Two Axis NC Indexer

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

12 Aug 2022 14:55 #249594

by hoffb77

Two Axis NC Indexer was created by hoffb77

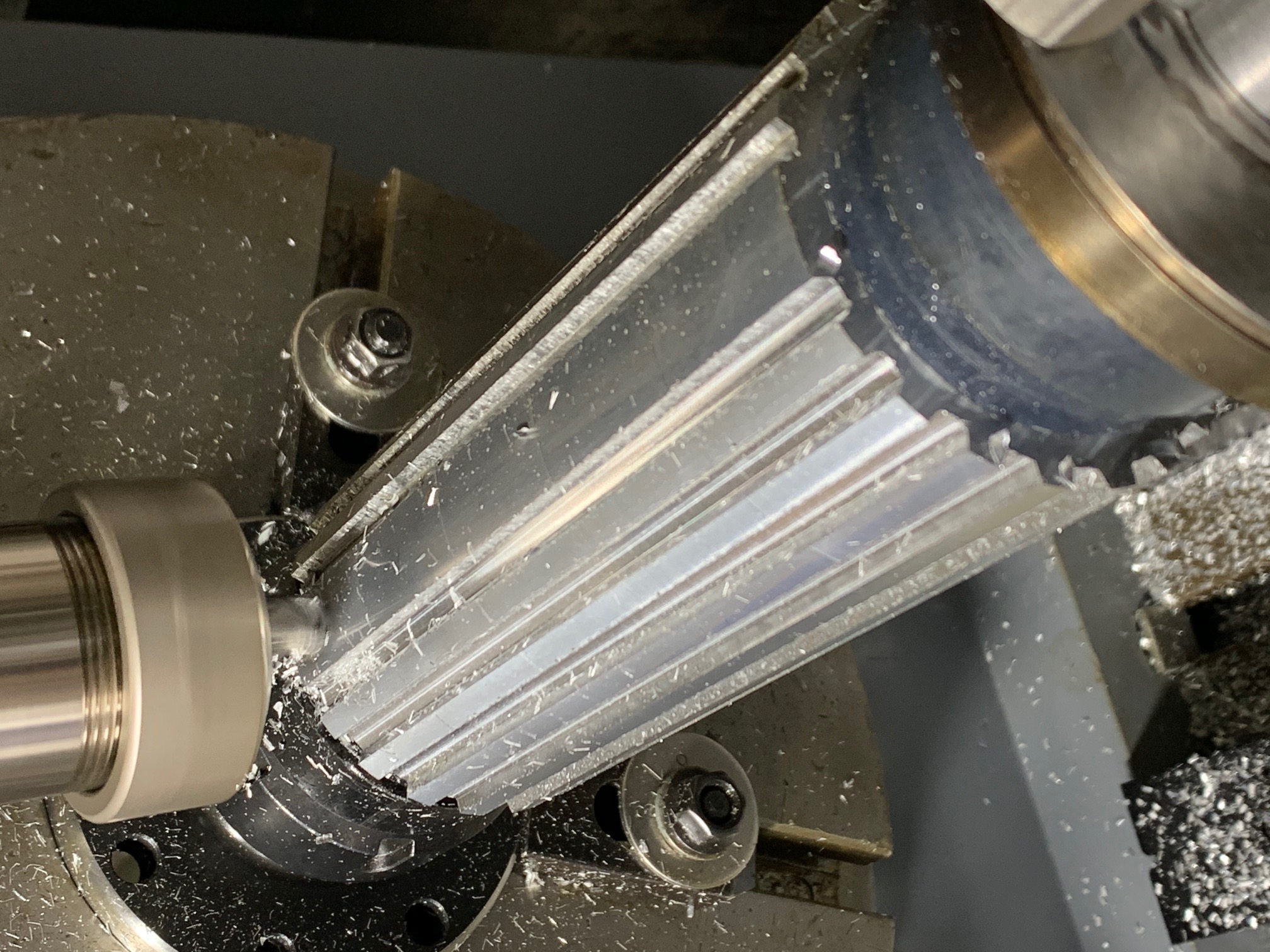

I needed to cut a set of gears for my lathe conversion. While I was sorting out what I had and what I needed to get to make that happen, I came across a job cutting some toothed pulleys. The OEM price left a lot of room for profit so I got this machine done as fast as I could to get the work.

