[solved] How to set manual tool change remapping in qtdragon. Z limit error

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

22 Jul 2024 14:42 - 25 Jul 2024 14:29 #305860

by SanzuiWorks

[solved] How to set manual tool change remapping in qtdragon. Z limit error was created by SanzuiWorks

I am having trouble setting up manual tool changes and remaps in QTDragon.

I'm trying to migrate from Gmoccapy, but I just can't get it to work.

I am setting it up from scratch, but currently the replacement instruction window is displayed and the tool probe and workpiece are moved.

In this state, the Z-axis height above the pre-beam appears to be about twice the maximum height.

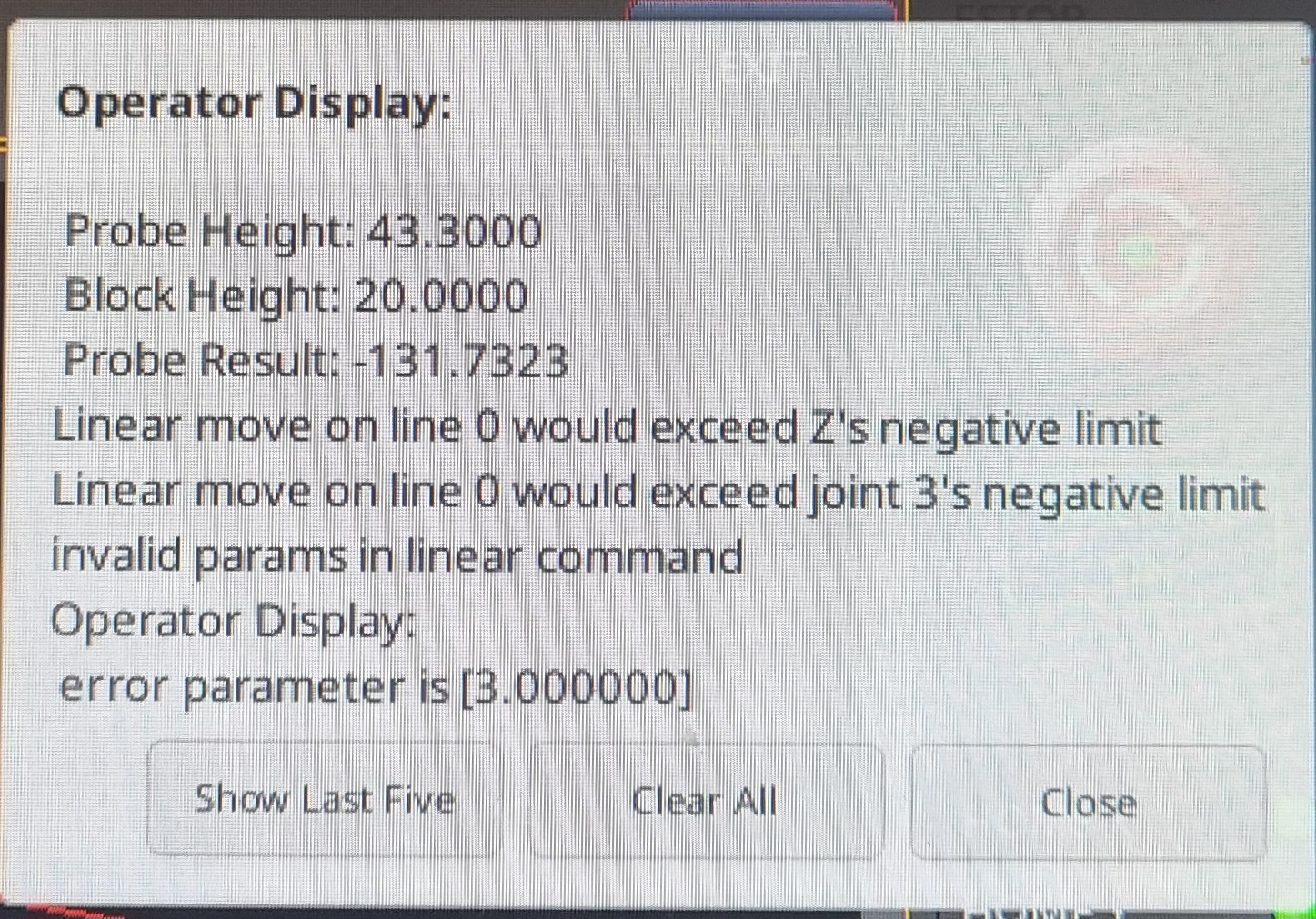

The message reads:

