Almost done but questions

- cere19

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 2

03 Mar 2024 12:22 #295026

by cere19

Almost done but questions was created by cere19

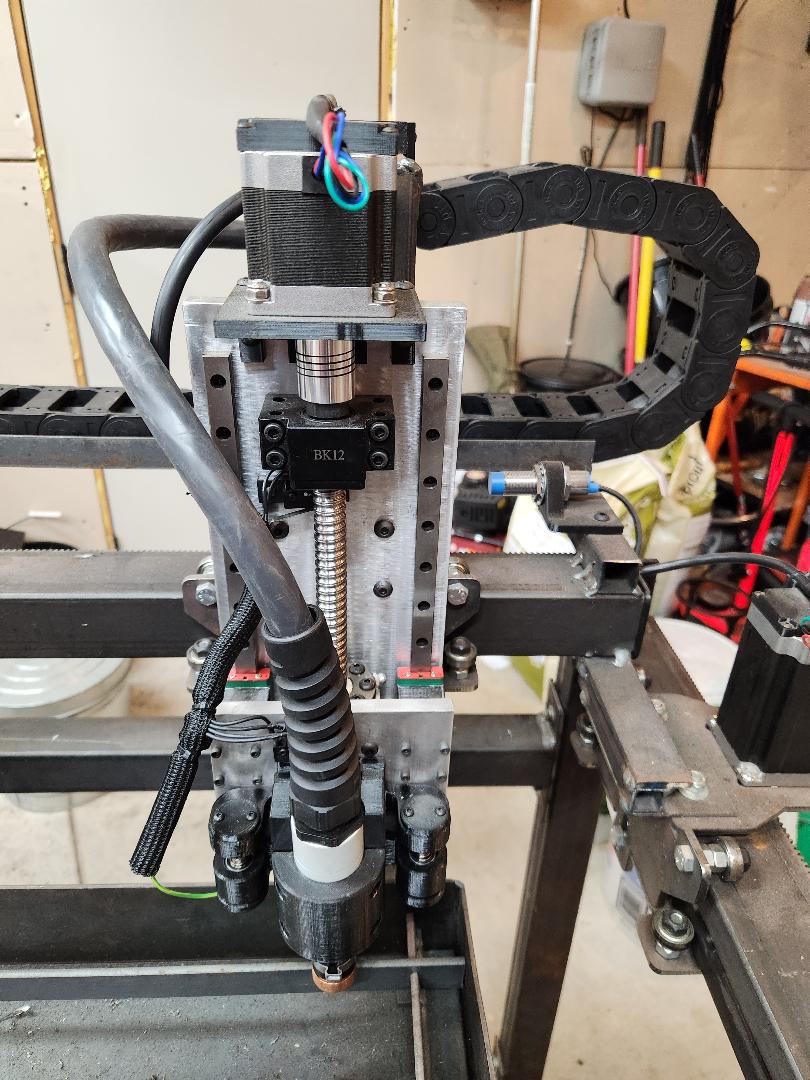

Been working on building my 2' x 4' table for a couple years but have a young family. I want to finally get it done and I may of known my plan at times but with breaks in the build I have forgotten all the details. Table is built I literally have a small list of items to do but need help. I plan to have both Torch Height Control and Ohmic Sensing, I have the Hypertherm 45XP with the port on the back that I will be using on this table. Have a small Hypertherm machine torch that I purchased because I didn't want the long version of the Hypertherm Machine Torch with the added weight. This table will be using rack and pinion for movement on the X and Y axis and a ball screw for the Z axis that I designed and built. Have a water pan that I made to cut down on the dust.

Rundown of parts that I have for this

Mesa 7I96 card and Mesa THCAD-10 for the Torch Height Control and THCAD-5 for the Ohmic Sensing

