- User Interfaces

- Other User Interfaces

- QtPyVCP

- problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17732

- Thank you received: 5187

19 Nov 2025 14:52 - 19 Nov 2025 22:35 #338726

by PCW

Replied by PCW on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Are you dropping packets? that is, what is:

hm2_7i76e.0.packet-error-total

A dropped packet will result in a (bogus) following error spike,

as stale stepgen position (from the previous cycle) will be compared

with the commanded position. At a 2 ms servo thread period and 125 mm/sec

velocity, a .25 mm reported following error value is possible from a dropped

packet. Note the this does not mean that there is an actual path deviation

of this magnitude, this is bounded by the max_error PID pin to ~.0127 mm

per dropped packet.

I still think the physical error is most likely mechanical as it only shows up on Y.

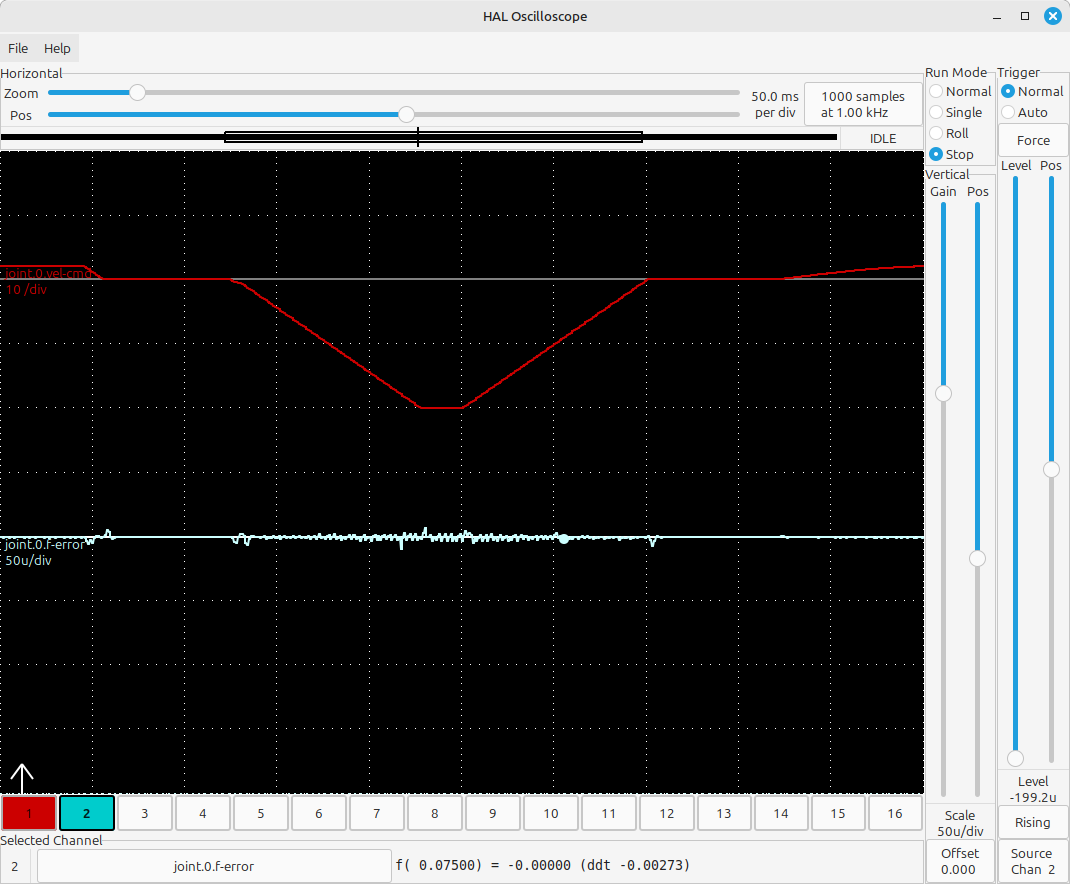

To diagnose stepgen errors, the best thing is to plot the following error

with halscope like this:

Note that this is in inches, but the velocity and acceleration are about 4x and 6X your machines values

and the inherent stepgen error is less than 0.25 micron.

