Making DIY 3 axis Cheese mill

- toplakd

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 7

16 Nov 2019 09:56 - 16 Nov 2019 09:58 #150460

by toplakd

Making DIY 3 axis Cheese mill was created by toplakd

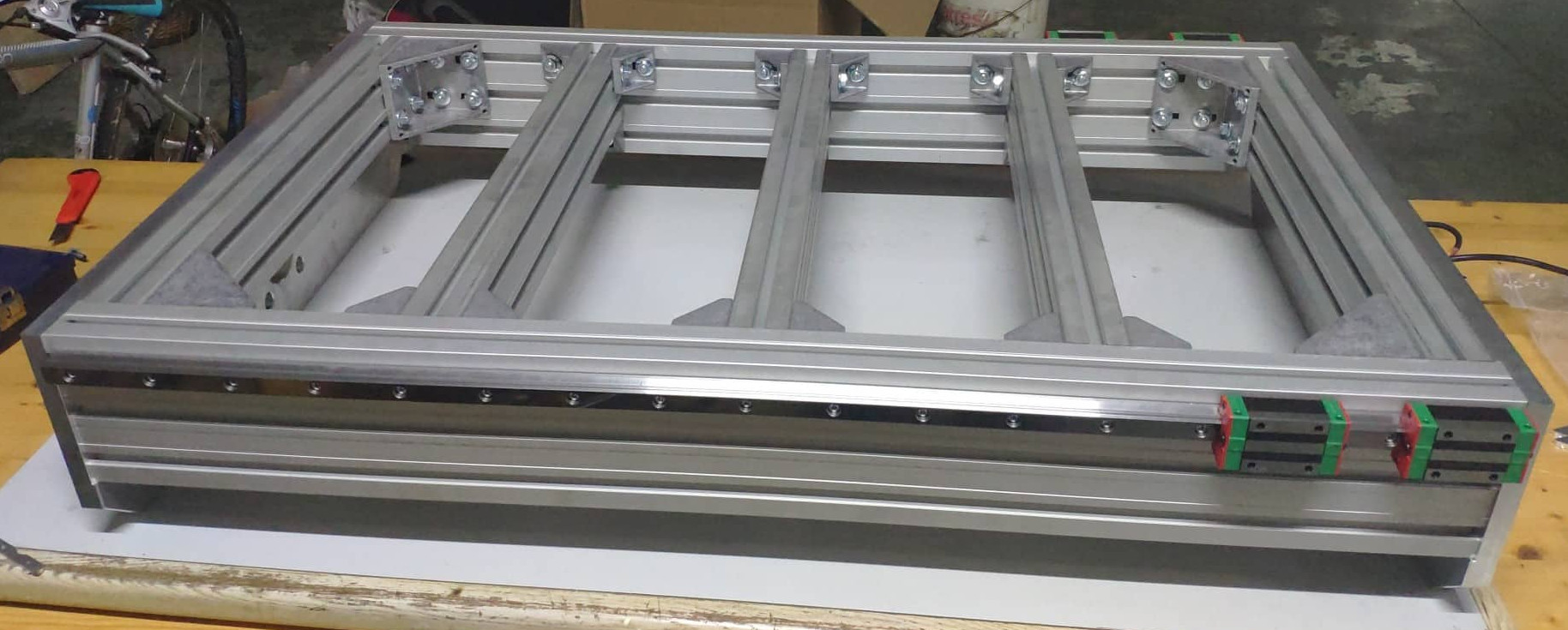

Decided to make myself one DIY CNC so I can make some other stuff when main machine is working.

Machine is made out of aluminium profiles, and 6082-T6 Aluminium plates.

It will run with parallel port, which will be later reconected through Mesa 7i92.

Here some pics from the process:

Assembled the base (135x45 & 45x90 heavy profiles are used)

Prepared for drilling holes for M8 and milliing M8 threads on 710x200x30mm main portal plate

Assembled and now ready for making the bottom table and wiring.

Machine is made out of aluminium profiles, and 6082-T6 Aluminium plates.

It will run with parallel port, which will be later reconected through Mesa 7i92.

Here some pics from the process:

Assembled the base (135x45 & 45x90 heavy profiles are used)

Prepared for drilling holes for M8 and milliing M8 threads on 710x200x30mm main portal plate

Assembled and now ready for making the bottom table and wiring.

Attachments:

Last edit: 16 Nov 2019 09:58 by toplakd.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

16 Nov 2019 10:10 #150461

by Leon82

Replied by Leon82 on topic Making DIY 3 axis Cheese mill

That came out really nice.

Are those profiles rigid when bolted and gusseted like that?

Are those profiles rigid when bolted and gusseted like that?

Please Log in or Create an account to join the conversation.

- toplakd

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 7

16 Nov 2019 10:24 - 16 Nov 2019 10:26 #150462

by toplakd

Replied by toplakd on topic Making DIY 3 axis Cheese mill

They are rigid enough for a hobby mill.

I started with way way more lighter "machine" 9 years ago, and milled tons of aluminium from 2-8mm before I bought new steel machine.

On the picture below is the Mixware P1 Kit I bought 9 years ago when I started.

Pic does not show my actual machine from that time as it's from manufacturers website.

It was made out of 45x90mm light profiles and tiny portal plates.

However I was cutting only aluminium on it.

45X90 Light main profile from my first machine:

Moment of inertia Ix [cm4] 87.15

45x135 Heavy main profile from my diy:

Moment of inertia Ix [cm4] 376.27

For the cross connection I used 45x90 Heavy which i mounted verticaly, where most mount them horizontaly and they are connected to main profile with 3 45x45 brackets on each side. 1 on each side of the profile, and 1 at the bottom side.

Front and rear cross profile are connected with 90x90 bracket on each side.

Picture of Mixware P1 Kit, with this i started to learn CNC and LinuxCNC

I started with way way more lighter "machine" 9 years ago, and milled tons of aluminium from 2-8mm before I bought new steel machine.

On the picture below is the Mixware P1 Kit I bought 9 years ago when I started.

Pic does not show my actual machine from that time as it's from manufacturers website.

It was made out of 45x90mm light profiles and tiny portal plates.

However I was cutting only aluminium on it.

45X90 Light main profile from my first machine:

Moment of inertia Ix [cm4] 87.15

45x135 Heavy main profile from my diy:

Moment of inertia Ix [cm4] 376.27

For the cross connection I used 45x90 Heavy which i mounted verticaly, where most mount them horizontaly and they are connected to main profile with 3 45x45 brackets on each side. 1 on each side of the profile, and 1 at the bottom side.

Front and rear cross profile are connected with 90x90 bracket on each side.

Picture of Mixware P1 Kit, with this i started to learn CNC and LinuxCNC

Attachments:

Last edit: 16 Nov 2019 10:26 by toplakd.

The following user(s) said Thank You: Leon82

Please Log in or Create an account to join the conversation.

Time to create page: 0.219 seconds