Barnworks shop update

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

30 Oct 2021 20:17 #224729

by anfänger

Replied by anfänger on topic Barnworks shop update

Thanks for the tips, I think there are also ways to tinker with the high voltage part. But all is just buying time. And There is a quite good visible ghost screen.

I think I will start a linuxcnc conversion at some point.

But I would prefer to be able to use the mitt for half a year without any changes, to get her to know a bit. Maybe export some cycles and see what I would change. And the 1000mm x travel will be fun.

I think I will start a linuxcnc conversion at some point.

But I would prefer to be able to use the mitt for half a year without any changes, to get her to know a bit. Maybe export some cycles and see what I would change. And the 1000mm x travel will be fun.

Please Log in or Create an account to join the conversation.

- Muzzer

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 41

30 Oct 2021 21:40 #224733

by Muzzer

Replied by Muzzer on topic Barnworks shop update

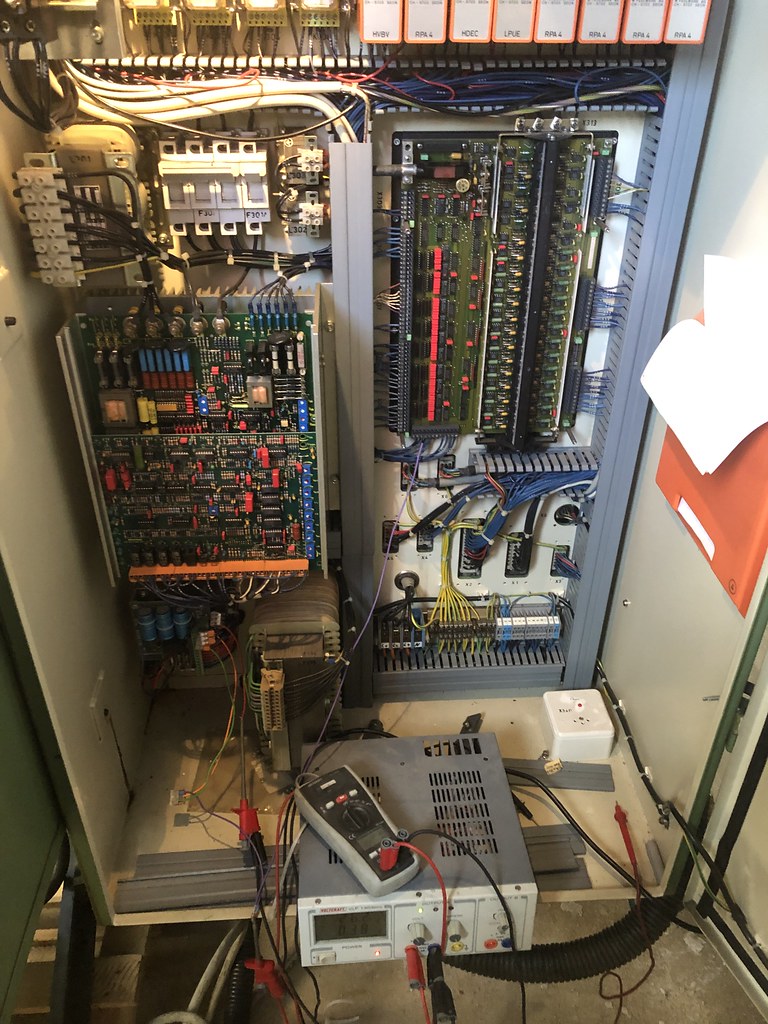

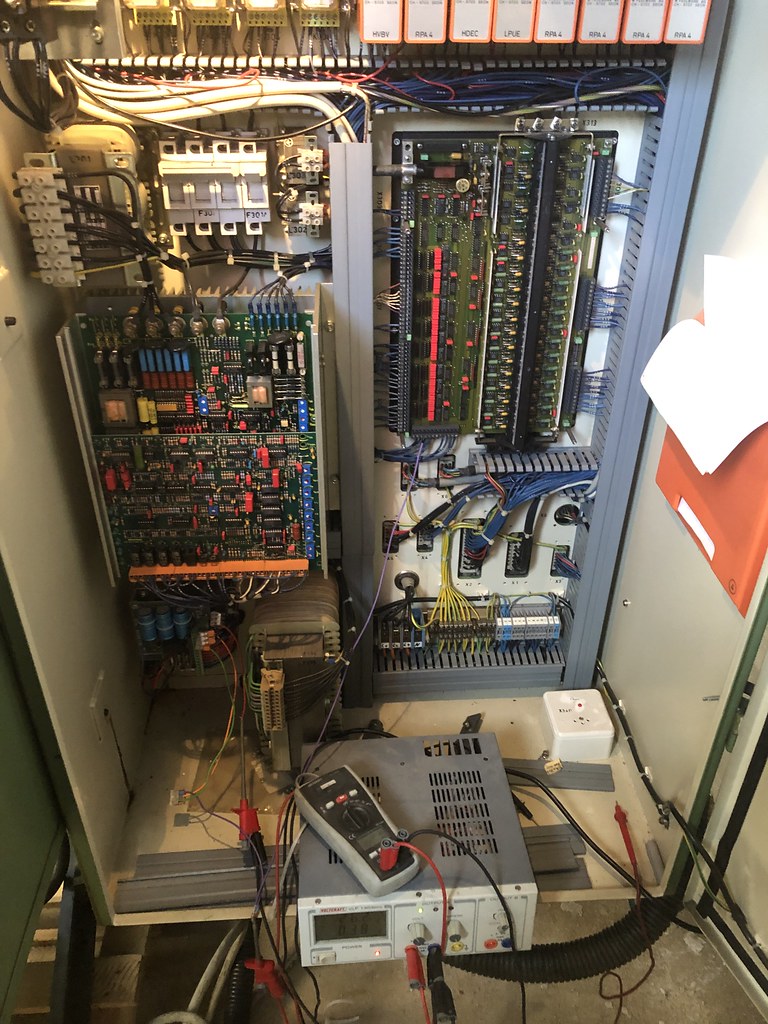

I can't read any of the date codes on the compts but the electronics look very 1980s vintage - are they analogue (DC brushed motors)?. Whether or not it can be persuaded to work as it stands, the electronics will be difficult to repair or replace if anything fails. The more time you devote to it in its current state, the more you will lose when it fails.

You are surely going to be doing a replacement with modern digital drives sooner than later. With today's toolpaths and controls, it will fly along in a way the original manufacturer could never have imagined. Looks like a nice machine and I assume it was built as a CNC machine in the factory?

