Using HAL lincurve and offset to correct for a not-so-straight axis

- finnstrom

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 4

28 Feb 2024 07:10 #294669

by finnstrom

Using HAL lincurve and offset to correct for a not-so-straight axis was created by finnstrom

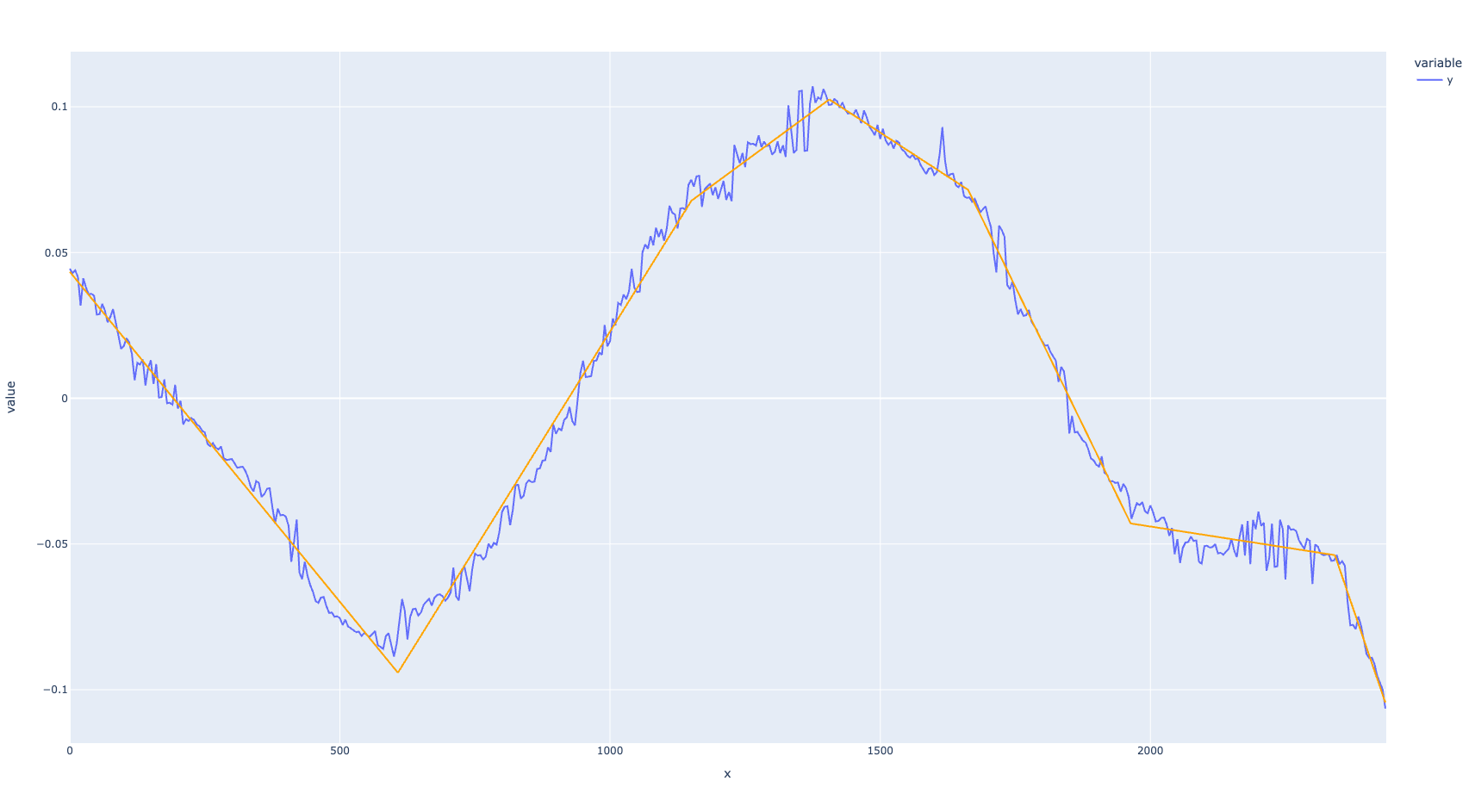

I built my own CNC router with the long axis (I called it X for various reasons) at about 2.7m. It's all on 8020 profile and no matter how I tweaked it, I could never get the gantry to move in a straight line. It would shift reliably +/- 0.1mm (or about 0.005in), so I had an accuracy problem that was too large for my liking.

