THC for laser

- Ronniecnc

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

18 Mar 2022 21:18 #237677

by Ronniecnc

THC for laser was created by Ronniecnc

Hello. I'm new on here

I'm creating a fiber laser cutting machine. The fiber laser module, laser head and chiller is on the way and I already have a mesa card 7i93 for this purpose. I don't want to use plasmaC I plan to use only Axis. At this moment the "problem" is the THC comp is working but the Z axis dont want to move. I made a simple capacitance to frequency converter and i have a potentiometer to simulate the laser head gap the frequency is in one of the 7i93 encoders the value reads good but no z response. The THC can work without PlasmaC ?

I'm creating a fiber laser cutting machine. The fiber laser module, laser head and chiller is on the way and I already have a mesa card 7i93 for this purpose. I don't want to use plasmaC I plan to use only Axis. At this moment the "problem" is the THC comp is working but the Z axis dont want to move. I made a simple capacitance to frequency converter and i have a potentiometer to simulate the laser head gap the frequency is in one of the 7i93 encoders the value reads good but no z response. The THC can work without PlasmaC ?

Please Log in or Create an account to join the conversation.

- Ronniecnc

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

19 Mar 2022 15:00 #237717

by Ronniecnc

Replied by Ronniecnc on topic THC for laser

The signal requirements for the fiber laser to turn on are.

1) 1 to 10volt dc to set the laser power (10 to 100%)

The 1 to 10 Volts can get off the mesa 7i93 pwm and then use a simple low pass filter and then convert them to 10V with an OP amp or a transistor. My idea is to make a pyvcp panel to set the laser power from 10 to 100% before starting the cut

2) A 24Volt @ 20khz PWM signal

The 24 Volt pwm same way without the low pass filter.

I plan to use M3 S command to laser-enable and S for modulation but i need to vary the frequency before starting the cut or by Gcode, which depends on the thickness of the material. To piercing i need one frequency (generally lower), and to cut another, for example. I tried to make a pyvcp panel to configure the pwm on the fly but it won't let me do it I can only put a fixed value of the frequency in hal with step command

3) A 24Volt Enable signal

Easy

4) Laser Interlock

Easy.

I also need activate a solenoid valve for the shielding gases before the cut start and wait N seconds then run M3 S, it needs to stay on until there is no movement. I think I can do it with a m100 and classicladder.

Another thing is that I need to know exactly where the material is without touching it The fiber laser THC works with a capacitive THC which provides a voltage from 0 to 10V or a frequency depending on the height of the material with respect to the head. My idea was to use the hal comparator and set one of the values to a known frequency and to a known height, for example at 3mm, the frequency is 3khz when the laser head goes down and is with 3khz the output of the comparator will change that signal is net to motion.probe-input and i can do the probe routine.

But I don't know how to make the THC work. Z axis works normal with jog and in Gcode.

Thanks.

1) 1 to 10volt dc to set the laser power (10 to 100%)

The 1 to 10 Volts can get off the mesa 7i93 pwm and then use a simple low pass filter and then convert them to 10V with an OP amp or a transistor. My idea is to make a pyvcp panel to set the laser power from 10 to 100% before starting the cut

2) A 24Volt @ 20khz PWM signal

The 24 Volt pwm same way without the low pass filter.

I plan to use M3 S command to laser-enable and S for modulation but i need to vary the frequency before starting the cut or by Gcode, which depends on the thickness of the material. To piercing i need one frequency (generally lower), and to cut another, for example. I tried to make a pyvcp panel to configure the pwm on the fly but it won't let me do it I can only put a fixed value of the frequency in hal with step command

3) A 24Volt Enable signal

Easy

4) Laser Interlock

Easy.

I also need activate a solenoid valve for the shielding gases before the cut start and wait N seconds then run M3 S, it needs to stay on until there is no movement. I think I can do it with a m100 and classicladder.

Another thing is that I need to know exactly where the material is without touching it The fiber laser THC works with a capacitive THC which provides a voltage from 0 to 10V or a frequency depending on the height of the material with respect to the head. My idea was to use the hal comparator and set one of the values to a known frequency and to a known height, for example at 3mm, the frequency is 3khz when the laser head goes down and is with 3khz the output of the comparator will change that signal is net to motion.probe-input and i can do the probe routine.

But I don't know how to make the THC work. Z axis works normal with jog and in Gcode.

Thanks.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

23 Mar 2022 00:14 #238056

by andypugh

Replied by andypugh on topic THC for laser

LinuxCNC is very modular, so if you mean linuxcnc.org/docs/html/man/man9/thc.9.html then it can work with anything, even with you typing in numbers from a ruler :-)The THC can work without PlasmaC ?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

23 Mar 2022 00:22 #238057

by andypugh

linuxcnc.org/docs/html/man/man9/hostmot2.9.html#pwmgen

But this suggests that the PWM frequency is a HAL pin, so you should be able to change it on-the-fly.

One way would be a G-code "analog output" using M67 linuxcnc.org/docs/html/gcode/m-code.html#mcode:m67

Replied by andypugh on topic THC for laser

This isn't a great manpage, and you definitely have to know where to look, so I am not surprised if you didn't find it:I plan to use M3 S command to laser-enable and S for modulation but i need to vary the frequency before starting the cut or by Gcode, which depends on the thickness of the material. To piercing i need one frequency (generally lower), and to cut another,

linuxcnc.org/docs/html/man/man9/hostmot2.9.html#pwmgen

But this suggests that the PWM frequency is a HAL pin, so you should be able to change it on-the-fly.