Another possibility if the system latency is really bad, is loss of DPLL sync, so you might try increasing

the DPLL time from -250 to -500 usec

hm2_7i76e.0.packet-error-total

A dropped packet will result in a (bogus) following error spike,

as stale stepgen position (from the previous cycle) will be compared

with the commanded position. At a 2 ms servo thread period and 125 mm/sec

velocity, a .25 mm reported following error value is possible from a dropped

packet. Note the this does not mean that there is an actual path deviation

of this magnitude, this is bounded by the max_error PID pin to ~.0127 mm

per dropped packet.

I still think the physical error is most likely mechanical as it only shows up on Y.

To diagnose stepgen errors, the best thing is to plot the following error

with halscope like this:

Note that this is in inches, but the velocity and acceleration are about 4x and 6X your machines values

and the inherent stepgen error is less than 0.25 micron.

Another possibility if the system latency is really bad, is loss of DPLL sync, so you might try increasing

the DPLL time from -250 to -500 usec

Attachments:

Last edit: 19 Nov 2025 22:35 by PCW.

The following user(s) said Thank You: Muftijaja

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1584

- Thank you received: 742

19 Nov 2025 14:59 #338727

by Lcvette

Replied by Lcvette on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

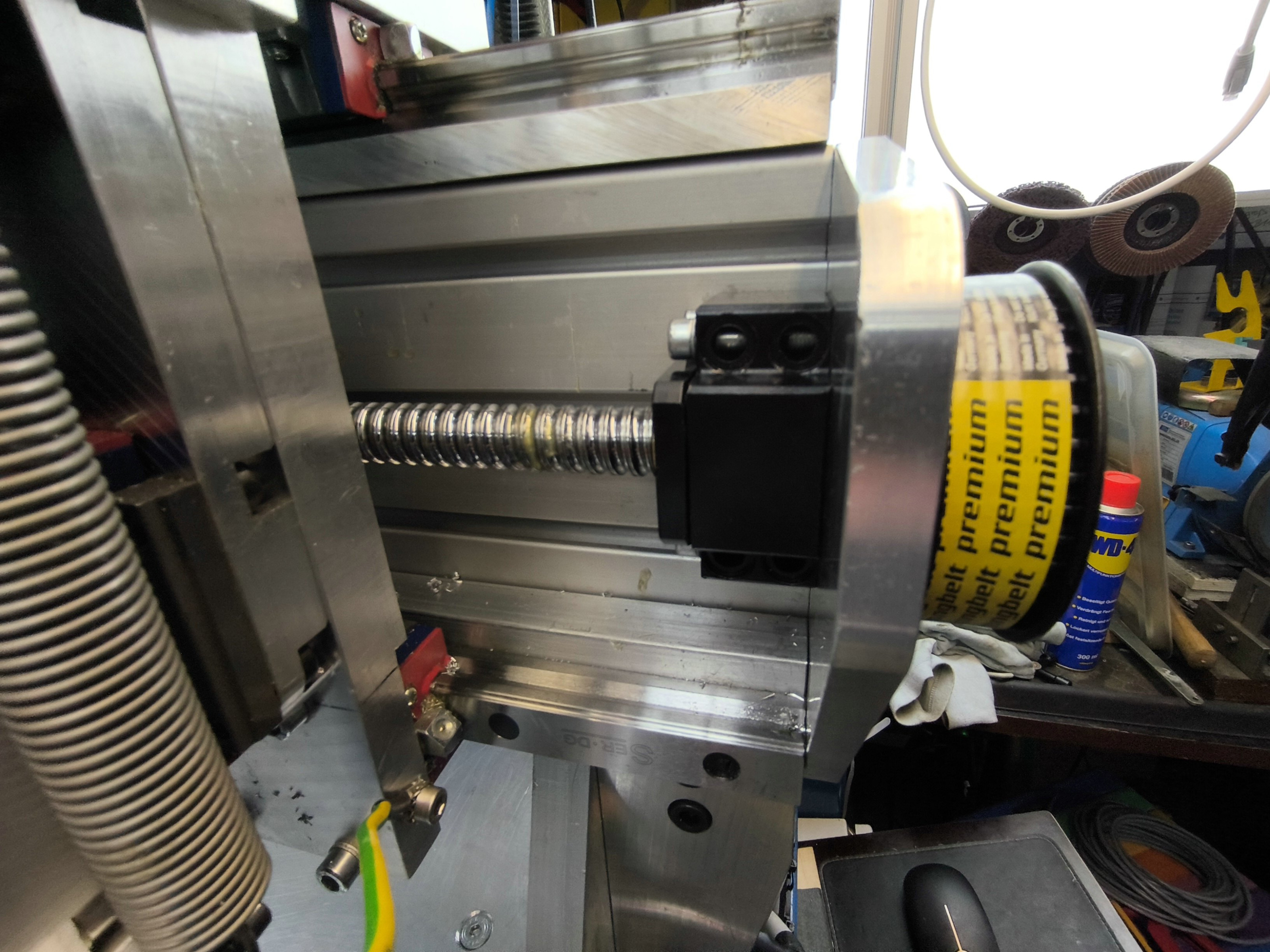

Also are those things correct for your steppers, they look big to me.

Please Log in or Create an account to join the conversation.

