Transferring integrated CNC build to Corsair 900D box

- AlexN

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 0

14 Jan 2015 11:30 #54991

by AlexN

Transferring integrated CNC build to Corsair 900D box was created by AlexN

A couple of years ago I was working on an integrated CNC enclosure build, but a move of house and consequent loss of workshop/space/storage knocked the project on the head for a while. A new workshop is nearing completion - I hope - and I am getting my head back around what was done and what need to be completed.

In the process I decided that the current rather small (125(H) x 334(D) x 426(W) mm (ext)) and therefore jam-packed enclosure really needed replacing from a point of both efficient cooling of components and maintenance, in that order.

I went searching for something much larger, and found the Corsair "Obsidian" 900D gamer's PC enclosure - 690(H) x 650(D) x 250(D) mm (ext). This case is aimed at serious-sized servers and multi-screen gaming, and is intended to house multiple liquid-cooling radiators, up to fifteen 120 mm diameter inlet plus one 140 mm exhaust fans, multiple graphics cards (up to 10 expansion slots on computer motherboards) and also supports the mounting of a wide range of ATX-type motherboard formats - including the min-ITX format of my original Intel Atom D525MW. It will be dwarfed in this monster case, but that is precisely not the problem: there will also be much more room for the original's toroid transformer, PMDX power board, Sound Logic "Combo" breakout board, four Gecko 203V drives and all the associated wiring, connectors, IC control boards, etc. In fact, you could fit roughly six of the original enclosures into the new one.

So why didn't I get one of the 900Ds when I started work on the original - and save a fiendish amount of bother? Simply because I didn't know about it (wrong internet search criteria, probably), and possibly because the 900D wasn't commercially available at the time when I sourced the original enclosure from a local (Jaycar) electronics chain.

The 900D has three 120 mm fans at the front of the case, one 140 mm exhaust fan at the rear, room for three 140/four 120 mm fans at the top of the case, and six 140/eight 120 mm fans at the bottom of the case (four each side). All inlet fan regions are covered in removable filter material, and are [protected by steel or aluminium grills or plates. The motherboard mounting plate is a very generous 420(H) x 435 (W) mm in dimensions, and has a 30 mm gap on its RHS for cable storage, a number of cable holes have useful rubber grommets to prevent cable chafing/cutting. There are three "hot-pluggable" drive cages of three 3.5"/SSD drives each mounted on the bottom of the case, and a cage for four 5.25" drives above the three fans at the front. (I've removed all three 3.5 " drive cages.) The case is a sturdy steel construction with a cast aluminium front panel and removable front aluminium filter protection plate. The LHS of the case has a perspex window so that various bits of gimmickry can be viewed (or to see if any of the cooling hoses/connectors are leaking, eek!); there is a version of the case available that has a full sheet-metal plate LHS instead. An couple of unsheathed wiring harnesses come pre-installed but I'll be reducing the number of supplied cables once I've worked out what I need. There is going to be enough extra wiring to be getting along with once the system is fully installed...

A separate PSU is required: I acquired a relatively new-tech Corsair AX760i modular digital PSU from the same supplier as the 900D (www.mwave.com.au). I'm mothballing the original's fanless "PicoPSU" 150 W unit.

I'm doing a bit of hunting on the web looking for fan reviews to see what's what before I start coughing up for said items. I'd rather have reliable, high throughput units than fancy multi-coloured LEDs and other gimmicks.

Next steps are the dismantling of the old box and separating out/disconnecting various components.Given the vastly bigger real estate available, pretty well all of the original connections will have to be rewired/rethought, and the layout, of course, will be different as well: the toroid/PMDX power train for the Gecko drives will most likely I've at the bottom of the case, where it will have the potential benefit - depending on cost - of eight 120 mm fans. I will keep an eye out when designing the layout to allow for a possible ATX-sized future replacement for the little Atom MB - just in case that might become necessary.

I have some snaps to put up later, which will, as is usual with me, derive from my Flickr account.