I got this same plot over and over at multiple Y locations, so lincurve would be a good solution here together with offset .

Essentially, lincurve lets you define an equation of sorts, then lets you map the x value to the y value. In this case, I would map the input of my X of where the spindle is to the output offset I want to move my Y axis. The reverse of the error you see in the graph above. Then I use that offset and implement it in the controller using HAL offset.

The "equation" that you give lincurve however is not your usual y=f(x), but multiple points (up to 16) on the x,y graph. The lincurve link above explains it better than I would.

Here is a snippet from my HAL:

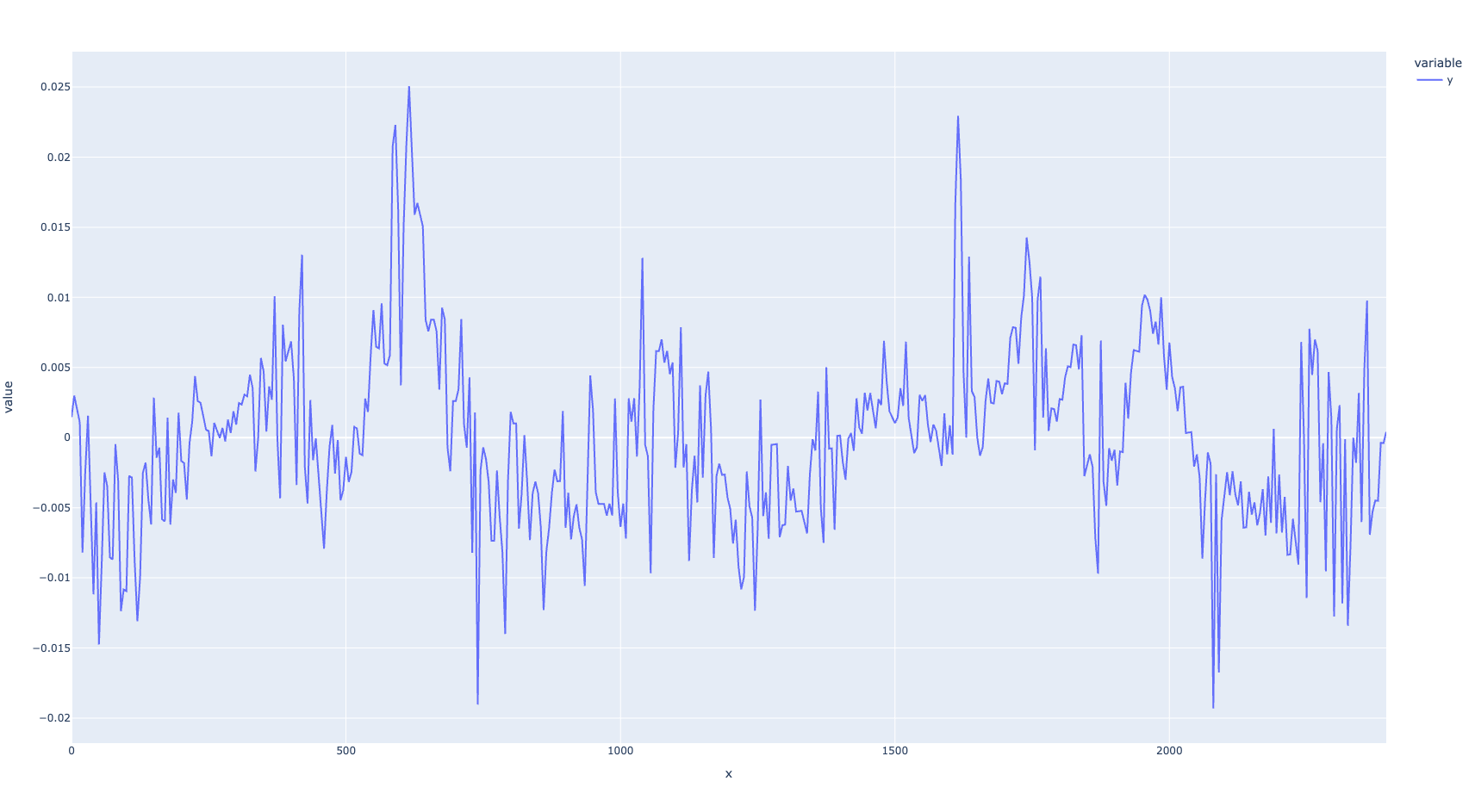

And voila:

I got this same plot over and over at multiple Y locations, so lincurve would be a good solution here together with offset .

