- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

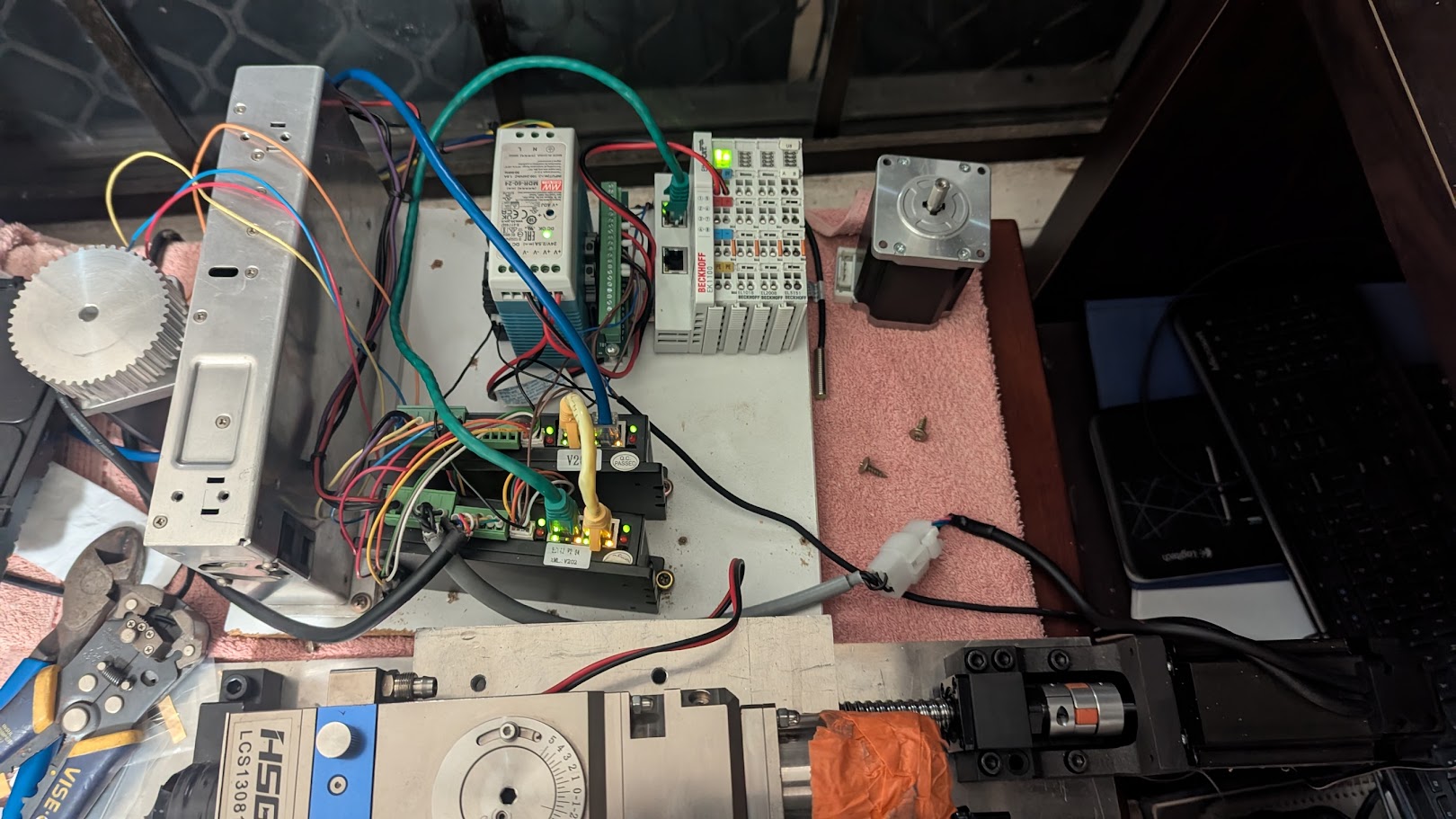

I would be happy to buy your sensor, but delivery to our country does not work. If possible, share basic information about your developments (source code is not needed), this is very interesting and can motivate many to develop their own sensors. From simple ideas, study the BCL-AMP circuit and create on one board together with a fast microcontroller (like on BCS100) and EtherCAT on LAN9252.