4 of TB6600 drivers from Amazon

3 of Nema 23 Bipolar 1.8deg 2.4Nm(339.87oz.in) 1.8A 57x57x104mm 4 Wires

1 of Nema 23 CNC Stepper Motor 2.8A 178.4oz.in/1.26Nm CNC Stepping Motor

1 of Meanwell MDR-40-24 to power stepper motors

1 of Meanwell MDR-20-5 to power the 5V on the board and other small power needs

Sensors I have homing on the X and Y's and also have max on those axis's as well

Z axis I have the spring loaded for homing and then I have a max travel as well

Questions I have

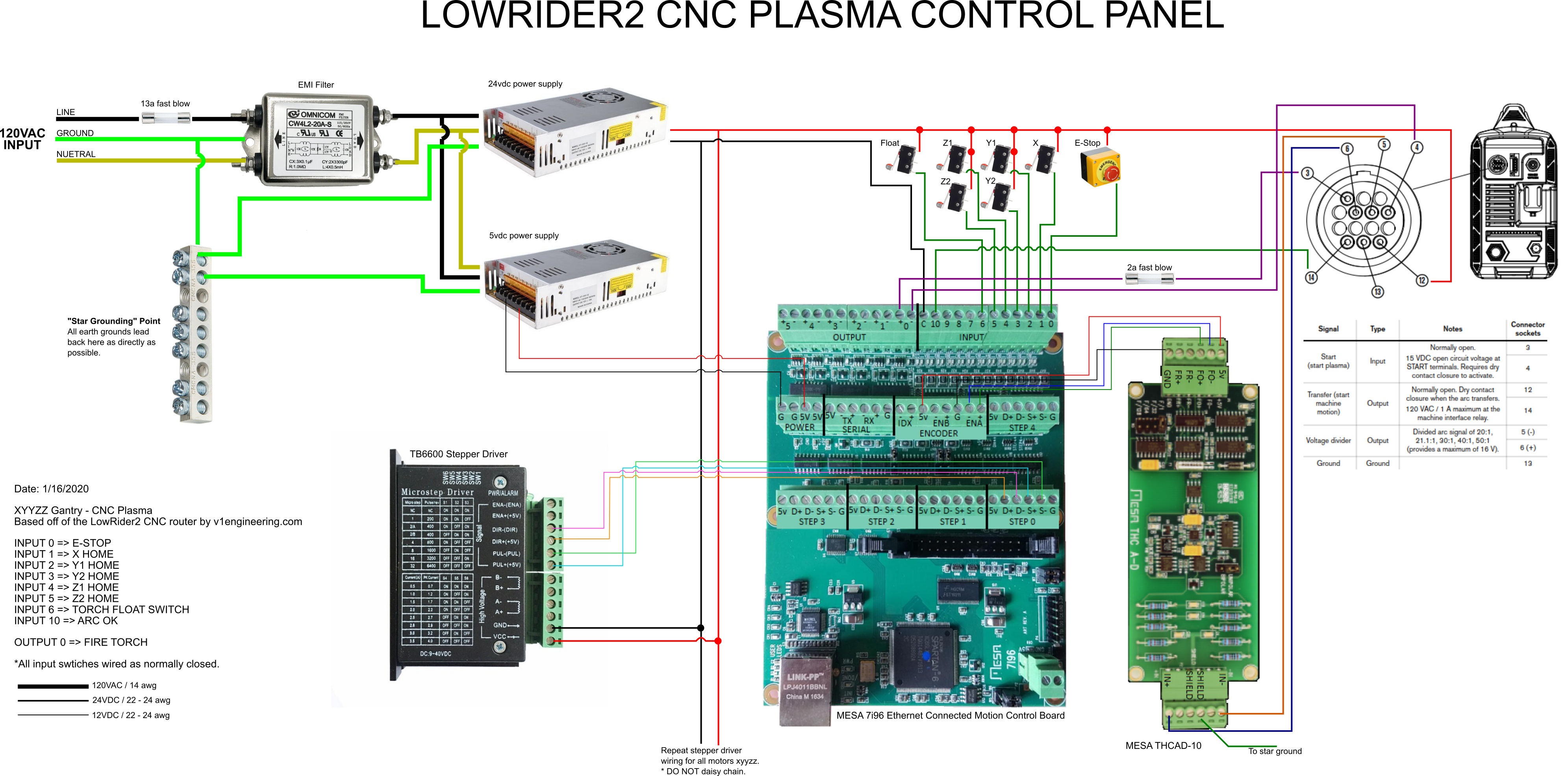

I've been using the below diagram that I had found on a different post for my wiring.