Essentially, lincurve lets you define an equation of sorts, then lets you map the x value to the y value. In this case, I would map the input of my X of where the spindle is to the output offset I want to move my Y axis. The reverse of the error you see in the graph above. Then I use that offset and implement it in the controller using HAL offset.

The "equation" that you give lincurve however is not your usual y=f(x), but multiple points (up to 16) on the x,y graph. The lincurve link above explains it better than I would.

Here is a snippet from my HAL:

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.01.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i76e.0.stepgen.01.dirhold [JOINT_2]DIRHOLD

setp hm2_7i76e.0.stepgen.01.steplen [JOINT_2]STEPLEN

setp hm2_7i76e.0.stepgen.01.stepspace [JOINT_2]STEPSPACE

setp hm2_7i76e.0.stepgen.01.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i76e.0.stepgen.01.step_type 0

setp hm2_7i76e.0.stepgen.01.control-type 1

setp hm2_7i76e.0.stepgen.01.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.01.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

# Alter Y position dependent on X position in order to straighten X axis

setp x_straight.x-val-00 0.0

setp x_straight.y-val-00 0.04341242632711628

setp x_straight.x-val-01 607.2917010709281

setp x_straight.y-val-01 -0.0941465387965644

setp x_straight.x-val-02 1150.4857125892602

setp x_straight.y-val-02 0.06777797847289474

setp x_straight.x-val-03 1405.8006869324868

setp x_straight.y-val-03 0.10253790211206171

setp x_straight.x-val-04 1662.603323359967

setp x_straight.y-val-04 0.07153820324398952

setp x_straight.x-val-05 1963.5065299510084

setp x_straight.y-val-05 -0.04292886830166562

setp x_straight.x-val-06 2341.4825252892224

setp x_straight.y-val-06 -0.053798901184427095

setp x_straight.x-val-07 2435.0

setp x_straight.y-val-07 -0.10441928397325695

net x-pos-fb => x_straight.in

net y-offset <= x_straight.out

net y-offset => x_straight_offset.offset

net y-pos-cmd-raw <= joint.2.motor-pos-cmd

net y-pos-cmd-raw => x_straight_offset.in

net y-pos-fb-raw <= hm2_7i76e.0.stepgen.01.position-fb

net y-pos-fb-raw => x_straight_offset.fb-in

net y-pos-cmd <= x_straight_offset.out

net y-vel-cmd <= joint.2.vel-cmd

net y-output => hm2_7i76e.0.stepgen.01.velocity-cmd

net y-pos-fb <= x_straight_offset.fb-out

net y-pos-fb => joint.2.motor-pos-fb

net y-enable <= joint.2.amp-enable-out

net y-enable => hm2_7i76e.0.stepgen.01.enableAnd voila:

Attachments:

Please Log in or Create an account to join the conversation.

- finnstrom

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 4

28 Feb 2024 07:19 #294670

by finnstrom

Replied by finnstrom on topic Using HAL lincurve and offset to correct for a not-so-straight axis

lincurve requires multiple linear regressions (up to 16-1=15) that have the constraint that all regression lines meet at their ends. For this minimization problem I used the python

piecewise linear fitting library

.

Broken down, you give it the x,y data, and in this case tell it how many breakpoints you want (for lincurve we can go up to 15), and if you have enough datapoints you usually get a globally minimum solution.

Here's the python code:

Just pip install the dependencies at the top. All my python is for 3, I haven't tested it on 2.

The datafile is generated from an ngc probing routine I wrote, and needs to look like a CSV (cut short for visibility) for the program above to read it correctly:

Broken down, you give it the x,y data, and in this case tell it how many breakpoints you want (for lincurve we can go up to 15), and if you have enough datapoints you usually get a globally minimum solution.

