CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

11 Nov 2019 14:06 - 11 Nov 2019 15:31 #150112

by tommylight

CNC engraver/etcher for Granite, Marbel, glass, or any hard surface. was created by tommylight

This will be more about the head/spindle assembly, with as much info as possible, so anyone can try to make something similar.

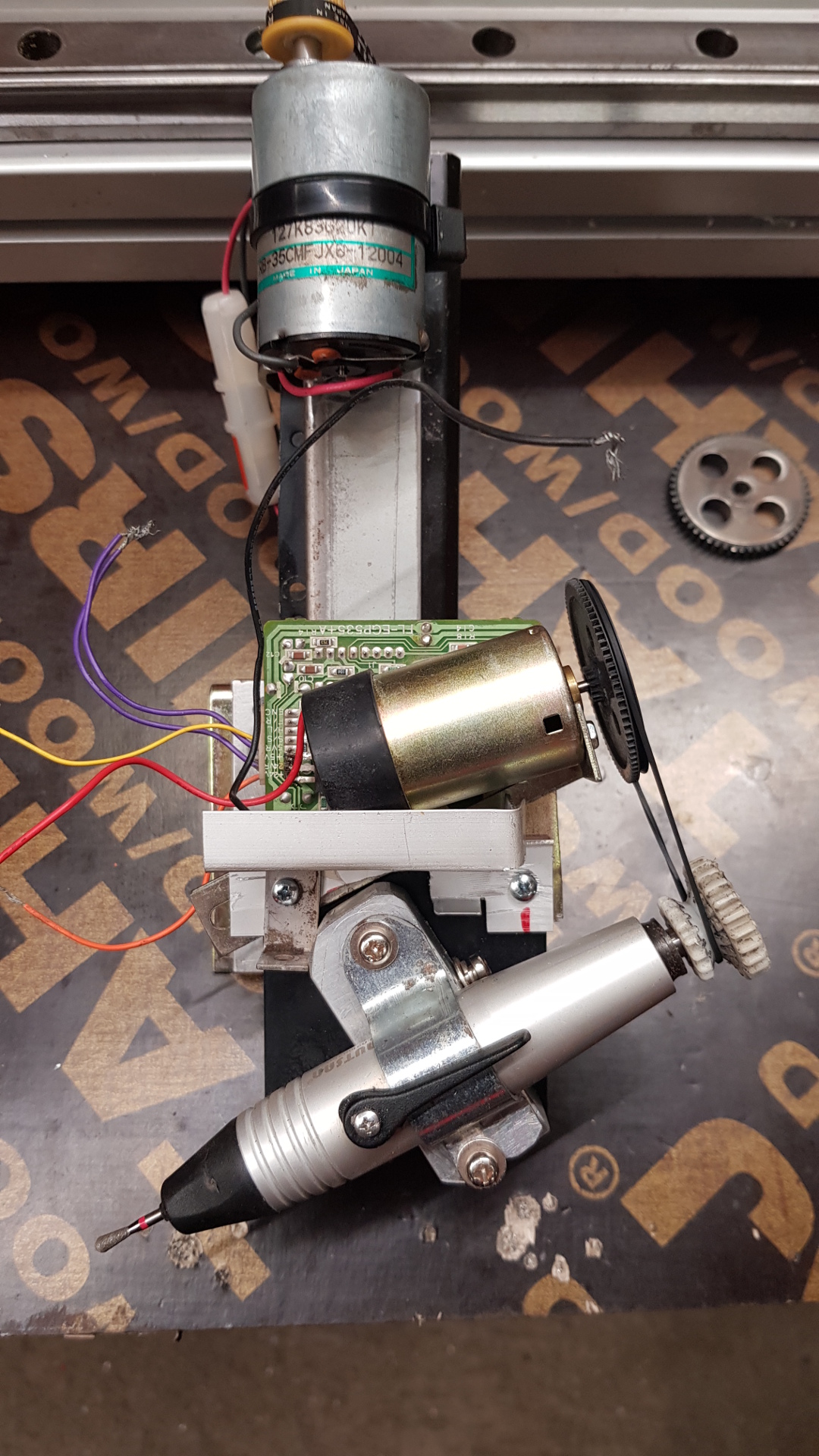

Here is a picture of one of those nearly finished:

And here are some pictures of the Z axis with the pressure motor ( 3 phase DC servo with it's own control electronics ), spindle and spindle DC motor, and the motor and all-thread used for lowering and raising the whole lower assembly.

