4th Axis Build

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 05:43 #70144

by Dale Lusby

4th Axis Build was created by Dale Lusby

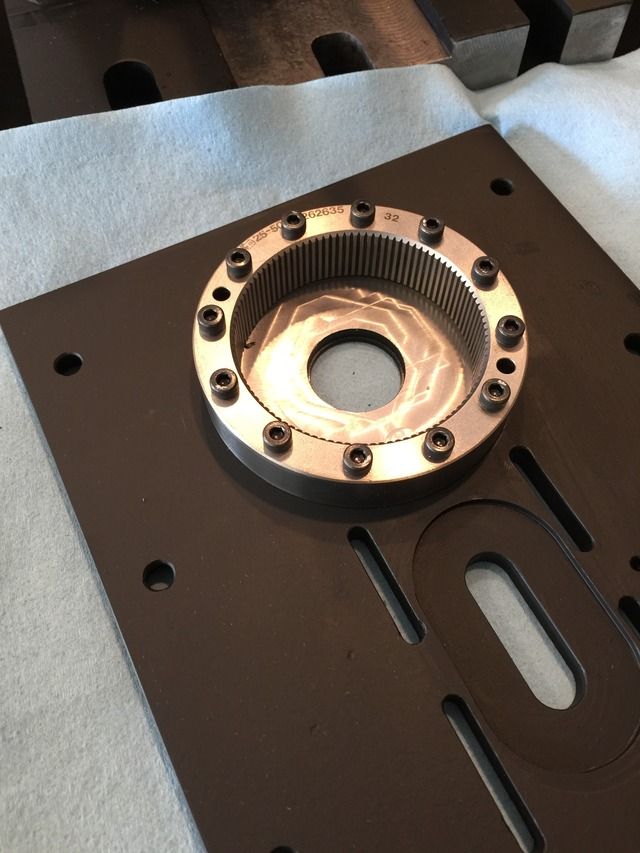

Recently I decided to build a 4th axis for my Shizuoka milling machine. I looked through some designs and decided on using a Harmonic Drive gear drive and found a good deal on a 50:1 gear reduction one. If you haven't seen a Harmonic Drive do a youtube search as they are quite interesting and work very well when the goal is to reduce lash to a minimum. I have purchased a second one and will be building the 5th axis that will attach to my 4th in the near future.