- Muftijaja

- Offline

- Premium Member

-

Less

More

- Posts: 102

- Thank you received: 4

20 Nov 2025 02:25 - 20 Nov 2025 02:26 #338766

by Muftijaja

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

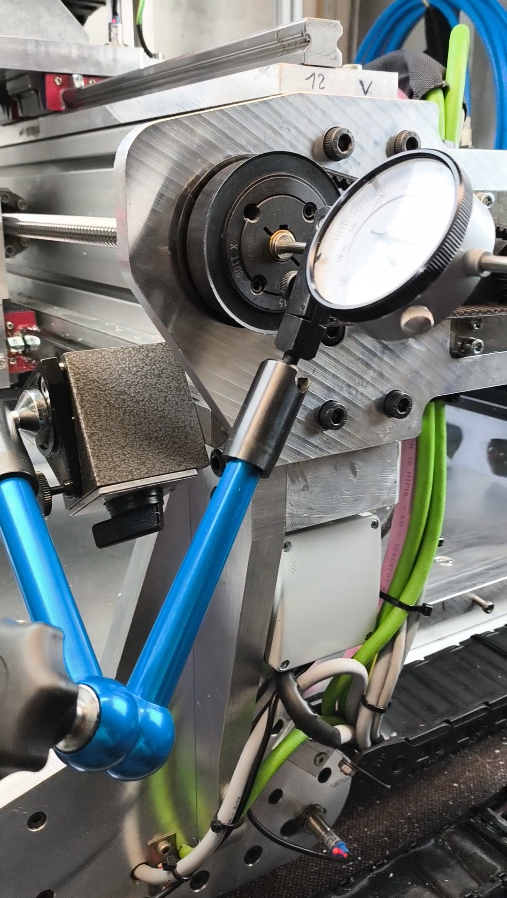

Thanks for your reply, Lcvette!The alarm comes at the motor, Lcnc does not even react on this, because my alarm loop does not work actually. I have to find out why, in the next steps. Yes, indeed, i have ballscrews and especially on Y, a C5 with double Nut. Yes, I know that paired bearings would be better, but i cannot afford them. The bearings are from NSK,and the dealer says I have to set a spacer in between (0.5mm) to set the backlash to exactly zero. Otherwise I would have a small amount of play within. So, I hope this information was ok. I know other bearings that are paired without backlash, but they are way more expensive. I took measurements today and found just 1/100mm backlash, measured at the end of the ballscrew. I found some more hundreds, measuring at high feeds, driven by my handwheel that makes stepping the axis, not smooth running, there were some more 2-3 hundreds, measured at the side part that holds the Bearing and the motor, I think it's a resonance of the whole system at that side. Maybe additionally triggered by the belt drive. Its a HTD15 mm belt, 2:1 reduction, same as at X axis. Belt tension is strong enough, I can move it just 5-6mm from above in the middle of the belt. Well, I dont have a feedback loop back to LCNC, the motor is a JMC 3.3 Nm Nema 24 CL Stepper with its own closed loop.