This is the motor used for moving the head assembly up or down, this part is not needed, it is just a feature, it does work without it.

The DC spindle motor is attached to pressure motor mounts (just the electronics can be seen here) and spindle is attached directly to pressure motor rotor. The two protruding metal parts above the spindle are used to limit the movement.

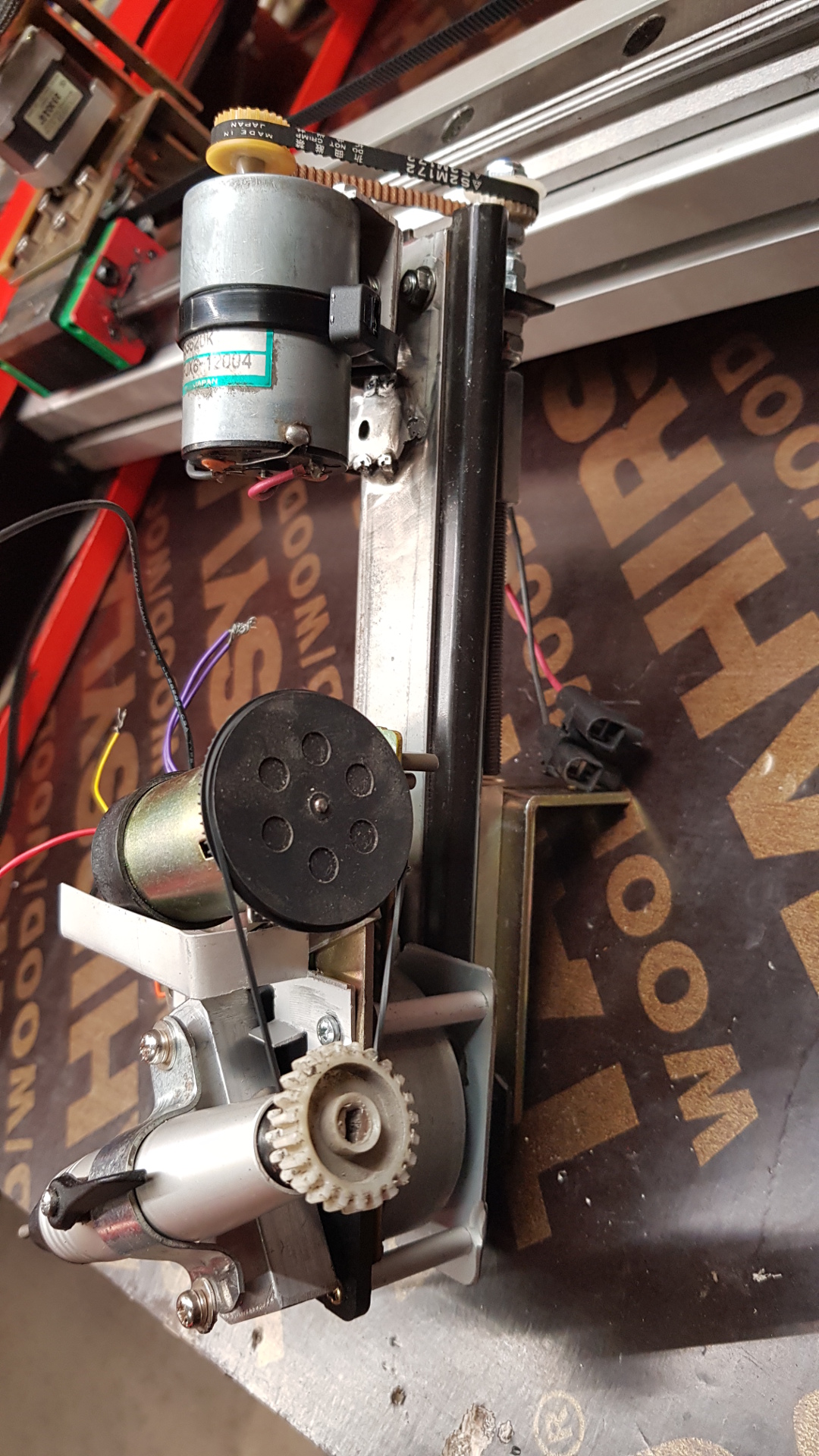

The right side of the assembly so the pressure motor can be seen, mounted to a back plate using spacers.