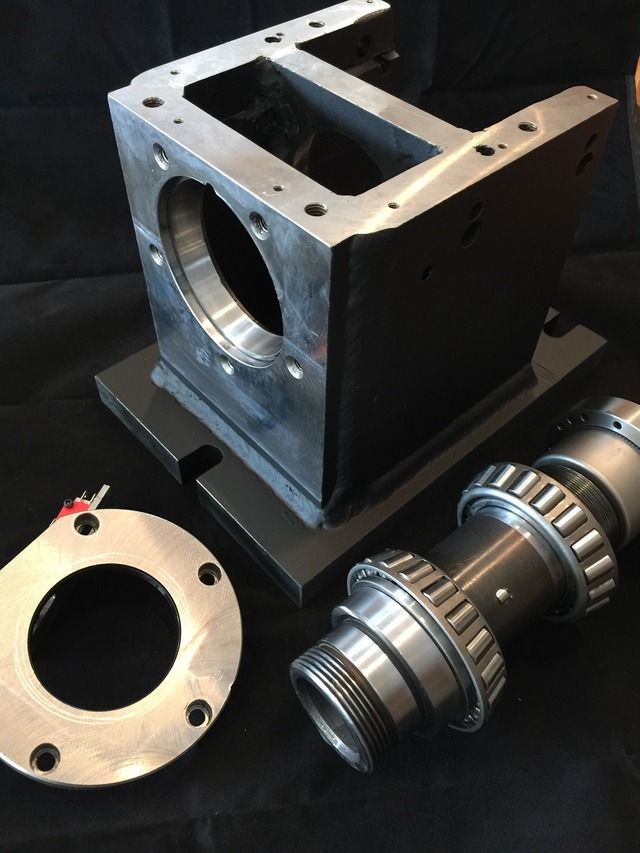

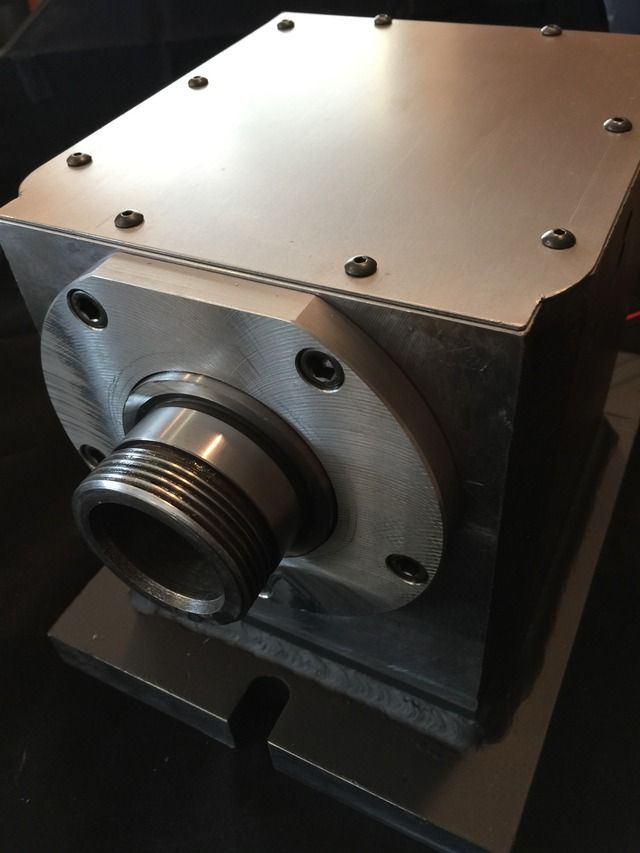

Now that I had the gear system figured out it was mostly a matter of designing the rest around it. I had a fixture acquired at auction a few years ago that was perfect for this application. It is 1" steel welded up and I added a 3/4" piece of steel to be the support for the rear bearing. For bearings I decided to use Timkens. I used the same that are in my trucks front axles which have an ID of 2.25" and the outer diameter of the race is near 4 inches. I would love to have had a through spindle design however the harmonic drive design would allow it. I did decide to have a threaded nose that matches my Tsugami turret lathe so the chucks would transfer over. I also decided to make the nose accept ER40 collets.

I must say have CNC capabilities has changed everything about how I go about machining. Here I setup to machine the bore for the race. Since going through the ball screws and getting the lash down below a thousandth I was easily able to hit the desired bore size. I'm still learning my machine and what I can and cannot get away with. The end mill cost has been steep with my goofs.

Here I have the races installed and the bolt pattern on the front for the seal plate.

More to follow:

Now that I had the gear system figured out it was mostly a matter of designing the rest around it. I had a fixture acquired at auction a few years ago that was perfect for this application. It is 1" steel welded up and I added a 3/4" piece of steel to be the support for the rear bearing. For bearings I decided to use Timkens. I used the same that are in my trucks front axles which have an ID of 2.25" and the outer diameter of the race is near 4 inches. I would love to have had a through spindle design however the harmonic drive design would allow it. I did decide to have a threaded nose that matches my Tsugami turret lathe so the chucks would transfer over. I also decided to make the nose accept ER40 collets.

I must say have CNC capabilities has changed everything about how I go about machining. Here I setup to machine the bore for the race. Since going through the ball screws and getting the lash down below a thousandth I was easily able to hit the desired bore size. I'm still learning my machine and what I can and cannot get away with. The end mill cost has been steep with my goofs.

Here I have the races installed and the bolt pattern on the front for the seal plate.