In the process I decided that the current rather small (125(H) x 334(D) x 426(W) mm (ext)) and therefore jam-packed enclosure really needed replacing from a point of both efficient cooling of components and maintenance, in that order.

I went searching for something much larger, and found the Corsair "Obsidian" 900D gamer's PC enclosure - 690(H) x 650(D) x 250(D) mm (ext). This case is aimed at serious-sized servers and multi-screen gaming, and is intended to house multiple liquid-cooling radiators, up to fifteen 120 mm diameter inlet plus one 140 mm exhaust fans, multiple graphics cards (up to 10 expansion slots on computer motherboards) and also supports the mounting of a wide range of ATX-type motherboard formats - including the min-ITX format of my original Intel Atom D525MW. It will be dwarfed in this monster case, but that is precisely not the problem: there will also be much more room for the original's toroid transformer, PMDX power board, Sound Logic "Combo" breakout board, four Gecko 203V drives and all the associated wiring, connectors, IC control boards, etc. In fact, you could fit roughly six of the original enclosures into the new one.

So why didn't I get one of the 900Ds when I started work on the original - and save a fiendish amount of bother? Simply because I didn't know about it (wrong internet search criteria, probably), and possibly because the 900D wasn't commercially available at the time when I sourced the original enclosure from a local (Jaycar) electronics chain.

The 900D has three 120 mm fans at the front of the case, one 140 mm exhaust fan at the rear, room for three 140/four 120 mm fans at the top of the case, and six 140/eight 120 mm fans at the bottom of the case (four each side). All inlet fan regions are covered in removable filter material, and are [protected by steel or aluminium grills or plates. The motherboard mounting plate is a very generous 420(H) x 435 (W) mm in dimensions, and has a 30 mm gap on its RHS for cable storage, a number of cable holes have useful rubber grommets to prevent cable chafing/cutting. There are three "hot-pluggable" drive cages of three 3.5"/SSD drives each mounted on the bottom of the case, and a cage for four 5.25" drives above the three fans at the front. (I've removed all three 3.5 " drive cages.) The case is a sturdy steel construction with a cast aluminium front panel and removable front aluminium filter protection plate. The LHS of the case has a perspex window so that various bits of gimmickry can be viewed (or to see if any of the cooling hoses/connectors are leaking, eek!); there is a version of the case available that has a full sheet-metal plate LHS instead. An couple of unsheathed wiring harnesses come pre-installed but I'll be reducing the number of supplied cables once I've worked out what I need. There is going to be enough extra wiring to be getting along with once the system is fully installed...

A separate PSU is required: I acquired a relatively new-tech Corsair AX760i modular digital PSU from the same supplier as the 900D (www.mwave.com.au). I'm mothballing the original's fanless "PicoPSU" 150 W unit.

I'm doing a bit of hunting on the web looking for fan reviews to see what's what before I start coughing up for said items. I'd rather have reliable, high throughput units than fancy multi-coloured LEDs and other gimmicks.

Next steps are the dismantling of the old box and separating out/disconnecting various components.Given the vastly bigger real estate available, pretty well all of the original connections will have to be rewired/rethought, and the layout, of course, will be different as well: the toroid/PMDX power train for the Gecko drives will most likely I've at the bottom of the case, where it will have the potential benefit - depending on cost - of eight 120 mm fans. I will keep an eye out when designing the layout to allow for a possible ATX-sized future replacement for the little Atom MB - just in case that might become necessary.

I have some snaps to put up later, which will, as is usual with me, derive from my Flickr account.

Please Log in or Create an account to join the conversation.

- AlexN

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 0

18 Jan 2015 16:21 - 18 Jan 2015 16:22 #55137

by AlexN

Replied by AlexN on topic Transferring integrated CNC build to Corsair 900D box

Here’s some snaps of the 900D and related items, as promised:

1. New enclosure for the CNC innards! A Corsair "Obsidian" Series 900D full tower case with room for 15 120 mm fans . It's a monster!

. It's a monster!

