Barnworks shop update

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

12 Oct 2021 08:09 #222905

by anfänger

Barnworks shop update was created by anfänger

I wanted to to improve a bit on my workshop so I decides to knock a hole in my rear wall:

and patch it up with a beam and a window

The main problem with this is, that I took some days off at wirkt to do it and spent to much time on eBay, so I ended up buying a „new“ machine.

so after finishing the window project it was time to rearrange my machines to make space for the new member of my family

Now i am sitting here at work wan waiting like a little kid for next two weeks to pass, and the machine to arrive:

Not really sure in what condition she is, the control throws an error message, which needs investigating. So not sure if there will be a retrofit to LinuxCNC necessary. She already got a 4th axis, so a lot of new opportunities come up

and patch it up with a beam and a window

The main problem with this is, that I took some days off at wirkt to do it and spent to much time on eBay, so I ended up buying a „new“ machine.

so after finishing the window project it was time to rearrange my machines to make space for the new member of my family

Now i am sitting here at work wan waiting like a little kid for next two weeks to pass, and the machine to arrive:

Not really sure in what condition she is, the control throws an error message, which needs investigating. So not sure if there will be a retrofit to LinuxCNC necessary. She already got a 4th axis, so a lot of new opportunities come up

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

12 Oct 2021 20:10 #222969

by tommylight

Replied by tommylight on topic Barnworks shop update

Very nice, and get help !

Really, get help, you are becoming like me (and some others here i will not mention) !

That is a joke.

Looks like a nice machine, looking forward to seeing how it ends up after you have a go at it.

Yesterday i was offered a Hurco 20 i retrofitted a while back, free of charge just have to finish everything they need on it for eternity, the NO out of my mouth was so fast, my teeth almost flew off!

Really, get help, you are becoming like me (and some others here i will not mention) !

That is a joke.

Looks like a nice machine, looking forward to seeing how it ends up after you have a go at it.

Yesterday i was offered a Hurco 20 i retrofitted a while back, free of charge just have to finish everything they need on it for eternity, the NO out of my mouth was so fast, my teeth almost flew off!

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

13 Oct 2021 06:41 - 13 Oct 2021 06:43 #223006

by anfänger

Replied by anfänger on topic Barnworks shop update

I need this to compensate for my normal job, wich is mostly E-Mail work, you don‘t really see what you are doing. In the workshop this is different. You see what you do.

Everything’s started with a shared workshop a long time ago.

The friend from back then, now will have some space for a workshop, so he will get all of my small machines, one torch, the old welder and a bunch of other stuff, basically everything from our first workshop.

The new mill is a replacement for the manual mill. On my cnc I can‘t really access the work under the spindle for sketchy setups . This will be better at the picomax and with the 4t axis I have everything I need (at least this is what I tell me everyday since I bought it)

. This will be better at the picomax and with the 4t axis I have everything I need (at least this is what I tell me everyday since I bought it)

Btw. My therapist gave up on my a long time ago. Most of my friend think I am a maniac. But that’s the comforting thing about the internet, you know there are people out there with the same problem…

Everything’s started with a shared workshop a long time ago.

The friend from back then, now will have some space for a workshop, so he will get all of my small machines, one torch, the old welder and a bunch of other stuff, basically everything from our first workshop.

The new mill is a replacement for the manual mill. On my cnc I can‘t really access the work under the spindle for sketchy setups

Btw. My therapist gave up on my a long time ago. Most of my friend think I am a maniac. But that’s the comforting thing about the internet, you know there are people out there with the same problem…

Last edit: 13 Oct 2021 06:43 by anfänger.

The following user(s) said Thank You: BigJohnT, tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

15 Oct 2021 22:00 #223241

by my1987toyota

Replied by my1987toyota on topic Barnworks shop update

WOW to have that much space to work with is amazing.

PS. it's not you, the rest of the world is crazy.

PS. it's not you, the rest of the world is crazy.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

22 Oct 2021 09:44 #223894

by anfänger

Replied by anfänger on topic Barnworks shop update

The space is the luxury of living in a small village. It‘s cheaper here and still just 20 min by car to work.

The downside is it‘s not heated, so the machines tend to rust a bit from oct to feb. But it getting better. And when the barn gets a new roof the roof of the workshop will get insulated, so it will get better then. In the meantime oil and fluid film help a lot.

Today the machine was loaded at the seller

Monday I have a day off for unloading. Then I can check if it will be a small fix, small control retrofit or full retrofit.

I hope for small fix to get her run quickly. Small retrofit, so just changing the control to Mesa an LinuxCNC would be ok to. Even convenient cause then I can use a tool length sensor.

Would have some challenges with 4th axis and the height adjustments for the head. The rest should be straight forward.

Sadly it has a SF32 spindle not the SK30, so I can’t share tools with my Chiron.

The downside is it‘s not heated, so the machines tend to rust a bit from oct to feb. But it getting better. And when the barn gets a new roof the roof of the workshop will get insulated, so it will get better then. In the meantime oil and fluid film help a lot.

Today the machine was loaded at the seller

Monday I have a day off for unloading. Then I can check if it will be a small fix, small control retrofit or full retrofit.

I hope for small fix to get her run quickly. Small retrofit, so just changing the control to Mesa an LinuxCNC would be ok to. Even convenient cause then I can use a tool length sensor.

Would have some challenges with 4th axis and the height adjustments for the head. The rest should be straight forward.

Sadly it has a SF32 spindle not the SK30, so I can’t share tools with my Chiron.