More to follow:

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 05:54 #70145

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

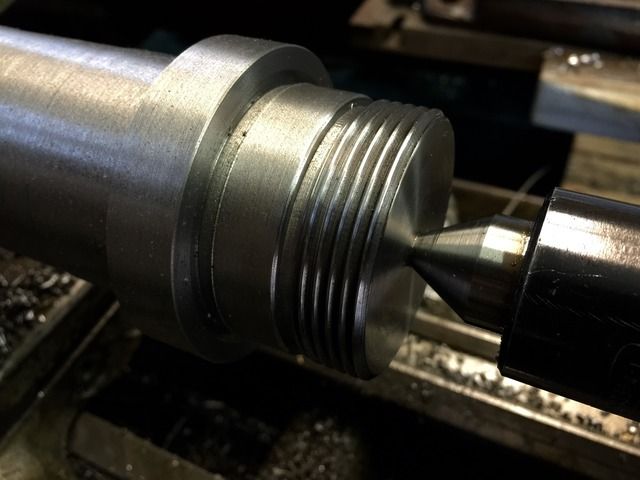

Now that the main casting was finished I needed to turn my attention to the spindle. I already had drawn up a workable model but needed some length dimensions from the main housing before I could finalize my numbers. I used my old Sidney lathe to rough turn the spindle down from some 3.5" stock I had.

Here is the rough profile and spindle thread after I finished turning it. I left the body oversized so I could grind it in on the Brown and Sharpe #13 grinder.

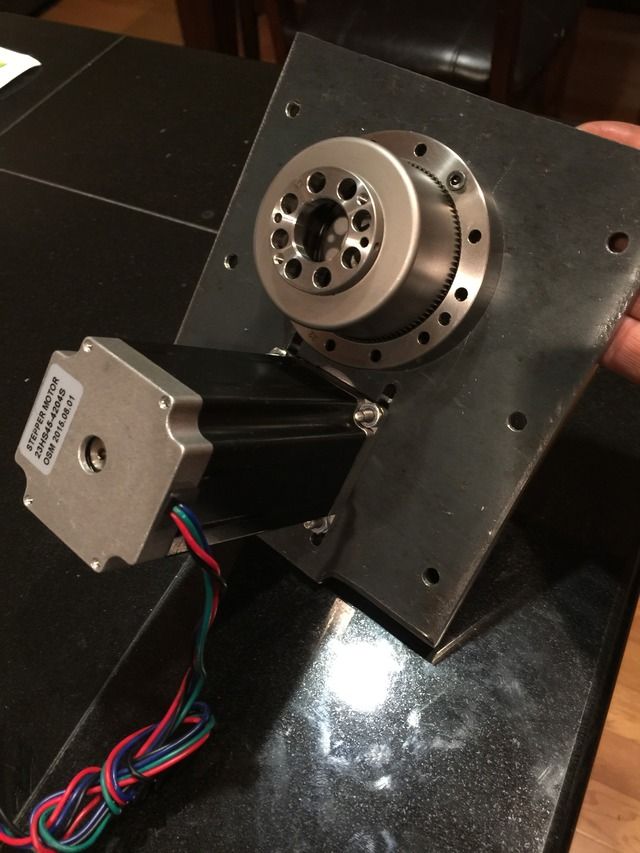

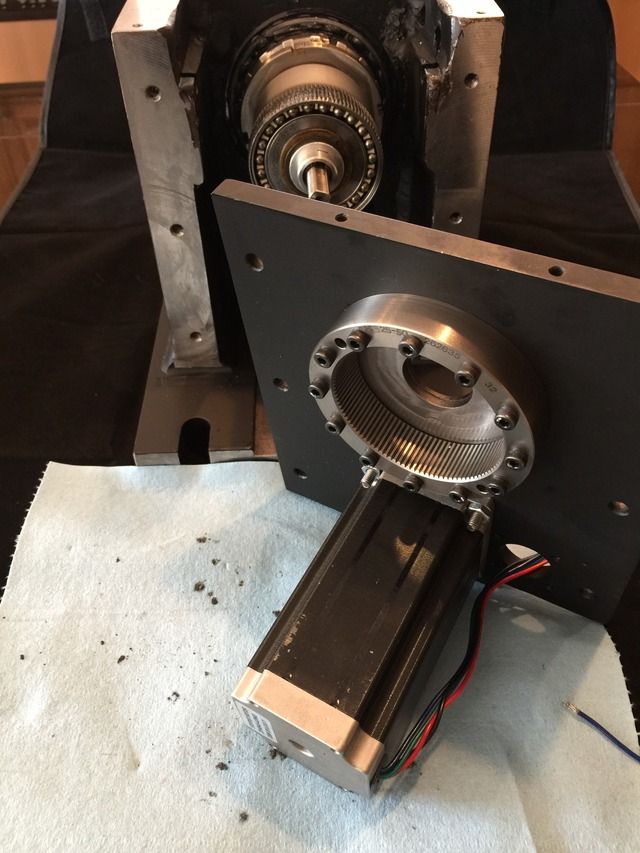

Coming along and starting to mock it up as I go. You can see the stepper motor (Nema 23 - 425 oz in) and how it will be tucked under the spindle.