Thanks in advance

Mike

Rundown of parts that I have for this

Mesa 7I96 card and Mesa THCAD-10 for the Torch Height Control and THCAD-5 for the Ohmic Sensing

4 of TB6600 drivers from Amazon

3 of Nema 23 Bipolar 1.8deg 2.4Nm(339.87oz.in) 1.8A 57x57x104mm 4 Wires

1 of Nema 23 CNC Stepper Motor 2.8A 178.4oz.in/1.26Nm CNC Stepping Motor

1 of Meanwell MDR-40-24 to power stepper motors

1 of Meanwell MDR-20-5 to power the 5V on the board and other small power needs

Sensors I have homing on the X and Y's and also have max on those axis's as well

Z axis I have the spring loaded for homing and then I have a max travel as well

Questions I have

- Will the 2 power supplies be sufficient?

- THCAD-5 wiring I'm assuming this is wired like the THCAD-*10 for Torch Height except the + is from the tip of the torch and the - is from the water table?

- Stepper motors will they be strong enough? I purchased them several years ago and was trying to watch my spend at the time.

- I have seen others gearing down their stepper motors I think 3:1, I currently wasn't planning on it will this cause me issues?

- I was planning to run water in the water table but I live in Minnesota so it get's cold and can freeze even in the garage, is there something else that people recommend in the cold climates?

I've been using the below diagram that I had found on a different post for my wiring.

Thanks in advance

Mike

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21317

- Thank you received: 7279

03 Mar 2024 13:06 #295033

by tommylight

Replied by tommylight on topic Almost done but questions

1 what is the current/power rating for the 24V one?

2 torch lead is negative on plasma cutters, always, clamp is positive

3 yes

4 gearing helps a lot, more torque, less vibration, smooth motion, better resolution

5 never use antifreeze! you can add alcohol although not a smart idea, fire and stuff. I just add baking soda to prevent rusting, nothing else. You can add food coloring to make it pretty while not in use.

2 torch lead is negative on plasma cutters, always, clamp is positive

3 yes

4 gearing helps a lot, more torque, less vibration, smooth motion, better resolution

5 never use antifreeze! you can add alcohol although not a smart idea, fire and stuff. I just add baking soda to prevent rusting, nothing else. You can add food coloring to make it pretty while not in use.

Please Log in or Create an account to join the conversation.

- cere19

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 2

03 Mar 2024 13:50 - 03 Mar 2024 13:55 #295043

by cere19

Replied by cere19 on topic Almost done but questions

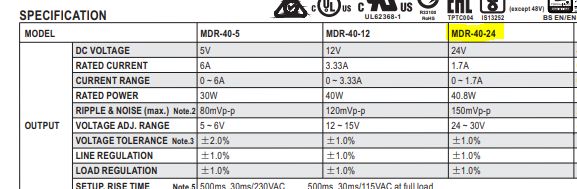

This is the table I just pulled up on the 24V power supply, I'm thinking it's 0-1.7 Amps

Thanks for the info on the torch being negative will wire it that way

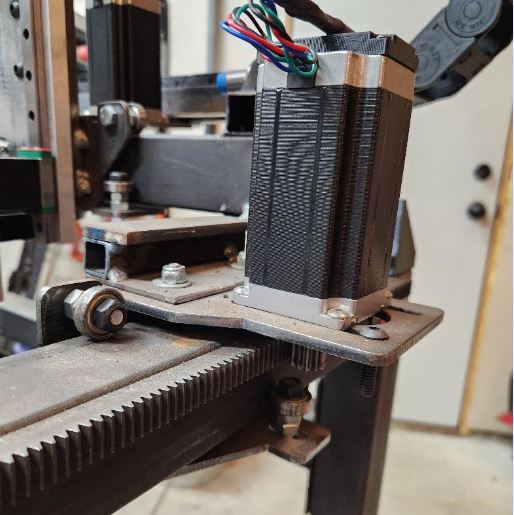

Gearing I'll try to figure out a way to gear it down with this type of bracket

How much baking soda? I had never considered antifreeze or alcohol so I will steer clear of them and use the baking soda like you recommended. Didn't know of fluid because I've seen others purchase a type of fluid before but can't remember what it was.

Thanks for the info on the torch being negative will wire it that way

Gearing I'll try to figure out a way to gear it down with this type of bracket

How much baking soda? I had never considered antifreeze or alcohol so I will steer clear of them and use the baking soda like you recommended. Didn't know of fluid because I've seen others purchase a type of fluid before but can't remember what it was.

