- Other Stuff

- Show Your Stuff

- Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3969

14 Mar 2025 17:58 #323945

by rodw

Replied by rodw on topic Building a 4-axis plasma table

About 8-10 years ago we looked at an entry level hi definition plasma table and it was AUD $130k direct from the manufacturer.

The following user(s) said Thank You: Daan96

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

14 Mar 2025 19:26 #323952

by tommylight

Replied by tommylight on topic Building a 4-axis plasma table

To normal people, those numbers seem very far fetched as there is no pricing info for anything like that.

As Americans say: if you have to ask for the price, you can not afford it.

And when you do ask, be sitting with a glass of cold water in hand and 911 on speed dial.

Only when you have invoices in hand for such stuff, you start believing (coupled with the headache it induces)

See if you can find pricing for commercial license 5 axis CAM and report back here, if you can!

As Americans say: if you have to ask for the price, you can not afford it.

And when you do ask, be sitting with a glass of cold water in hand and 911 on speed dial.

Only when you have invoices in hand for such stuff, you start believing (coupled with the headache it induces)

See if you can find pricing for commercial license 5 axis CAM and report back here, if you can!

The following user(s) said Thank You: Daan96

Please Log in or Create an account to join the conversation.

- Daan96

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 7

27 Mar 2025 08:40 #325038

by Daan96

Replied by Daan96 on topic Building a 4-axis plasma table

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Daan96

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 7

25 Jun 2025 12:51 - 25 Jun 2025 12:55 #330859

by Daan96

Replied by Daan96 on topic Building a 4-axis plasma table

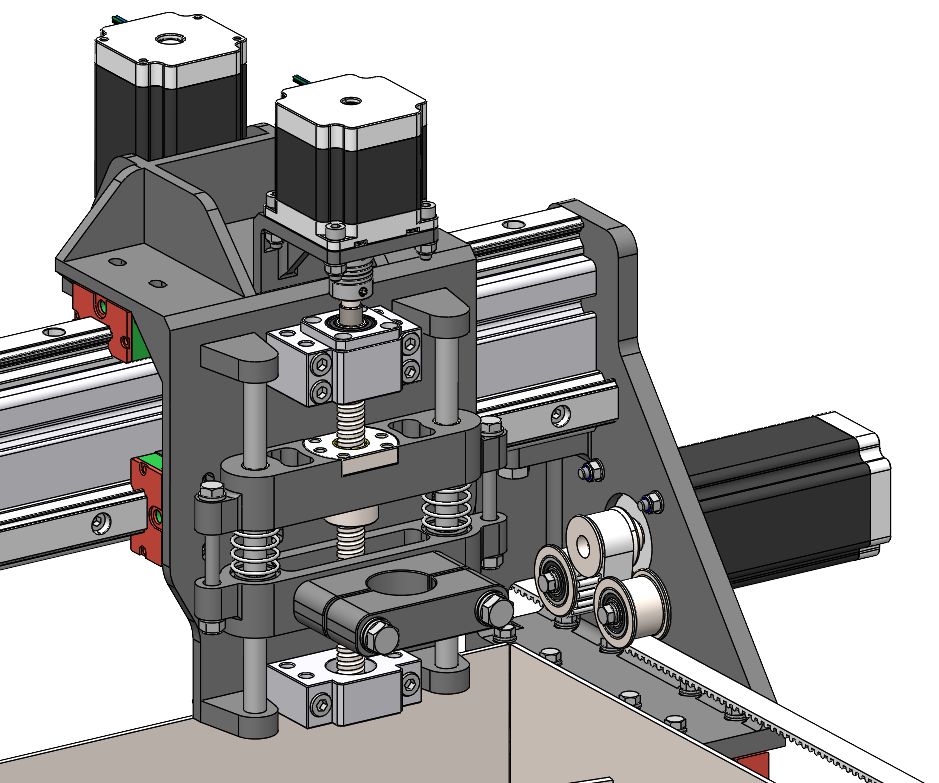

In the meantime, I’ve slowly started building the prototype.

I’ve decided to go with LinuxCNC in combination with the Mesa 7i96s and the THCAD-2.

All parts were initially 3D printed in ASA-CF.

In practice, it will have to be determined whether this material is strong and rigid enough.

If not, the parts will be replaced. For now, I want to test the concept first.

The axes are driven by 3Nm Nema 23 stepper motors and an HTD-5M timing belt with a 15-tooth pulley, without any gear reduction.

The frame will be made of stainless steel square tubing, 50x50x3 mm.

I’ve just started working on that.

Any tips or feedback are very welcome! I'm here to learn

I’ve decided to go with LinuxCNC in combination with the Mesa 7i96s and the THCAD-2.

All parts were initially 3D printed in ASA-CF.

In practice, it will have to be determined whether this material is strong and rigid enough.

If not, the parts will be replaced. For now, I want to test the concept first.

The axes are driven by 3Nm Nema 23 stepper motors and an HTD-5M timing belt with a 15-tooth pulley, without any gear reduction.

The frame will be made of stainless steel square tubing, 50x50x3 mm.

I’ve just started working on that.

Any tips or feedback are very welcome! I'm here to learn

Last edit: 25 Jun 2025 12:55 by Daan96.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

25 Jun 2025 15:05 #330864

by tommylight

Normally for plasma we aim at 20-25mm per motor revolution, and this does require reduction from 1:3 to 1:5 depending on final drive pulley.

Replied by tommylight on topic Building a 4-axis plasma table

That will do 75mm of motion for a single rotation of the motor, and will have plenty of vibrations, but since you already have that set, do give it a try.The axes are driven by 3Nm Nema 23 stepper motors and an HTD-5M timing belt with a 15-tooth pulley, without any gear reduction.

