THCAD-10 series resistor values

- chowderhead

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 12

23 Jun 2022 15:36 #245692

by chowderhead

THCAD-10 series resistor values was created by chowderhead

Hi, All:

I'm planning on using a THCAD-10 on a plasma welding (not cutting) system that applies a 6kV HF start and is expected to run ~20V during welding. I'll be connecting directly to the power lugs on the welder and read here that 1M series resistors are used in both positive and negative circuits for plasma cutters, which apply ~15-30kV startup potentials. I have two questions, one is to satisfy my curiosity, the other practical:

1) How do the 1M series resistors keep the THCAD-10 from frying when there's 15-30kV across the inputs?

2) Should I use 500k resistors since only a 6kV startup potential is applied on the welder? I want as high resolution as I can get.

Thanks for all your hard work - LinuxCNC is a gift to humanity!

I'm planning on using a THCAD-10 on a plasma welding (not cutting) system that applies a 6kV HF start and is expected to run ~20V during welding. I'll be connecting directly to the power lugs on the welder and read here that 1M series resistors are used in both positive and negative circuits for plasma cutters, which apply ~15-30kV startup potentials. I have two questions, one is to satisfy my curiosity, the other practical:

1) How do the 1M series resistors keep the THCAD-10 from frying when there's 15-30kV across the inputs?

2) Should I use 500k resistors since only a 6kV startup potential is applied on the welder? I want as high resolution as I can get.

Thanks for all your hard work - LinuxCNC is a gift to humanity!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

23 Jun 2022 16:17 #245696

by tommylight

Replied by tommylight on topic THCAD-10 series resistor values

Plasma welding?

In that case we need to know how the pilot arc works exactly and what does it use to strike the arc.

Plasma cutting strikes the arc between the nozzle and the electrode on inside the torch, while cutting is done between electrode and material. Meaning the THCAD never sees the full brunt of the 20KV ignition on both leads, hence not a "big" deal to protect from it.

Tig pilot is between electrode and material, so is the welding, so attaching the THCAD to it would most probably mess it up, although i never tried it, well yet!

All that out of the way, there is always a way to wire THCAD safely to all those, wire it directly to the rectifier output inside the box/welder/plasma/tig, as all of those must have protection against those 6 to 20KV going back to the rectifier that is usually rated at 1000V.

I have several (6 or 7 or 9 or...) of THCAD300 working with high frequency/high voltage start plasma's, despite all the warnings that they should not be used in those cases, they are all fine and dandy working 10-12 hours a day, every day, except for some of them on Sundays. They are all wired to the rectifier.

In that case we need to know how the pilot arc works exactly and what does it use to strike the arc.

Plasma cutting strikes the arc between the nozzle and the electrode on inside the torch, while cutting is done between electrode and material. Meaning the THCAD never sees the full brunt of the 20KV ignition on both leads, hence not a "big" deal to protect from it.

Tig pilot is between electrode and material, so is the welding, so attaching the THCAD to it would most probably mess it up, although i never tried it, well yet!

All that out of the way, there is always a way to wire THCAD safely to all those, wire it directly to the rectifier output inside the box/welder/plasma/tig, as all of those must have protection against those 6 to 20KV going back to the rectifier that is usually rated at 1000V.

I have several (6 or 7 or 9 or...) of THCAD300 working with high frequency/high voltage start plasma's, despite all the warnings that they should not be used in those cases, they are all fine and dandy working 10-12 hours a day, every day, except for some of them on Sundays. They are all wired to the rectifier.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

23 Jun 2022 16:18 #245697

by tommylight

Replied by tommylight on topic THCAD-10 series resistor values

I wholeheartedly agree.

Thanks for all your hard work - LinuxCNC is a gift to humanity!

Please Log in or Create an account to join the conversation.

- chowderhead

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 12

24 Jun 2022 14:56 #245792

by chowderhead

Replied by chowderhead on topic THCAD-10 series resistor values

Ah, hadn't thought about where the arc is started. The system I'm using starts the arc inside the nozzle then transfers the plasma to the workpiece when welding power is applied, which sounds like the same method used for plasma cutting.

I like the idea of connecting to the rectifier. Can you provide guidance on identifying it? I have no schematics.