Here is the rough profile and spindle thread after I finished turning it. I left the body oversized so I could grind it in on the Brown and Sharpe #13 grinder.

Coming along and starting to mock it up as I go. You can see the stepper motor (Nema 23 - 425 oz in) and how it will be tucked under the spindle.

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 05:58 #70146

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 06:04 #70147

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 06:09 #70148

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

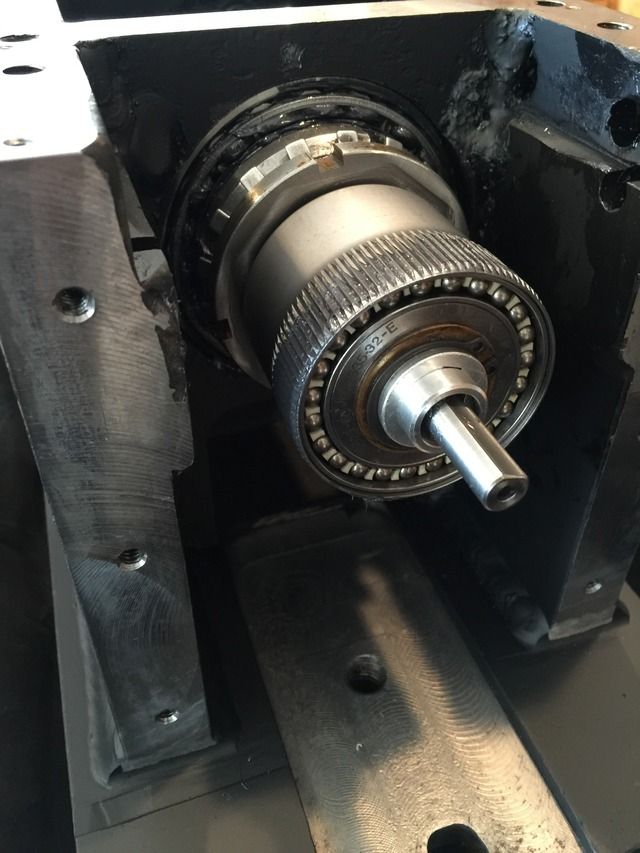

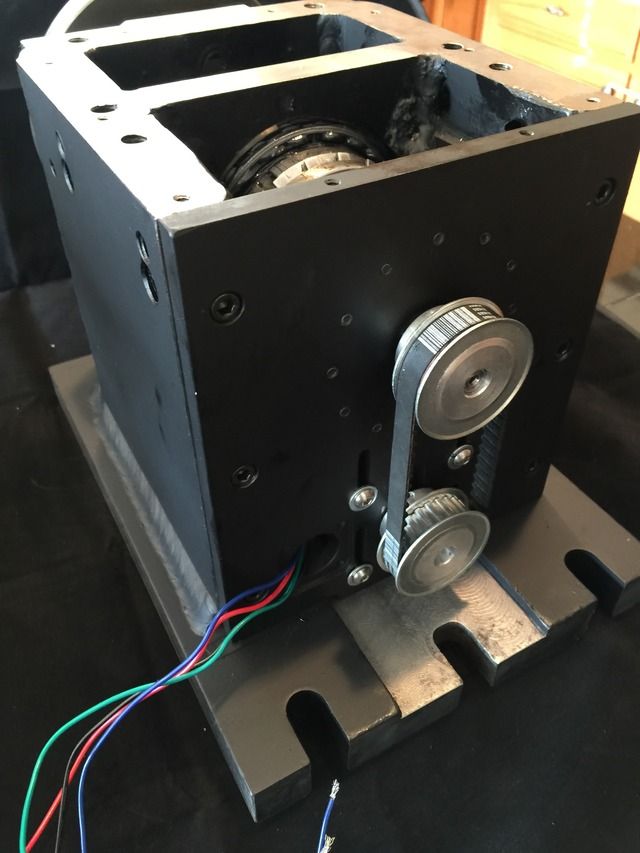

Here is a picture of the completed spindle. One thing I failed to mention is that there is a rear idler shaft out the back of the spindle to support the pulley for the harmonic drive. Inside the spindle I installed a small bearing and part of the harmonic drive there is a bearing. Worked out really well to keep it compact.

Here is a better view of the idler shaft on the spindle

Here is a better view of the idler shaft on the spindle

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 06:15 #70149

by Dale Lusby

]

I used an Amphenol connector for the electrical connection.

About ready to do some machining finally. I installed a 48v power supply for the motor along with the Geckodrive g201x which is the same as the other drivers for the mill. After fooling around with the setting for a bit I was able to get it to work. I'm looking forward to having some fun with the addition.

Replied by Dale Lusby on topic 4th Axis Build

]

I used an Amphenol connector for the electrical connection.

About ready to do some machining finally. I installed a 48v power supply for the motor along with the Geckodrive g201x which is the same as the other drivers for the mill. After fooling around with the setting for a bit I was able to get it to work. I'm looking forward to having some fun with the addition.

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 06:22 #70150

