DIY 800x800x300(mm) CNC Routeur

- macsddau

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 4

13 Sep 2019 16:53 #145064

by macsddau

DIY 800x800x300(mm) CNC Routeur was created by macsddau

Hello to the community.

My first language is french, so apologies me for my very bad english

Before showing my stuff, I will explain my project.

I'm a mechanical Designer.

I want to make master models to make molds for making composite parts.

In 2013, I bought a 3D printer kit. With a lots of difficulties I print some master models. But I was very despite.

In 2017 I found a basic Kit with motions and spindle to make a CNC routeur

It was in a corner of my workshop.

Recently I decide to check the components.

Last month, I have build the CNC terminal.

Its structure is based on Thomann.de 19" rack for musician.

The PC is a 1 unit height by 250mm depth with :

Spindle inverter is driven with RS485 connected to USB

I have installe The live CD of LinuxCNC

For me, this is the hardiest part of my milling machine. I will build the routing table when all the electronic will work correctly.

Thats all for this time.

My first language is french, so apologies me for my very bad english

Before showing my stuff, I will explain my project.

I'm a mechanical Designer.

I want to make master models to make molds for making composite parts.

In 2013, I bought a 3D printer kit. With a lots of difficulties I print some master models. But I was very despite.

In 2017 I found a basic Kit with motions and spindle to make a CNC routeur

It was in a corner of my workshop.

Recently I decide to check the components.

Last month, I have build the CNC terminal.

Its structure is based on Thomann.de 19" rack for musician.

The PC is a 1 unit height by 250mm depth with :

- an ASRock mini ITX J3355B mother board

- 4GB Ram

- a Radeon HD4650 Graphic card, recently added

- 120GB SSD Drive

Spindle inverter is driven with RS485 connected to USB

I have installe The live CD of LinuxCNC

For me, this is the hardiest part of my milling machine. I will build the routing table when all the electronic will work correctly.

Thats all for this time.

Attachments:

The following user(s) said Thank You: tommylight, Dinuka_Shehan

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

14 Sep 2019 17:01 #145145

by pl7i92

Replied by pl7i92 on topic DIY 800x800x300(mm) CNC Routeur

nice projekt

look in my YT channel for fetting some idees

www.youtube.com/channel/UCGuJsIoXW-exBAwdn38dXow/videos

look in my YT channel for fetting some idees

www.youtube.com/channel/UCGuJsIoXW-exBAwdn38dXow/videos

Please Log in or Create an account to join the conversation.

- macsddau

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 4

22 Sep 2019 13:35 #145839

by macsddau

Replied by macsddau on topic DIY 800x800x300(mm) CNC Routeur

First full run

Next step : build the router...

Next step : build the router...

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

22 Sep 2019 14:36 #145847

by pl7i92

Replied by pl7i92 on topic DIY 800x800x300(mm) CNC Routeur

Do you plan to use a Full KIT Sqare HGH vas it is the cheepest way to do it

and if you also can go for AL-Regular profile you will be fast in a chipping mode

and if you also can go for AL-Regular profile you will be fast in a chipping mode

Please Log in or Create an account to join the conversation.