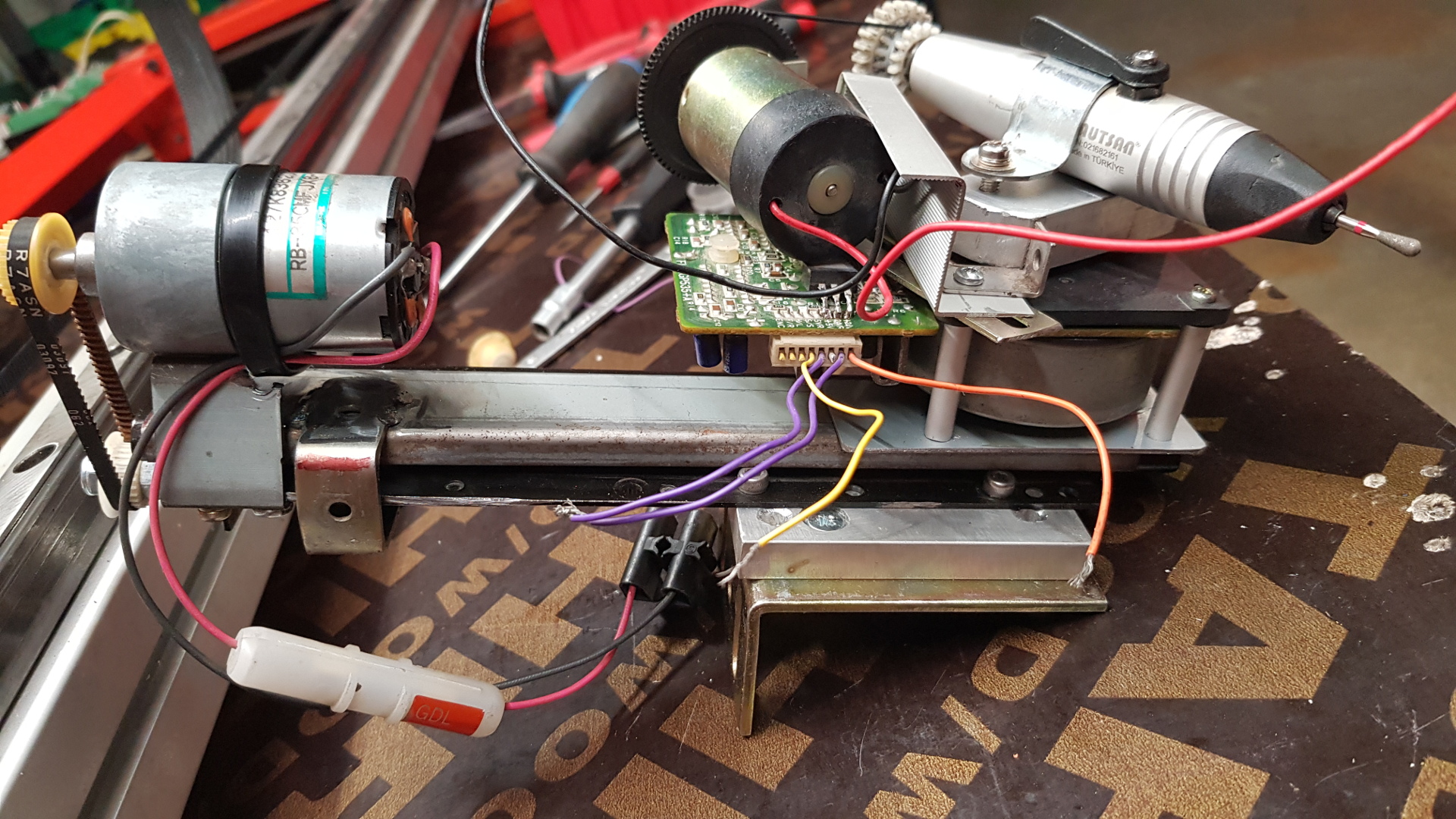

Left side of the assembly, pressure motor wires that are not needed are cut off. This one needs 24V and 5V supply, so a 7805 is soldered to the back of the board. Now there is only a 24V input, two grounds, and the PWM wire. This pin must be pulled low for the motor to spin (in this case it does not spin, it just puts pressure on the spindle), so an NPN transistor is added to the parallel port output such that PWM pulse activates the transistor and in turn it pulls this pin low.

Another side shot of the Z axis motor with all the parts visible. This motor ( and the up/down moving) is not controlled by the computer, but by two buttons ( can be seen on the right front of the machine ) and two relays. so manual control only.