Several people have analyzed BCL-AMP circuits – these are very simple LC generators built from just a few basic components like here:

BCL-AMP

Someone even posted a example schematic like the one below (not the same device but simply).

I tested it, and it works, but as you correctly pointed out, it requires advanced processing, like in BCS-100 controllers, for example, which is not a small cost. I had to look for other methods, and measuring the charging/discharging time of a capacitance with a very small variable current turned out to be a more effective approach, so I pursued that direction. The output interface is a completely separate matter – I chose a simple 0-10V signal and a variable frequency range of 20 kHz - 70 kHz.

Attachments:

Please Log in or Create an account to join the conversation.

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

delivery to our country does not work.

Where are you from ?

Please Log in or Create an account to join the conversation.

- stkvit

- Offline

- New Member

-

- Posts: 5

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

I was thinking about differential signals and if there is such a need I will introduce them, we will see after the tests. There was only one obstacle - I wanted to leave the size of the device exactly like most BCL type sensors so that it would fit perfectly in the place designated for it. I did not find a suitable connector convenient to use to accommodate so many cables. I thought about RJ45 but it gave rise to other problems.I converted the bcl-amp output to a differential signal (max485), at a long length it works much more stably and reliably. You should do the same (I understand that your frequency is linear and depends only on the height). A couple more questions, your sensor have temperature stabilization?

Fortunately, such a converter is not a problem and it can be added even externally along with galvanic separation, which is missing here.

Of course the temperature stabilization is needed - now introduced very basic and weak, it requires refinement. This still requires a lot of time. I have to collect a lot of measurement data and refine the algorithm but I am prepared for it. The current implementation should be completely sufficient for tests. There are other sensors apart from temperature that are more difficult to control and that spoil the measurement during cutting (dielectric parameters of the gas surrounding the nozzle).

Please Log in or Create an account to join the conversation.

- stkvit

- Offline

- New Member

-

- Posts: 5

- Thank you received: 0

I will reveal the details that I found out on my own and were hard to find on the Internet:As for AD7745/AD7746, I tried to use it as a controller for gas burners. It was not easy because it worked on the desk, but during cutting, the gas changed the parameters very much and the AD7745/AD7746 measurement method was not suitable.1. It is not suitable for lasers because the reading is too slow 90Hz.To make sense for Lasers, the absolute minimum sampling is 500Hz (2ms), I have 3650Hz sampling but I do not want/cannot reveal why this value is chosen and it should be selected for a specific type of processing.2. AD7745/AD7746 have a measurement range of 17pF (60pF tollerant), which is definitely too little because the parasitic capacitances on the wire, head, etc. are 50-200pF3. The useful measurement range of the distance is 0.1pF - 30pF, although for some types of nozzles the range may be wider4. I chose the method of measuring the capacitance charging time, although I also experimented with measuring the frequency as in BCL-AMP BCS, which was a bit less stable but also very good.5. Unfortunately, I did not find any ready-made circuit like AD7745/AD7746 that would be suitable, and I had to design everything from scratch.

Please Log in or Create an account to join the conversation.

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

You have a very lot of knowledge so I think that you will be able to create such a open-source sensor using any of basic methods. The easiest way is to use one of ready to use CHIPs that you gave as an example ( now i haven't time to analise it / *conversion time should be fast ) or add any converter to good and very cheap BCL 1-3MHz generator.

I everything projected handly without use ready to use external chips but it required a huge amount of time for experiments and optimal selection of component values. It was not easy.

Please Log in or Create an account to join the conversation.