2. The other side of the Corsair enclosure box

3. 900D out of its box... 140 mm exhaust fan visible at top of case

4. Front of case has 3 x 120 mm fans pre-installed (not visible here). Much of the case is mild steel framework with heavy-duty die cast aluminium panels. All inlet fan bays are filtered. Note the ding in the cast aluminium front of the case: as shipped - not of my making...

5. Old case (and contents) next to the new. Clockwise from top left: 50-0-50 V toroid transformer; 90 mm fan (CPU); PMDX-125 rectifier board; Intel Atom D525MW mini-ITX board; 4 x 3 XLR socket array; Campbell Designs/Sound Logic "Combo" board

6. Old in front of new

7. Overall size "comparison". Volume for volume, the new case is six times bigger than the old. Old case here has collapsed on account of removal of all screws...

8. Corsair AX760i PSU carton: a lot bigger than the actual unit!

9. AX760i carton contents. Clockwise from top left: velvet bag congaing PSU; vecro-sealed bag containing all modular leads/cables plus USB "iLink" dongle; small bag of zip ties, badge and mounting screws; warranty cards; instruction manual. Some of my oboe reed making gear snuck into the photo (bottom left) as well

10. AX760i unit out of box - and bag. Actually back to front here, showing modular cable sockets - which is why I snapped this way around...

11. AX760i PSU in relation to Obsidian 900D case

12. AX760i cable socket panel

13. AX760i in position inside the 900D case; still back to front in this photo. Lower RH filter screen visible in this snap. Note also the extent of the exhaust grill-work on the rear panel of the case: even the motherboard slot-blanking plates are slotted...

14. 50-0-50 V toroid and PMDX-125 next to AX760i in bottom of case. This is the most obvious place for these given the weight of the toroid and the overall shapes/sizes of the powertrain, although I may switch the toroid and PMDX-125 around

15. Intel D525MW motherboard completely dwarfed inside the 900D case!

Compare with photo of "opened" original enclosure below. Note that the three 3 x 3.5: drive cages have been removed from the 900D case

