4th Axis Build

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

13 Oct 2016 14:15 #81606

by Lcvette

Replied by Lcvette on topic 4th Axis Build

This is an awesome build! I am wanting to do the same thing and have been shipping harmonic drives. I've been trying to decipher the connections and this thread was very illuminating, thank you very much for shading your project!

The united I've been looking at are different, they appear to be a housed unit with a cross t roller bearing. Was hoping to use it as one side of the bearing sports and a roller bearing on the other side. Any insights as to why you used the type of harmonic drive you used?

Also any feedback of how everything is working or notes on things you would do differently?

Thanks in advance!

Chris

The united I've been looking at are different, they appear to be a housed unit with a cross t roller bearing. Was hoping to use it as one side of the bearing sports and a roller bearing on the other side. Any insights as to why you used the type of harmonic drive you used?

Also any feedback of how everything is working or notes on things you would do differently?

Thanks in advance!

Chris

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

13 Oct 2016 14:40 #81609

by Dale Lusby

Replied by Dale Lusby on topic 4th Axis Build

Hi Chris,

I used this type of harmonic drive as there was one on eBay at the time at a decent price. I've bought others recently to use for a 5th axis which is different and same reason as it was available at decent price. It has worked very well and I've been happy with the speed and holding power. I only have CAM ability for running 3+1 so no 4th axis continuous machining. I hope to upgrade software soon and be able to get more use out of it.

One thing I would have considered changing would be not using a threaded spindle however it hasn't unscrewed as of yet. It was mere convenience to go this route as one of my lathes has the same spindle nose. I also still need to take this to my grinder and grind the collet taper on the inside of the nose so I can use ER40 collets. I will probably do that his winter.

Let me know if you have any other questions I can help with.

Dale

I used this type of harmonic drive as there was one on eBay at the time at a decent price. I've bought others recently to use for a 5th axis which is different and same reason as it was available at decent price. It has worked very well and I've been happy with the speed and holding power. I only have CAM ability for running 3+1 so no 4th axis continuous machining. I hope to upgrade software soon and be able to get more use out of it.

One thing I would have considered changing would be not using a threaded spindle however it hasn't unscrewed as of yet. It was mere convenience to go this route as one of my lathes has the same spindle nose. I also still need to take this to my grinder and grind the collet taper on the inside of the nose so I can use ER40 collets. I will probably do that his winter.

Let me know if you have any other questions I can help with.

Dale

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

13 Oct 2016 14:46 #81610

by andypugh

Those sound perfect.

Replied by andypugh on topic 4th Axis Build

The united I've been looking at are different, they appear to be a housed unit with a cross t roller bearing

Those sound perfect.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

13 Oct 2016 17:37 #81619

by Lcvette

Replied by Lcvette on topic 4th Axis Build

That is encouraging to hear it's working out!! Do you know which model you used in the 4th build? I am looking at the 25-100 servo actuator units which have a torque rating of 75Nm and have a 100:1 ratio. They are hollow core type units that direct drive the harmonic drive with a built in encoder., they are reasonably affordable considering they come with the servo and drive, I've found then sound $500 from time to time in great shape and as mentioned have the cross roller bearing support which will make the rest of the design a little easier to work with and the over all length of the unit more compact.

I need to do some further research on appropriate drives for them still, some are listed but I'm not sure if they are CNC type of more automation type drives.

Very cool gadgets to be sure and your build is very impressive! Do you have any YouTube videos of your build in action, would love some inspirational viewing media!!

Chris

I need to do some further research on appropriate drives for them still, some are listed but I'm not sure if they are CNC type of more automation type drives.

Very cool gadgets to be sure and your build is very impressive! Do you have any YouTube videos of your build in action, would love some inspirational viewing media!!