invalid params in linear command error parameter is [3.000000]

Linear move on line 17 would exceed Z's negative limit

I've been doing this all day today. It seemed to work once, but I can't reproduce it. I've set it up from scratch many times, but it's stuck in the same place.

LinuxCNC2.9.3

I'm trying to migrate from Gmoccapy, but I just can't get it to work.

I am setting it up from scratch, but currently the replacement instruction window is displayed and the tool probe and workpiece are moved.

In this state, the Z-axis height above the pre-beam appears to be about twice the maximum height.

The message reads:

invalid params in linear command error parameter is [3.000000]

Linear move on line 17 would exceed Z's negative limit

I've been doing this all day today. It seemed to work once, but I can't reproduce it. I've set it up from scratch many times, but it's stuck in the same place.

LinuxCNC2.9.3

Last edit: 25 Jul 2024 14:29 by SanzuiWorks.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

23 Jul 2024 04:35 #305886

by cmorley

Replied by cmorley on topic How to set manual tool change remapping in QTDRAGON. Z limit error

Can you figure out in what part of the process it is failing?

ie before the tool change? During the probe? etc

You could add some msg() commands to qt_auto_probe_tool.ngc to help in that regard.

ie before the tool change? During the probe? etc

You could add some msg() commands to qt_auto_probe_tool.ngc to help in that regard.

Please Log in or Create an account to join the conversation.

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

23 Jul 2024 13:04 #305900

by SanzuiWorks

Replied by SanzuiWorks on topic How to set manual tool change remapping in QTDRAGON. Z limit error

Thanks for the reply!I tried the installation again.I got to the point where the machine was working, but REMAP didn't work.I want to get back to that point soon.MDI↓T1 M6↓Move to [CHANGE_POSITION]↓Nothing happens. No dialog box appears.I don't know why, but I'm sure I'm missing something.No matter how many times I try to configure it, I can't keep up with it.

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 425

- Thank you received: 57

23 Jul 2024 19:38 - 23 Jul 2024 19:39 #305920

by COFHAL

Replied by COFHAL on topic How to set manual tool change remapping in QTDRAGON. Z limit error

I notice this error after having changed a tool with M6 Tx. I attach my INI file and that of qtdragon_hd.pref. The entire change process makes it correct. The problem is that once it has measured the new height of the tool, the Z axis goes up and stops with that error.

Attachments:

Last edit: 23 Jul 2024 19:39 by COFHAL.

Please Log in or Create an account to join the conversation.

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

24 Jul 2024 04:05 - 24 Jul 2024 04:06 #305942

by SanzuiWorks

Replied by SanzuiWorks on topic How to set manual tool change remapping in QTDRAGON. Z limit error

The error occurs after a tool change.

**************************

Cycle Start

↓

Move to [Tool_change_position]

↓

Replacement instructions

↓

Go to [VERSA_TOOLSETTER] and measure the tool

↓

Go to WORK

↓

Z limit error

Linear move on line 17 would exceed Z's negative limit

Linear move on line 17 would exceed joint 2's negative limit

invalid params in linear command

error parameter is [3.000000]

Cannot switch pages while in AUTO mode

****************************

It looks like the z-axis is now jumping out of the machine area.