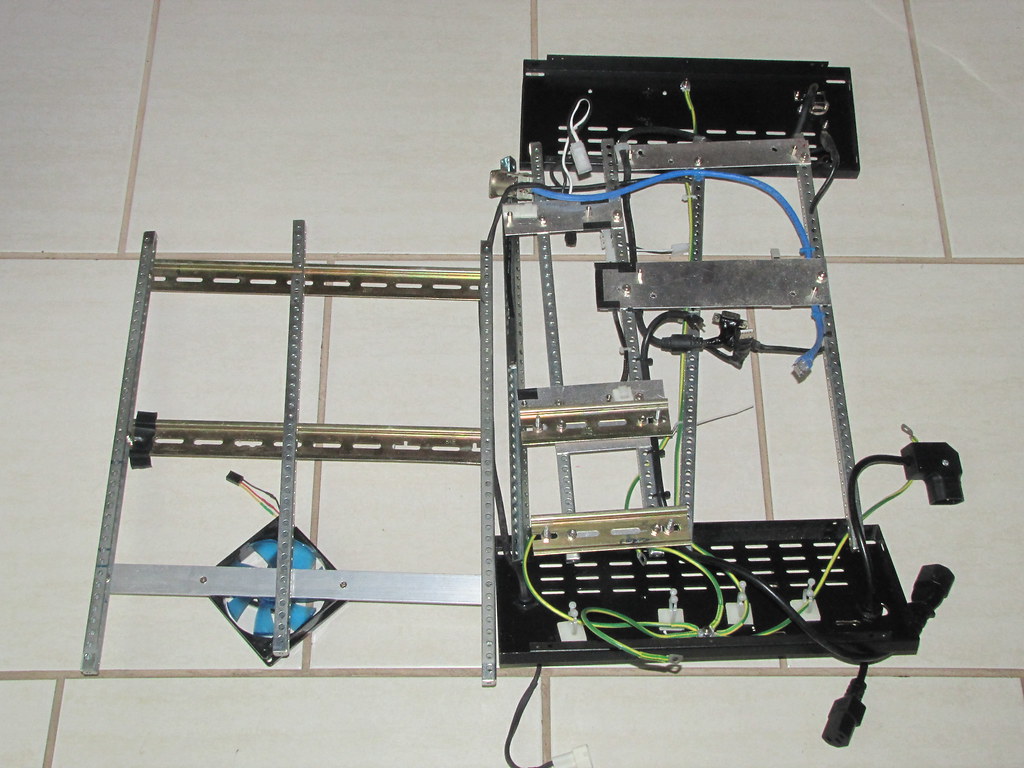

16. The skeletal remnants of the old enclosure: just a fan and some (laboriously-added!) support cabling left...

Follow this link to my Flickr account

Follow this link to my CNC Flickr set - lots more snaps of the construction and otherwise of the original box…

More snaps as I progress with the build. I am still waiting for the manufacturer of my new workshop structure to deliver it, then there will be another wait while I get 3-phase power on to the house, then another wait while power and lighting are put onto the shed... Hopefully not too much longer. there's still stuff that I can do on the box inside the house, however.

Cheers,

Alex.

1. New enclosure for the CNC innards! A Corsair "Obsidian" Series 900D full tower case with room for 15 120 mm fans

2. The other side of the Corsair enclosure box

3. 900D out of its box... 140 mm exhaust fan visible at top of case

4. Front of case has 3 x 120 mm fans pre-installed (not visible here). Much of the case is mild steel framework with heavy-duty die cast aluminium panels. All inlet fan bays are filtered. Note the ding in the cast aluminium front of the case: as shipped - not of my making...

5. Old case (and contents) next to the new. Clockwise from top left: 50-0-50 V toroid transformer; 90 mm fan (CPU); PMDX-125 rectifier board; Intel Atom D525MW mini-ITX board; 4 x 3 XLR socket array; Campbell Designs/Sound Logic "Combo" board

6. Old in front of new

7. Overall size "comparison". Volume for volume, the new case is six times bigger than the old. Old case here has collapsed on account of removal of all screws...

8. Corsair AX760i PSU carton: a lot bigger than the actual unit!

9. AX760i carton contents. Clockwise from top left: velvet bag congaing PSU; vecro-sealed bag containing all modular leads/cables plus USB "iLink" dongle; small bag of zip ties, badge and mounting screws; warranty cards; instruction manual. Some of my oboe reed making gear snuck into the photo (bottom left) as well

10. AX760i unit out of box - and bag. Actually back to front here, showing modular cable sockets - which is why I snapped this way around...

11. AX760i PSU in relation to Obsidian 900D case

12. AX760i cable socket panel

13. AX760i in position inside the 900D case; still back to front in this photo. Lower RH filter screen visible in this snap. Note also the extent of the exhaust grill-work on the rear panel of the case: even the motherboard slot-blanking plates are slotted...

14. 50-0-50 V toroid and PMDX-125 next to AX760i in bottom of case. This is the most obvious place for these given the weight of the toroid and the overall shapes/sizes of the powertrain, although I may switch the toroid and PMDX-125 around

15. Intel D525MW motherboard completely dwarfed inside the 900D case!

Compare with photo of "opened" original enclosure below. Note that the three 3 x 3.5: drive cages have been removed from the 900D case

16. The skeletal remnants of the old enclosure: just a fan and some (laboriously-added!) support cabling left...

Follow this link to my Flickr account

Follow this link to my CNC Flickr set - lots more snaps of the construction and otherwise of the original box…

More snaps as I progress with the build. I am still waiting for the manufacturer of my new workshop structure to deliver it, then there will be another wait while I get 3-phase power on to the house, then another wait while power and lighting are put onto the shed... Hopefully not too much longer. there's still stuff that I can do on the box inside the house, however.

Cheers,

Alex.

Last edit: 18 Jan 2015 16:22 by AlexN.

Please Log in or Create an account to join the conversation.

Time to create page: 0.478 seconds