So, what FF do you mean, FF1 that is set to 1.0? Because somebody else said a tiny amount of maybe 0,003 should help too.

(photo from whole machine is not accepted althoug it is under 1 MB)

Thanks a lot for thinking about my problem!

Ahh just seeing your next posting - what exactly does seem too big for you!

So, what FF do you mean, FF1 that is set to 1.0? Because somebody else said a tiny amount of maybe 0,003 should help too.

(photo from whole machine is not accepted althoug it is under 1 MB)

Thanks a lot for thinking about my problem!

Ahh just seeing your next posting - what exactly does seem too big for you!

Attachments:

Last edit: 20 Nov 2025 02:26 by Muftijaja.

Please Log in or Create an account to join the conversation.

- Muftijaja

- Offline

- Premium Member

-

Less

More

- Posts: 102

- Thank you received: 4

20 Nov 2025 02:39 - 21 Nov 2025 21:24 #338767

by Muftijaja

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

PCW, thanks again for your hints!

Maybe you remember, that I have had that latency problem posted somewhere this year and had it solved. But, I will follow your advice and go through this process agein, tomorrow. I did never do that diagnosis with HALscope but I will do this, too.

Yes, my thoughts up to yesterday was mechanical fault but the measurements today say no. These hundreds that I found are totally acceptable for me, but the tenths not. I really don't know where these deviations come from. Maybe I check the latency again, and take a look at Halscope, and got to all screws that fix the Z axis.

BTW _ I made measurements at the milling spindle head with a spring scale: I got 1/10 in Y direction at 10 kg, 2/10th in X direction at 10kg, so this is way under my deviations at the milled part.

I will report my findings, thanks for your hints again!

Hanno

Maybe you remember, that I have had that latency problem posted somewhere this year and had it solved. But, I will follow your advice and go through this process agein, tomorrow. I did never do that diagnosis with HALscope but I will do this, too.

Yes, my thoughts up to yesterday was mechanical fault but the measurements today say no. These hundreds that I found are totally acceptable for me, but the tenths not. I really don't know where these deviations come from. Maybe I check the latency again, and take a look at Halscope, and got to all screws that fix the Z axis.

BTW _ I made measurements at the milling spindle head with a spring scale: I got 1/10 in Y direction at 10 kg, 2/10th in X direction at 10kg, so this is way under my deviations at the milled part.

I will report my findings, thanks for your hints again!

Hanno

Attachments:

Last edit: 21 Nov 2025 21:24 by Muftijaja.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1584

- Thank you received: 742

21 Nov 2025 16:09 - 21 Nov 2025 16:21 #338908

by Lcvette

Replied by Lcvette on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

i would review the stepper motor docs and make sure your timings match what the drives are looking for, this may help resolve your drive side following error, the timings are usually listed in a graph showing the uSec for step and dir and would be entered in the configuration file, yours seem quite big to me from what i am used too seeing.

the first thing I would be looking at is resolving the drive errors to ensure that what linuxcnc is commanding is actually being executed by the drive without faults, otherwise is doesn't matter what linuxcnc is sending. verify your stepper timings are set correctly, then try resetting the config to the basic stepper settings without any "fixes". test and ensure no drive faults and get another test cut measurement, once you have no drive faults you can begin troubleshooting the linuxcnc side of things. I would set any scaling to preliminary settings for the motion components advertised ratios such as lead and transmission reductions for pulleys. remove any fixes here from the equation so you have a good base point to start from. I have found that any deviations here will be very very small and certainly not in the realm of tenths of a mm. also remove any backlash compensation. you really want to run your test cuts without anything except the very base setting requirements to ensure something you did while running with drive faults isn't skewing your results.

other things to verify. drive settings for microstepping, ensure these are correctly set and not beyond what the drive can handle at 200khz step frequency and linuxcnc output. sometimes setting these a little more conservatively is better.