And, seriously, LinuxCNC is awesome, second only to Debian in my list of favorite FOSS. I love working with it and am regularly blown away by how flexible it is.

I like the idea of connecting to the rectifier. Can you provide guidance on identifying it? I have no schematics.

And, seriously, LinuxCNC is awesome, second only to Debian in my list of favorite FOSS. I love working with it and am regularly blown away by how flexible it is.

Please Log in or Create an account to join the conversation.

- chowderhead

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 12

24 Jun 2022 16:16 #245796

by chowderhead

Replied by chowderhead on topic THCAD-10 series resistor values

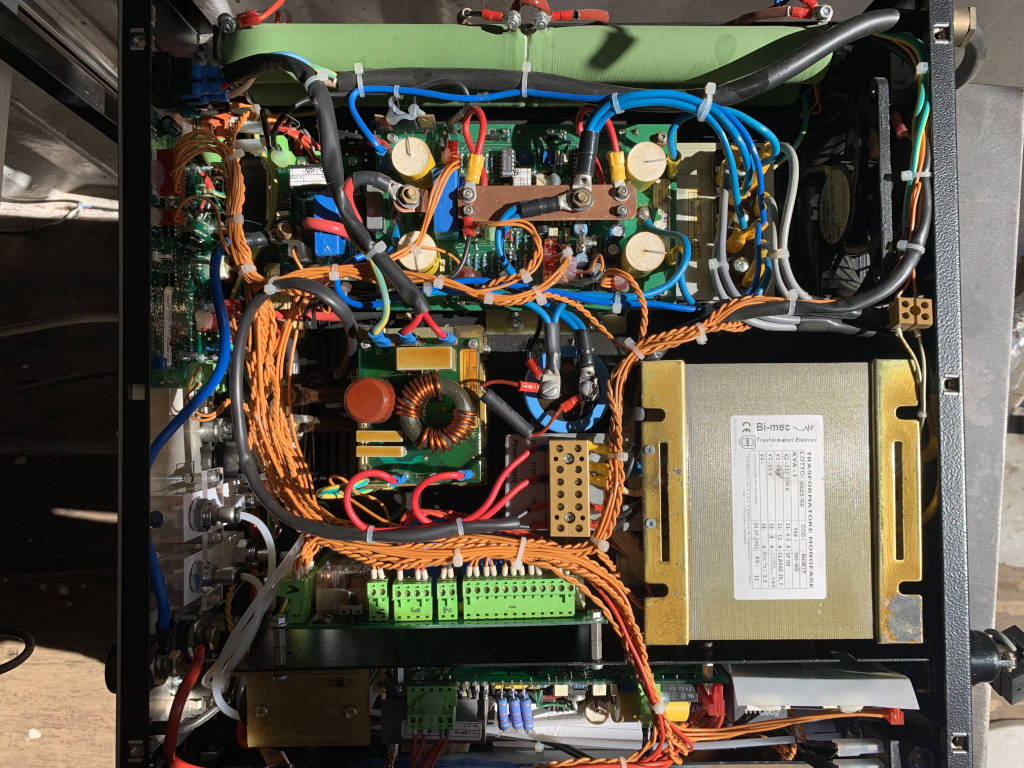

I think I found the rectifier. Right after the transformer, stuck to the biggest heatsink in the box. Even has a couple of nice taps for me to use.

Just to confirm, to maximize resolution, the series resistance should be set per the equation in the THCAD manual for the welder's open circuit voltage (65V), yes? Is it necessary halve it and install a resistor on each of the legs?

Just to confirm, to maximize resolution, the series resistance should be set per the equation in the THCAD manual for the welder's open circuit voltage (65V), yes? Is it necessary halve it and install a resistor on each of the legs?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

24 Jun 2022 16:17 #245797

by tommylight

Replied by tommylight on topic THCAD-10 series resistor values

Take some pictures of the insides and post them here.

Please Log in or Create an account to join the conversation.

- chowderhead

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 12

24 Jun 2022 16:36 - 24 Jun 2022 16:42 #245799

by chowderhead

Replied by chowderhead on topic THCAD-10 series resistor values

Attachments:

Last edit: 24 Jun 2022 16:42 by chowderhead. Reason: Add picture?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.104 seconds