home build cnc cutting fabric machine

- proff

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

31 May 2025 00:15 #329414

by proff

home build cnc cutting fabric machine was created by proff

hello all

I'm planning to build a fabric laser cutting machine

but as I have not enough space (and money) for buying a real machine and as I need to cut very long part, I've come up with an idea

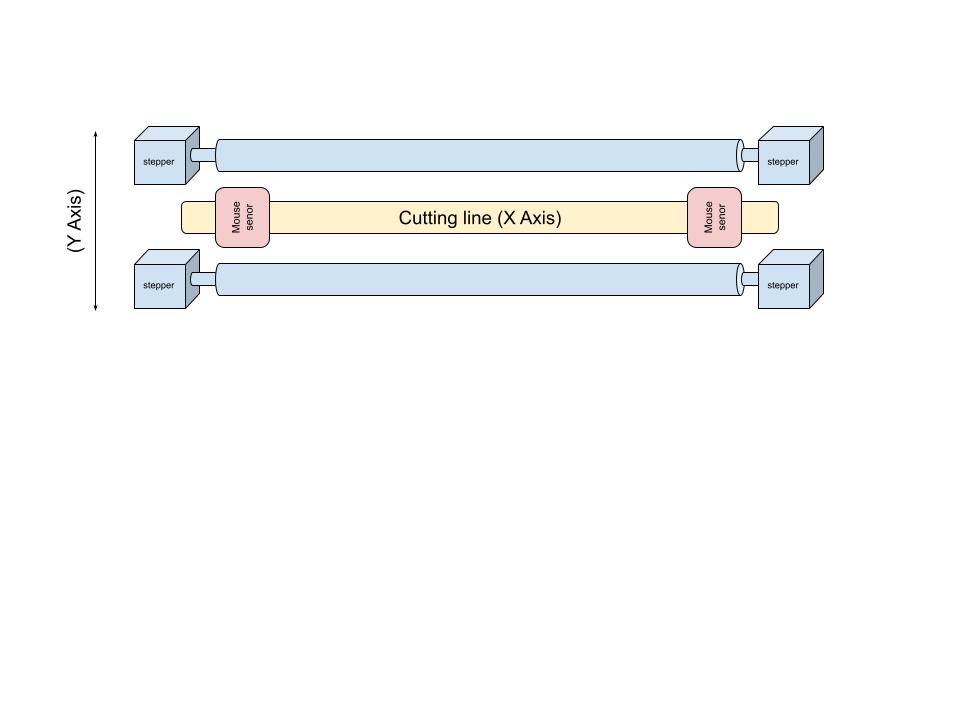

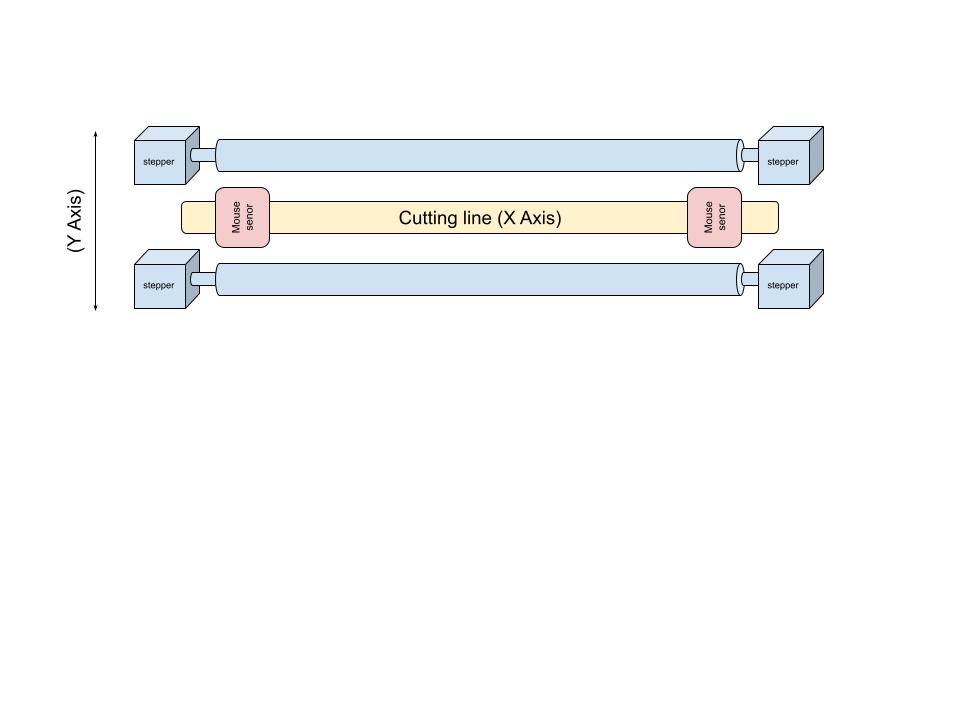

I will keep fabric on 2 rollers (1.5 m long) passing from one side on another from a cutting line (Y axis) with a moving laser diode head (X axis)

if it was so simple I would use a cheap 3D printer / cn machin controler but whatbrings me here is that I need a closed loop position controller

idea is that roller will be motorised by 2 motors ( left and right ) and will only working by pulling on fabric ( meaning that 2 motors will work in +Y and 2 in -Y) but I can't rely only on steps on motor to move accurately the fabric as depending on roller fabric diameter changing the distance of fabric moving on cutting line

on the other hand fabric can also moves on X axis when rolling and unrolling and objective is to use differential of both right and left motors to correct position

in my idea the close loop in postion control can be supporte by an optical mouse sensor that can track X and Y moves and I can put 2 on each side right and left

my question is: is linux cnc can be configured to adapt of this strange machine ?