One way would be a G-code "analog output" using M67 linuxcnc.org/docs/html/gcode/m-code.html#mcode:m67

net some-phrase-about-pwm motion.analog-out-00 => hm2_7i93.0.pwmgen.0.pwm-frequencyPlease Log in or Create an account to join the conversation.

- Ronniecnc

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

24 Mar 2022 14:54 #238229

by Ronniecnc

Replied by Ronniecnc on topic THC for laser

Thank you very much for your response.

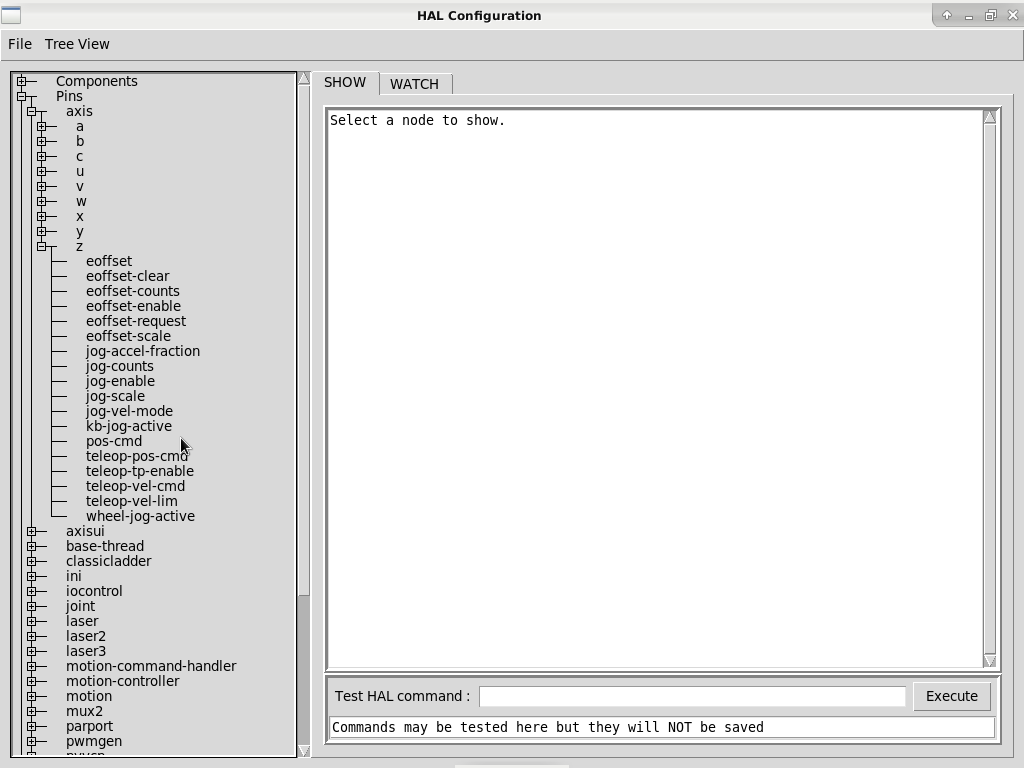

I have had many problems with THC comp, I do not know how to connect the thc feedback in the hal. I can't find the following pins in the hal config:

motor.02.pos-fb

axis.2.motor-pos-fb

And therefore I can not do the net thc.z-fb-out in hal

net motor.02.pos-fb axis.2.motor-pos-fb <= thc.z-fb-out

I found an old THC post with configuration in StepConf:

forum.linuxcnc.org/forum/search?query=th...er=inc&childforums=1

net zpos-cmd sum2.0.in0 <= axis.2.motor-pos-cmd

net zpos-sum sum2.0.out => stepgen.2.position-cmd

net zpos-fb stepgen.2.position-fb => axis.2.motor-pos-fb

net zoffset sum2.0.in1 <= pyvcp.OffsetDial

The same i cant pin axis.2.motor-pos-fb.So i swapped them for these:

net zpos-cmd joint.2.motor-pos-cmd sum2.0.in0

net zpos-sum sum2.0.out => stepgen.2.position-cmd

net zpos-fb stepgen.2.position-fb => joint.2.motor-pos-fb

net zoffset sum2.0.in1 <=

It works but Linuxcnc throws me " joint 2 following error " the only way i found to work is by changing MIN_FERROR to MIN_FERROR = 100

I have had many problems with THC comp, I do not know how to connect the thc feedback in the hal. I can't find the following pins in the hal config:

motor.02.pos-fb

axis.2.motor-pos-fb

And therefore I can not do the net thc.z-fb-out in hal

net motor.02.pos-fb axis.2.motor-pos-fb <= thc.z-fb-out

I found an old THC post with configuration in StepConf:

forum.linuxcnc.org/forum/search?query=th...er=inc&childforums=1

net zpos-cmd sum2.0.in0 <= axis.2.motor-pos-cmd

net zpos-sum sum2.0.out => stepgen.2.position-cmd

net zpos-fb stepgen.2.position-fb => axis.2.motor-pos-fb

net zoffset sum2.0.in1 <= pyvcp.OffsetDial

The same i cant pin axis.2.motor-pos-fb.So i swapped them for these:

net zpos-cmd joint.2.motor-pos-cmd sum2.0.in0

net zpos-sum sum2.0.out => stepgen.2.position-cmd

net zpos-fb stepgen.2.position-fb => joint.2.motor-pos-fb

net zoffset sum2.0.in1 <=

It works but Linuxcnc throws me " joint 2 following error " the only way i found to work is by changing MIN_FERROR to MIN_FERROR = 100

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.078 seconds