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11664

- Thank you received: 3930

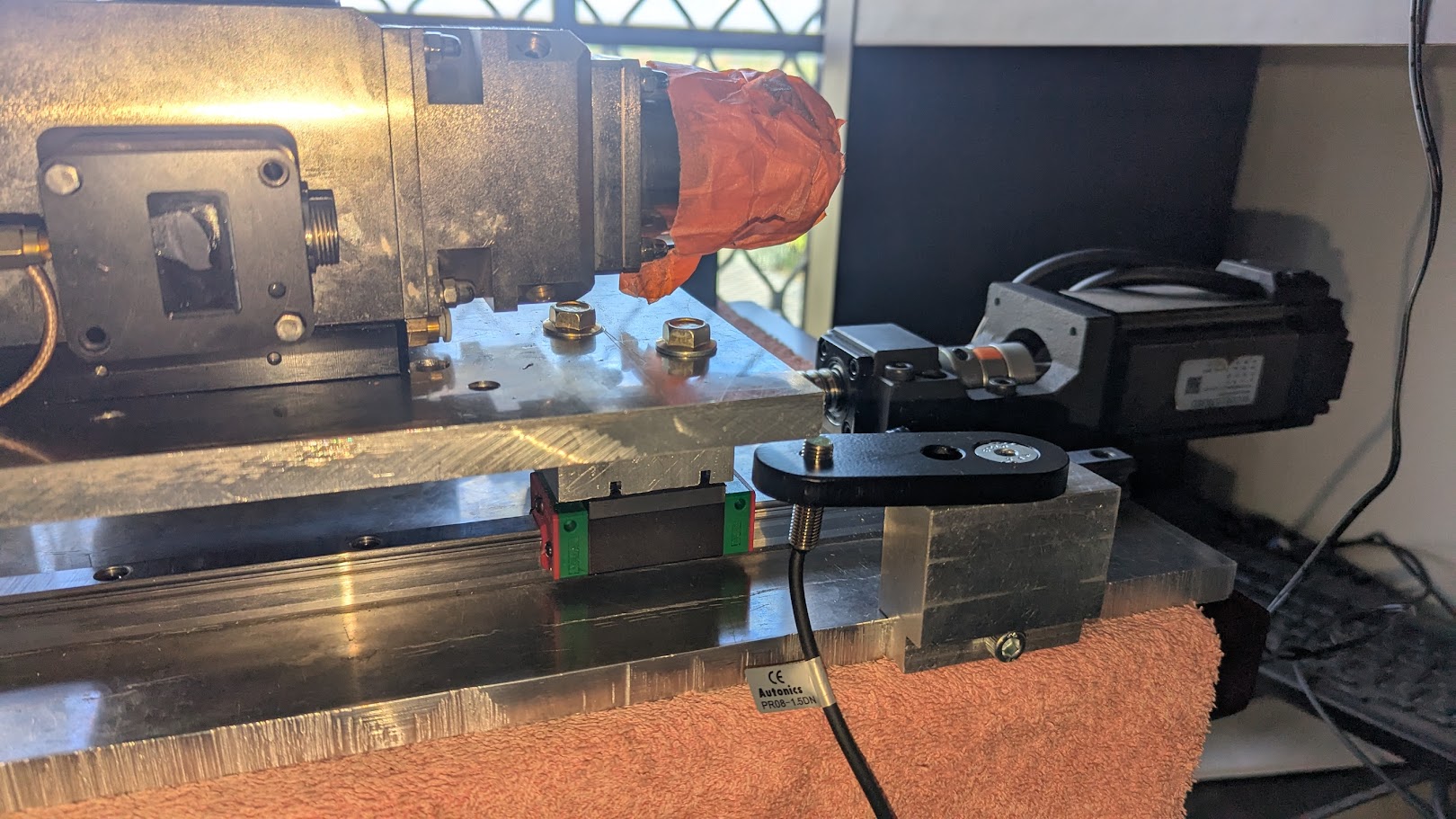

I still have to get the homing switch working. The 8mm sensor does not see the aluminium so it needs a strip of steel fitted

Attachments:

Please Log in or Create an account to join the conversation.

- prokopcio

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 35

- Thank you received: 23

But it's simply stepper motor only

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11664

- Thank you received: 3930

Please Log in or Create an account to join the conversation.

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Laser Head Height Sensor – Looking for a Beta Tester