CNC Ornamental Lathe - Big Thank You!

- cts1085

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 3

31 May 2014 20:25 - 31 May 2014 20:27 #47575

by cts1085

CNC Ornamental Lathe - Big Thank You! was created by cts1085

This is a chunk of Maple that I formed manually then used LinuxCNC and home-built mechanics to do the engraving. Most of the code was in Python/NGCGUI feeding AXIS.

The lathe is setup as an XZC lathe with rotation around the Z axis.

Dewey Garrett gave me the idea of "probing" along the surface and using those data-points in the code to provide a consistent depth of engraving. Works great!

I used a 1/8" ball-mill for the octagon engraving and a 1/2" round-nose router bit for the fluting.

Many thanks to the people of this forum for their advise, counsel and ideas....

-Tom

The lathe is setup as an XZC lathe with rotation around the Z axis.

Dewey Garrett gave me the idea of "probing" along the surface and using those data-points in the code to provide a consistent depth of engraving. Works great!

I used a 1/8" ball-mill for the octagon engraving and a 1/2" round-nose router bit for the fluting.

Many thanks to the people of this forum for their advise, counsel and ideas....

-Tom

Last edit: 31 May 2014 20:27 by cts1085. Reason: Updated picture

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1744

- Thank you received: 288

31 May 2014 22:28 #47578

by cncbasher

Replied by cncbasher on topic CNC Ornamental Lathe - Big Thank You!

excellent Tom ,

could you perhaps post your configuration fles for other willing to give this a try ,

and perhaps an example .

i feel this should perhaps be placed in the wiki Tom

could you perhaps post your configuration fles for other willing to give this a try ,

and perhaps an example .

i feel this should perhaps be placed in the wiki Tom

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1175

01 Jun 2014 00:22 #47581

by BigJohnT

Replied by BigJohnT on topic CNC Ornamental Lathe - Big Thank You!

Nice! You might also post a photo of the machine that made it.

JT

JT

Please Log in or Create an account to join the conversation.

- Sterling

-

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 1

13 Jun 2014 05:42 #47953

by Sterling

Replied by Sterling on topic CNC Ornamental Lathe - Big Thank You!

That is some mighty fine work!

Please Log in or Create an account to join the conversation.

- skeeter

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

15 Jul 2014 00:45 #48772

by skeeter

Replied by skeeter on topic CNC Ornamental Lathe - Big Thank You!

Thanks , For posting that picture . Mighty fine work . This is something I would like to do after I get this first project done . please post more photos and talk about your setups .

Regards

Terry

Regards

Terry

Please Log in or Create an account to join the conversation.

- cts1085

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 3

11 Aug 2014 22:23 - 11 Aug 2014 22:27 #49701

by cts1085

Replied by cts1085 on topic CNC Ornamental Lathe - Big Thank You!

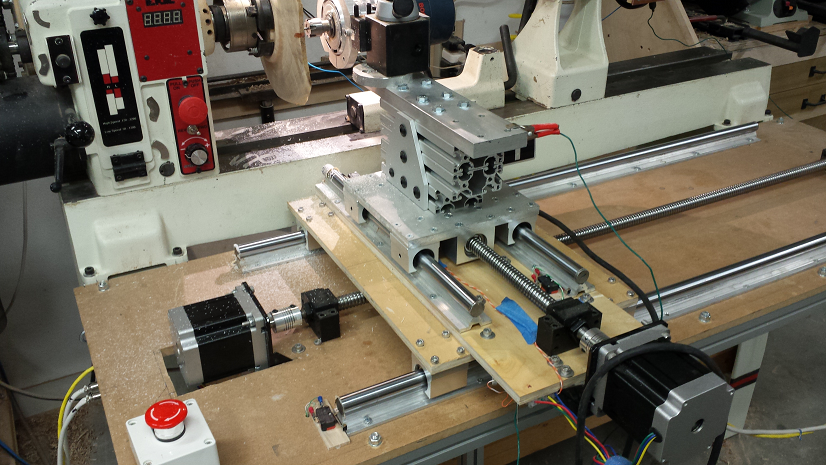

Here is a picture of the machine configured to engrave in the XC plane - the router can be adjusted to cut either from the end or from the side or anywhere in between.

Also, as requested, are the configuration files for my "mill" - I call it a mill because it does control 3 axis - although I can drop the C-Axis and run it as a 2-axis lathe with the lathe running under its own power.

Also, as requested, are the configuration files for my "mill" - I call it a mill because it does control 3 axis - although I can drop the C-Axis and run it as a 2-axis lathe with the lathe running under its own power.

Last edit: 11 Aug 2014 22:27 by cts1085. Reason: Added Picture

The following user(s) said Thank You: BigJohnT, skeeter

Please Log in or Create an account to join the conversation.

- skeeter

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

12 Aug 2014 00:49 #49713

by skeeter

Replied by skeeter on topic CNC Ornamental Lathe - Big Thank You!

Hi, CTS . Thanks for sharing . If you or anyone else want to see some similar work . I call his stuff eye candy. His name is Bill Ooms www.billooms.com

he has some cool software too . Check him out .

Terry

he has some cool software too . Check him out .

Terry

Please Log in or Create an account to join the conversation.

Time to create page: 0.231 seconds