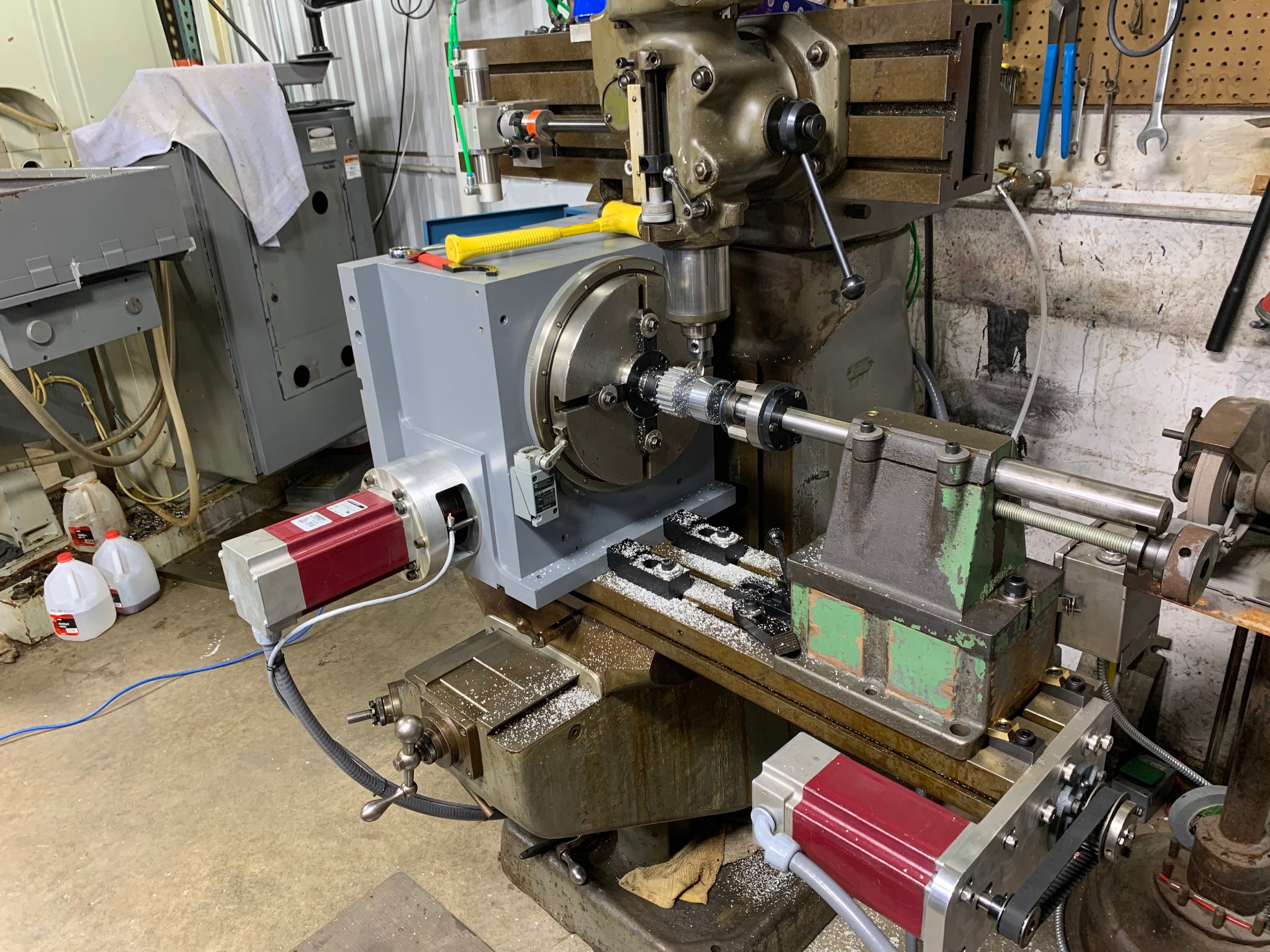

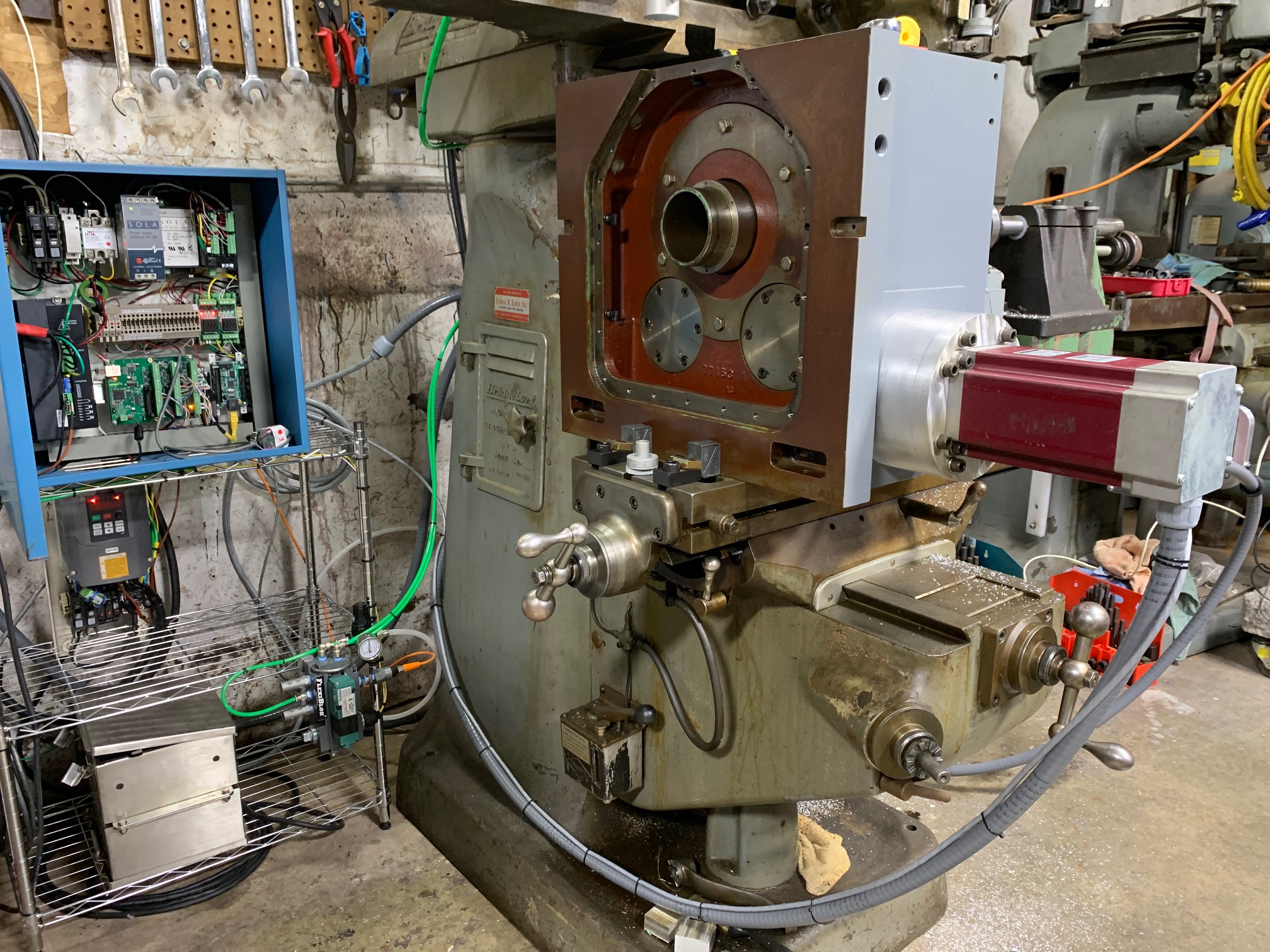

The mill is a Bridgeport "True Trace". It was an eBay find with all the hydraulic drive components missing(along with random things stolen off it over the years). But it was lightly used, the J2 spindle was in good working order and happened to be a good platform for what I wanted to do. The Y axis never looked to have a drive on it and was a blessing to be as is. I added the stepper to the X axis after tying up the missing drive components for the lead screw.

The rotary indexer is another eBay find. It was in fair shape but had been sitting for a couple decades. The drive for it was a massive 156v DC servo and the feedback was an "Inductosyn" similar to a resolver. The circuitry for that fed into a Bendix brand card with no numbers on it. Someone did adjust one of the pots on the board in December of 1983. He left a nice note. Although I haven't given up on the Inductosyn I embedded a rotary encoder inside the stepper mount.