I'm planning to build a fabric laser cutting machine

but as I have not enough space (and money) for buying a real machine and as I need to cut very long part, I've come up with an idea

I will keep fabric on 2 rollers (1.5 m long) passing from one side on another from a cutting line (Y axis) with a moving laser diode head (X axis)

if it was so simple I would use a cheap 3D printer / cn machin controler but whatbrings me here is that I need a closed loop position controller

idea is that roller will be motorised by 2 motors ( left and right ) and will only working by pulling on fabric ( meaning that 2 motors will work in +Y and 2 in -Y) but I can't rely only on steps on motor to move accurately the fabric as depending on roller fabric diameter changing the distance of fabric moving on cutting line

on the other hand fabric can also moves on X axis when rolling and unrolling and objective is to use differential of both right and left motors to correct position

in my idea the close loop in postion control can be supporte by an optical mouse sensor that can track X and Y moves and I can put 2 on each side right and left

my question is: is linux cnc can be configured to adapt of this strange machine ?

Please Log in or Create an account to join the conversation.

- proff

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

31 May 2025 00:17 #329415

by proff

Replied by proff on topic home build cnc cutting fabric machine

thank's for any advice / idea / help

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21126

- Thank you received: 7217

31 May 2025 01:55 #329422

by tommylight

Replied by tommylight on topic home build cnc cutting fabric machine

Most probably, yes.

Stuff helpful to know:

-what is the maximum Y length in one go?

Stuff randomly wandering through my tired brain:

-would be easier to use ESP-CAM for side monitoring and adjustment

-encoders can be tracking the material on both sides as LinuxCNC can use 2 or more encoder feedback's for the same joint/axis

-see "bottle labeling machine" for the type of sensor used for aligning the labeling foil (stuck my finger between the cutting and gluing rollers on one of those 2 weeks ago, what a mess! )

)

Stuff helpful to know:

-what is the maximum Y length in one go?

Stuff randomly wandering through my tired brain:

-would be easier to use ESP-CAM for side monitoring and adjustment

-encoders can be tracking the material on both sides as LinuxCNC can use 2 or more encoder feedback's for the same joint/axis

-see "bottle labeling machine" for the type of sensor used for aligning the labeling foil (stuck my finger between the cutting and gluing rollers on one of those 2 weeks ago, what a mess!

The following user(s) said Thank You: proff

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 109

- Thank you received: 52

31 May 2025 04:23 #329424

by juliankoenig87

Replied by juliankoenig87 on topic home build cnc cutting fabric machine

Cool idea. I also think this shoul be possible.

I am thinking of servos instead of steppers. Reason is build in encoders (ok cl steppers have it too) and the possibility to change to torque mode. So the two pulling servos in position mode doing the move and the two servos in torque mode can build up adjustable tension.

This setup than could be used as an initial meassure of the layer thickness and correct values for that.

I can imagine some kind of tape at the sides for all corrections. Like the tape on the shaper woodworking cnc handheld machine (dont know the exact name right now). This way you can use a camera like system an be on track all the time I guess.

I am thinking of servos instead of steppers. Reason is build in encoders (ok cl steppers have it too) and the possibility to change to torque mode. So the two pulling servos in position mode doing the move and the two servos in torque mode can build up adjustable tension.

This setup than could be used as an initial meassure of the layer thickness and correct values for that.

I can imagine some kind of tape at the sides for all corrections. Like the tape on the shaper woodworking cnc handheld machine (dont know the exact name right now). This way you can use a camera like system an be on track all the time I guess.

The following user(s) said Thank You: proff

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4621

- Thank you received: 2045

31 May 2025 08:53 #329429

by Aciera

Replied by Aciera on topic home build cnc cutting fabric machine

I would think that your biggest issue is going to be the stretching of the fabric and that partly cut sections are going to get bunched up as you move the material back and forth.

The following user(s) said Thank You: proff

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11595

- Thank you received: 3898

31 May 2025 09:15 #329432

by rodw

Replied by rodw on topic home build cnc cutting fabric machine

Once the fabric is tensioned, linuxcnc should be able to use the joint axes to control 4 motors in unison. Normally, it is just used for 2 on both sides of a gantry but I know its Been used on a 4 joint Z axis where all 4 corners are lifted..

The following user(s) said Thank You: proff

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11595

- Thank you received: 3898

31 May 2025 09:16 #329433

by rodw

Replied by rodw on topic home build cnc cutting fabric machine

Oops, just thought. the tension should be able to be done using home offsets

Please Log in or Create an account to join the conversation.

- proff

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

01 Jun 2025 15:23 #329516

by proff

Replied by proff on topic home build cnc cutting fabric machine

hello every one thank's a lot for your supporting reviews

I will try to reply all your questions

maximumm Y length : could be mostly infinite but more probably arround 10 to 50 m as I'm mainly intrested in kite building (or hot air balloons if it works )

)

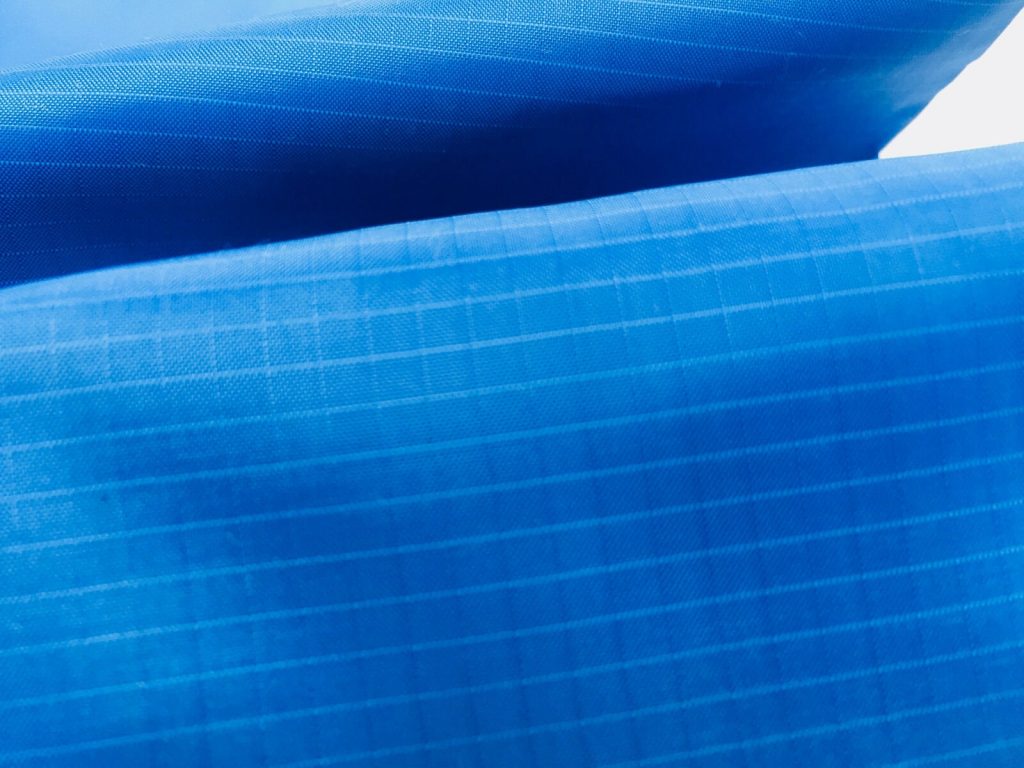

fabric to be cut will be mainly spinaker nylon witch is unstrechable and has 2 different sizes of frame that make a small patern easyly sens by optical mouse sensors

ESP cam is a great idea if it could keep track of move even when speed rising up mouse sensor is mainly a very low res grey scale cam

fabric tension : first idea was only to add a bit aof static friction on non pulling side motors but torque management is a good point too

it could also avoid me to do somthing I've not explain yet I was planning to make in cutting back plate 2 serries of holes and hook it to small but enough vacuum source to suck the fabric on the back plate and cut between tow lines of holes

to avoid wrinkles and other disasters when roolling and unrolling already cut parts I was thinking doing some kind of timestamping or tabs like on pcb pannels or others flat milling machines or wood or composites pannels

thank's for all your advice

now I think the best thing is to try few things

can you please advise me some harware in order to connect all of this

6 stepper controller (may be I will use one more small stepper to focus laser beam)

and 2 or 3 esp cam or mouse sensors (may be I can also get a closed loop on X axis)

I will try to reply all your questions

maximumm Y length : could be mostly infinite but more probably arround 10 to 50 m as I'm mainly intrested in kite building (or hot air balloons if it works

fabric to be cut will be mainly spinaker nylon witch is unstrechable and has 2 different sizes of frame that make a small patern easyly sens by optical mouse sensors

ESP cam is a great idea if it could keep track of move even when speed rising up mouse sensor is mainly a very low res grey scale cam

fabric tension : first idea was only to add a bit aof static friction on non pulling side motors but torque management is a good point too

it could also avoid me to do somthing I've not explain yet I was planning to make in cutting back plate 2 serries of holes and hook it to small but enough vacuum source to suck the fabric on the back plate and cut between tow lines of holes

to avoid wrinkles and other disasters when roolling and unrolling already cut parts I was thinking doing some kind of timestamping or tabs like on pcb pannels or others flat milling machines or wood or composites pannels

thank's for all your advice

now I think the best thing is to try few things

can you please advise me some harware in order to connect all of this

6 stepper controller (may be I will use one more small stepper to focus laser beam)

and 2 or 3 esp cam or mouse sensors (may be I can also get a closed loop on X axis)

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.073 seconds