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Oct 2021 16:29 #224279

by anfänger

Replied by anfänger on topic Barnworks shop update

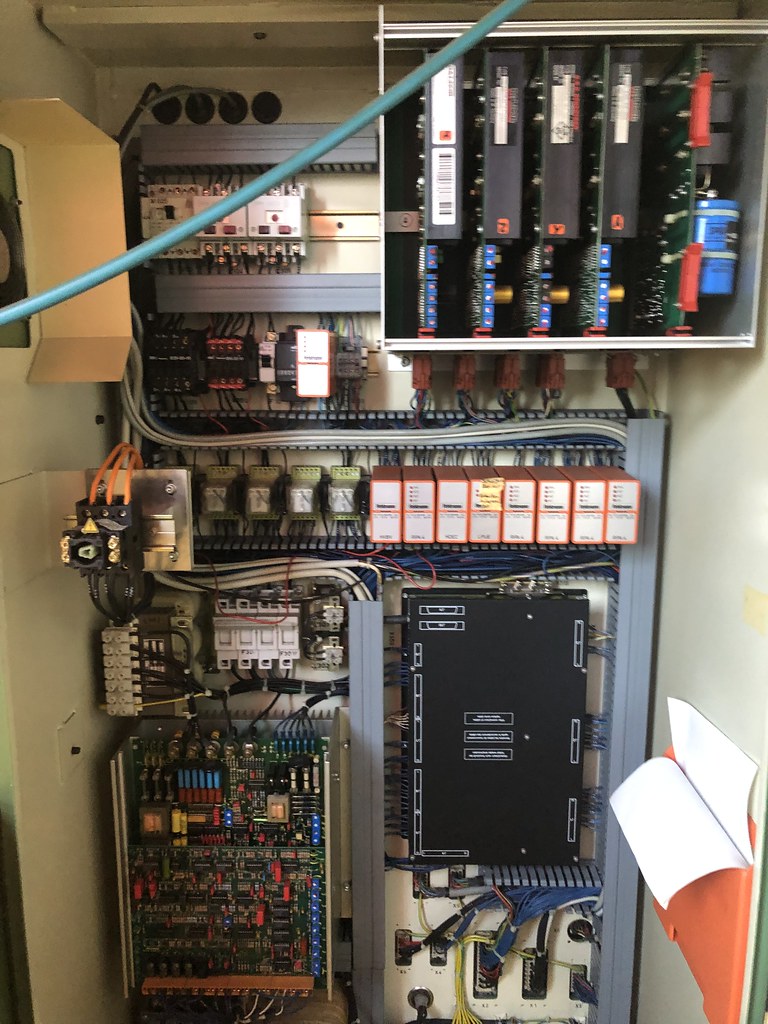

she is here now:

and seams to be alive, but has lost her parameters (the batteries were more than empty)

so next step is to enter the parameters and see if she runs. The Monitor is quite dark and has definitely seen better days. So the plan is, if she runs, to get her to know and prepare for a control retrofit. To be ready when the monitor dies.

There is more tan enough space in the old control box and the cabinet looks really wenn organized:

and seams to be alive, but has lost her parameters (the batteries were more than empty)

so next step is to enter the parameters and see if she runs. The Monitor is quite dark and has definitely seen better days. So the plan is, if she runs, to get her to know and prepare for a control retrofit. To be ready when the monitor dies.

There is more tan enough space in the old control box and the cabinet looks really wenn organized:

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

29 Oct 2021 11:10 #224640

by my1987toyota

Replied by my1987toyota on topic Barnworks shop update

Is the electrical cabinet direct air cooled or is it using a heat sink system?

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

30 Oct 2021 08:32 #224706

by anfänger

Replied by anfänger on topic Barnworks shop update

It‘s simply aircooled, nothing fancy.

She stand on her own feet now:

[/url]

Next week it will try to reset the parameters and se if I gan get her to move And see if I can breathe some more life into the monitor. I will prepare the LinuxCNC retrofit in case the monitor dies on me. Cause I am not willing to pay 600€ or more for an replacement.

She stand on her own feet now:

[/url]

Next week it will try to reset the parameters and se if I gan get her to move And see if I can breathe some more life into the monitor. I will prepare the LinuxCNC retrofit in case the monitor dies on me. Cause I am not willing to pay 600€ or more for an replacement.

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

30 Oct 2021 16:04 #224718

by Clive S

If the monitor is dark an old tip is if you gently tap the neck of the tube near the heater this will knock a bit of crap of the cathode This has to be done with the monitor on ie heater on.. At your own risk of course

Replied by Clive S on topic Barnworks shop update

It‘s simply aircooled, nothing fancy.

She stand on her own feet now:

If the monitor is dark an old tip is if you gently tap the neck of the tube near the heater this will knock a bit of crap of the cathode This has to be done with the monitor on ie heater on.. At your own risk of course

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

30 Oct 2021 16:24 #224719

by tommylight

Replied by tommylight on topic Barnworks shop update

@Clive,

You had to go there ...

On the back of the CRT there is a detachable board, find the two pins that power the heater inside the tube, cut those lines then take a long piece of whatever thin isolated wire and wind it twice around the ferite part of the high voltage transformer and solder the ends to those two pins on the tube side.

That will bring it back nicely, but it will not last long.

You had to go there ...

On the back of the CRT there is a detachable board, find the two pins that power the heater inside the tube, cut those lines then take a long piece of whatever thin isolated wire and wind it twice around the ferite part of the high voltage transformer and solder the ends to those two pins on the tube side.

That will bring it back nicely, but it will not last long.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

Time to create page: 0.100 seconds