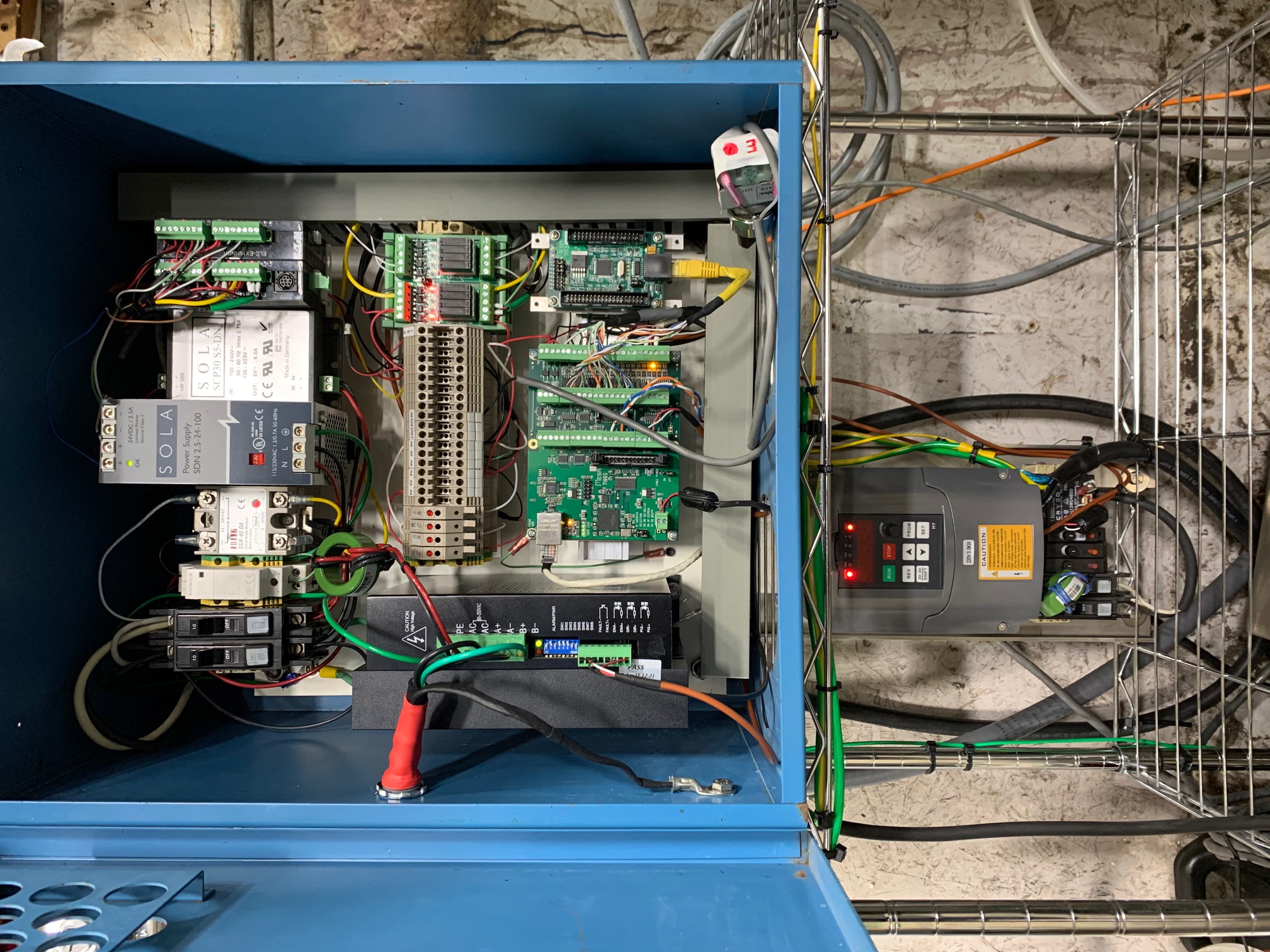

The controls are an Eaton PLC and a Mesa 7i96s. I have a VFD running constant 60hz to the spindle to accommodate my 240v single phase primary. I have a 7i73 I need to build a op panel for but I'm still using the keyboard until I get time for it. Its just riding the rail for now. Besides that and adding some options to the interface I'm about done with this one.

Id like to thank this great community again for being my primary resource for knowledge. This is the 3rd NC machine I have running parts in my shop on LinuxCNC.