You are surely going to be doing a replacement with modern digital drives sooner than later. With today's toolpaths and controls, it will fly along in a way the original manufacturer could never have imagined. Looks like a nice machine and I assume it was built as a CNC machine in the factory?

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

31 Oct 2021 09:06 #224754

by anfänger

Replied by anfänger on topic Barnworks shop update

Yea the machine is from 86, and has an analog DC servo control with gals scales as feedback. And was build as a CNC.

Iv‘e already converted a 89 cnc machine to linuxcnc keeping servo an sprinkle drive. As long as they are running I don‘t see any reason to change them. Especially when they are well documented like Sinumerik or Heidenhein. And when they fail and I can‘t repair, they will be replaced with something modern.

I just think it would be fun to get her running as she is to play a bit around. After all there is no real need for this machine yet. I bought it for the fun of it. And she is a really nice addition to have fun with in the shop.

Iv‘e already converted a 89 cnc machine to linuxcnc keeping servo an sprinkle drive. As long as they are running I don‘t see any reason to change them. Especially when they are well documented like Sinumerik or Heidenhein. And when they fail and I can‘t repair, they will be replaced with something modern.

I just think it would be fun to get her running as she is to play a bit around. After all there is no real need for this machine yet. I bought it for the fun of it. And she is a really nice addition to have fun with in the shop.