Some additional info as this might look easy, but it is not in any way, shape or form:

Pressure motor

- IT DOES NOT SPIN - when used in such a machine, it is just for putting pressure on the spindle.

- can be any small DC motor with 1:3 or 1:4 reduction, requires a voltage regulator and a Darlington transistor

- or the type shown in this case a small 3 phase servo, requires only a NPN transistor

- can not be to weak or to strong, it has to put 3 to 5 Kg of pressure at the tip of the diamond bit

Spindle motor

- Any small DC motor will do just fine, the faster it is the better

Z axis

- Not obligatory, added just to remove the need for levelling at the beginning of every job

- It works without it

Machine

- In total it needs two stepper drives, 2 or 3 stepper motors, an NPN transistor OR an NPN Darlington transistor and a voltage regulator like LM338, a power supply. Some wires would be nice, and some rails and some belts, some metal to attach all that to, and that's about it.

- Start from the head assembly, always, and build up the machine from there. I always start from the frame and always have to move things around after they have been belted down!

- It can not move fast, as a reference never ever more than 3 meters/minute, so any type of drives will do even the cheap L298 ones, Nema 17 motors are usually enough as the forces during work are small, GT2 belts at 6mm wide will do fine directly driven by 16 tooth pulleys.

Here is a picture of one of those nearly finished:

And here are some pictures of the Z axis with the pressure motor ( 3 phase DC servo with it's own control electronics ), spindle and spindle DC motor, and the motor and all-thread used for lowering and raising the whole lower assembly.

This is the motor used for moving the head assembly up or down, this part is not needed, it is just a feature, it does work without it.

The DC spindle motor is attached to pressure motor mounts (just the electronics can be seen here) and spindle is attached directly to pressure motor rotor. The two protruding metal parts above the spindle are used to limit the movement.

The right side of the assembly so the pressure motor can be seen, mounted to a back plate using spacers.

Left side of the assembly, pressure motor wires that are not needed are cut off. This one needs 24V and 5V supply, so a 7805 is soldered to the back of the board. Now there is only a 24V input, two grounds, and the PWM wire. This pin must be pulled low for the motor to spin (in this case it does not spin, it just puts pressure on the spindle), so an NPN transistor is added to the parallel port output such that PWM pulse activates the transistor and in turn it pulls this pin low.

Another side shot of the Z axis motor with all the parts visible. This motor ( and the up/down moving) is not controlled by the computer, but by two buttons ( can be seen on the right front of the machine ) and two relays. so manual control only.

Some additional info as this might look easy, but it is not in any way, shape or form:

Pressure motor

- IT DOES NOT SPIN - when used in such a machine, it is just for putting pressure on the spindle.

- can be any small DC motor with 1:3 or 1:4 reduction, requires a voltage regulator and a Darlington transistor

- or the type shown in this case a small 3 phase servo, requires only a NPN transistor

- can not be to weak or to strong, it has to put 3 to 5 Kg of pressure at the tip of the diamond bit

Spindle motor

- Any small DC motor will do just fine, the faster it is the better

Z axis

- Not obligatory, added just to remove the need for levelling at the beginning of every job

- It works without it

Machine

- In total it needs two stepper drives, 2 or 3 stepper motors, an NPN transistor OR an NPN Darlington transistor and a voltage regulator like LM338, a power supply. Some wires would be nice, and some rails and some belts, some metal to attach all that to, and that's about it.

- Start from the head assembly, always, and build up the machine from there. I always start from the frame and always have to move things around after they have been belted down!

- It can not move fast, as a reference never ever more than 3 meters/minute, so any type of drives will do even the cheap L298 ones, Nema 17 motors are usually enough as the forces during work are small, GT2 belts at 6mm wide will do fine directly driven by 16 tooth pulleys.

Attachments:

Last edit: 11 Nov 2019 15:31 by tommylight. Reason: more info

The following user(s) said Thank You: phillc54, Clive S

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

11 Nov 2019 14:24 - 11 Nov 2019 14:26 #150114

by pl7i92

Replied by pl7i92 on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Last edit: 11 Nov 2019 14:26 by pl7i92.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

11 Nov 2019 14:49 - 11 Nov 2019 14:50 #150119

by tommylight

The spindle has to be very light or it does not work. Heavy spindle can not move fast enough so the pictures end up bad. The spindle costs 33 Euro without a motor.