The mill is a Bridgeport "True Trace". It was an eBay find with all the hydraulic drive components missing(along with random things stolen off it over the years). But it was lightly used, the J2 spindle was in good working order and happened to be a good platform for what I wanted to do. The Y axis never looked to have a drive on it and was a blessing to be as is. I added the stepper to the X axis after tying up the missing drive components for the lead screw.

The rotary indexer is another eBay find. It was in fair shape but had been sitting for a couple decades. The drive for it was a massive 156v DC servo and the feedback was an "Inductosyn" similar to a resolver. The circuitry for that fed into a Bendix brand card with no numbers on it. Someone did adjust one of the pots on the board in December of 1983. He left a nice note. Although I haven't given up on the Inductosyn I embedded a rotary encoder inside the stepper mount.

The controls are an Eaton PLC and a Mesa 7i96s. I have a VFD running constant 60hz to the spindle to accommodate my 240v single phase primary. I have a 7i73 I need to build a op panel for but I'm still using the keyboard until I get time for it. Its just riding the rail for now. Besides that and adding some options to the interface I'm about done with this one.

Id like to thank this great community again for being my primary resource for knowledge. This is the 3rd NC machine I have running parts in my shop on LinuxCNC.

Attachments:

The following user(s) said Thank You: arvidb, tommylight, spumco

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21157

- Thank you received: 7223

12 Aug 2022 15:41 #249599

by tommylight

Replied by tommylight on topic Two Axis NC Indexer

Wow, that is a big rotary axis!

Very nice, thank you.

Very nice, thank you.

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

12 Aug 2022 16:36 #249601

by hoffb77

Replied by hoffb77 on topic Two Axis NC Indexer

It is massive but not over weight limit on that knee....getting close though. I only gave $400 for it. Compared to 12" rotary prices, I got a hell of a deal.

When I find an 8" Ill swap it out.. I'm building a machine to cut tapered accelerating pitch feed screws out of cored poly bar stock and I need another rotary A axis to do that. I'm on the hunt for an 8" if you see a deal. :-D

FYI....... the OEM price on those pulleys is $400+ US. The puck I shape them out of is about $5 in aluminum. They need 112 now and will need other sizes once those are done. I might be able to buy some new stuff one of these days........

When I find an 8" Ill swap it out.. I'm building a machine to cut tapered accelerating pitch feed screws out of cored poly bar stock and I need another rotary A axis to do that. I'm on the hunt for an 8" if you see a deal. :-D

FYI....... the OEM price on those pulleys is $400+ US. The puck I shape them out of is about $5 in aluminum. They need 112 now and will need other sizes once those are done. I might be able to buy some new stuff one of these days........

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

12 Aug 2022 19:30 #249617

by spumco

Replied by spumco on topic Two Axis NC Indexer

Do like.

Your tailstock and outboard support is...interesting. I see a taperlock bushing, and maybe a bearing carrier, but the rest is hard to figure out.

But with that long lead screw I bet you could tension the upcoming poly bar threading job to cut down on stock flex. If you haven't seen it yet, Area 51 machine shop has a pretty slick fixturing setup for fluting rifle barrels. They built a table-mounted stock support that adjusts to the tapered barrel on the back (Y-pos) and they do the fluting on the Y-neg side with a lollipop cutter.

Your poly bar job sounds just like a barrel fluting job...only different pitch and with a pool noodle for stock.

Your tailstock and outboard support is...interesting. I see a taperlock bushing, and maybe a bearing carrier, but the rest is hard to figure out.

But with that long lead screw I bet you could tension the upcoming poly bar threading job to cut down on stock flex. If you haven't seen it yet, Area 51 machine shop has a pretty slick fixturing setup for fluting rifle barrels. They built a table-mounted stock support that adjusts to the tapered barrel on the back (Y-pos) and they do the fluting on the Y-neg side with a lollipop cutter.

Your poly bar job sounds just like a barrel fluting job...only different pitch and with a pool noodle for stock.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1967

- Thank you received: 801

12 Aug 2022 19:32 #249618

by spumco

Replied by spumco on topic Two Axis NC Indexer

And another thing...

What's the PLC for?

What's the PLC for?

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

12 Aug 2022 19:48 #249619

by hoffb77

Replied by hoffb77 on topic Two Axis NC Indexer

I have them on all my machines now. I use them for all I/O and redundant for servo power and machine enable parallel with the Mesa for safety. It keeps the motion card isolated from any high voltage as well.