I also just saw in your ini config you shared that your step scale is different for x and y axis, but you state you are running the same screws and 2:1 reduction, the step scale here should be the same provided the drive microstepping settings are the same for both axis (and they should be) both should be set to the systems axis setting test with the least granular microstepping setting for continuity.

the first thing I would be looking at is resolving the drive errors to ensure that what linuxcnc is commanding is actually being executed by the drive without faults, otherwise is doesn't matter what linuxcnc is sending. verify your stepper timings are set correctly, then try resetting the config to the basic stepper settings without any "fixes". test and ensure no drive faults and get another test cut measurement, once you have no drive faults you can begin troubleshooting the linuxcnc side of things. I would set any scaling to preliminary settings for the motion components advertised ratios such as lead and transmission reductions for pulleys. remove any fixes here from the equation so you have a good base point to start from. I have found that any deviations here will be very very small and certainly not in the realm of tenths of a mm. also remove any backlash compensation. you really want to run your test cuts without anything except the very base setting requirements to ensure something you did while running with drive faults isn't skewing your results.

other things to verify. drive settings for microstepping, ensure these are correctly set and not beyond what the drive can handle at 200khz step frequency and linuxcnc output. sometimes setting these a little more conservatively is better.

I also just saw in your ini config you shared that your step scale is different for x and y axis, but you state you are running the same screws and 2:1 reduction, the step scale here should be the same provided the drive microstepping settings are the same for both axis (and they should be) both should be set to the systems axis setting test with the least granular microstepping setting for continuity.

Last edit: 21 Nov 2025 16:21 by Lcvette.

The following user(s) said Thank You: Muftijaja

Please Log in or Create an account to join the conversation.

- Muftijaja

- Offline

- Premium Member

-

Less

More

- Posts: 102

- Thank you received: 4

21 Nov 2025 22:22 #338928

by Muftijaja

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Hello Lcvette,

Thanks for your time and ideas!

The motor on the Y axis is a JMC iHSSC60-36-35-21-38-POCA. The manual says the pulse and pause should not be shorter than 2.5 µs; I have set this in the .ini file to 2,500 ns. This worked fine until now. Today, I changed this to 4000 ns, thinking it would be safer. After that change, an error occurred: 'stepgen.01.maxvel is too big for current step timings and position scale; clipping to maximum possible', so I reduced my Vel settings to 100 mm/s and 125 for overhead. This means that I cannot drive the axis at 7.5 m/min as before, but only at 6 m/min. I would accept this if the axis runs correctly afterwards. I will check this tomorrow.

Indeed, I change the motor-spindle gear in the X-axis a while ago to 20/32 teeth, which gives me a 640-step scale on the X-axis. This is not 1:2 as in the Y-axis, but 1:1.25.

My motor settings are 2000 steps/rev, which is not a problem for the motor or LCNC. The motor can run up to a frequency of 200 kHz, but I did tests with an oscillator and found the limit to be 180 kHz. So, 4000 ns will be safer.

Could the motor be losing steps at the shorter 2500 setting? I mean, it's a closed-loop motor that corrects lost steps. I changed to this motor from a 400 W OMC servo motor to check whether the motor and parametric settings were at fault with regard to my dimensions. That is not the case, as I can see. So I will go back to the servo if I get the problem solved.

The motor settings, especially the step scale, are correct; I measured them and found no deviations on a 400 mm straight line on a steel scale. Straight cuts were very accurate before. The problem was elliptical deviations when cutting circles.

OK, I will do another test cut tomorrow and report back.