Attachments:

Last edit: 03 Mar 2024 13:55 by cere19. Reason: Pictures showed as a weird mess of letters

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21317

- Thank you received: 7279

03 Mar 2024 14:14 #295046

by tommylight

Replied by tommylight on topic Almost done but questions

Yeah, i was sure from the model number that it was a 40W one, so no that is not enough for safely running the machine, but will do just fine for testing and setting up the machine while you wait for another bigger one, say 250W or 400W, see if you can find a 36V one for motors/drives and leave the 24V one for Mesa stuff if you need it for sensors and/or relays, or ohmic probing if you intend to use that.

Baking soda, half a kilo or one pound, it is dirt cheap at 2 Euro/KG here.

-

Antifreeze uses Glycol, not god for ingesting, even worse when boiled.

Alcohol would evaporate very quickly risking to make the perfect mix of fuel/air and boom! Chances are pretty slim, but in a small closed shop, those chances go sky high. Reminds me, never ever cut with plasma in a small enclosed space, it is evaporating metal, not nice to breathe in.

The specialized coolants on sale for plasma are just that, water with food coloring.

Baking soda, half a kilo or one pound, it is dirt cheap at 2 Euro/KG here.

-

Antifreeze uses Glycol, not god for ingesting, even worse when boiled.

Alcohol would evaporate very quickly risking to make the perfect mix of fuel/air and boom! Chances are pretty slim, but in a small closed shop, those chances go sky high. Reminds me, never ever cut with plasma in a small enclosed space, it is evaporating metal, not nice to breathe in.

The specialized coolants on sale for plasma are just that, water with food coloring.

Please Log in or Create an account to join the conversation.

- cere19

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 2

03 Mar 2024 16:21 #295063

by cere19

Replied by cere19 on topic Almost done but questions

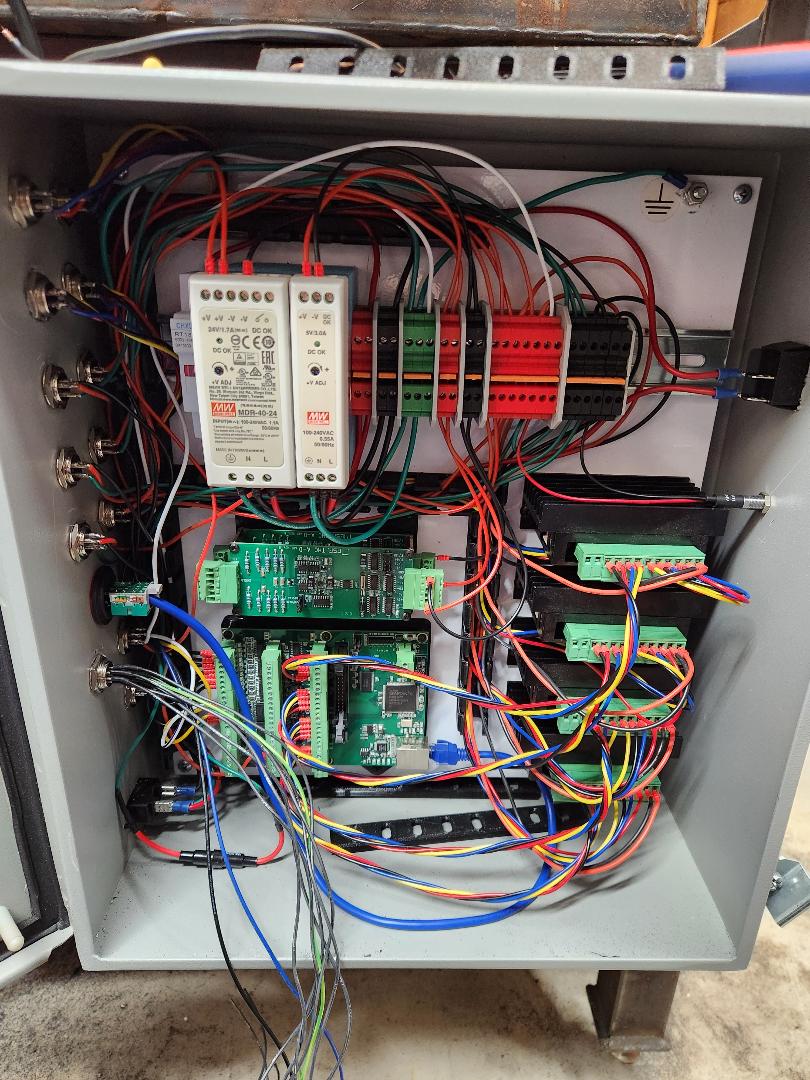

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21317

- Thank you received: 7279

03 Mar 2024 16:29 #295064

by tommylight

Replied by tommylight on topic Almost done but questions

Nice machine!