**************************

Cycle Start

↓

Move to [Tool_change_position]

↓

Replacement instructions

↓

Go to [VERSA_TOOLSETTER] and measure the tool

↓

Go to WORK

↓

Z limit error

Linear move on line 17 would exceed Z's negative limit

Linear move on line 17 would exceed joint 2's negative limit

invalid params in linear command

error parameter is [3.000000]

Cannot switch pages while in AUTO mode

****************************

It looks like the z-axis is now jumping out of the machine area.

Last edit: 24 Jul 2024 04:06 by SanzuiWorks.

Please Log in or Create an account to join the conversation.

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

25 Jul 2024 10:50 - 25 Jul 2024 11:53 #306003

by SanzuiWorks

Replied by SanzuiWorks on topic How to set manual tool change remapping in QTDRAGON. Z limit error

I still don't know the cause, but I think I'm getting a little closer to the answer.

What value does <zworkoffset> represent?

qt_auto_probe_tool.ngc

When calculating using <touch_result>, the results will be more accurate if you omit <zworkoffset>.

qt_auto_probe_tool.ngc

In other words, when G92/G52 = 0 and G54, the value of <zworkoffset> is "0", right?

<zeorkoffset> value is around "110", so I think that's the cause.

I don't know if the "ini" settings are wrong or what the cause is. Do you know anything?

What value does <zworkoffset> represent?

qt_auto_probe_tool.ngc

#<zworkoffset> = [#[5203 + #5220 * 20] + #5213 * #5210]When calculating using <touch_result>, the results will be more accurate if you omit <zworkoffset>.

qt_auto_probe_tool.ngc

#<touch_result> = [#5063 + #<zworkoffset>]In other words, when G92/G52 = 0 and G54, the value of <zworkoffset> is "0", right?

<zeorkoffset> value is around "110", so I think that's the cause.

I don't know if the "ini" settings are wrong or what the cause is. Do you know anything?

Last edit: 25 Jul 2024 11:53 by SanzuiWorks.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

25 Jul 2024 11:14 #306005

by Aciera

Typing this command in MDI should show the current value of parameter 5063:

linuxcnc.org/docs/html/gcode/overview.ht...:numbered-parameters

Replied by Aciera on topic How to set manual tool change remapping in QTDRAGON. Z limit error

That is correct.In other words, when G92/G52 = 0 and G54, the value of <zworkoffset> is "0", right?

this would indicate that #5063 (which should hold the Z coordinate value at the time the probe tripped) has the value 'around 110'.The value is around "110", so I think that's the cause.

Typing this command in MDI should show the current value of parameter 5063:

(DEBUG, value = #5063)linuxcnc.org/docs/html/gcode/overview.ht...:numbered-parameters

Please Log in or Create an account to join the conversation.

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

25 Jul 2024 11:34 - 25 Jul 2024 11:45 #306008

by SanzuiWorks

Replied by SanzuiWorks on topic How to set manual tool change remapping in QTDRAGON. Z limit error

I wrote it poorly.

The value of “110” is indicated by <zworkoffset>.

This value is -120.

When I changed it to this it worked fine.

I don't know what the results would be if there was an offset.

The value of “110” is indicated by <zworkoffset>.

(DEBUG, value = #5063)#<touch_result> = #5063When I changed it to this it worked fine.

I don't know what the results would be if there was an offset.

Last edit: 25 Jul 2024 11:45 by SanzuiWorks.

Please Log in or Create an account to join the conversation.

- SanzuiWorks

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 4

25 Jul 2024 13:19 - 25 Jul 2024 13:22 #306012

by SanzuiWorks

Replied by SanzuiWorks on topic How to set manual tool change remapping in QTDRAGON. Z limit error

Resets the Z value of the active coordinate system.

Before getting #<zworkoffset>, you must reset the Z value of the active coordinate system.

Before getting #<zworkoffset>, you must reset the Z value of the active coordinate system.

;Resets the Z value of the active coordinate system

G10 L2 P#5220 Z0

#<zworkoffset> = [#[5203 + #5220 * 20] + #5213 * #5210]

Last edit: 25 Jul 2024 13:22 by SanzuiWorks.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.226 seconds