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

05 Nov 2021 22:21 #225440

by my1987toyota

Replied by my1987toyota on topic Barnworks shop update

It's nice when you can keep old iron operating. It's even better when you can improve it with modern electronics.

I hope the project goes well.

I hope the project goes well.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

06 Nov 2021 18:58 #225516

by anfänger

Replied by anfänger on topic Barnworks shop update

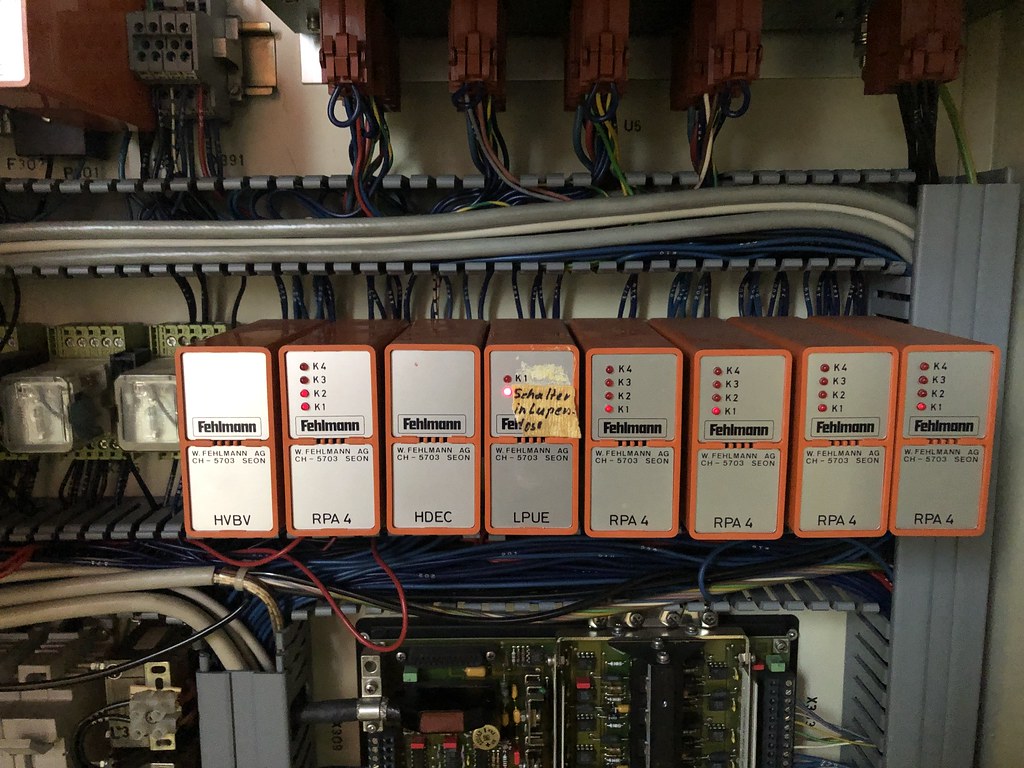

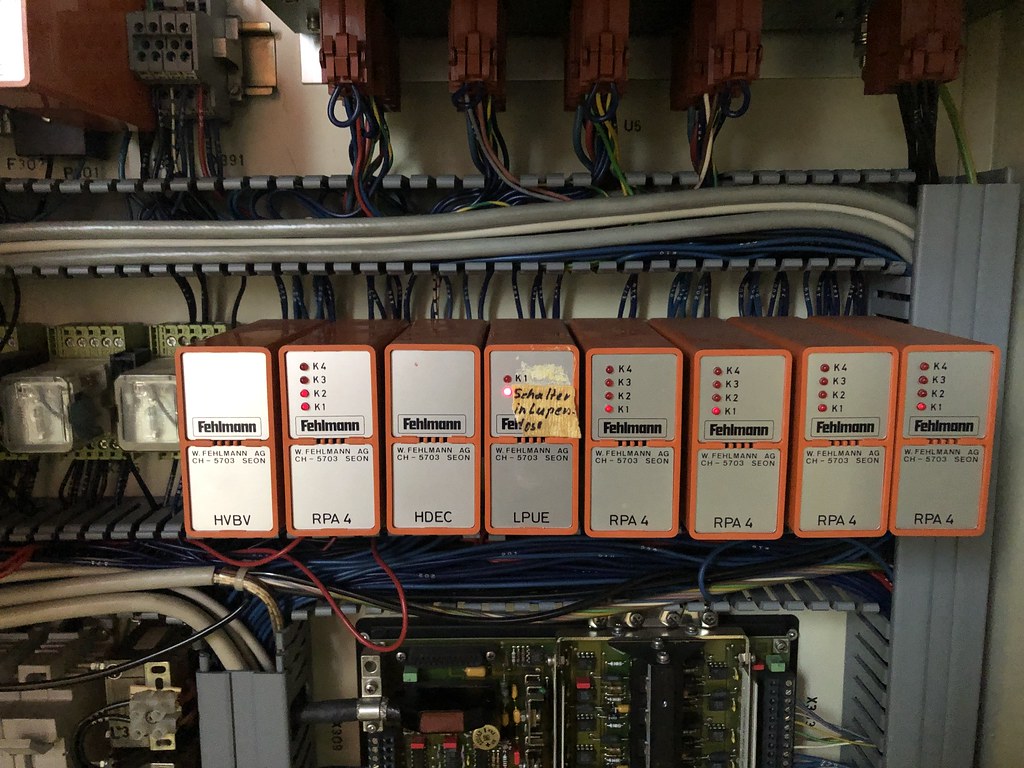

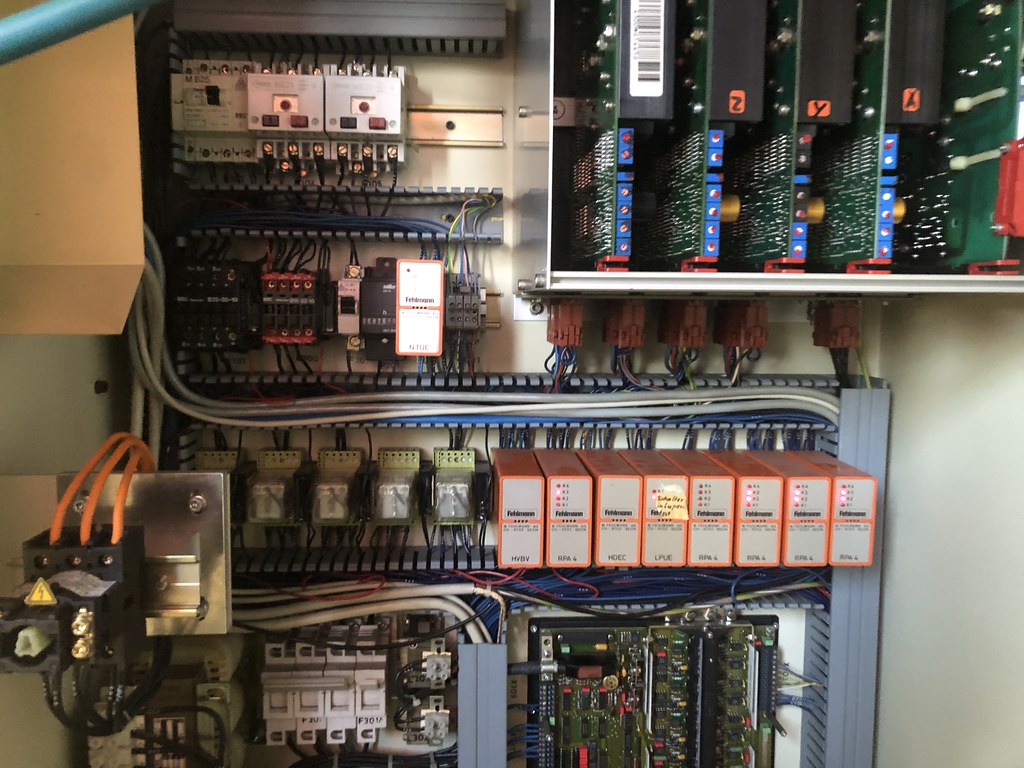

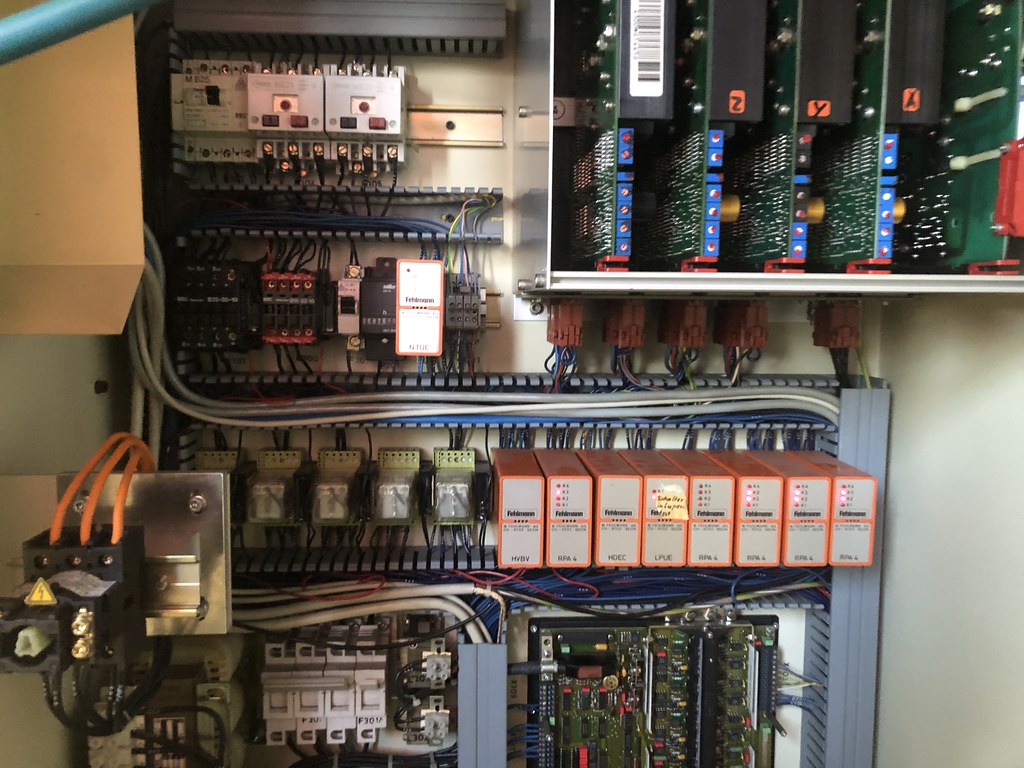

Started to look a the Fehlmann, First she got new batteries and her won socket (no more extension cords lying around and I really appreciate the cable channels, they were a good decision)

the I reset the parameters but still got an error message:

this kind of points towards E-Stop or Power Supply. So I checked the E-Stop and found an open connection, but it sill didn't start.

So I took the multimeters and found all Inputs are low, wich is kind of odd. Also the LED's of some of the thingies in the cabinet look darker than others.

I DIsconnected two signals the should habe been high from the Circus board and the they were high.