Normally for plasma we aim at 20-25mm per motor revolution, and this does require reduction from 1:3 to 1:5 depending on final drive pulley.

The following user(s) said Thank You: EW_CNC, Daan96

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

Less

More

- Posts: 135

- Thank you received: 42

26 Jun 2025 04:30 #330880

by jimmyrig

Replied by jimmyrig on topic Building a 4-axis plasma table

Agreed on the gear reduction or machining a smaller pulley. I think they make htd in 3mm pitch so you can reduce pulley size.

The goal with plasma is to accelerate as fast as possible to the desired cutting speed to minimize slag...... That's basically the entire goal..... The less time you are in-between stopping and cut speed the less slag you will have. So keep all motion components as light and strong as possible. That 80/20 t slot extrusion is heavy and weak (for the weight), use square tube instead.

Also 3d printed parts are fine for a prototype/hobby machine but you are building a machine that shoots sparks everywhere and makes things very hot. Plan for machining the parts out of AL if you want to use it in an industrial environment.

Hope that helps

The goal with plasma is to accelerate as fast as possible to the desired cutting speed to minimize slag...... That's basically the entire goal..... The less time you are in-between stopping and cut speed the less slag you will have. So keep all motion components as light and strong as possible. That 80/20 t slot extrusion is heavy and weak (for the weight), use square tube instead.

Also 3d printed parts are fine for a prototype/hobby machine but you are building a machine that shoots sparks everywhere and makes things very hot. Plan for machining the parts out of AL if you want to use it in an industrial environment.

Hope that helps

The following user(s) said Thank You: Daan96

Please Log in or Create an account to join the conversation.

- Daan96

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 7

26 Jun 2025 06:12 - 26 Jun 2025 06:18 #330881

by Daan96

Replied by Daan96 on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Thanks, well spotted! I was hoping that 1/3200 microstepping would work.

Perhaps I will have to do a 1/3 reduction later. For now I think I'll try how this works.

The goal is to get linuxcnc up and running first and try to configure everything properly

The point of the 80x40 extrusion profile I certainly do not agree with as a mechanical engineer.

The 80/40 extrusion profile has a much higher stiffness compared to a normal tube. Especially compared to an aluminum tube.

For axample:

Aluminium extrusion profile L=1200mm (2.9 kg) vs aluminium 50x50x2 tube L=1200mm (3.6kg)

Comparison of Bending Resistance

ProfileDirection (axis) Section Modulus (W)

80x40 extrusion

Major axis (80 mm high) → bending about X = 8,898,884 mm³

Minor axis (40 mm high) → bending about Y = 120,303 mm³

50x50x2 mm box

Any axis (symmetric) → c = 25 mm X and Y = 5,912 mm³

Key Differences:

In the x-axis, the 80x40 profile has ~1500× higher section modulus (1500x stronger!) and is 20% less heavy than the 50x50x2 box.

In the y-axis, it still has ~20× higher section modulus (20x stronger!).

Perhaps I will have to do a 1/3 reduction later. For now I think I'll try how this works.

The goal is to get linuxcnc up and running first and try to configure everything properly

The point of the 80x40 extrusion profile I certainly do not agree with as a mechanical engineer.

The 80/40 extrusion profile has a much higher stiffness compared to a normal tube. Especially compared to an aluminum tube.

For axample:

Aluminium extrusion profile L=1200mm (2.9 kg) vs aluminium 50x50x2 tube L=1200mm (3.6kg)

Comparison of Bending Resistance

ProfileDirection (axis) Section Modulus (W)

80x40 extrusion

Major axis (80 mm high) → bending about X = 8,898,884 mm³

Minor axis (40 mm high) → bending about Y = 120,303 mm³

50x50x2 mm box

Any axis (symmetric) → c = 25 mm X and Y = 5,912 mm³

Key Differences:

In the x-axis, the 80x40 profile has ~1500× higher section modulus (1500x stronger!) and is 20% less heavy than the 50x50x2 box.

In the y-axis, it still has ~20× higher section modulus (20x stronger!).

Last edit: 26 Jun 2025 06:18 by Daan96.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4658

- Thank you received: 2078

26 Jun 2025 06:59 - 26 Jun 2025 07:11 #330885

by Aciera

I must say that the weight comparison seems very counter intuitive.

[edit]

you are comparing aluminium extrusion profile to 50x50x2 steel tubing (8000kg/m3).

Replied by Aciera on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

For axample:

Aluminium extrusion profile L=1200mm (2.9 kg) vs aluminium 50x50x2 tube L=1200mm (3.6kg)

I must say that the weight comparison seems very counter intuitive.

[edit]

you are comparing aluminium extrusion profile to 50x50x2 steel tubing (8000kg/m3).

Last edit: 26 Jun 2025 07:11 by Aciera.

The following user(s) said Thank You: Daan96

Please Log in or Create an account to join the conversation.

- Daan96

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 7

26 Jun 2025 14:23 #330896

by Daan96

Replied by Daan96 on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

My bad, aluminium is about 1.2 kg for 1200mm

So it is about 2.5 times as heavy but many times stronger against deflection.

That is why the choice was made for the 80x40 extrusion profile.

The guides weigh a lot more there, more could be gained there.

So it is about 2.5 times as heavy but many times stronger against deflection.

That is why the choice was made for the 80x40 extrusion profile.

The guides weigh a lot more there, more could be gained there.

Please Log in or Create an account to join the conversation.

- Daan96

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 7

01 Jul 2025 08:31 #331060

by Daan96

Replied by Daan96 on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Time to create page: 0.145 seconds