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

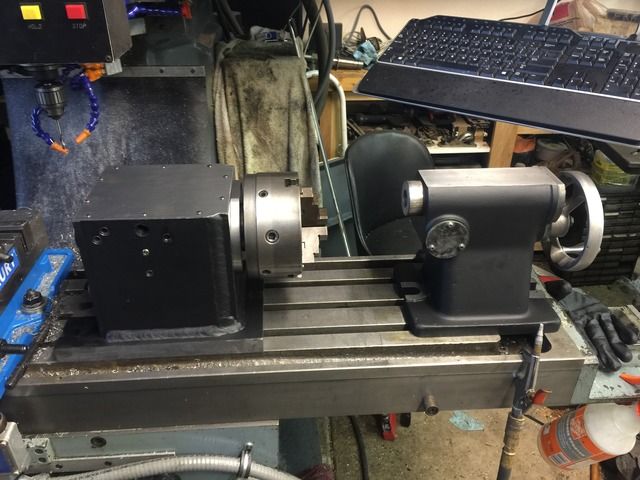

Here it is on the mill. A local seller had a tailstock on Craigslist that I purchased for the tailstock side. It's taller than I could make mine so I will be making a riser to align the two.

I am working to setup a youtube account so I can upload videos to share. Right now I'm using Fusion360 for my CAD/CAM. They don't support continuous machining on 4th and 5th axis so I will have to settle for indexing for now. Hopefully they will have it released soon and in the meantime I'm working on my 5th axis which will be a trunnion style axis.

I am working to setup a youtube account so I can upload videos to share. Right now I'm using Fusion360 for my CAD/CAM. They don't support continuous machining on 4th and 5th axis so I will have to settle for indexing for now. Hopefully they will have it released soon and in the meantime I'm working on my 5th axis which will be a trunnion style axis.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

15 Feb 2016 12:21 #70157

by BigJohnT

Replied by BigJohnT on topic 4th Axis Build

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

15 Feb 2016 12:47 #70158

by cncbasher

Replied by cncbasher on topic 4th Axis Build

Very Nice Build , theirs no stopping you now

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

23 Feb 2016 15:34 #70522

by andypugh

Replied by andypugh on topic 4th Axis Build

I assume that the spindle nose thread is matched to the lathe. You might find that an A1 or Camlock nose would work better for 4th-axis work where the forces can act in any direction.

That said, the dividing head I converted for my 4th-axis has a Myford spinde threaded nose, and so far that hasn't come loose at an inopportune time.

That said, the dividing head I converted for my 4th-axis has a Myford spinde threaded nose, and so far that hasn't come loose at an inopportune time.

Please Log in or Create an account to join the conversation.

Time to create page: 0.225 seconds