- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Ultimate guidance to avoid Electromagnetic Interference

Ultimate guidance to avoid Electromagnetic Interference

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

29 Jul 2021 22:39 - 30 Jul 2021 10:16 #216279

by shpatb

Ultimate guidance to avoid Electromagnetic Interference was created by shpatb

Last edit: 30 Jul 2021 10:16 by shpatb.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

29 Jul 2021 22:45 #216280

by thefabricator03

Replied by thefabricator03 on topic Ultimate guidance to avoid Electromagnetic

Do you have a wiring diagram you can post? What problems are you having exactly?

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

29 Jul 2021 22:52 #216281

by Bari

Replied by Bari on topic Ultimate guidance to avoid Electromagnetic

Star grounding to avoid ground loops is one.

www.loopslooth.com/Safety%20&%20Star%20Gnd.html

www.epanorama.net/documents/groundloop/

www.loopslooth.com/Safety%20&%20Star%20Gnd.html

www.epanorama.net/documents/groundloop/

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

29 Jul 2021 23:08 - 29 Jul 2021 23:09 #216283

by rodw

Replied by rodw on topic Ultimate guidance to avoid Electromagnetic

Do everything in the attached. (Note better motors include a grounding point to attach the star ground wires.)

Add an RFI/EMI filter on the mains inlet

Use a quality industrial 24 volt power supply eg Meanwell etc

Make sure there is a grounding patch across all linear guides.

That should solve your problem.

The biggest source of noise I found was entering via the mains power earth so the EMI filter is critical.

EDIT: Also layout of your control panel is critical to keep mains power, motor power and logic power seperated.

Add an RFI/EMI filter on the mains inlet

Use a quality industrial 24 volt power supply eg Meanwell etc

Make sure there is a grounding patch across all linear guides.

That should solve your problem.

The biggest source of noise I found was entering via the mains power earth so the EMI filter is critical.

EDIT: Also layout of your control panel is critical to keep mains power, motor power and logic power seperated.

Last edit: 29 Jul 2021 23:09 by rodw.

The following user(s) said Thank You: thefabricator03, shpatb

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

30 Jul 2021 05:48 #216307

by shpatb

Replied by shpatb on topic Ultimate guidance to avoid Electromagnetic

Thanks for you replies.

problems : Inaccurate cutting ,arc will start for pierce then stop for 1-2 mm then continue ,keyboard freezes , etc etc

problems : Inaccurate cutting ,arc will start for pierce then stop for 1-2 mm then continue ,keyboard freezes , etc etc

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

30 Jul 2021 05:51 - 30 Jul 2021 05:52 #216309

by shpatb

Replied by shpatb on topic Ultimate guidance to avoid Electromagnetic

I Have seperate groundings : One for the plasma table , and one for pc and electronics.

Last edit: 30 Jul 2021 05:52 by shpatb.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

30 Jul 2021 06:32 #216320

by rodw

Replied by rodw on topic Ultimate guidance to avoid Electromagnetic

More information please.

What plasma cutter (with URL for it)?

What control hardware?

What sized motors?

What voltage for motors?

What power supplies are you using in the control box?

What Plasmac Mode?

How are you obtaining an ArcOK?

If you run that job with the torch disabled, does it follow the correct path?

What plasma cutter (with URL for it)?

What control hardware?

What sized motors?

What voltage for motors?

What power supplies are you using in the control box?

What Plasmac Mode?

How are you obtaining an ArcOK?

If you run that job with the torch disabled, does it follow the correct path?