Here's the python code:

from absl import app

from absl import flags

import pandas as pd

from sklearn.linear_model import LinearRegression

import plotly.express as px

import pwlf

_MIN = -74.0

_MAX = 2450.0

_REGRESSION_SECTIONS = 5

FLAGS = flags.FLAGS

flags.DEFINE_string('data_file', '', 'Data file')

flags.DEFINE_string('data_file_comp', None, 'Data file to compare to')

def main(argv):

if FLAGS.data_file is None:

print('ERROR')

df = pd.read_csv(FLAGS.data_file)

# Calculate the total linear regression for plotting

model = LinearRegression()

model.fit(df[['x']], df[['y']])

df['y'] = df['y'] - model.intercept_ - df['x'] * model.coef_[0][0]

df['x'] = df['x'] - df['x'][0]

# initialize piecewise linear fit with your x and y data

my_pwlf = pwlf.PiecewiseLinFit(df['x'].to_numpy(), df['y'].to_numpy())

# Fit the data for line segments

regression = my_pwlf.fit(_REGRESSION_SECTIONS)

slope = my_pwlf.calc_slopes()

intercept = my_pwlf.intercepts

# Data file to compare to

if FLAGS.data_file_comp is not None:

df_comp = pd.read_csv(FLAGS.data_file_comp)

df_comp['y'] = df_comp['y'] - model.intercept_ - df_comp['x'] * model.coef_[0][0]

df_comp['x'] = df_comp['x'] - df_comp['x'][0]

df_comp = df_comp.rename(columns={'y': 'y_comp'})

df = pd.concat([df, df_comp])

df = pd.melt(df, id_vars=['x'], value_vars=['y', 'y_comp'])

else:

df = pd.melt(df, id_vars=['x'], value_vars=['y'])

# Plot

fig = px.line(df, x='x', y='value', color='variable')

regression_i = 0

while regression_i < _REGRESSION_SECTIONS:

fig.add_shape(

type="line",

x0=regression[regression_i],

y0=regression[regression_i] * slope[regression_i] + intercept[regression_i],

x1=regression[regression_i + 1],

y1=regression[regression_i + 1] * slope[regression_i] + intercept[regression_i],

line=dict(width=2, dash="solid", color="Orange",),

)

print(f"setp x_straight.x-val-{regression_i:02d} {regression[regression_i]}")

print(f"setp x_straight.y-val-{regression_i:02d} {regression[regression_i] * slope[regression_i] + intercept[regression_i]}")

regression_i = regression_i + 1

print(f"setp x_straight.x-val-{regression_i:02d} {regression[regression_i]}")

print(f"setp x_straight.y-val-{regression_i:02d} {regression[regression_i] * slope[regression_i - 1] + intercept[regression_i - 1]}")

fig.show()

if __name__ == '__main__':

app.run(main)

Just pip install the dependencies at the top. All my python is for 3, I haven't tested it on 2.

The datafile is generated from an ngc probing routine I wrote, and needs to look like a CSV (cut short for visibility) for the program above to read it correctly:

x,y

5.000000,1161.072689

10.000000,1161.074890

15.000000,1161.074590

20.000000,1161.074291

25.000000,1161.065659

30.000000,1161.072027

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- DEVILHUNTER

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 11

10 May 2024 05:09 #300289

by DEVILHUNTER

Replied by DEVILHUNTER on topic Using HAL lincurve and offset to correct for a not-so-straight axis

Really cool, and usefull. I have created a similar software as had the same problem on my machine. In my case I created a kinematics component (so I couold correct errors in all axis) that takes a lookup table for each error and correct the perpendicular axis. The lookup table is set every milimeter of machine movement, so you get really smooth curve. To creat the lookup table just take a bunch of measurements and interpolated it externally, so you can get the number of measurements you want and use a polynomial interpolation.

On the Z axis, the most problematic one if the guides are not straight, it also takes into account the angle created by the guides and the distance to the tool tip. This way we correct the biggest error point that is located in the tool tip (and is different for each tool lenght).

In the end I got my machine mechanically in 0.02mm in the tool tip so I didn't even tested the software. But I think this could be interesting to implement, as industrial controls have software compensation for small errors too.

On the Z axis, the most problematic one if the guides are not straight, it also takes into account the angle created by the guides and the distance to the tool tip. This way we correct the biggest error point that is located in the tool tip (and is different for each tool lenght).

In the end I got my machine mechanically in 0.02mm in the tool tip so I didn't even tested the software. But I think this could be interesting to implement, as industrial controls have software compensation for small errors too.

Please Log in or Create an account to join the conversation.

Time to create page: 0.114 seconds