Those can be found at dentist equipment shops.

Replied by tommylight on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Ne, die spindel muss sehr licht sein oder es funct nicht. Schwere spindel can nisch shnell genug bewegen und das macht sehr schlehte bild. Spindel costet 33 Euro, ohne motor.T tom ist dir das Geld ausgegangen nach dem Heisen Teil nun ein lowtec low cost spindel setup

The spindle has to be very light or it does not work. Heavy spindle can not move fast enough so the pictures end up bad. The spindle costs 33 Euro without a motor.

Those can be found at dentist equipment shops.

Last edit: 11 Nov 2019 14:50 by tommylight. Reason: more info

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

11 Nov 2019 15:32 #150128

by tommylight

Replied by tommylight on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Added more info to the first post.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 Nov 2019 17:07 - 11 Nov 2019 17:17 #150138

by machinedude

thank god for translators otherwise i would be more clueless than usual

wondered why the translator repeated itself should have kept reading and seen you did that work for me. see how clueless i really am now

see how clueless i really am now

Replied by machinedude on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Ne, die spindel muss sehr licht sein oder es funct nicht. Schwere spindel can nisch shnell genug bewegen und das macht sehr schlehte bild. Spindel costet 33 Euro, ohne motor.T tom ist dir das Geld ausgegangen nach dem Heisen Teil nun ein lowtec low cost spindel setup

The spindle has to be very light or it does not work. Heavy spindle can not move fast enough so the pictures end up bad. The spindle costs 33 Euro without a motor.

Those can be found at dentist equipment shops.

thank god for translators otherwise i would be more clueless than usual

wondered why the translator repeated itself should have kept reading and seen you did that work for me.

Last edit: 11 Nov 2019 17:17 by machinedude. Reason: missed the translation at the bottom

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

11 Nov 2019 18:44 #150147

by rodw

Replied by rodw on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

I think I finally get it! The pressure motor is "pancake" style hidden behind the spindle.

I think you had done one before which raised and lowered the engraver with a solenoid.

I think you had done one before which raised and lowered the engraver with a solenoid.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 Nov 2019 23:45 #150162

by machinedude

Replied by machinedude on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

on a serious note what kind of cam software would you use on a machine of this nature? i'm not up on engraving or artistic side of programming at all. only engraving i do is part numbers for identification which is pretty basic at best.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

12 Nov 2019 02:55 #150168

by tommylight

There are two companies in Germany that manufacture similar machines that do it the same way as i did with the use of a DC motor and a bit of reduction, it works really nice and has plenty of discernable pressure levels.

This latest iteration ( circa 3 years ) with "pancakes" has proven more reliable at getting the right pressure, before it would take 2 days just to set it properly, now i can do a complete head in a day and start the frame.

I wonder what will Clive do as i gave him one of those assemblies when he visited here.

Replied by tommylight on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Yes, that is it, usually found on old photocopiers and new ones, but new ones do require another clock signal or they will not work and even then after about 1 second the protection kicks in as the motor is not spinning. Finding them has become difficult at best.I think I finally get it! The pressure motor is "pancake" style hidden behind the spindle.

I never did any with solenoid, i just did some test with them and they proved useless as they can do about 2 to 3 pressure levels at best. All the machines i did service came with that type of solenoid or a big electromagnet, hence i was searching for better solutions.I think you had done one before which raised and lowered the engraver with a solenoid.

There are two companies in Germany that manufacture similar machines that do it the same way as i did with the use of a DC motor and a bit of reduction, it works really nice and has plenty of discernable pressure levels.

This latest iteration ( circa 3 years ) with "pancakes" has proven more reliable at getting the right pressure, before it would take 2 days just to set it properly, now i can do a complete head in a day and start the frame.

I wonder what will Clive do as i gave him one of those assemblies when he visited here.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

12 Nov 2019 02:56 #150169

by tommylight

Replied by tommylight on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

Scorchworks has a nice piece of free software named dmap2gcode that does a wonderful job for this, i just had to modify it a bit so it outputs M67 values instead of Z values.on a serious note what kind of cam software would you use on a machine of this nature?

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

12 Nov 2019 08:24 #150176

by Clive S

And there was I trying to keep that a secret

Replied by Clive S on topic CNC engraver/etcher for Granite, Marbel, glass, or any hard surface.

I wonder what will Clive do as i gave him one of those assemblies when he visited here.

And there was I trying to keep that a secret

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.252 seconds