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

30 Jul 2021 10:05 #216331

by shpatb

Replied by shpatb on topic Ultimate guidance to avoid Electromagnetic

Thanks for reply Mr.Rod

1.stahwerk cut 70 igbt

2.2x breakoutboards

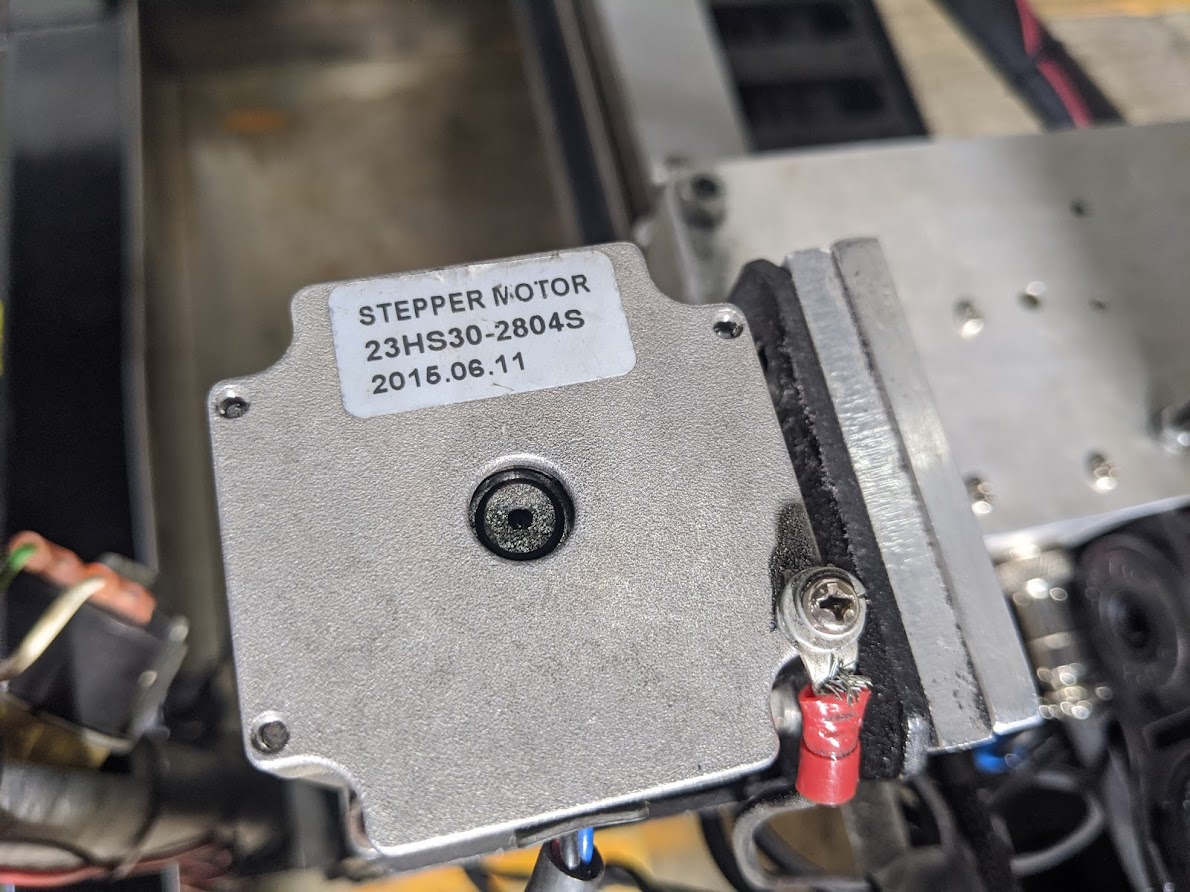

3.3Nm stepper motors

4.36V DC

5.Act motor psu-s

4.latest plasmaC

Yes with torch disabled it runs perfectly . i have dual configs with mach 3 and PlasmaC , perfectly on both.

Attached some pictures to make it more clear.

regards Shpat

1.stahwerk cut 70 igbt

2.2x breakoutboards

3.3Nm stepper motors

4.36V DC

5.Act motor psu-s

4.latest plasmaC

Yes with torch disabled it runs perfectly . i have dual configs with mach 3 and PlasmaC , perfectly on both.

Attached some pictures to make it more clear.

regards Shpat

Please Log in or Create an account to join the conversation.

- shpatb

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

30 Jul 2021 10:12 #216332

by shpatb

Replied by shpatb on topic Ultimate guidance to avoid Electromagnetic

Today ill order new plasma of CNC stamos s85 , will change the cables of motors to shielded ones , will change the power supply cable of my shop from 5G2.5 copper to 4x25 alu ,Will add a mesa controller , if this doesnt solve this problem ill definetely sell this machine for scrap.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

30 Jul 2021 10:27 #216333

by rodw

Replied by rodw on topic Ultimate guidance to avoid Electromagnetic Interference

Looks like its a HF start machine?

Lower voltage on the BOBs is not helping.

Make sure you use 24V with the mesa for greater noise immunity.

Move your PC away from the control box as the ethernet cable will add more isolation

Add a RFI filter to the mains power entering the control box.

Try and run your shielded stepper cables right to the stepper drive and ground the shield right there.

Try and earth to the motor across to your existing earths.

Lower voltage on the BOBs is not helping.

Make sure you use 24V with the mesa for greater noise immunity.

Move your PC away from the control box as the ethernet cable will add more isolation

Add a RFI filter to the mains power entering the control box.

Try and run your shielded stepper cables right to the stepper drive and ground the shield right there.

Try and earth to the motor across to your existing earths.

Attachments:

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Ultimate guidance to avoid Electromagnetic Interference

Time to create page: 0.174 seconds