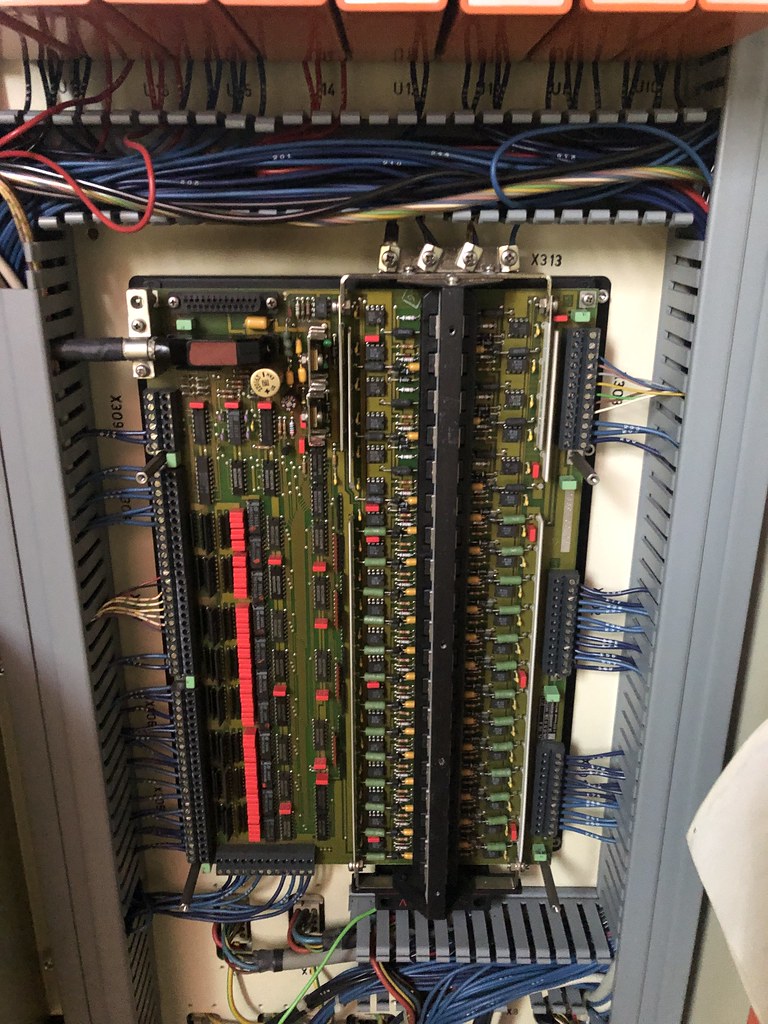

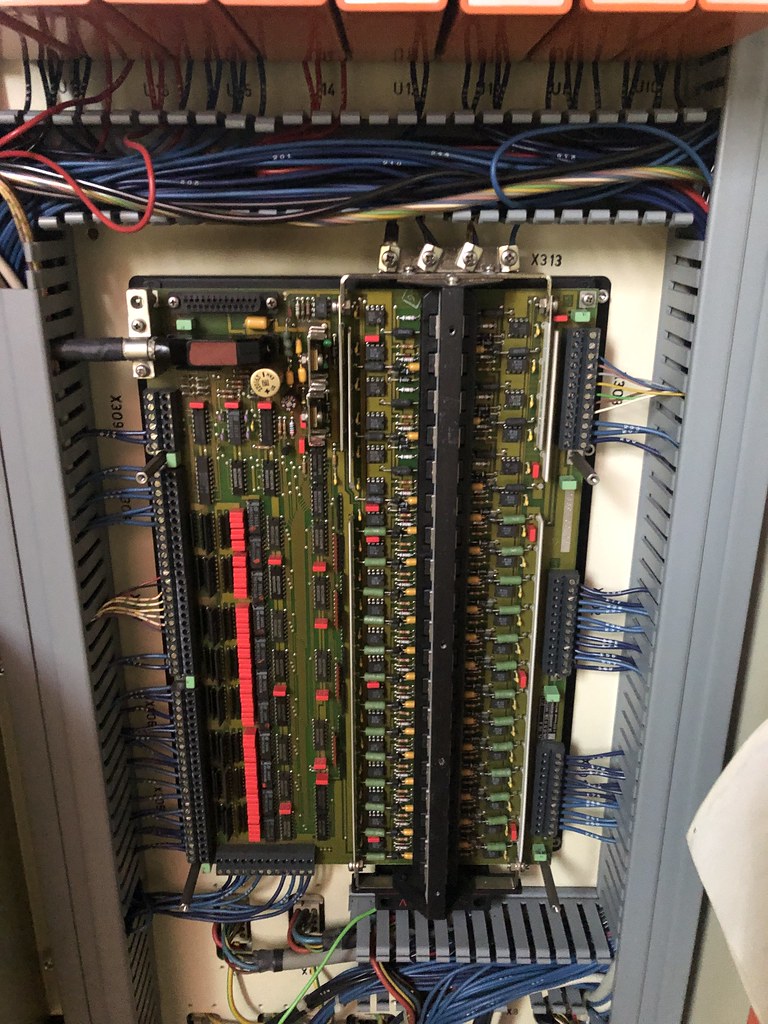

So my guess at the moment is the 24 / 12 / 6V Powersupply or this circuit board:

Tomorrow I will have a look at the powers supply but also started an IO List and cam to the conclusion I would need an 7I97 and 7IA0 (hope this card is supported) to get enough IO's and I would be able to add Glas scales to the column later.

I would like to keep the key pads but they have a bit logic. You get an button pressed signal and 5 Inputs are used to make a pattern, the led's can get and feedback on the same way. I wonder if this would be possible to get this running. The I Can also keep the hand device cause this works the same way.

the I reset the parameters but still got an error message:

this kind of points towards E-Stop or Power Supply. So I checked the E-Stop and found an open connection, but it sill didn't start.

So I took the multimeters and found all Inputs are low, wich is kind of odd. Also the LED's of some of the thingies in the cabinet look darker than others.

I DIsconnected two signals the should habe been high from the Circus board and the they were high.

So my guess at the moment is the 24 / 12 / 6V Powersupply or this circuit board:

Tomorrow I will have a look at the powers supply but also started an IO List and cam to the conclusion I would need an 7I97 and 7IA0 (hope this card is supported) to get enough IO's and I would be able to add Glas scales to the column later.

I would like to keep the key pads but they have a bit logic. You get an button pressed signal and 5 Inputs are used to make a pattern, the led's can get and feedback on the same way. I wonder if this would be possible to get this running. The I Can also keep the hand device cause this works the same way.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

06 Nov 2021 22:18 #225534

by anfänger

Replied by anfänger on topic Barnworks shop update

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

07 Nov 2021 12:26 #225556

by db1981

Replied by db1981 on topic Barnworks shop update

Hi ,

Tnc 355

You have to press the ce Button at the num Block After power on .

To Enable for switching estop on .

Tnc 355

You have to press the ce Button at the num Block After power on .

To Enable for switching estop on .

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

07 Nov 2021 14:54 #225558

by anfänger

Replied by anfänger on topic Barnworks shop update

Hi, It's a TNC 155 and I've already tried that.

I thought it was the power supply an I found the the second 24V section dead, so I used another power supply to feed 24V to the machine. And also fed the power good and E-stop directly from the power supply.

I checked all the contactors if they were working and they did.

But nothing really changed except the drives now get power. I tried to read the status f the it's in the control but the control doesn't react to anything. Not even trying ti change parameters.

I guess I will get new power supplies.

12 V and 6 V I can skip, cause they are for a lamp and the optics, which I won't use or have.

I need to find out what is using 24V AC maybe I can remove / replace that too.

And I will need to get the Mesa boards and a 5V power supply.

So be prepares for a retrofit thread coming soon, where I will as a lot of strange questions like:

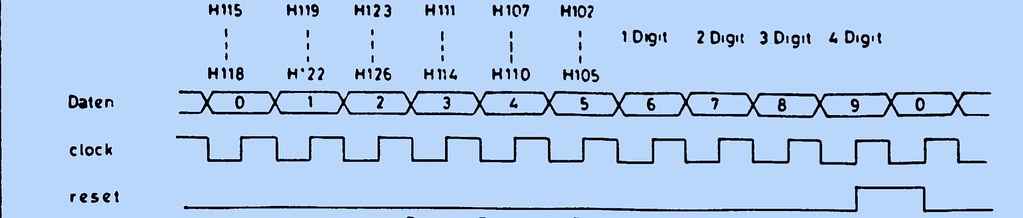

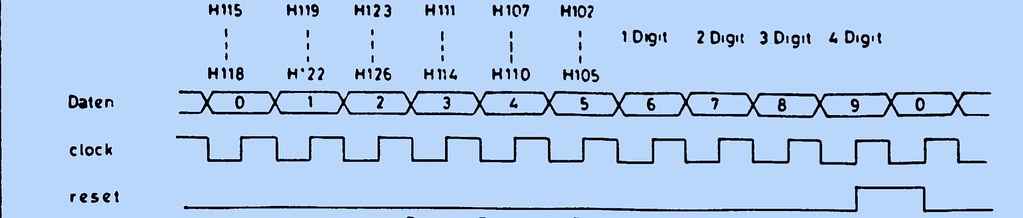

how mad is the idea to use python and 6 O's from the mesa board to send data to the control panel:

my guess is they use the rising flank to trigger the read of the four data bits, so speed isn't crucial.

Or can I use two joints overlaying each other where one is the column wich can't be PID controlled and has a simple single speed up and down.

Bit ist be able to get its position from a glas scale. Z improve the Z Axis So don't need to reset the WCS when I move the column.

I thought it was the power supply an I found the the second 24V section dead, so I used another power supply to feed 24V to the machine. And also fed the power good and E-stop directly from the power supply.

I checked all the contactors if they were working and they did.

But nothing really changed except the drives now get power. I tried to read the status f the it's in the control but the control doesn't react to anything. Not even trying ti change parameters.

I guess I will get new power supplies.

12 V and 6 V I can skip, cause they are for a lamp and the optics, which I won't use or have.

I need to find out what is using 24V AC maybe I can remove / replace that too.

And I will need to get the Mesa boards and a 5V power supply.

So be prepares for a retrofit thread coming soon, where I will as a lot of strange questions like:

how mad is the idea to use python and 6 O's from the mesa board to send data to the control panel:

my guess is they use the rising flank to trigger the read of the four data bits, so speed isn't crucial.

Or can I use two joints overlaying each other where one is the column wich can't be PID controlled and has a simple single speed up and down.

Bit ist be able to get its position from a glas scale. Z improve the Z Axis So don't need to reset the WCS when I move the column.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 967

- Thank you received: 424

07 Nov 2021 18:20 #225571

by my1987toyota

Replied by my1987toyota on topic Barnworks shop update

This site has a lot of very knowledgeable people on it. You might however have an easier time contacting MESA Electronics directly

they may have a few Idea's for you .

they may have a few Idea's for you .

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

07 Nov 2021 18:33 #225572

by anfänger

Replied by anfänger on topic Barnworks shop update

There is a lot of space in the old control bit, so I am planning a more integrated solution here and keeping the lower button thing.

in the left side will be an Touch monitor (PC includes If it's quick enough for linuxcnc, I've already got one here but never bothered to test it)

right to the monitor would a custom key panel handy:

X; Y; Z; A; M; G; S; F; I; J; P; Q; R; L; 0; 1; 2; 3; 4; 5; 6; 7; 8; 9; ,; Enter; Tab; +; -;

But I am not sure if there is something like that out there. Has anyone a good sugestion?

for Jogging I can rest the old handheld device:

But I think a wireless more modern one like I use in my other mill might be more useful.

thanks Patrick

in the left side will be an Touch monitor (PC includes If it's quick enough for linuxcnc, I've already got one here but never bothered to test it)

right to the monitor would a custom key panel handy:

X; Y; Z; A; M; G; S; F; I; J; P; Q; R; L; 0; 1; 2; 3; 4; 5; 6; 7; 8; 9; ,; Enter; Tab; +; -;

But I am not sure if there is something like that out there. Has anyone a good sugestion?

for Jogging I can rest the old handheld device:

But I think a wireless more modern one like I use in my other mill might be more useful.

thanks Patrick

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.095 seconds