Chris

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

13 Oct 2016 17:43 #81620

by Lcvette

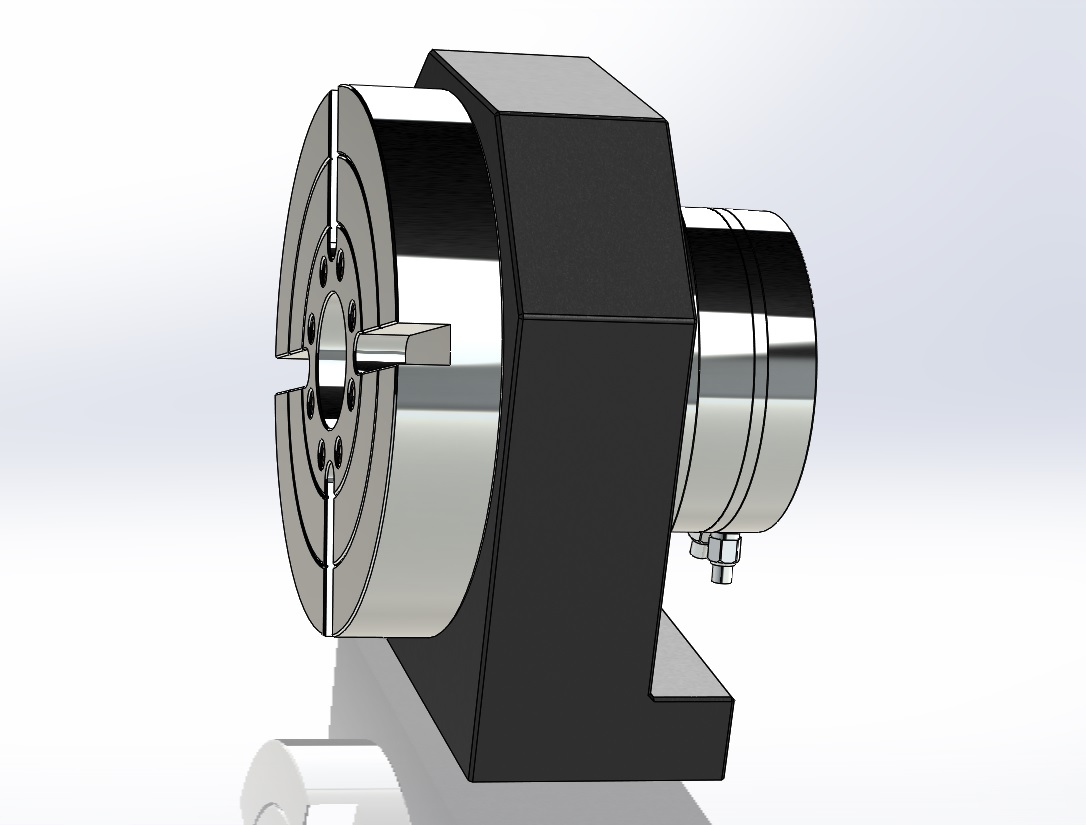

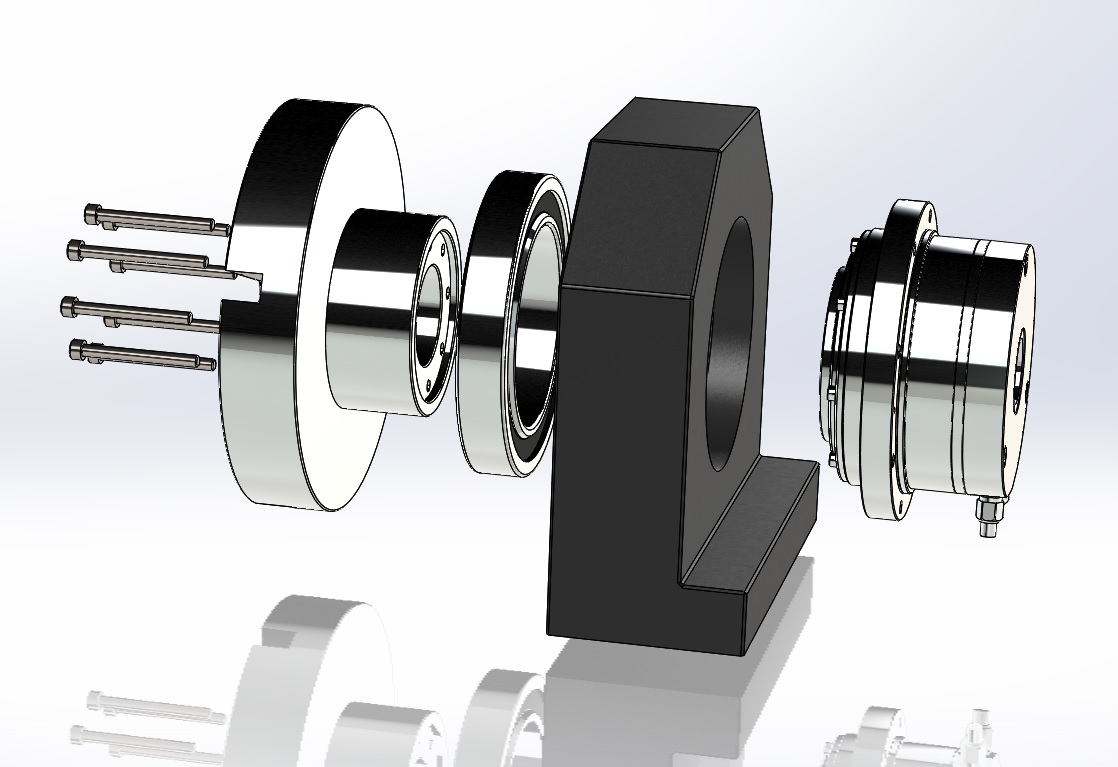

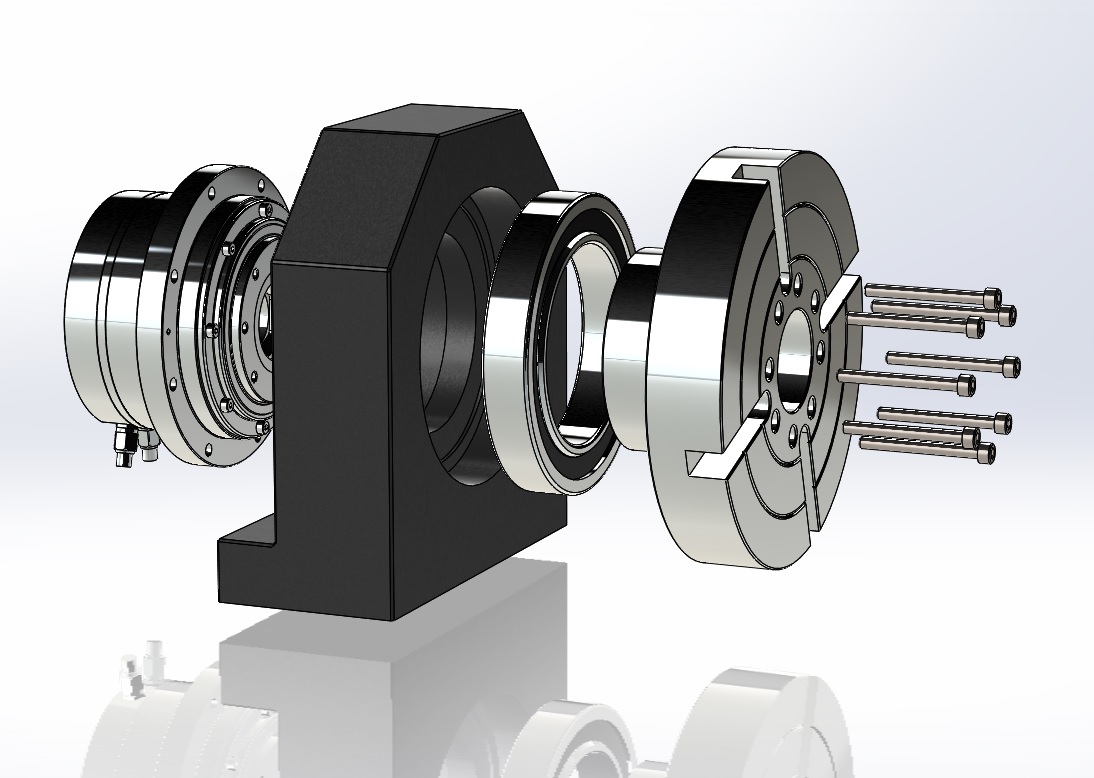

Yeah that's what I'm thinking too! Here is one of the units in considering:

Replied by Lcvette on topic 4th Axis Build

The united I've been looking at are different, they appear to be a housed unit with a cross t roller bearing

Those sound perfect.

Yeah that's what I'm thinking too! Here is one of the units in considering:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

13 Oct 2016 18:57 #81624

by andypugh

Replied by andypugh on topic 4th Axis Build

The FHA look like they make a rotary axis almost too easy.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

13 Oct 2016 22:14 #81626

by Lcvette

I know right! That was exactly what I thought where I saw it.. I just received a step file of the FHA 25-100 e250 which looks perfect for an 8" rotary table build. If you would like a copy let me know! Email This email address is being protected from spambots. You need JavaScript enabled to view it..

Chris

Replied by Lcvette on topic 4th Axis Build

The FHA look like they make a rotary axis almost too easy.

