- User Interfaces

- Other User Interfaces

- QtPyVCP

- Can't succesfully release Tool (according to Probe Basic GUI)

Can't succesfully release Tool (according to Probe Basic GUI)

- tsaG

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 4

09 Mar 2025 23:40 - 09 Mar 2025 23:49 #323569

by tsaG

Can't succesfully release Tool (according to Probe Basic GUI) was created by tsaG

Hi,

I am currently integrating my ATC. However, I get the Error "Failed to release Tool" message when I clamp the tool.

My HAL looks like the following. I get a 0-14V Signal which is converted into a HIGH LOW for the Motion controller.

I am currently integrating my ATC. However, I get the Error "Failed to release Tool" message when I clamp the tool.

My HAL looks like the following. I get a 0-14V Signal which is converted into a HIGH LOW for the Motion controller.

#ATC Settings

net analog1 hm2_7i76e.0.7i76.0.0.analogin1

setp comp.0.in1 10.0

net analog1 comp.0.in0

net ventil-spindel hm2_7i76e.0.7i76.0.0.output-12 <= motion.digital-out-02

net spindel-released comp.0.out <= motion.digital-in-02

In the HAL Show, I can see that spindle-released goes high when I press the "Release tool" button in the GUI. I also do not get an error message. However, when I insert the tool and click "clamp tool" I get the message "Failed to release tool" although everything works fine (and the spindle-released goes back to low).

I found that I need to connect the motion.digital-in-02 [url=https://github.com/dpslwk/probe_basic/tree/subroutine_unify_and_move_to_nc_files/linuxcnc/nc_files/probe_basic/atc_carousel]here on the PB Github (manual is hard to find).

I was unable to find more information on the PB Website. The current PB Github also doesn't have this Readme file/instructions.

Does anyone know what needs to be done here?

Thanks![/url]

Last edit: 09 Mar 2025 23:49 by tsaG.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1561

- Thank you received: 734

09 Mar 2025 23:48 #323572

by Lcvette

Replied by Lcvette on topic Can't succesfully release Tool (according to Probe Basic GUI)

Are you using a sensor for the drawbar?

Please Log in or Create an account to join the conversation.

- tsaG

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 4

09 Mar 2025 23:51 #323573

by tsaG

Replied by tsaG on topic Can't succesfully release Tool (according to Probe Basic GUI)

yes, that is the "spindle-released" sensor. As mentioned above I have to convert it to a binary value as the 14V is below the (60% of 24V) digital threshold of my 7i76e.

I can see the "spindle-released" going high when the drawbar is pulled (so, no error when releasing the tool) but get the error when clamping the tool.

I can see the "spindle-released" going high when the drawbar is pulled (so, no error when releasing the tool) but get the error when clamping the tool.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1561

- Thank you received: 734

09 Mar 2025 23:54 #323574

by Lcvette

Replied by Lcvette on topic Can't succesfully release Tool (according to Probe Basic GUI)

Then something in your hall isn't correct or in the macro. Maybe the delay time?

Please Log in or Create an account to join the conversation.

- tsaG

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 4

10 Mar 2025 00:03 - 10 Mar 2025 00:14 #323575

by tsaG

Replied by tsaG on topic Can't succesfully release Tool (according to Probe Basic GUI)

Hmm.. I see. I checked the clamp tool.ngc? I see that the script waits for the sensor to be high. As I connected the "release" sensor, my sensor is high when the spindle is released and not when the tool is clamped. Could this be the issue?

Does PB use two different scripts for releasing (which works) and clamping (which fails in my case)? Anyway, it looks like I need to invert the value in the script. However, then the debug text in the script should say "(abort, Failed to clamp tool) ; abort if the sensor does not activate in 2 seconds". Correct?

EDIT: Got it working by changing the LT to GT (waiting for it to be low). Is there a current list about the expected signals in PB? Like ATC drawbar to be connected to motion.digital-out-02, sensor to x, another sensor to y etc.

Does PB use two different scripts for releasing (which works) and clamping (which fails in my case)? Anyway, it looks like I need to invert the value in the script. However, then the debug text in the script should say "(abort, Failed to clamp tool) ; abort if the sensor does not activate in 2 seconds". Correct?

EDIT: Got it working by changing the LT to GT (waiting for it to be low). Is there a current list about the expected signals in PB? Like ATC drawbar to be connected to motion.digital-out-02, sensor to x, another sensor to y etc.

Last edit: 10 Mar 2025 00:14 by tsaG.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1561

- Thank you received: 734

10 Mar 2025 00:16 #323576

by Lcvette

Replied by Lcvette on topic Can't succesfully release Tool (according to Probe Basic GUI)

Those are just templates, you need to define and edit for your machines sensors and requirements. My machine uses two sensors one for clamped and one for released because it's only reporting when the plunger is actual at the released or clamped height. If you're have just one sensor that's high or low, than you may need to remove a line from the macro. The best thing to do is to map everything out and then review your sensors and the macro sensor inputs and ensure everything is accounted for.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1561

- Thank you received: 734

10 Mar 2025 00:41 #323579

by Lcvette

Replied by Lcvette on topic Can't succesfully release Tool (according to Probe Basic GUI)

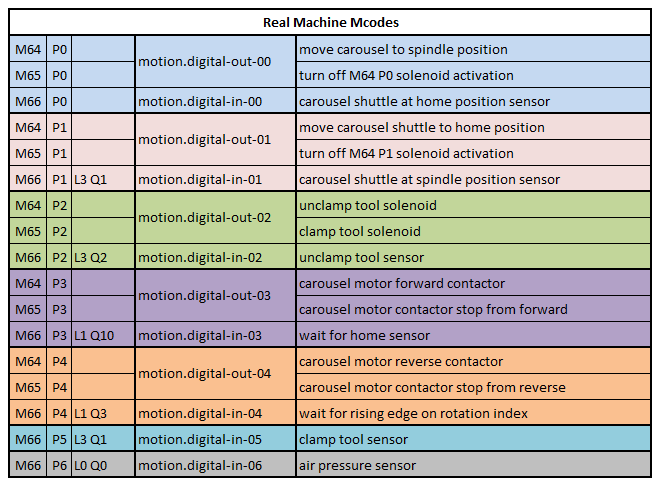

I made one for my machine, but i don't recall what was changed. you can use it as a template to create your own machines requirements and make sure the macros are correctly setup. the docs explain the different M-codes for DIO.

linuxcnc.org/docs/stable/html/gcode/m-code.html#mcode:m62-m65

linuxcnc.org/docs/stable/html/gcode/m-code.html#mcode:m66

again these are changed to work with my machine and may not completely align with the sim macro requirements:

linuxcnc.org/docs/stable/html/gcode/m-code.html#mcode:m62-m65

linuxcnc.org/docs/stable/html/gcode/m-code.html#mcode:m66

again these are changed to work with my machine and may not completely align with the sim macro requirements:

Attachments:

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1561

- Thank you received: 734

10 Mar 2025 00:45 #323581

by Lcvette

Replied by Lcvette on topic Can't succesfully release Tool (according to Probe Basic GUI)

changing LT is incorrect. you should instead rewrite the portion of the macro to correctly wait for the available signal. ie use the correct M66 Pn input so the macro verifies the drawbar is in fact in the correct position.

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

- User Interfaces

- Other User Interfaces

- QtPyVCP

- Can't succesfully release Tool (according to Probe Basic GUI)

Time to create page: 1.463 seconds