If you do not need to much current for the motors, try using the existing power supply, see if it trips when all 3 or4 motors are in use, if it does not trip = leave it as is.

If you do not need to much current for the motors, try using the existing power supply, see if it trips when all 3 or4 motors are in use, if it does not trip = leave it as is.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

03 Mar 2024 20:58 #295084

by rodw

Replied by rodw on topic Almost done but questions

I really wish somebody would burn that lowrider circuit diagram, its just plain wrong with its power supplies!

Its good to see you adding a 36 volt power supply!

As a rule of thumb the total power you can take from a power supply for steppers is about 1.4x based on the stepper motor current setting eg. an 11 amp supply will handle 15 amps of motors which is a bit over rated ror 8.2 amps of motors. 7 amp would be OK (eg 9.8 amps max motors) but may not save you much cash or space. The Meanwell 24v 1.7 amp power supply just won't cut it!

Its good to see you adding a 36 volt power supply!

As a rule of thumb the total power you can take from a power supply for steppers is about 1.4x based on the stepper motor current setting eg. an 11 amp supply will handle 15 amps of motors which is a bit over rated ror 8.2 amps of motors. 7 amp would be OK (eg 9.8 amps max motors) but may not save you much cash or space. The Meanwell 24v 1.7 amp power supply just won't cut it!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21317

- Thank you received: 7279

03 Mar 2024 21:38 #295091

by tommylight

Replied by tommylight on topic Almost done but questions

Yeah, that math is OK for servo systems, but for stepper systems the current rating on the power supply can go lower, much lower, but is a safe bet to make sure it will always work, and power supplies are cheap.

Stepper motors almost always have a Voltage rating besides current rating and step angle, there is a very good reason for that, as an example, 10A/1V stepper motor (this would count as low inductance motor) can be run safely from a 24V 0.5A power supply, including some losses along the way in drive and cabling.

To simplify the math 10A/1V motor with 10V/1A power supply and no losses. Adding 50% more for losses is always good, 100% is better, or just wing it and get the biggest one from all the motor currents.

-

Working examples,

-24V/1.5A power supply for 4 of 1.5A motors/drives, in use for over 10 years probably

-several machines with 32V/1.7A power supplies for 2 motors at 2.5A, 1 motor at 2A and 1 motor at 1.5A, all in daily use for several years.

-plenty of machines with laptop power supplies 19V/3.84A running 4 motors, usually all from 1.5-3A

Be warned that these are all low inductance motors form Japanese manufacturers!

Using high inductance motors will raise the required current and also limit the top speed the motors can achieve.

-

As for his 24V/1.7A power supply, if he has low inductance motors, he can easily push 1.5A per motor, so trying 1A per motor should be the first thing to do.

Power on the machine, make it move/dance/sing!

Stepper motors almost always have a Voltage rating besides current rating and step angle, there is a very good reason for that, as an example, 10A/1V stepper motor (this would count as low inductance motor) can be run safely from a 24V 0.5A power supply, including some losses along the way in drive and cabling.

To simplify the math 10A/1V motor with 10V/1A power supply and no losses. Adding 50% more for losses is always good, 100% is better, or just wing it and get the biggest one from all the motor currents.

-

Working examples,

-24V/1.5A power supply for 4 of 1.5A motors/drives, in use for over 10 years probably

-several machines with 32V/1.7A power supplies for 2 motors at 2.5A, 1 motor at 2A and 1 motor at 1.5A, all in daily use for several years.

-plenty of machines with laptop power supplies 19V/3.84A running 4 motors, usually all from 1.5-3A

Be warned that these are all low inductance motors form Japanese manufacturers!

Using high inductance motors will raise the required current and also limit the top speed the motors can achieve.

-

As for his 24V/1.7A power supply, if he has low inductance motors, he can easily push 1.5A per motor, so trying 1A per motor should be the first thing to do.

Power on the machine, make it move/dance/sing!

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.323 seconds