- macsddau

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 4

22 Sep 2019 17:33 #145874

by macsddau

Replied by macsddau on topic DIY 800x800x300(mm) CNC Routeur

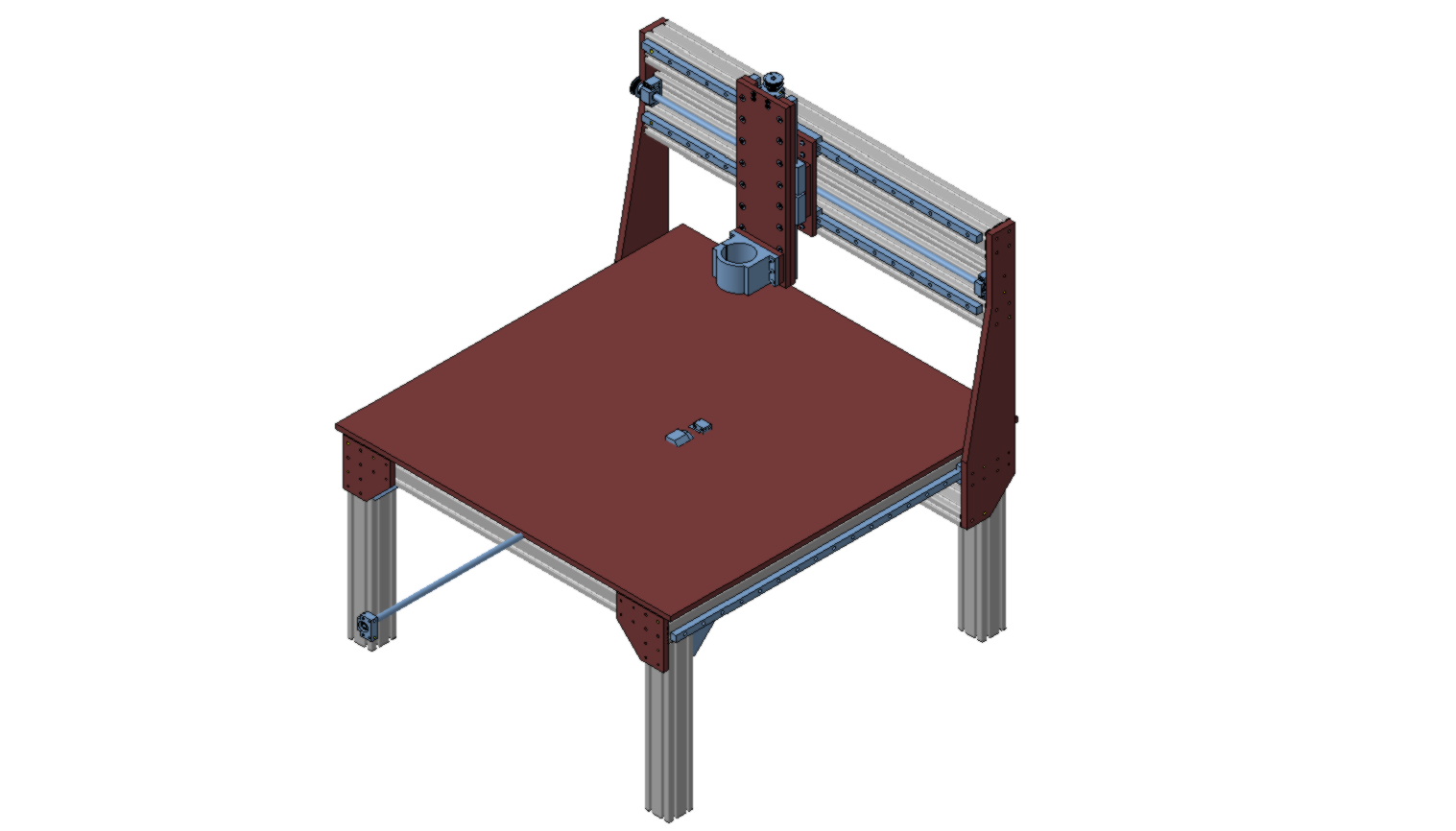

The second picture of this subject show all the hardware that I bought in 2017.

Sliding are mades of 20mm square HGH. Motion is made with d.16 & 5mm pitch ball screen. Link between ball screw and stepper motors will be made with synchro belt with 1:1 transmission. You can see one of the pulley in the above video.

I have drawn my 8th project and I'm not decided of the way to build the frame. It will be probably AL profile ( Motedis ) and AL plate (wood @ for the beginning ?).

Sliding are mades of 20mm square HGH. Motion is made with d.16 & 5mm pitch ball screen. Link between ball screw and stepper motors will be made with synchro belt with 1:1 transmission. You can see one of the pulley in the above video.

I have drawn my 8th project and I'm not decided of the way to build the frame. It will be probably AL profile ( Motedis ) and AL plate (wood @ for the beginning ?).

Attachments:

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

23 Sep 2019 14:35 #145965

by pl7i92

Replied by pl7i92 on topic DIY 800x800x300(mm) CNC Routeur

very good to start

and as time goes by 8th Projekt you will get into

Q: is there a reason for the leg length

and the HSS86 will get cheeper and cheeper on time

no need to go stepper from now as 4Nm is the same at 10times speed and more control

SEPtember 2019

and as time goes by 8th Projekt you will get into

Q: is there a reason for the leg length

and the HSS86 will get cheeper and cheeper on time

no need to go stepper from now as 4Nm is the same at 10times speed and more control

SEPtember 2019

Please Log in or Create an account to join the conversation.

- macsddau

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 4

23 Sep 2019 20:05 #145995

by macsddau

Replied by macsddau on topic DIY 800x800x300(mm) CNC Routeur

The legs connect the y-axis to the x guide rails installed on the sides of the table. x ball screws are under the table. the z stroke is 300mm. This explains the length. But this solution does not please me.

Please Log in or Create an account to join the conversation.

- macsddau@linuxcnc

-

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 28

31 May 2020 08:44 - 31 May 2020 09:08 #169494

by macsddau@linuxcnc

Replied by macsddau@linuxcnc on topic DIY 800x800x300(mm) CNC Routeur

Q for admin ?

Is it possible to move mytopic subject to the right place : Hardware & Machines > CNC Machines ?

Is it possible to move my

Last edit: 31 May 2020 09:08 by macsddau@linuxcnc.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7285

31 May 2020 09:08 #169495

by tommylight

Replied by tommylight on topic DIY 800x800x300(mm) CNC Routeur

Yes it is, but i think it belongs here.Q for admin ?

Is it possible to move my topic to the right place : Hardware & Machines > CNC Machines ?

The following user(s) said Thank You: macsddau@linuxcnc

Please Log in or Create an account to join the conversation.

- macsddau@linuxcnc

-

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 28

31 May 2020 09:10 #169496

by macsddau@linuxcnc

Replied by macsddau@linuxcnc on topic DIY 800x800x300(mm) CNC Routeur

Ok, don't change any thingYes it is, but i think it belongs here.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.328 seconds