I have a base program I start with now retros and new builds. I can test all connections from the laptop before I hook up to kinetic parts too. They go so smooth now I cant wait for the next :-D

I have a base program I start with now retros and new builds. I can test all connections from the laptop before I hook up to kinetic parts too. They go so smooth now I cant wait for the next :-D

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

12 Aug 2022 20:01 #249620

by hoffb77

Replied by hoffb77 on topic Two Axis NC Indexer

I use a QD bushing with a sheave I turned down for a back stop. I tapped the sheave with 1/2-13 and use those nuts to press and hold the work tight. The tailstock is tapered and seated inside there with a bushing. The dead center shaft is 1-1/2" and my pulley bore is 28mm. So I turned down the end of the work holding shaft and made a bushing to bring it together. I made up two work shafts and have the next set turned to diameter as the Knob Hobber cuts teeth.Do like.

Your tailstock and outboard support is...interesting. I see a taperlock bushing, and maybe a bearing carrier, but the rest is hard to figure out.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4599

18 Aug 2022 13:33 #250017

by andypugh

Maybe keep an eye out on eBay for an FHA-25B harmonic drive.

bodgesoc.blogspot.com/2017/05/harmonic.html

What is that tooth profile? It looks unusual.

I picked up a proper hob for T5 pulleys some time ago:

Replied by andypugh on topic Two Axis NC Indexer

When I find an 8" Ill swap it out.. I'm building a machine to cut tapered accelerating pitch feed screws out of cored poly bar stock and I need another rotary A axis to do that. I'm on the hunt for an 8" if you see a deal.

Maybe keep an eye out on eBay for an FHA-25B harmonic drive.

bodgesoc.blogspot.com/2017/05/harmonic.html

FYI....... the OEM price on those pulleys is $400+ US.

What is that tooth profile? It looks unusual.

I picked up a proper hob for T5 pulleys some time ago:

The following user(s) said Thank You: tommylight, hoffb77

Please Log in or Create an account to join the conversation.

- hoffb77

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 53

- Thank you received: 21

19 Aug 2022 12:56 #250071

by hoffb77

Replied by hoffb77 on topic Two Axis NC Indexer

The belt we use is T-10 but the teeth are cut deeper. I would imagine the OEM did this to make room for debris, especially glue. They are for a german labeler. The 21T pulley is for a small condensed can of soup. A 26T is used on a 24oz jar of sauce. The bigger diameter bottles, jars and cans use a taller pulley. It times the jar to the machine during the application cycle. It passes the sensor as the pulley engages the belt. It does one rev and the can gets hit with glue dots/swirls. The next rev rolls those dots into the label magazine. It does another rev to guide the label on and then the label code is read by a cognex scanner and its picture is taken. After all that it comes off the belt and discharges the machine.

The closest I have seen to one of these is some idler pulleys. Im thinking if run the taller pulleys I will need to program the dimensional changes or get another tool shaped. Luckily I have plenty of different sizes of these OEM to make sure my geometry is right.

I will look at a harmonic drive and the proper equipment for the long term. Id like to get a hold of all the part work locally for these machines. Its tough to get parts quickly out of Germany and its only becoming worse. All of these parts were run on LinuxCNC driven machines......

There are three pulleys stacked there. 22T 26T 33T. The belt get moved to match the production run. for 14oz 24oz 48oz.

These bottle plates are what the product sits on in the machine and the shaft is where the pulleys mount underneath the turret.

These are third party chucks the plates snap onto. I made some changes to them.

These are the wheels that put product on the machine and than back on the conveyer.

The closest I have seen to one of these is some idler pulleys. Im thinking if run the taller pulleys I will need to program the dimensional changes or get another tool shaped. Luckily I have plenty of different sizes of these OEM to make sure my geometry is right.

I will look at a harmonic drive and the proper equipment for the long term. Id like to get a hold of all the part work locally for these machines. Its tough to get parts quickly out of Germany and its only becoming worse. All of these parts were run on LinuxCNC driven machines......

There are three pulleys stacked there. 22T 26T 33T. The belt get moved to match the production run. for 14oz 24oz 48oz.

These bottle plates are what the product sits on in the machine and the shaft is where the pulleys mount underneath the turret.

These are third party chucks the plates snap onto. I made some changes to them.

These are the wheels that put product on the machine and than back on the conveyer.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.228 seconds