Thanks, and have a good Friday!

Hanno

Thanks for your time and ideas!

The motor on the Y axis is a JMC iHSSC60-36-35-21-38-POCA. The manual says the pulse and pause should not be shorter than 2.5 µs; I have set this in the .ini file to 2,500 ns. This worked fine until now. Today, I changed this to 4000 ns, thinking it would be safer. After that change, an error occurred: 'stepgen.01.maxvel is too big for current step timings and position scale; clipping to maximum possible', so I reduced my Vel settings to 100 mm/s and 125 for overhead. This means that I cannot drive the axis at 7.5 m/min as before, but only at 6 m/min. I would accept this if the axis runs correctly afterwards. I will check this tomorrow.

Indeed, I change the motor-spindle gear in the X-axis a while ago to 20/32 teeth, which gives me a 640-step scale on the X-axis. This is not 1:2 as in the Y-axis, but 1:1.25.

My motor settings are 2000 steps/rev, which is not a problem for the motor or LCNC. The motor can run up to a frequency of 200 kHz, but I did tests with an oscillator and found the limit to be 180 kHz. So, 4000 ns will be safer.

Could the motor be losing steps at the shorter 2500 setting? I mean, it's a closed-loop motor that corrects lost steps. I changed to this motor from a 400 W OMC servo motor to check whether the motor and parametric settings were at fault with regard to my dimensions. That is not the case, as I can see. So I will go back to the servo if I get the problem solved.

The motor settings, especially the step scale, are correct; I measured them and found no deviations on a 400 mm straight line on a steel scale. Straight cuts were very accurate before. The problem was elliptical deviations when cutting circles.

OK, I will do another test cut tomorrow and report back.

Thanks, and have a good Friday!

Hanno

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1584

- Thank you received: 742

22 Nov 2025 17:40 #338985

by Lcvette

Replied by Lcvette on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

could be lost steps causing some errors. i would set the drive settings to fault for ANY lost steps and tune the system until it is not faulting. this would eliminate that. you don't want to run the system in a state where it is losing steps because of motor sizing and machine mass problems.

also i would make sure that your acceleration calculations for both axes come out to be the same.and ideally give both axis the same reduction. just takes several things out of the equation.

also i would make sure that your acceleration calculations for both axes come out to be the same.and ideally give both axis the same reduction. just takes several things out of the equation.

The following user(s) said Thank You: Muftijaja

Please Log in or Create an account to join the conversation.

- Muftijaja

- Offline

- Premium Member

-

Less

More

- Posts: 102

- Thank you received: 4

24 Nov 2025 02:16 - 24 Nov 2025 02:18 #339113

by Muftijaja

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

I'm sorry to say that I have to pause my efforts on this chapter with elliptical faults. As I tried yesterday to get new corrected lines in my Hal and INI to try out what helps (the day before yesterday, I tried to change the Y axis to stepgen.03 what did'nt work, I did'nt change wires but changed the plugs from stepgen.01 to stepgen.03) and I found that stepgen.01 was dead. I changed then stepgen.01 to stepgen.02 and motor-01 was working correctly.

So, I have to send my MESA card to a friend to repair the burned stepgen chip, this will last several days.

Meanwhile, I will consider if I could change to my free 7i96S, the problem there will be spindle settings and several other things to adapt.

So, I have to send my MESA card to a friend to repair the burned stepgen chip, this will last several days.

Meanwhile, I will consider if I could change to my free 7i96S, the problem there will be spindle settings and several other things to adapt.

Last edit: 24 Nov 2025 02:18 by Muftijaja.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Moderator

-

Less

More

- Posts: 1584

- Thank you received: 742

24 Nov 2025 02:20 #339114

by Lcvette

Replied by Lcvette on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Ah, bummer, sorry to hear that, hopefully it's repairable! Keep us posted!

The following user(s) said Thank You: Muftijaja

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

- User Interfaces

- Other User Interfaces

- QtPyVCP

- problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Time to create page: 0.179 seconds