I know right! That was exactly what I thought where I saw it.. I just received a step file of the FHA 25-100 e250 which looks perfect for an 8" rotary table build. If you would like a copy let me know! Email This email address is being protected from spambots. You need JavaScript enabled to view it..

Chris

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

13 Oct 2016 22:25 #81627

by Lcvette

Replied by Lcvette on topic 4th Axis Build

In my research I ran across this and believe that's exactly what he's doing is using a cross roller harmonic drive and bolting the tally directly to it..

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1547

- Thank you received: 726

14 Oct 2016 04:58 #81634

by Lcvette

Replied by Lcvette on topic 4th Axis Build

I whipped this up, it is an 8" Rotary Table design, it isn't finished, but it works out to be 4 parts, the harmonic drive, the frame casting, the table and a cylindrical roller bearing for table support right at the frame edge behind the table. the thrust load will be on the cross roller bearing in the harmonic drive to keep things compact. depth from the table face to the back face of the harmonic drive is 6" pretty good. from the table face to the back edge of the frame casting is 5". I think this is about as simple of a design as you could have, the table would be made from a solid casting and machined to finish. it bolts directly to the harmonic drive so no slop can be introduced into the system. the only backlash in the system will be what the harmonic drive has in it which should be very very low. I think this is a winnder! Thoughts?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

14 Oct 2016 09:12 #81636

by andypugh

Replied by andypugh on topic 4th Axis Build

What is your lathe spindle nose? (assuming you have a lathe). If it is camlock then you could consider adjusting the T-slot number to fit camlock pins between them. (you could have a loose spigot for centering).

Consider tool access to the work for small diameters too.

You might want to copy your milling machine spindle taper in the centre of the rotary. You can then hold smaller work in collets easily.

This is a real-world 4th-axis job I had to use an overlength piece of stock to get the tool to the work. Often you are likely to end up with a small spigot on the stock held in a collet just to get tool access to the end.

Consider tool access to the work for small diameters too.

You might want to copy your milling machine spindle taper in the centre of the rotary. You can then hold smaller work in collets easily.

This is a real-world 4th-axis job I had to use an overlength piece of stock to get the tool to the work. Often you are likely to end up with a small spigot on the stock held in a collet just to get tool access to the end.

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds