steve

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

14 Jul 2021 14:54 #214750

by tommylight

Replied by tommylight on topic Downunder 4x2 build

Second picture, set step to 5000 both and dir to 20000 both .

The following user(s) said Thank You: OxxAndBert

Please Log in or Create an account to join the conversation.

- OxxAndBert

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 17

15 Jul 2021 09:52 - 15 Jul 2021 09:53 #214830

by OxxAndBert

Replied by OxxAndBert on topic Downunder 4x2 build

That's worked, and I now have steppers that do a few turns

Thanks so much Tommy - you're a legend!!

Were those numbers just from experience or should I have been able to work them out somehow?

I've realised I miscalculated somewhat, as I was planning to run my prox sensors off the same 36v power supply as the steppers - but overlooked that the 7i96 can only handle 24v for TB3 inputs. I should have bought the 5v version of the sensors and I could have used the one 5v power supply for both the board and the sensors/switches. I'll have to dig out an old PC power supply with both 5 and 12v I think...

It seems a bit pointless connecting up all the sensors etc on the bench before they are mounted to the machine, so unless there's something else worthwhile at this point I'll just make sure I've saved that working stepper config and get back onto the physical build ??

Steve

Thanks so much Tommy - you're a legend!!

Were those numbers just from experience or should I have been able to work them out somehow?

I've realised I miscalculated somewhat, as I was planning to run my prox sensors off the same 36v power supply as the steppers - but overlooked that the 7i96 can only handle 24v for TB3 inputs. I should have bought the 5v version of the sensors and I could have used the one 5v power supply for both the board and the sensors/switches. I'll have to dig out an old PC power supply with both 5 and 12v I think...

It seems a bit pointless connecting up all the sensors etc on the bench before they are mounted to the machine, so unless there's something else worthwhile at this point I'll just make sure I've saved that working stepper config and get back onto the physical build ??

Steve

Last edit: 15 Jul 2021 09:53 by OxxAndBert.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

15 Jul 2021 12:11 #214853

by tommylight

Replied by tommylight on topic Downunder 4x2 build

Those values are about the minimum for making sure the drives are working properly, they can be changed later but i would leave it as is. The values given by some drive manufacturers are mostly off by a lot.

Old laptop power supplies are very good and very cheap, i use them a lot as i can get them for 15 Euro each. See if you have one...

You should connect one sensor and make sure the wiring is OK, also helps later a lot knowing what goes where and how to set them up.

Old laptop power supplies are very good and very cheap, i use them a lot as i can get them for 15 Euro each. See if you have one...

You should connect one sensor and make sure the wiring is OK, also helps later a lot knowing what goes where and how to set them up.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.124 seconds